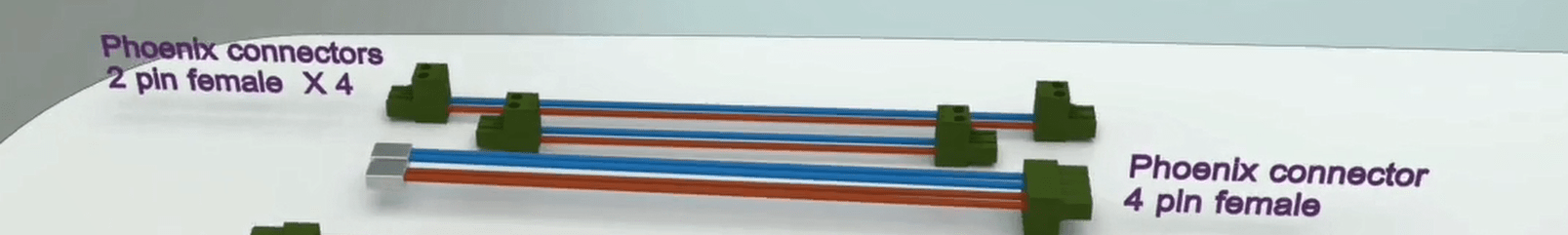

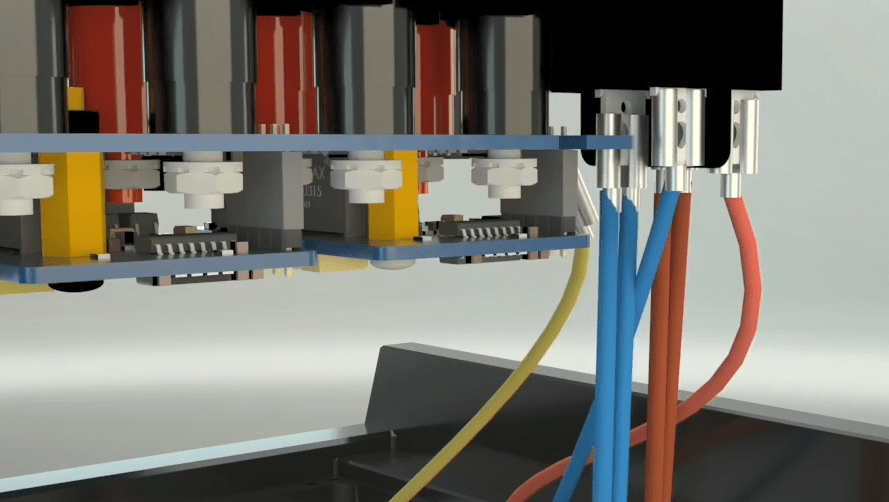

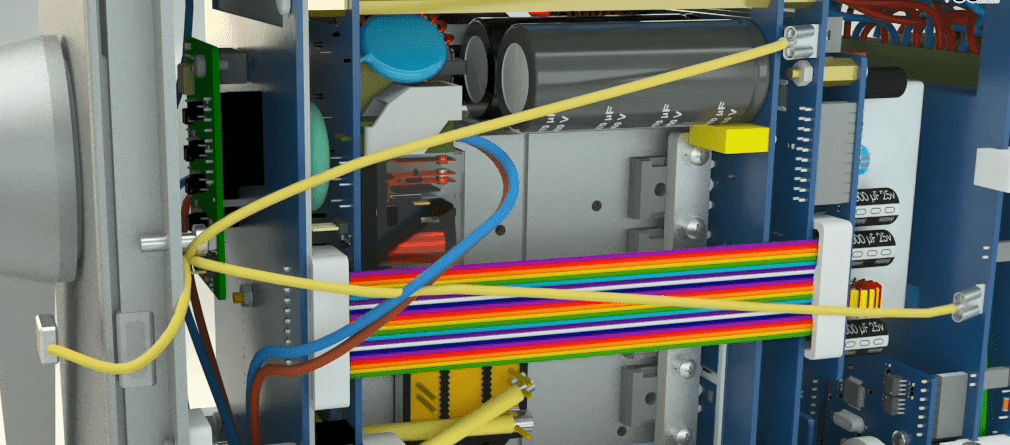

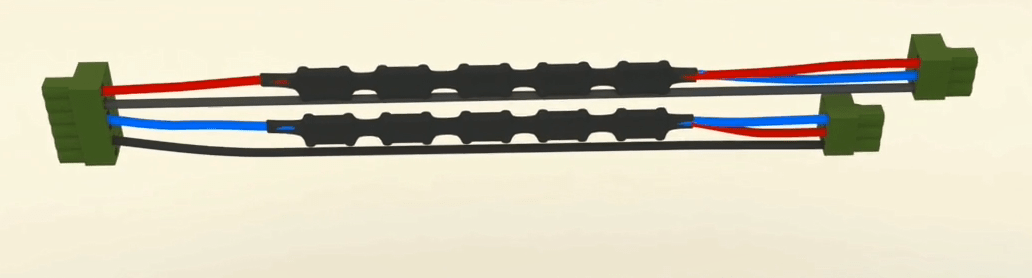

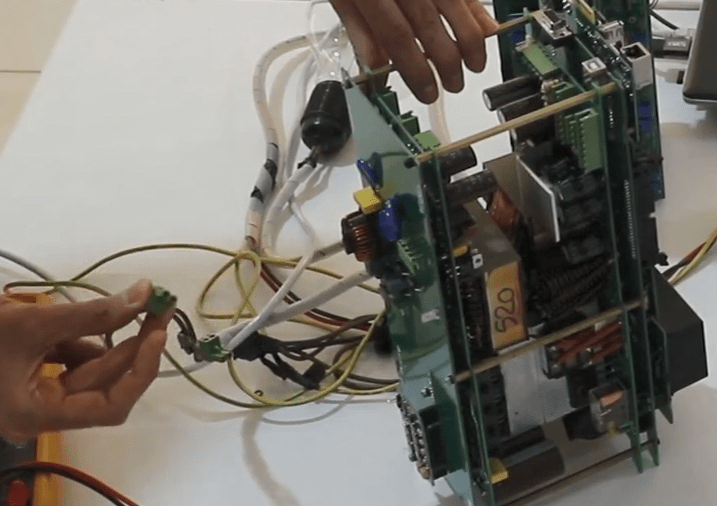

Four wires with 4 pin female Phoenix connectors

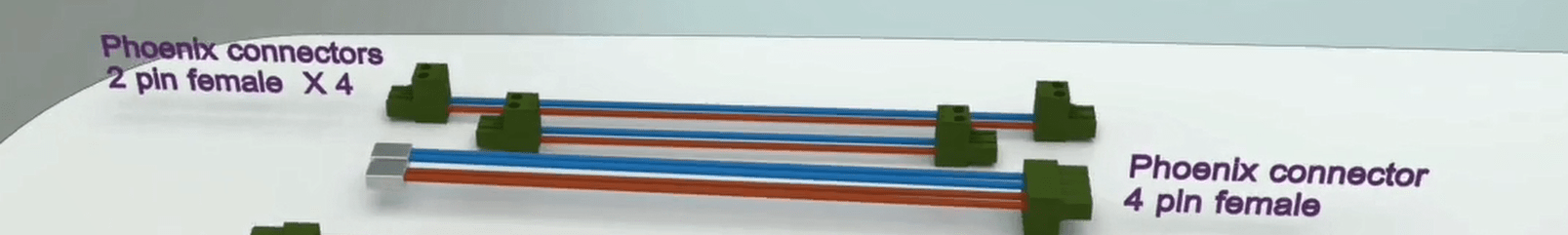

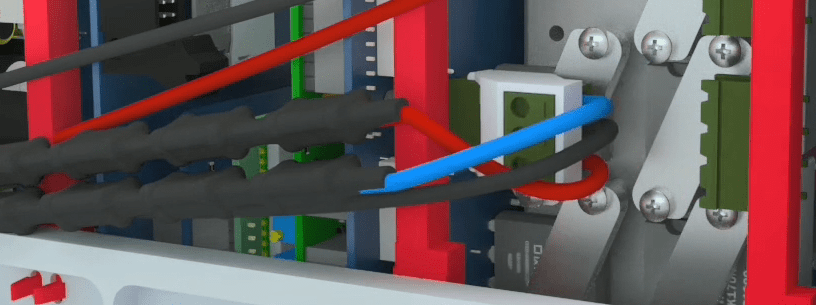

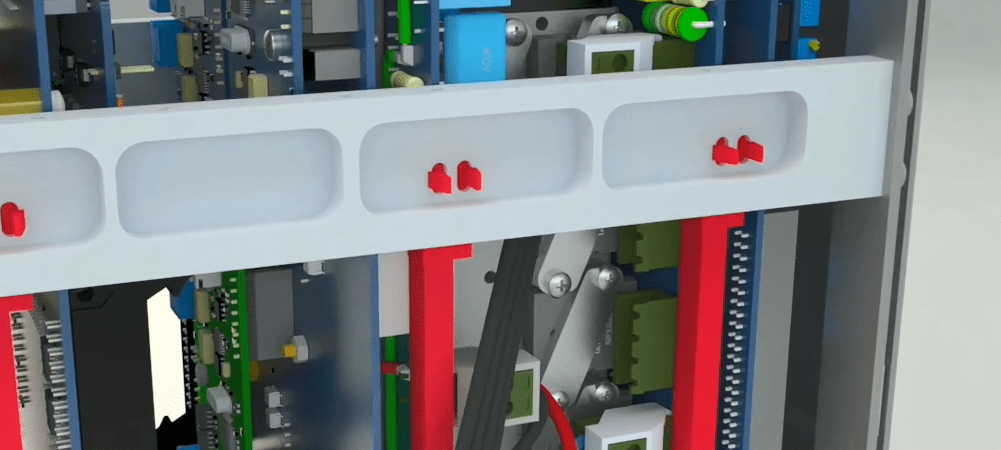

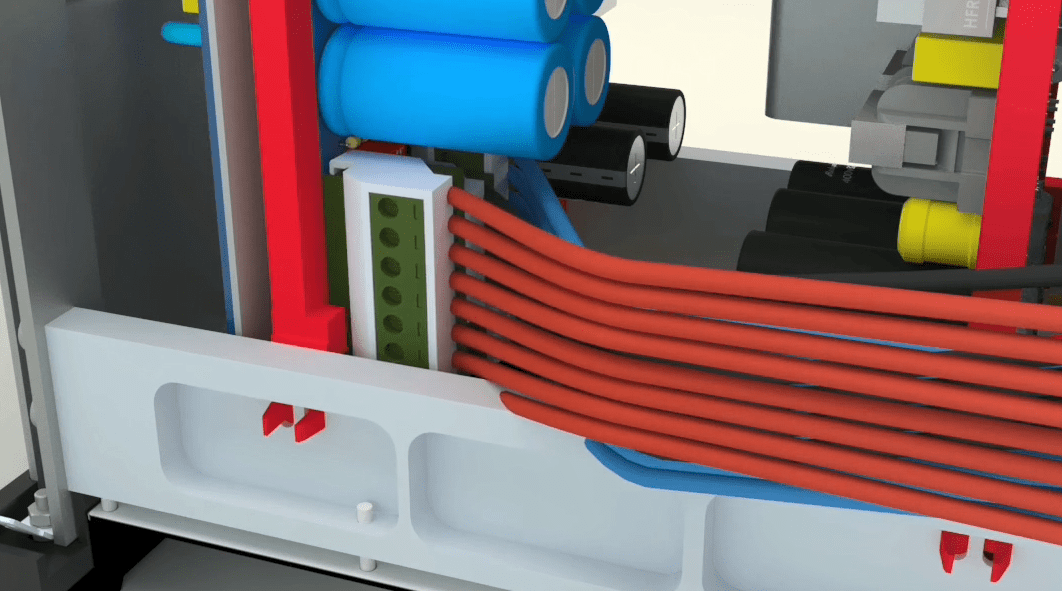

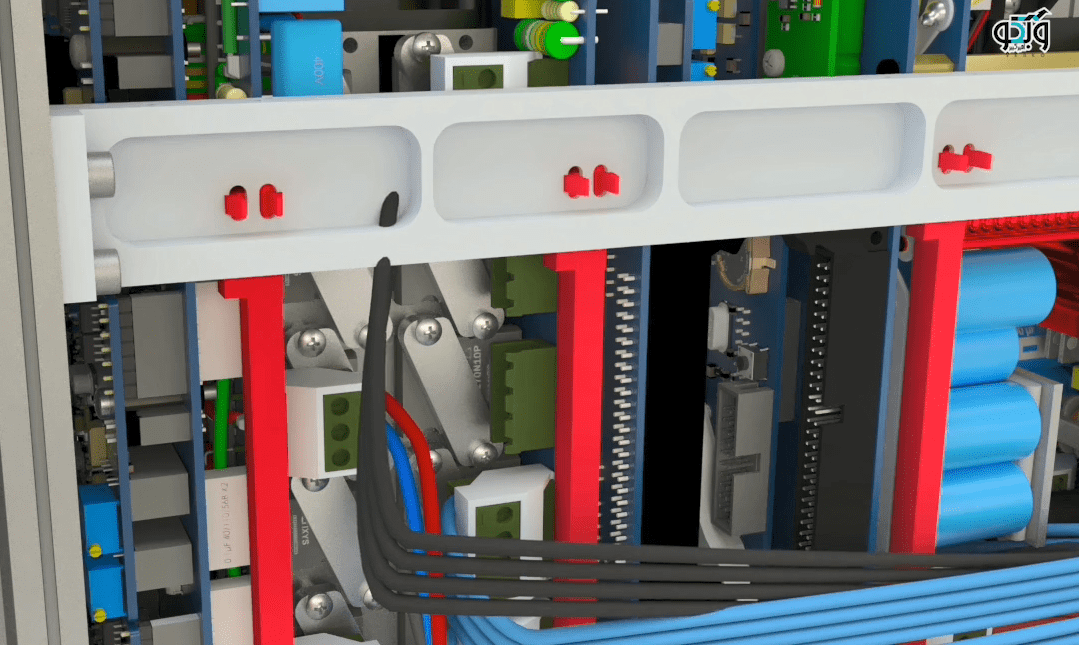

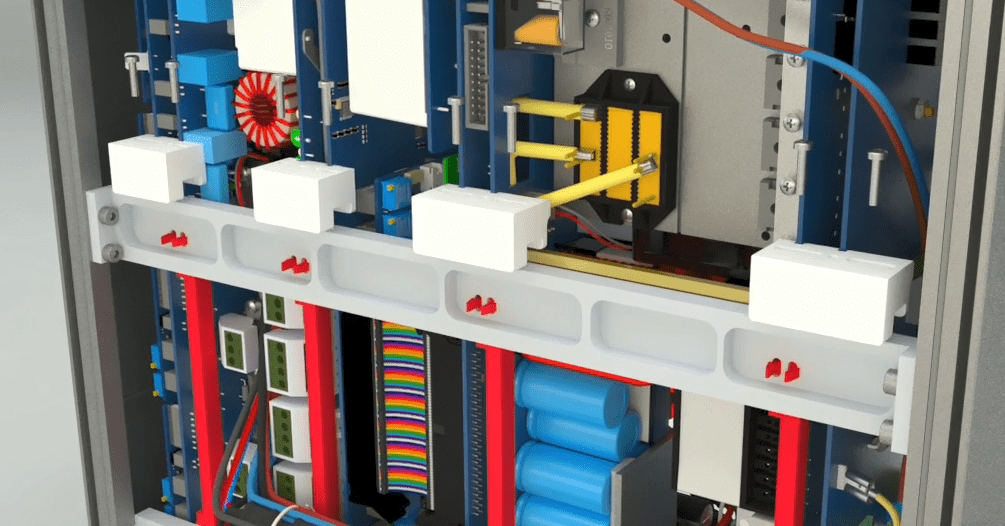

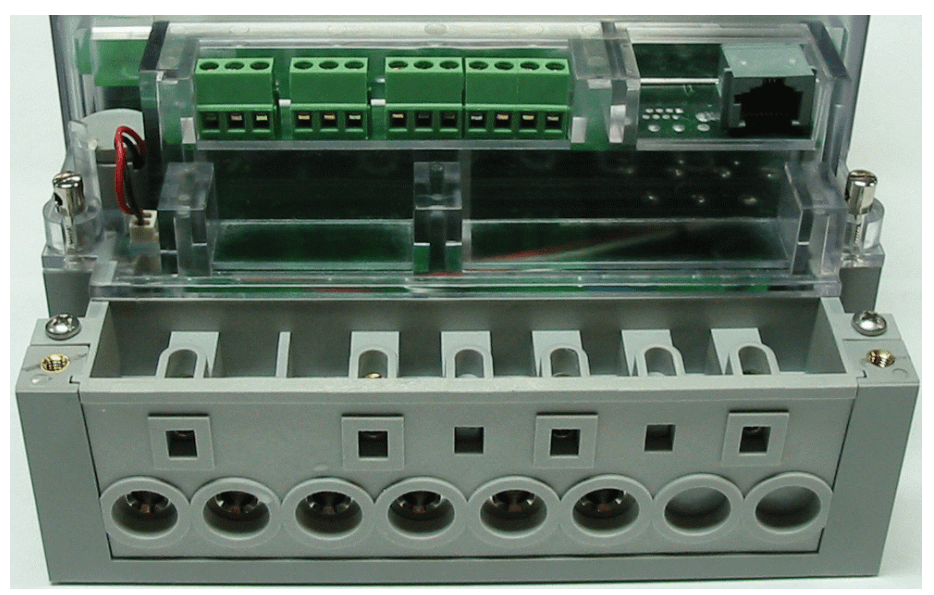

Current connectors

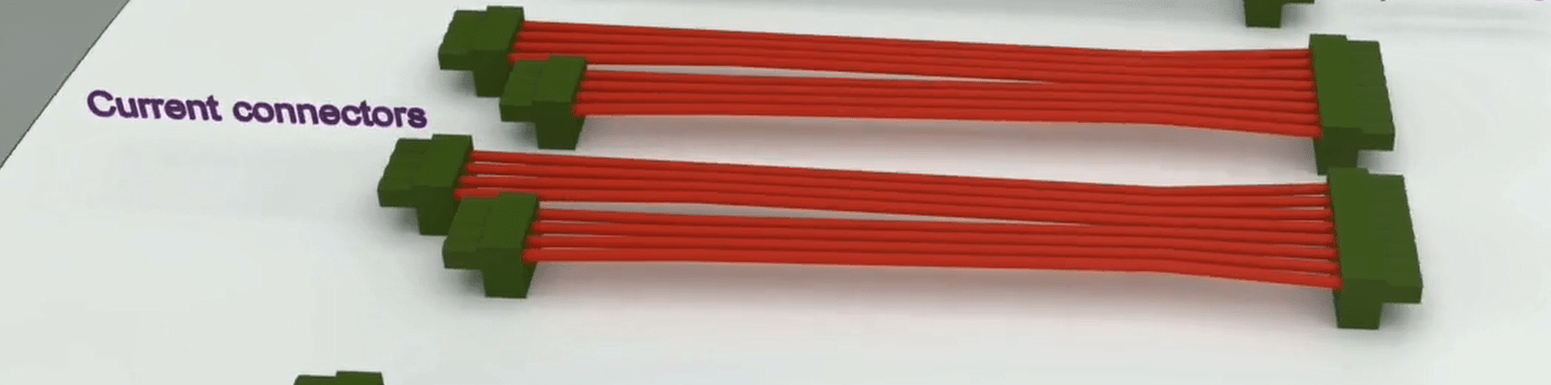

Voltage connectors

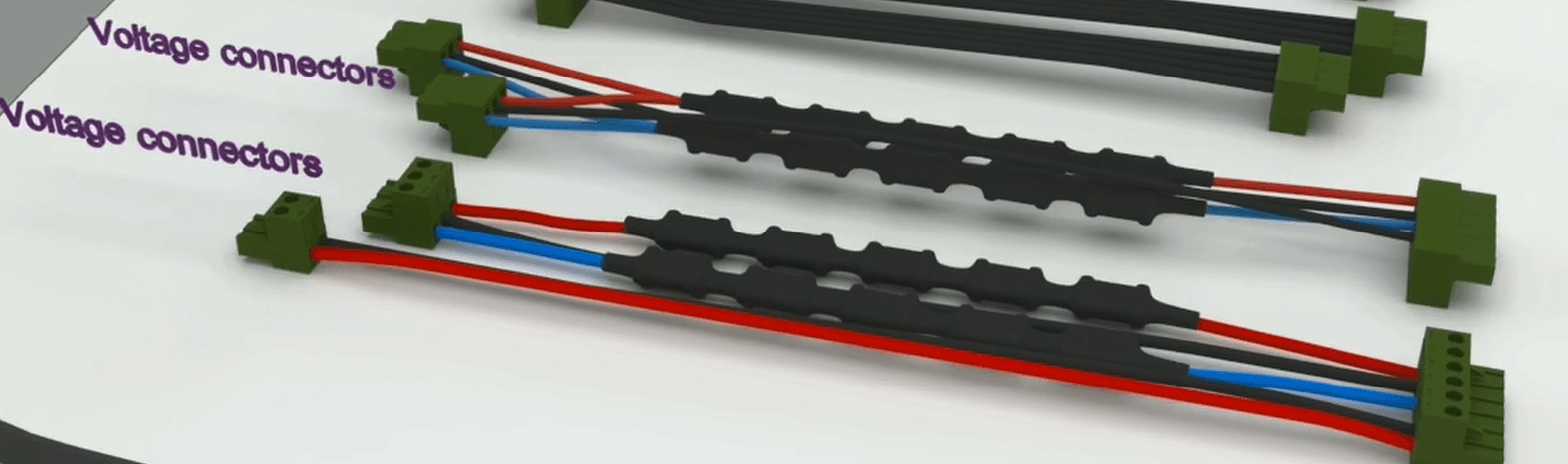

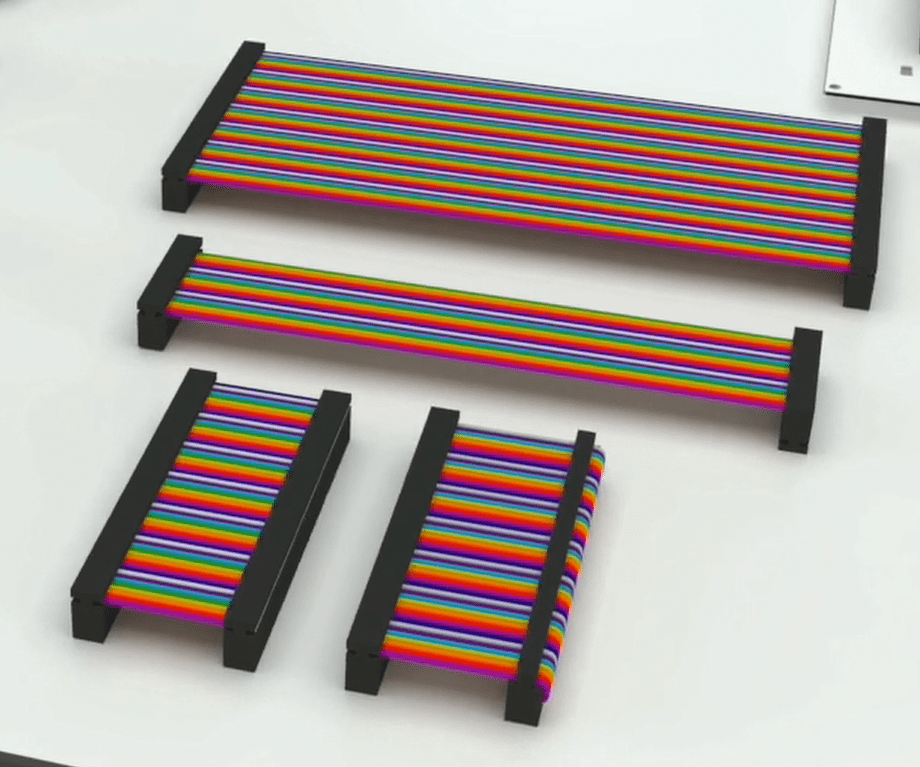

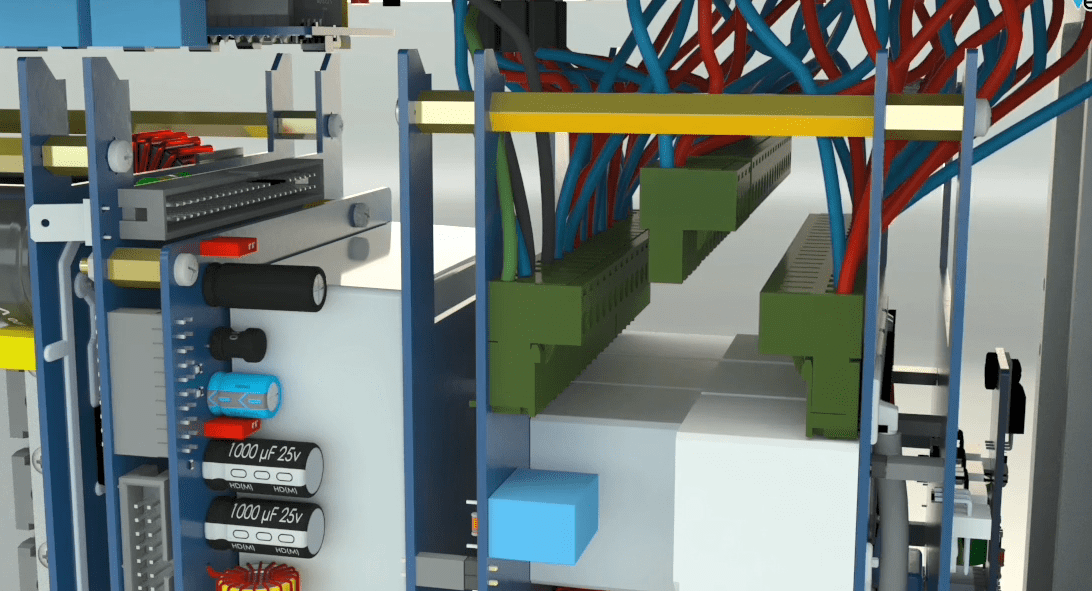

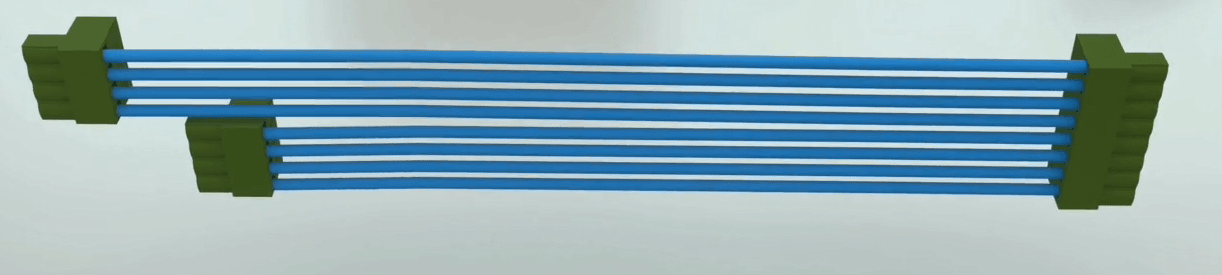

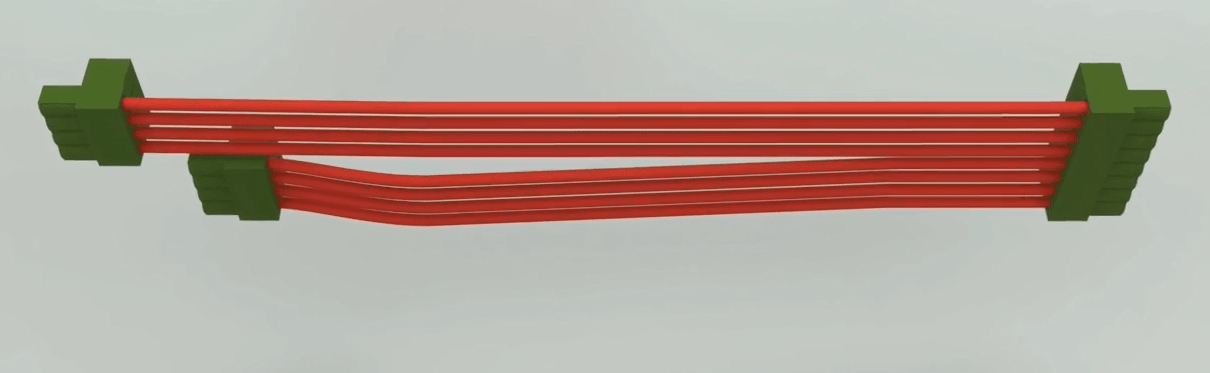

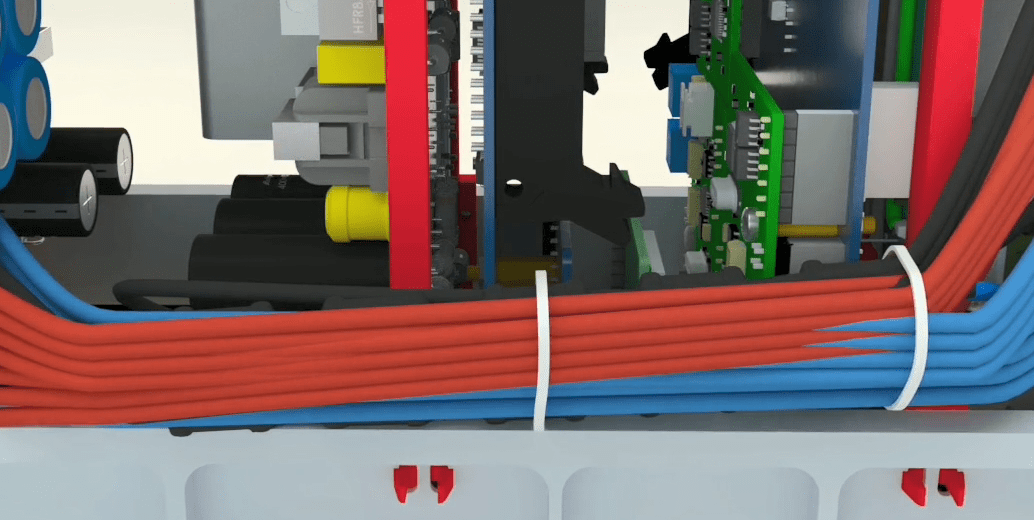

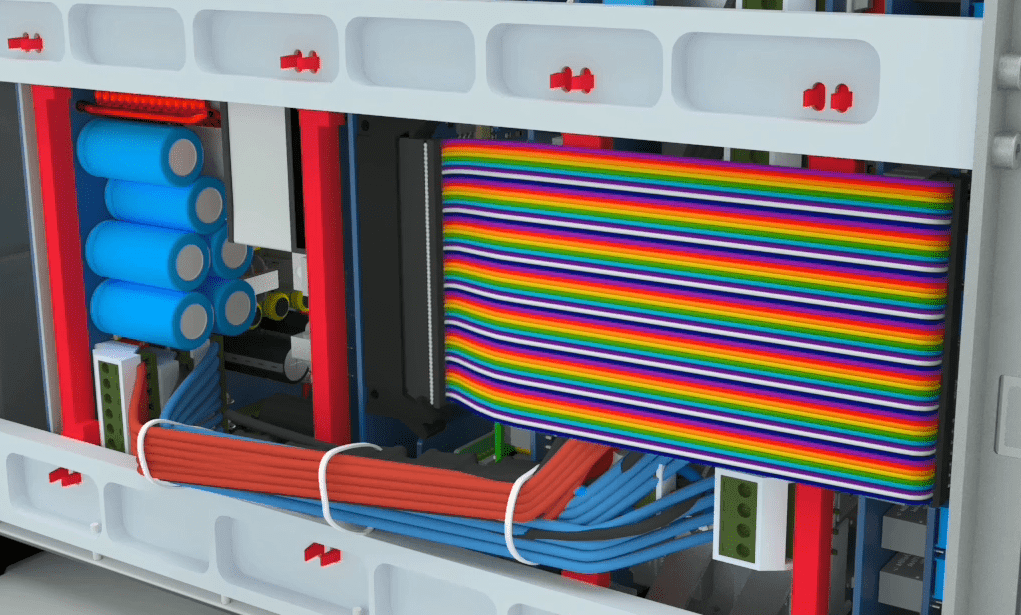

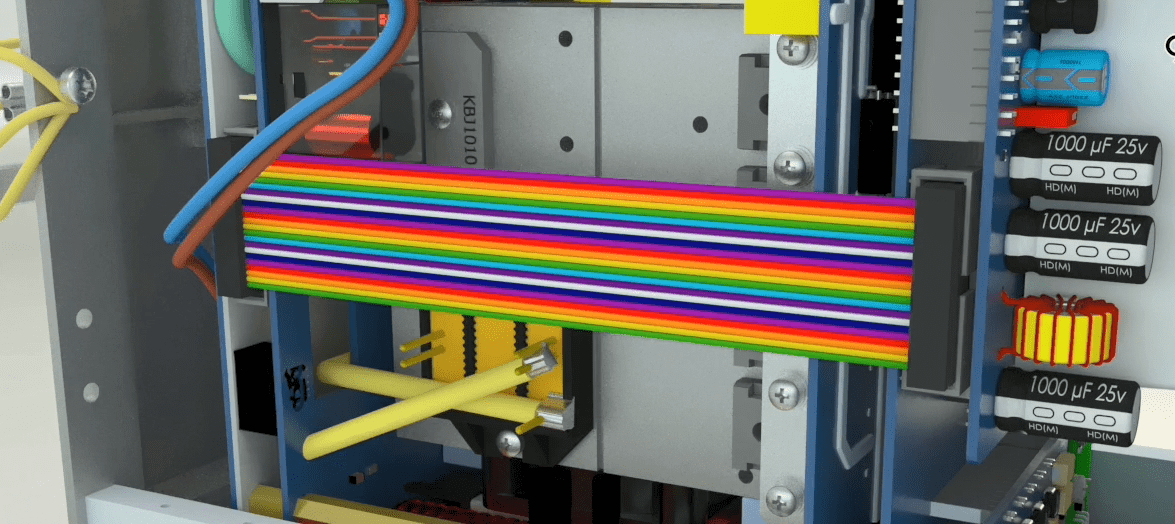

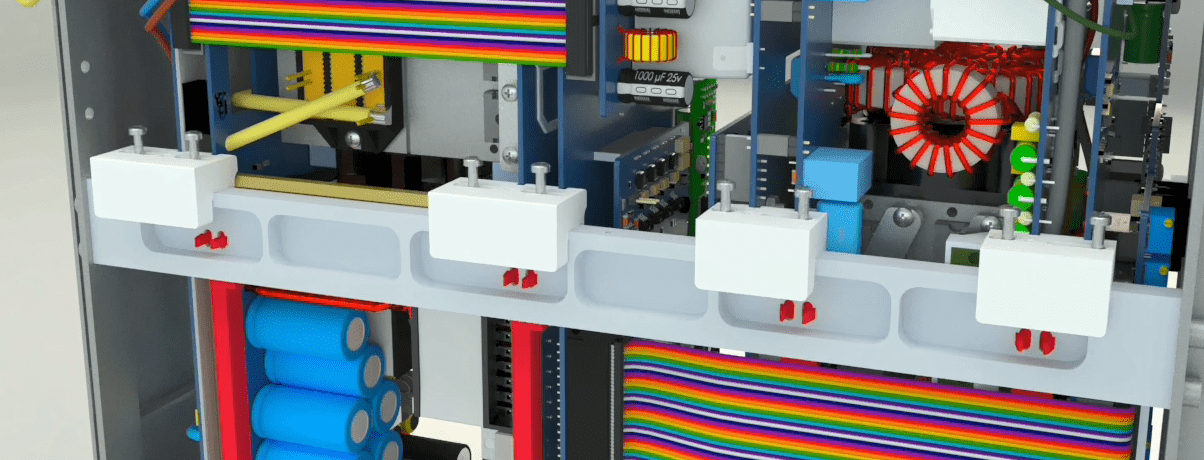

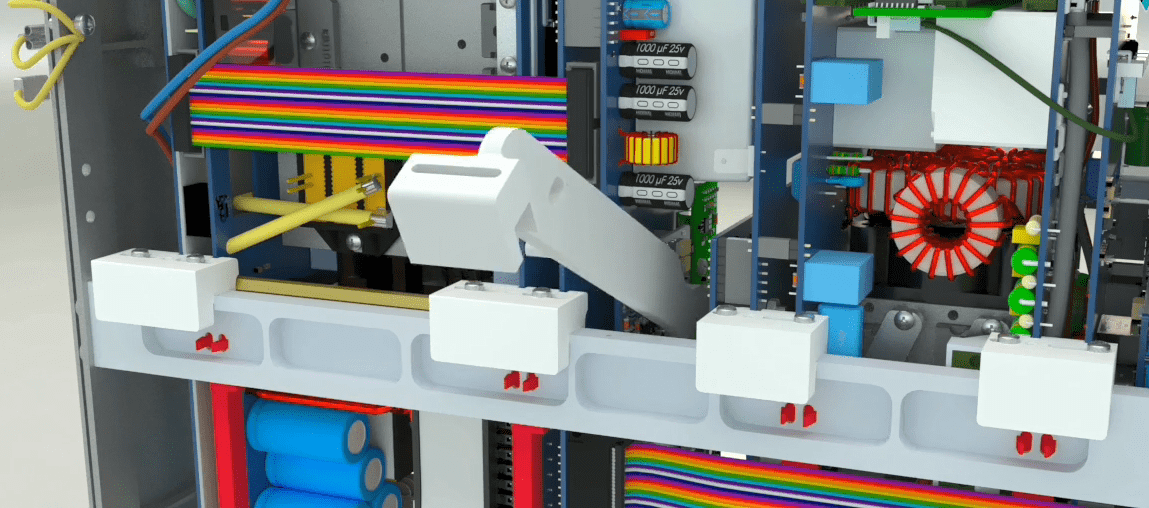

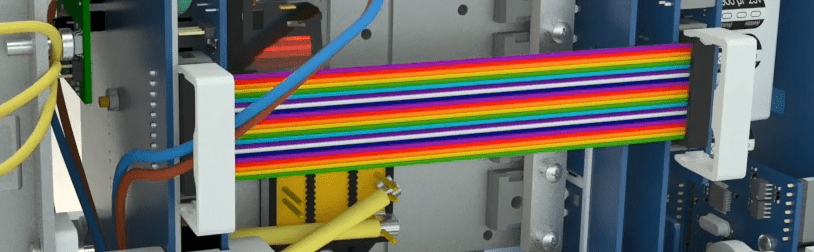

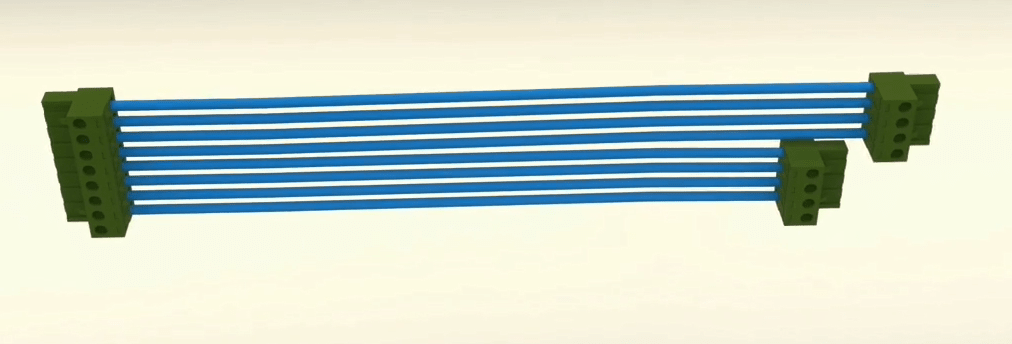

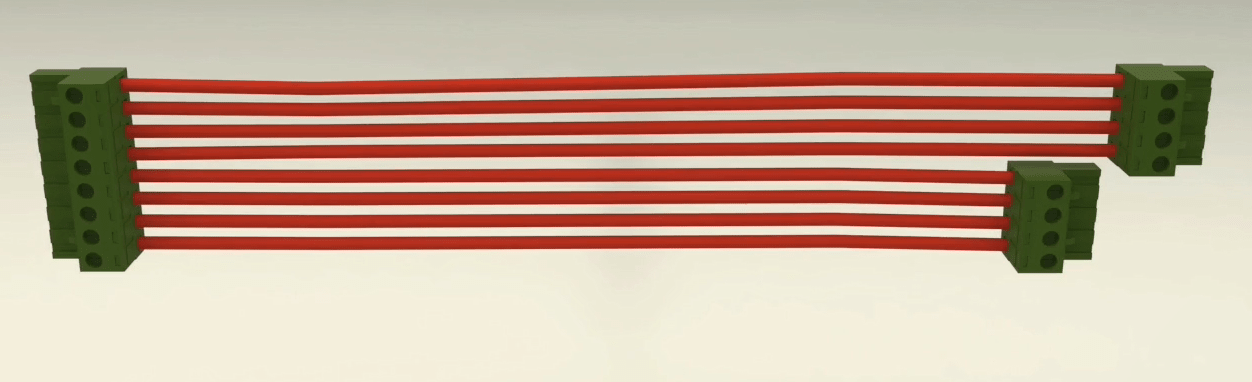

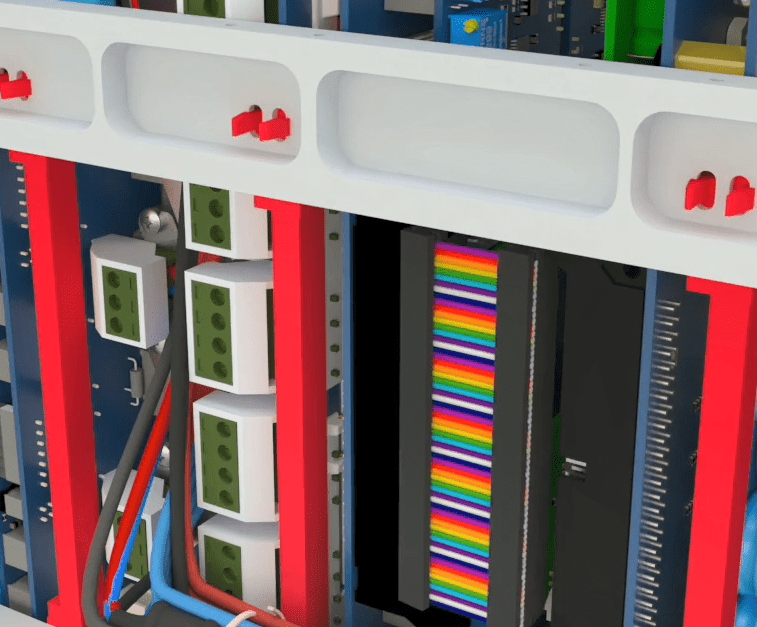

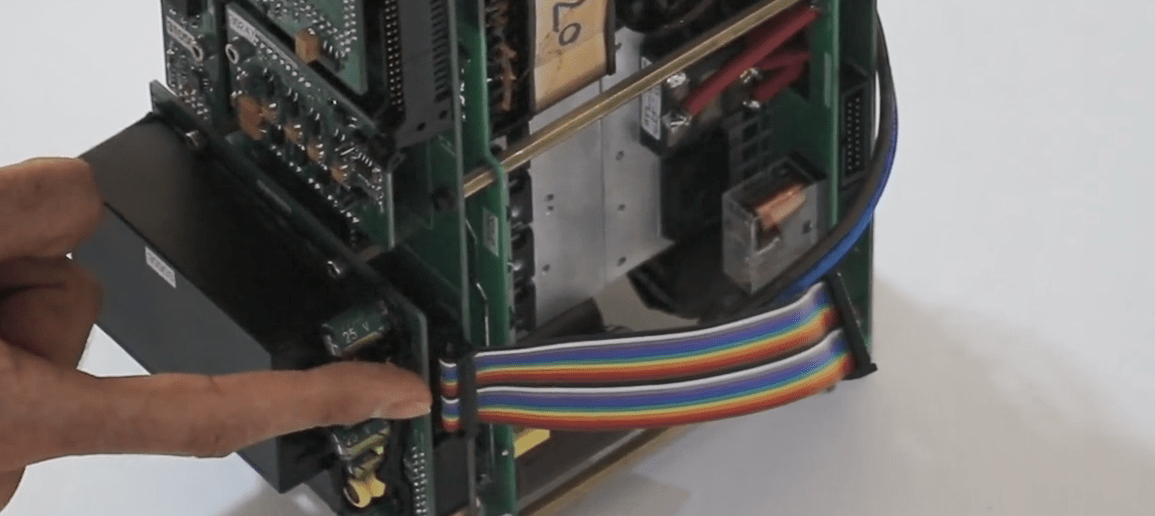

Ribbon cables

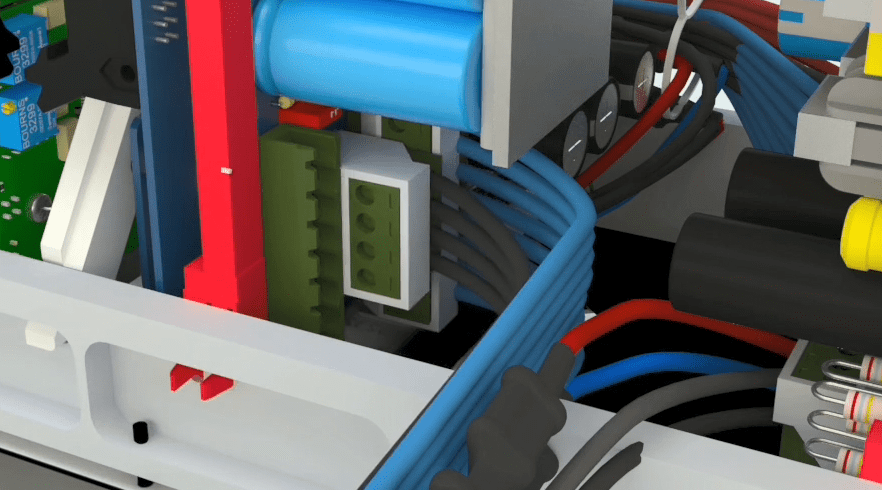

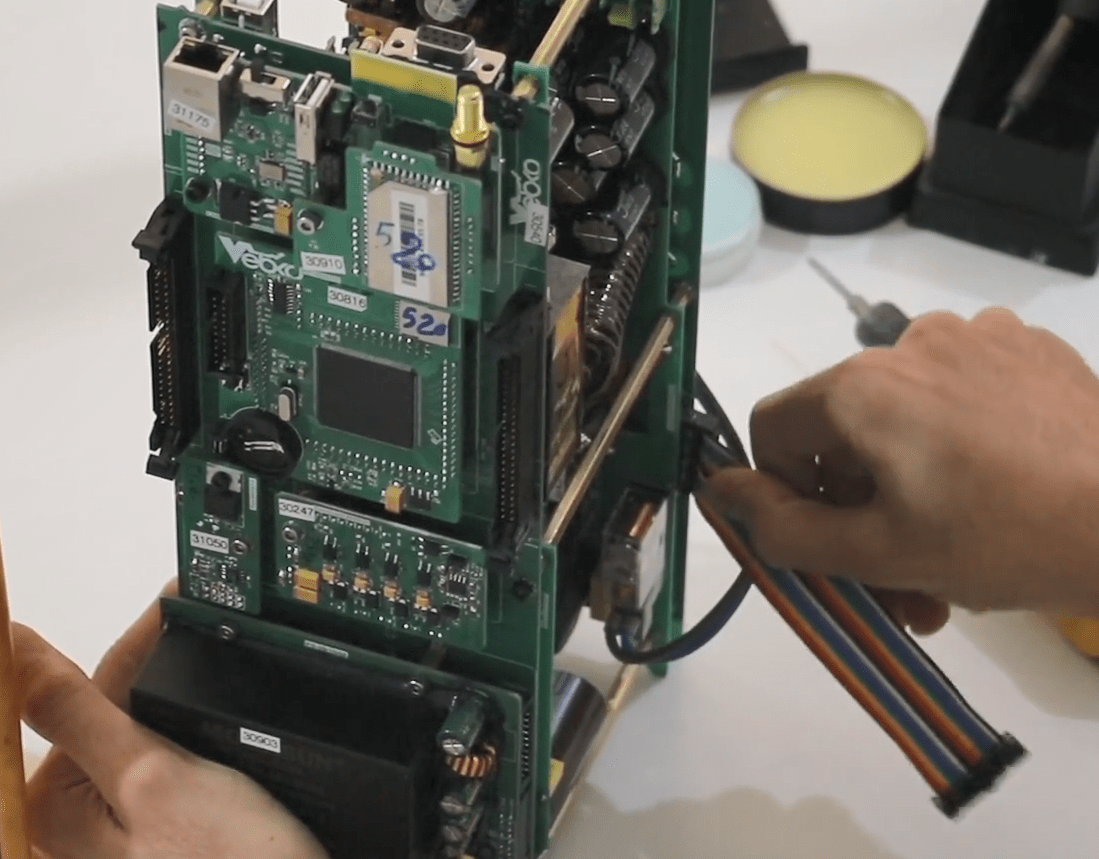

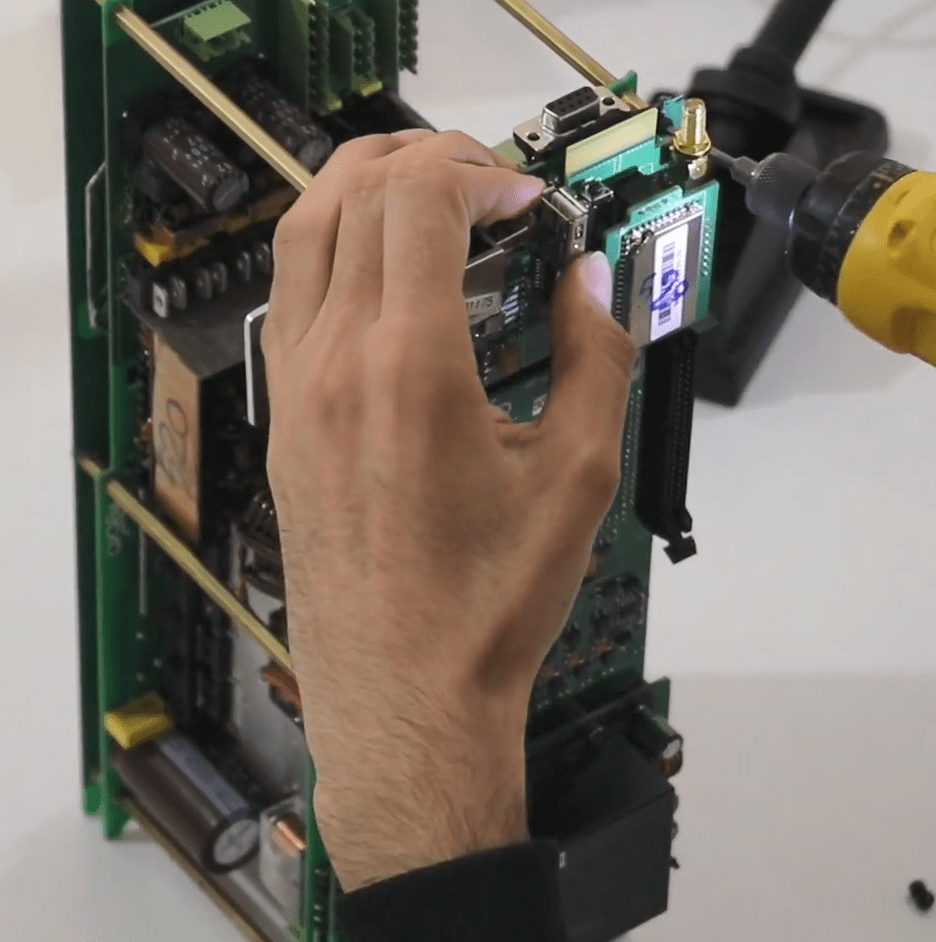

Neutrik board

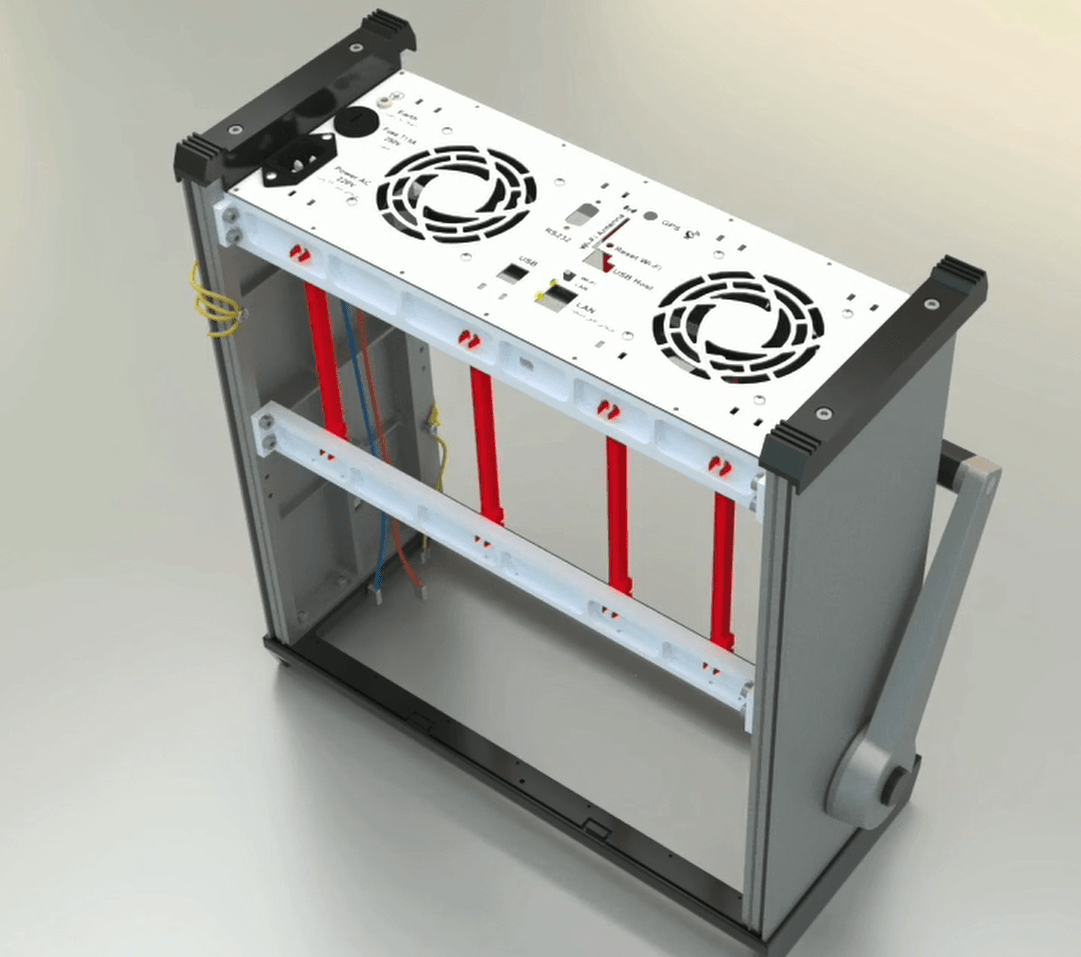

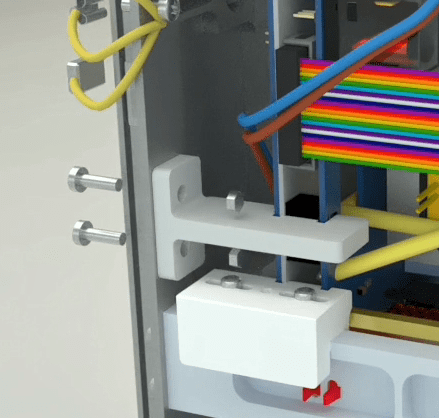

Back panel

Front panel

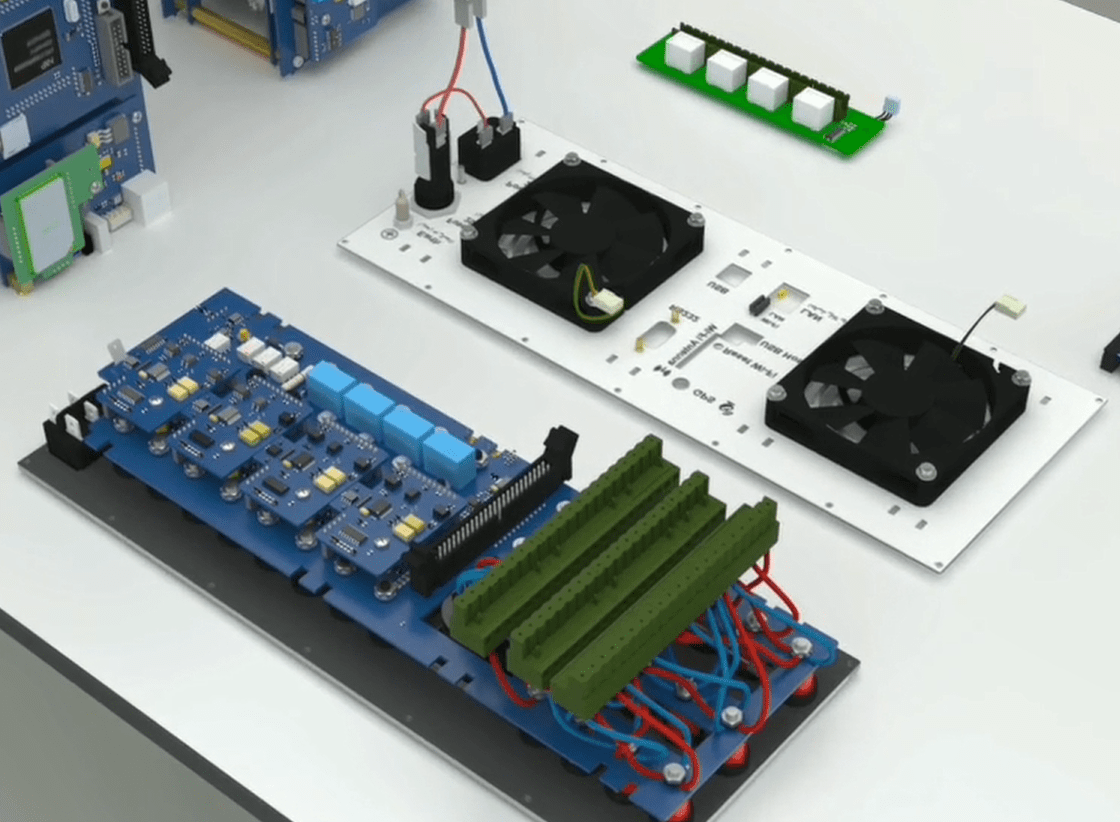

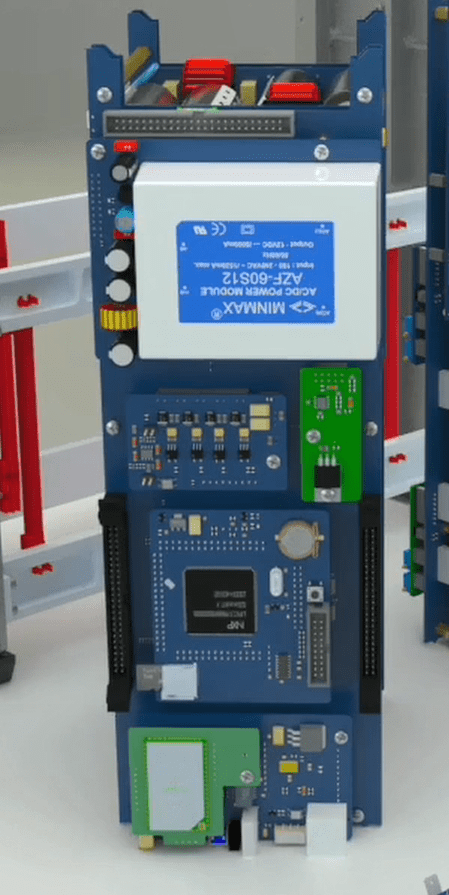

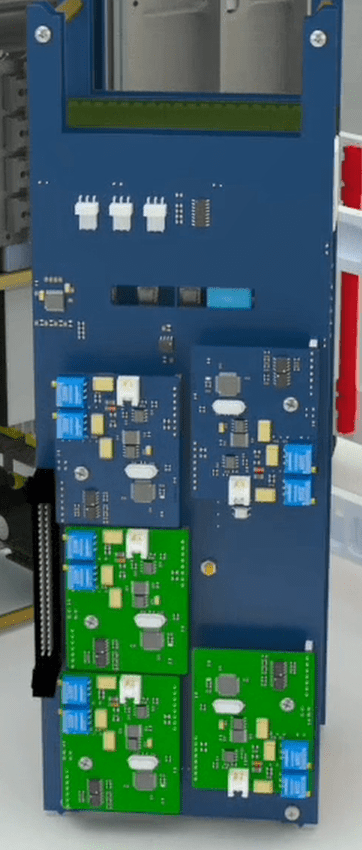

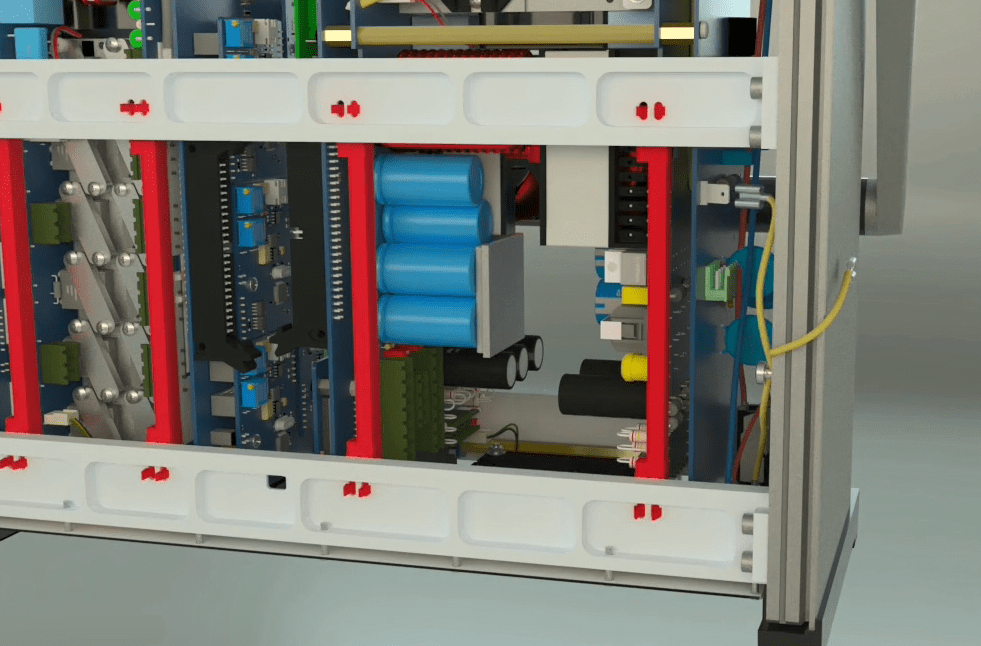

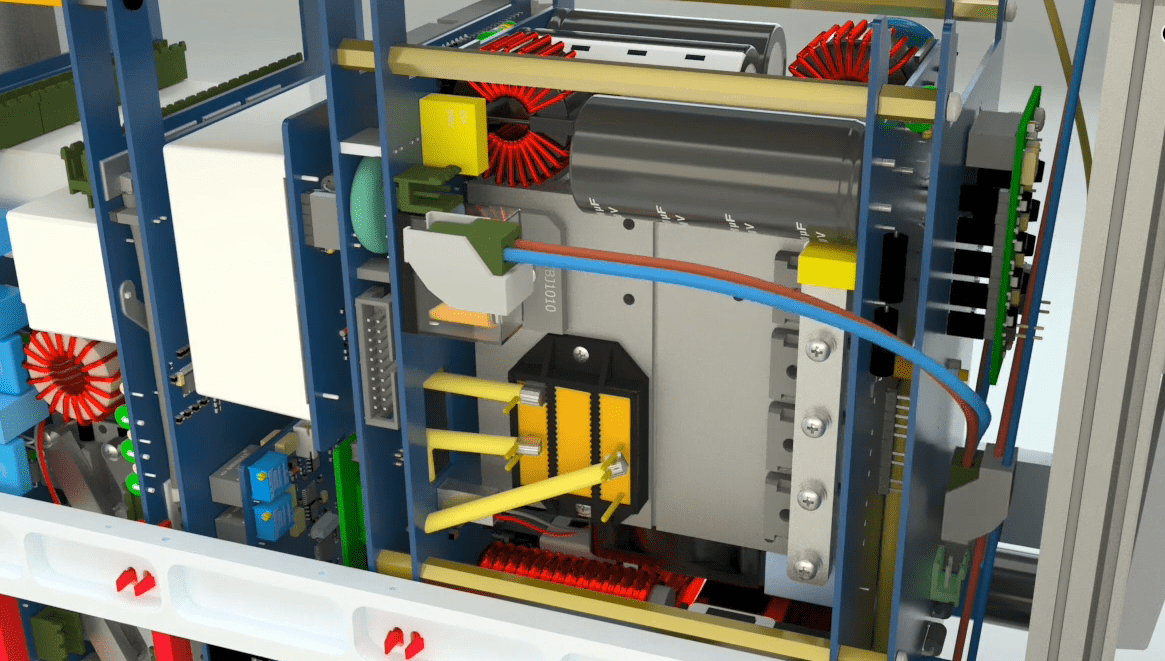

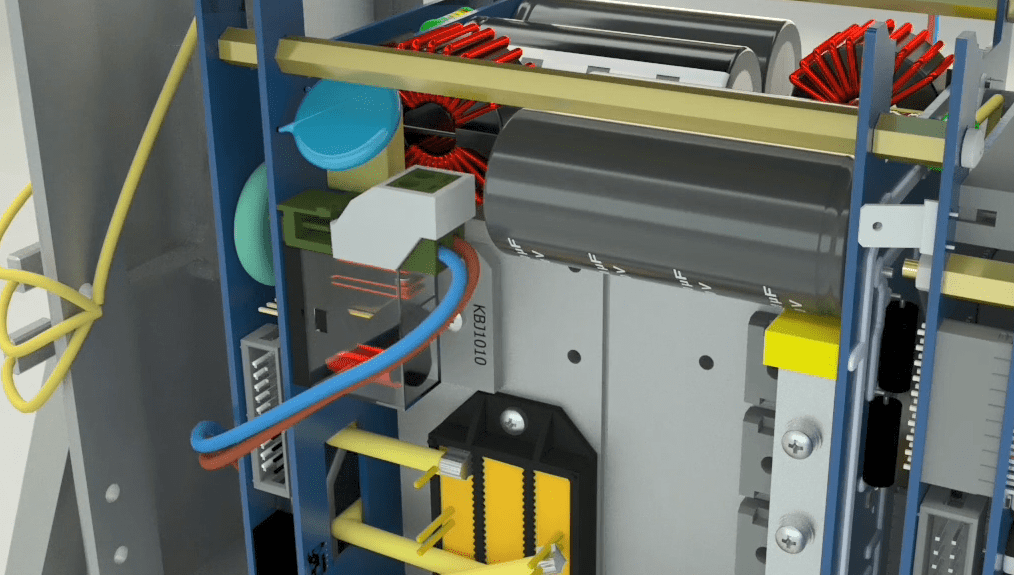

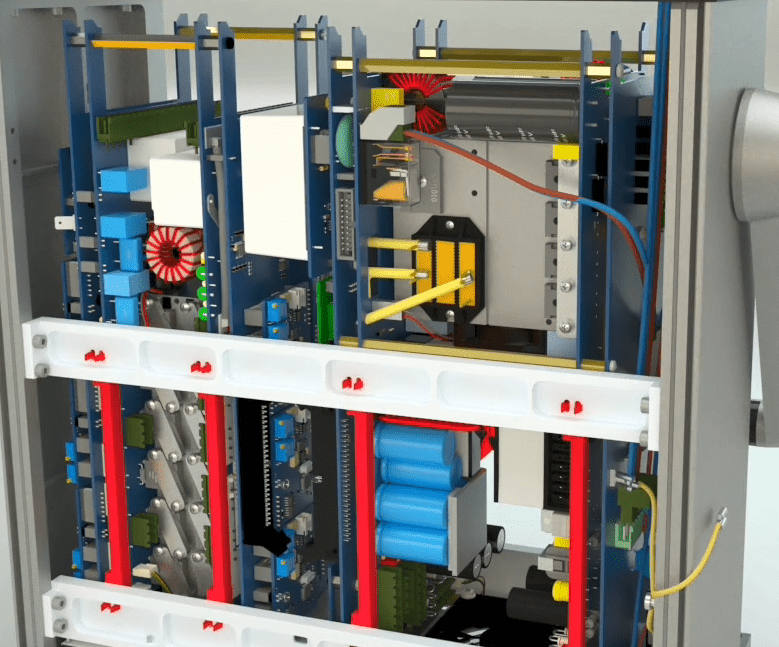

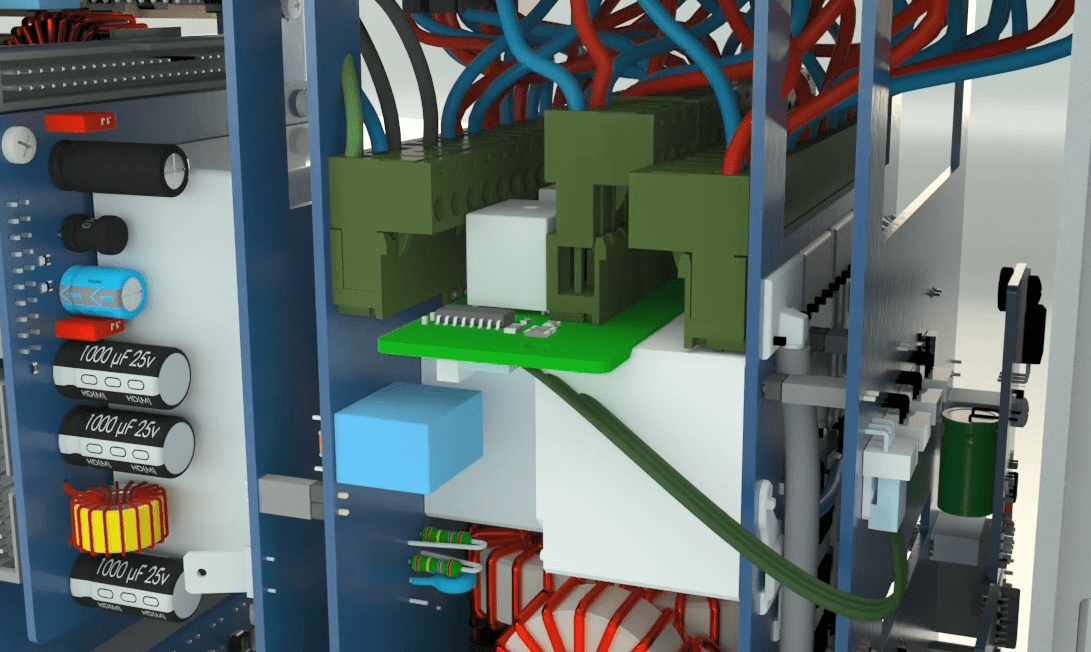

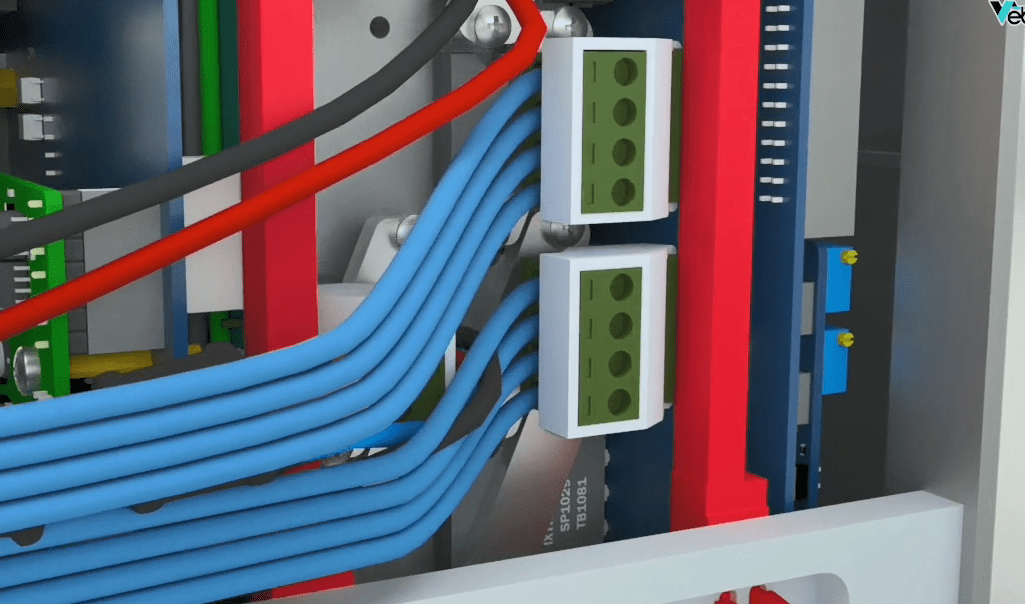

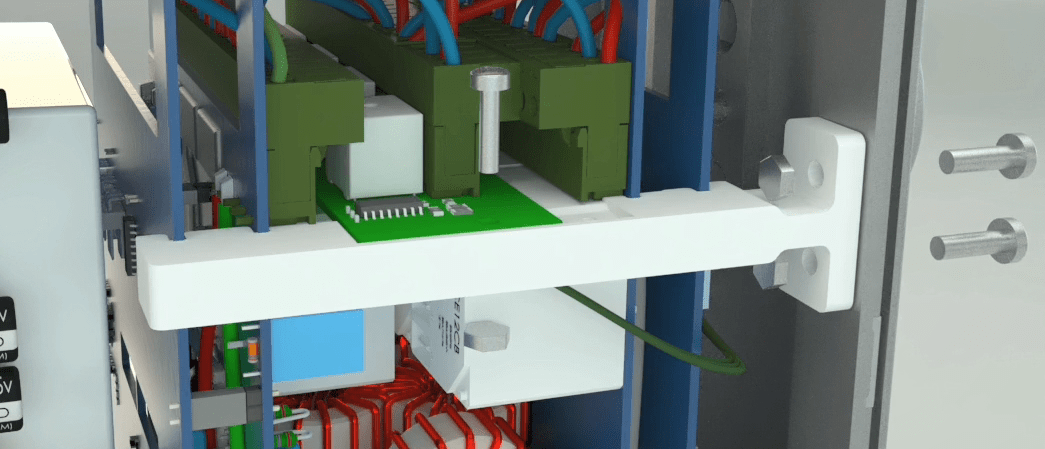

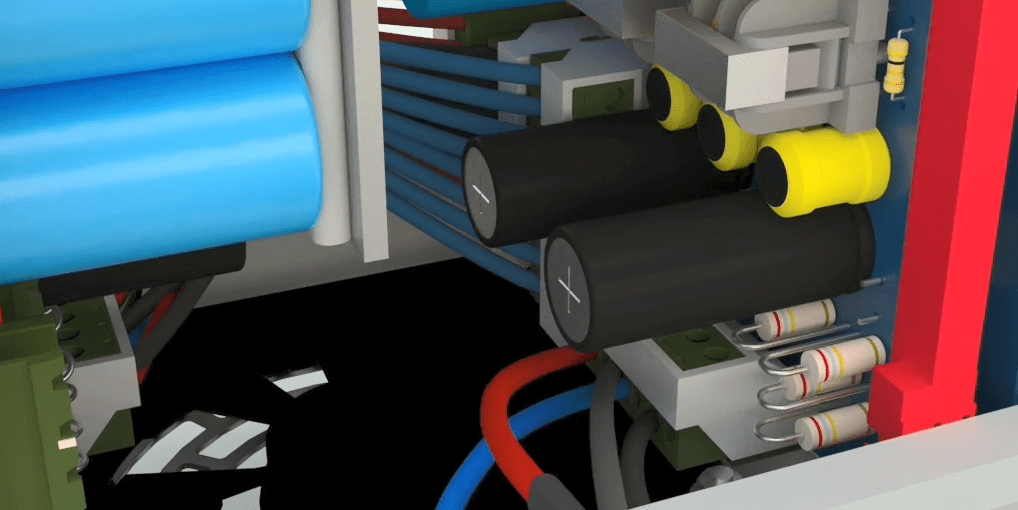

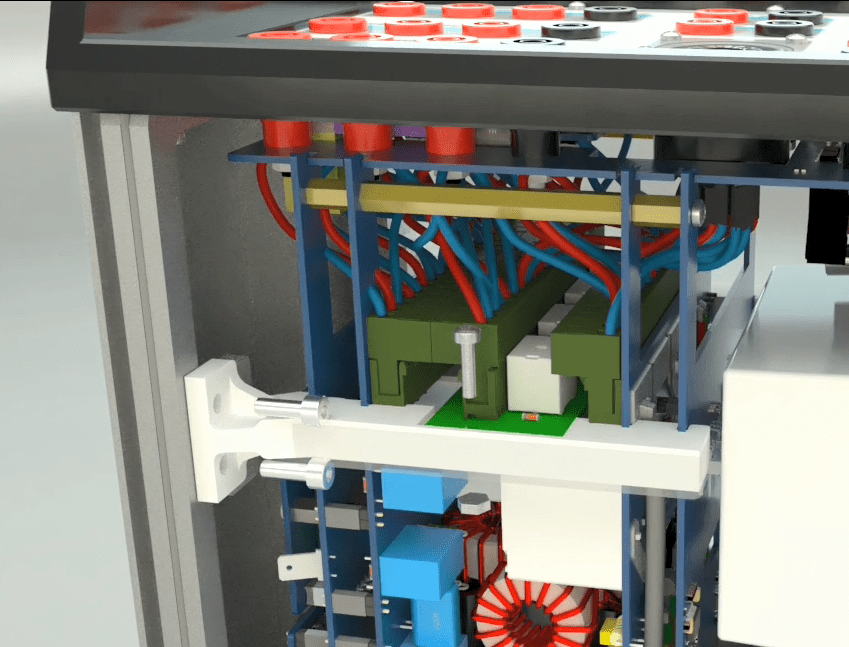

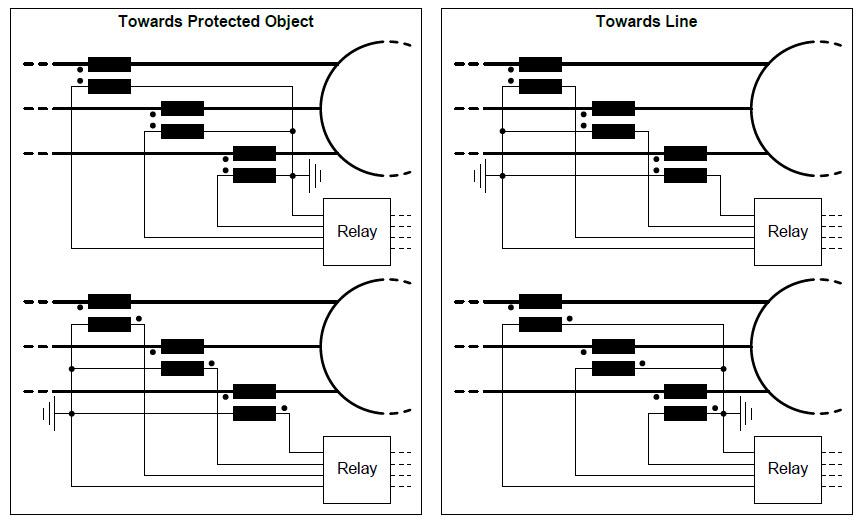

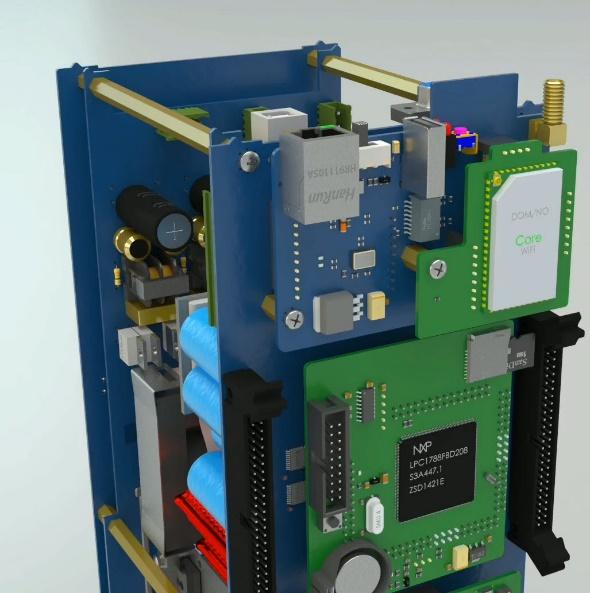

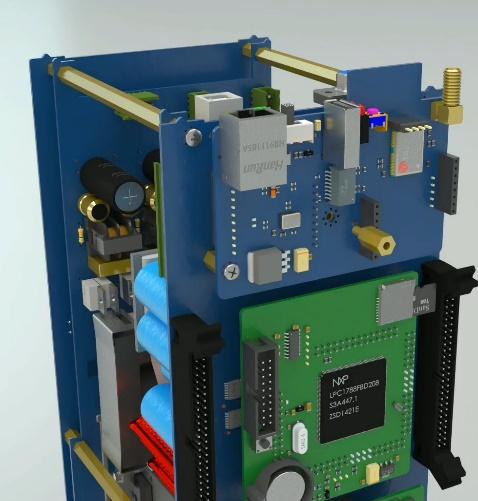

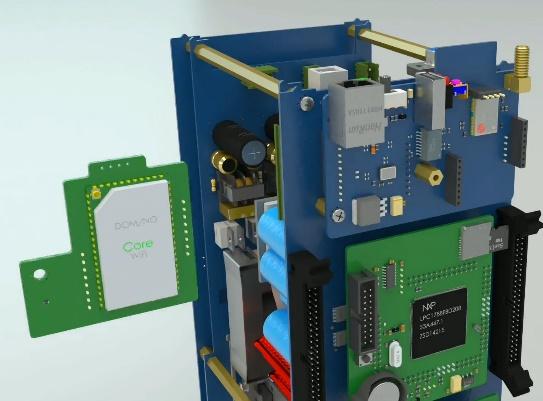

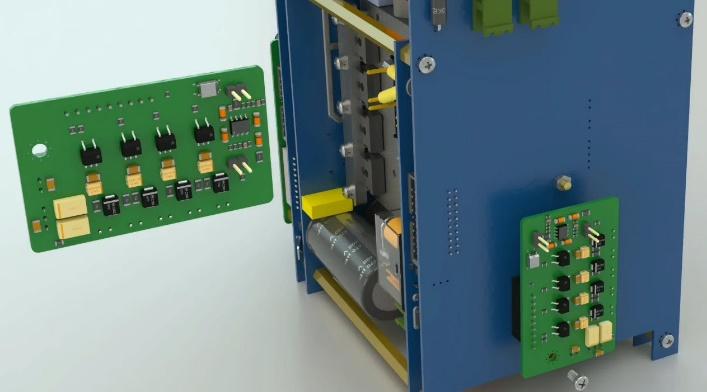

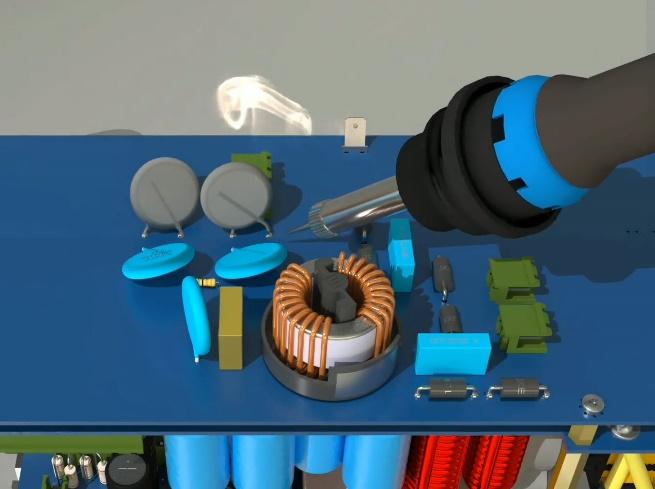

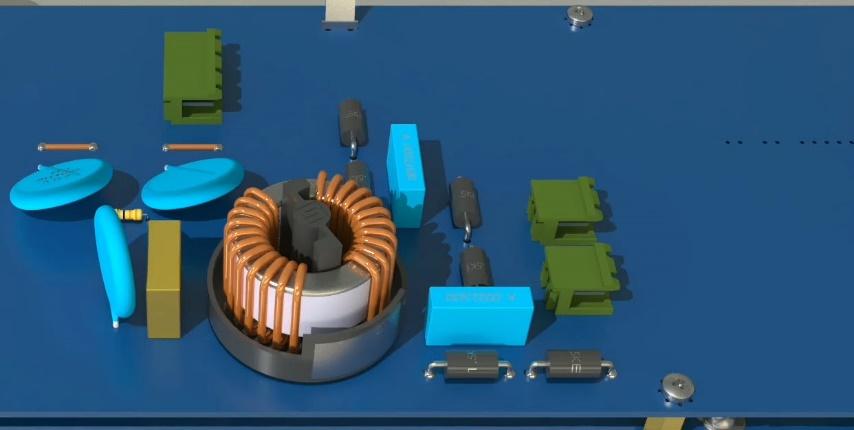

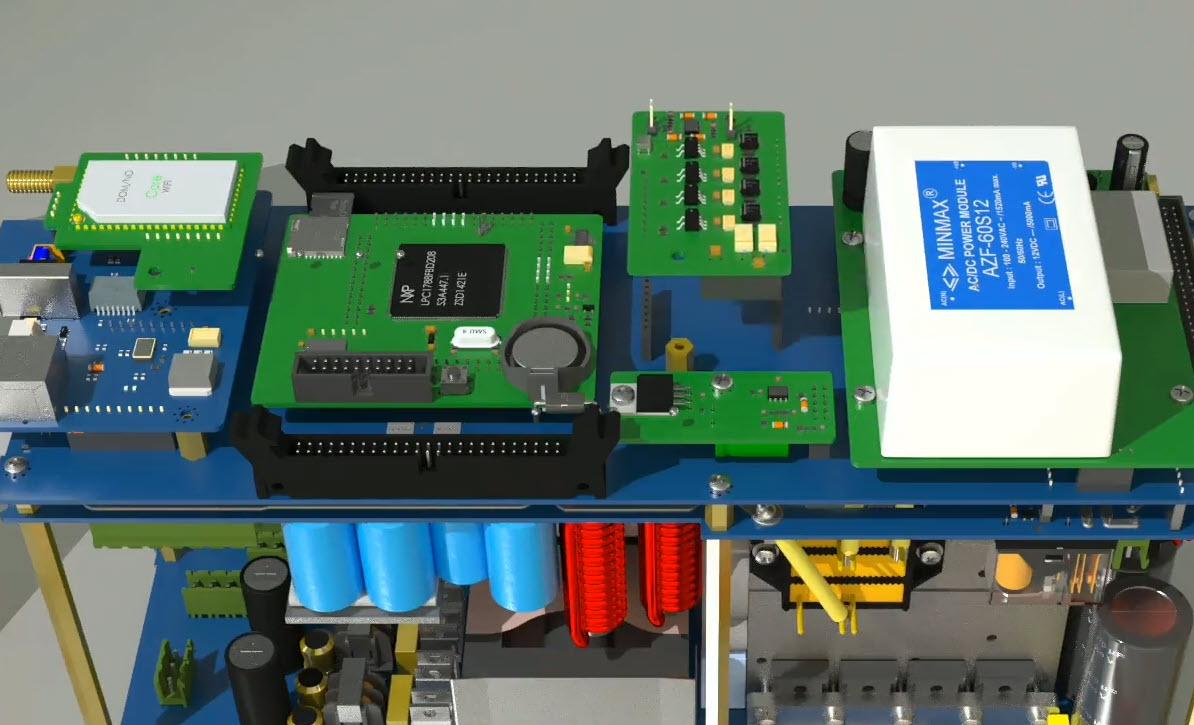

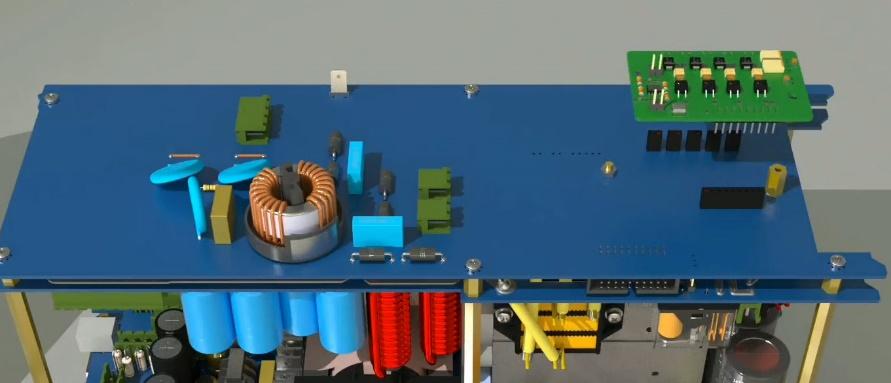

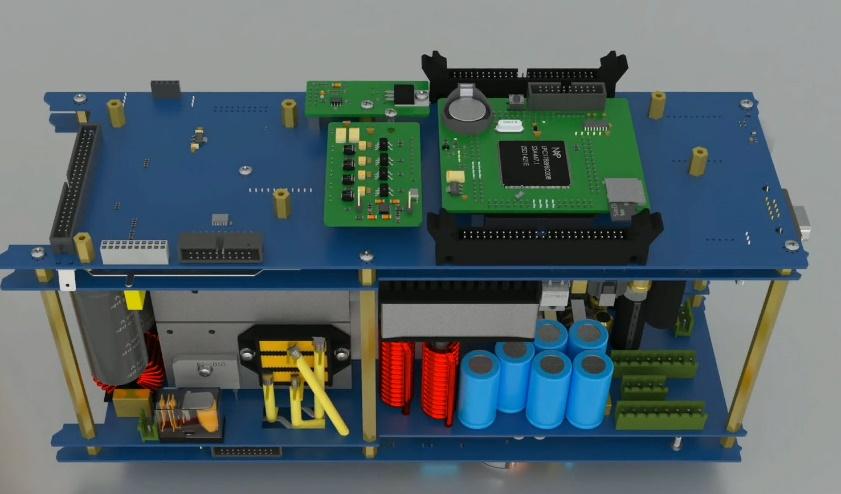

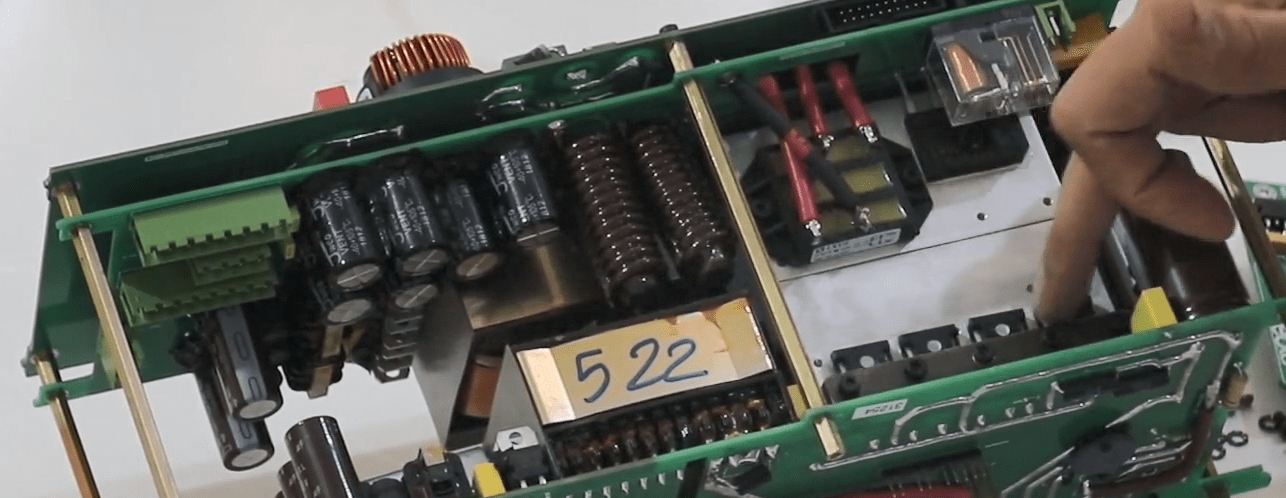

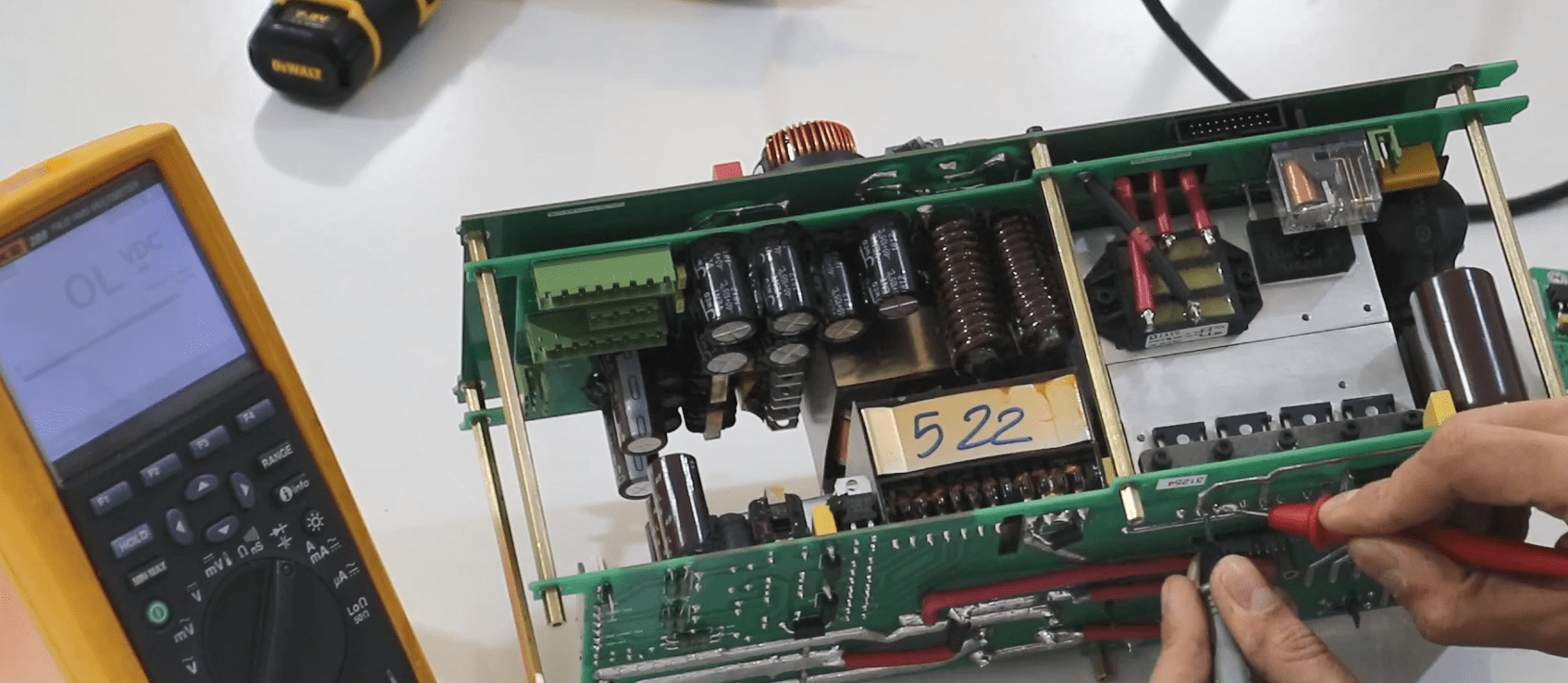

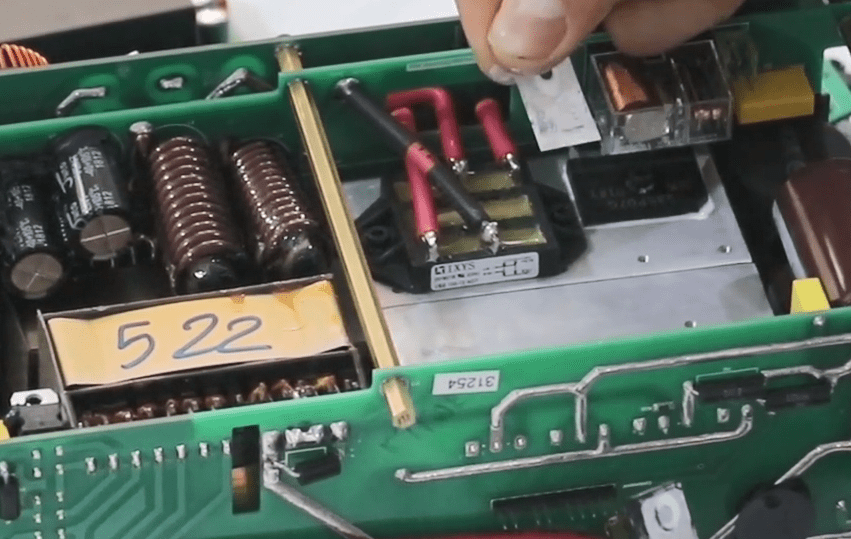

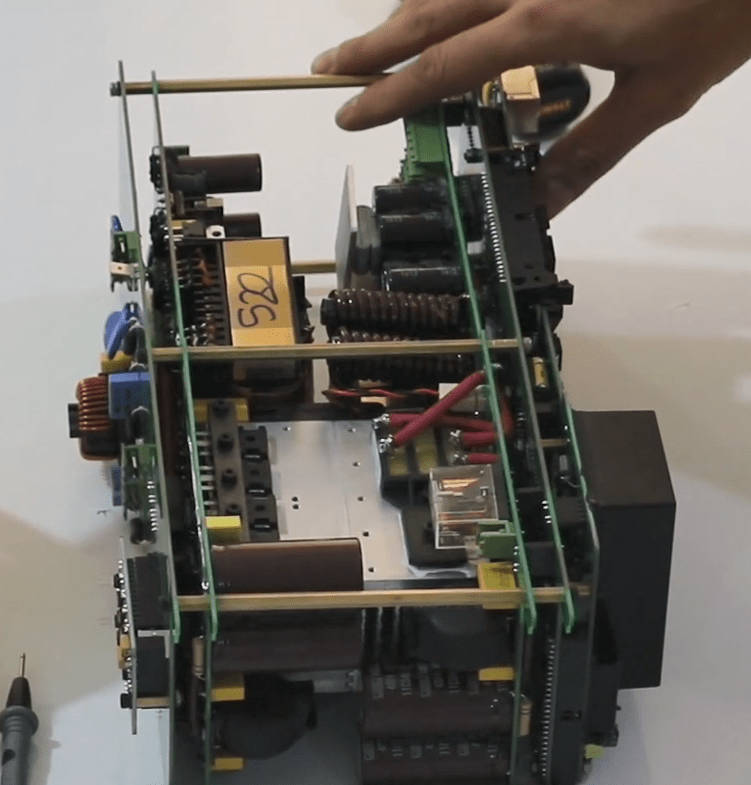

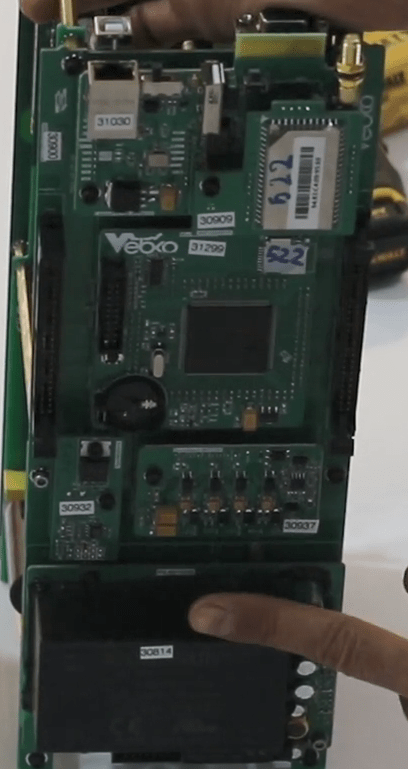

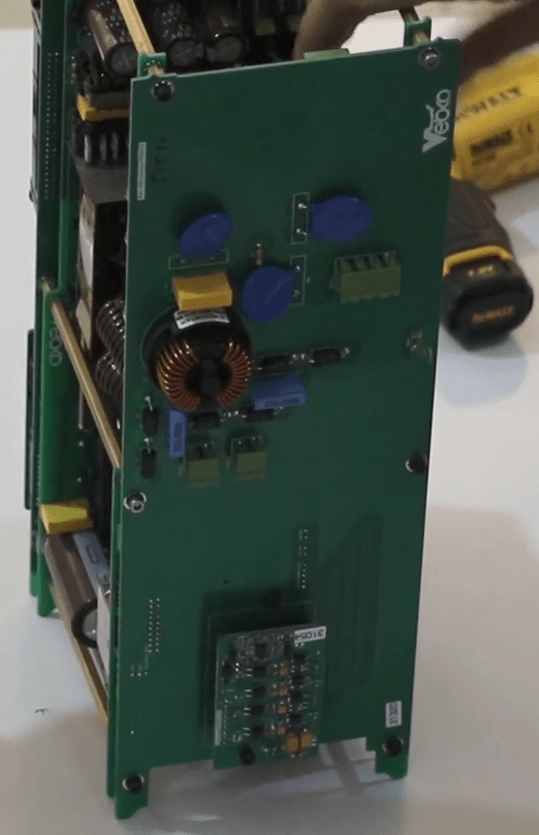

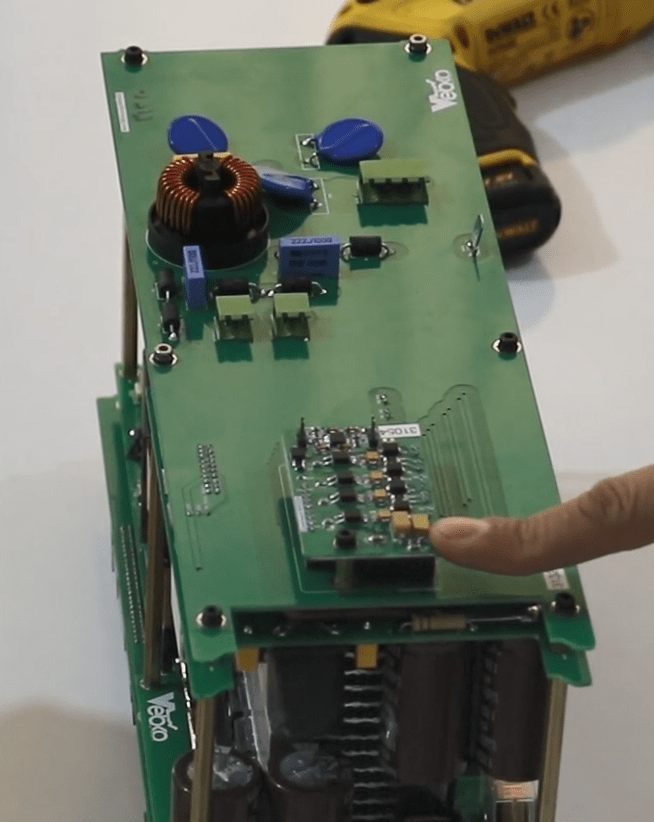

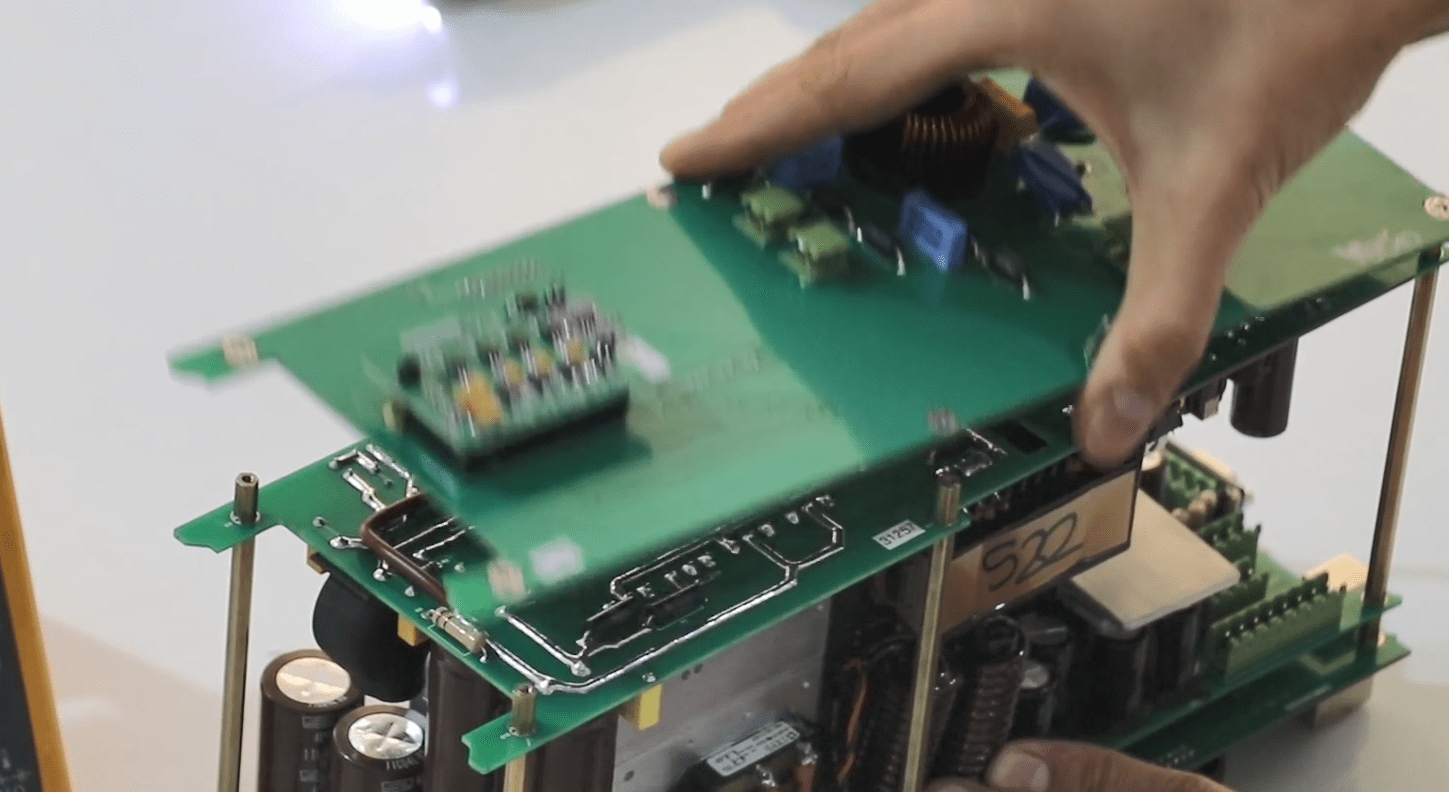

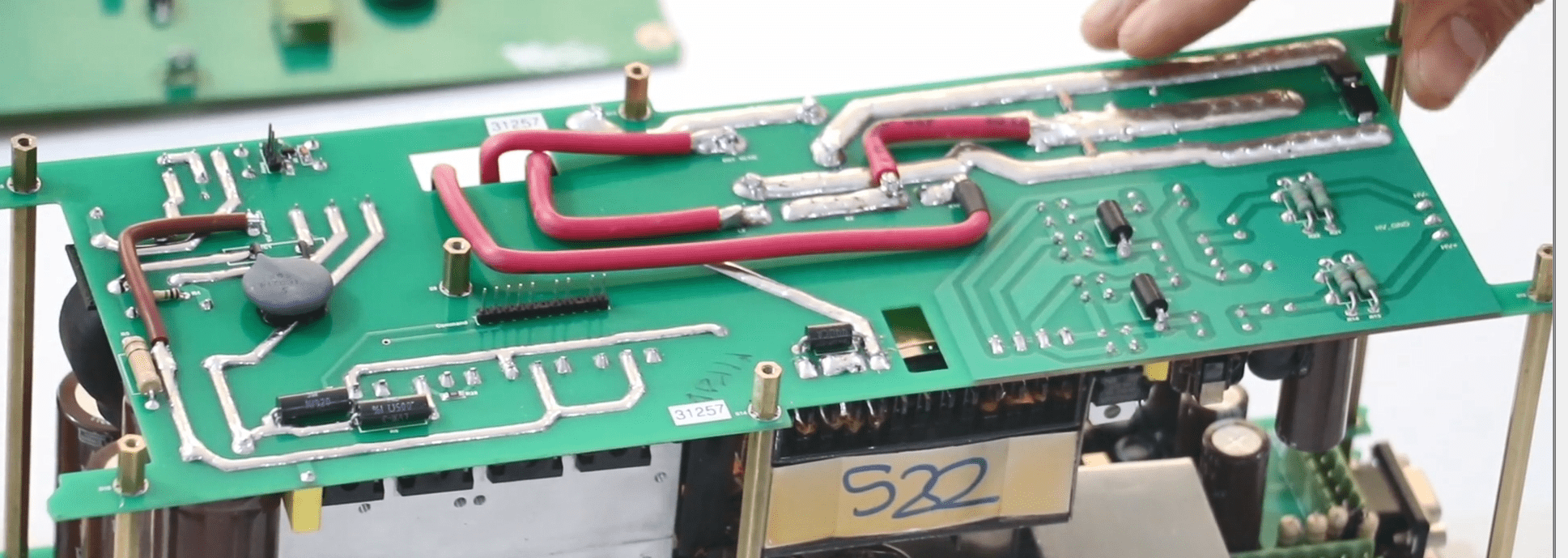

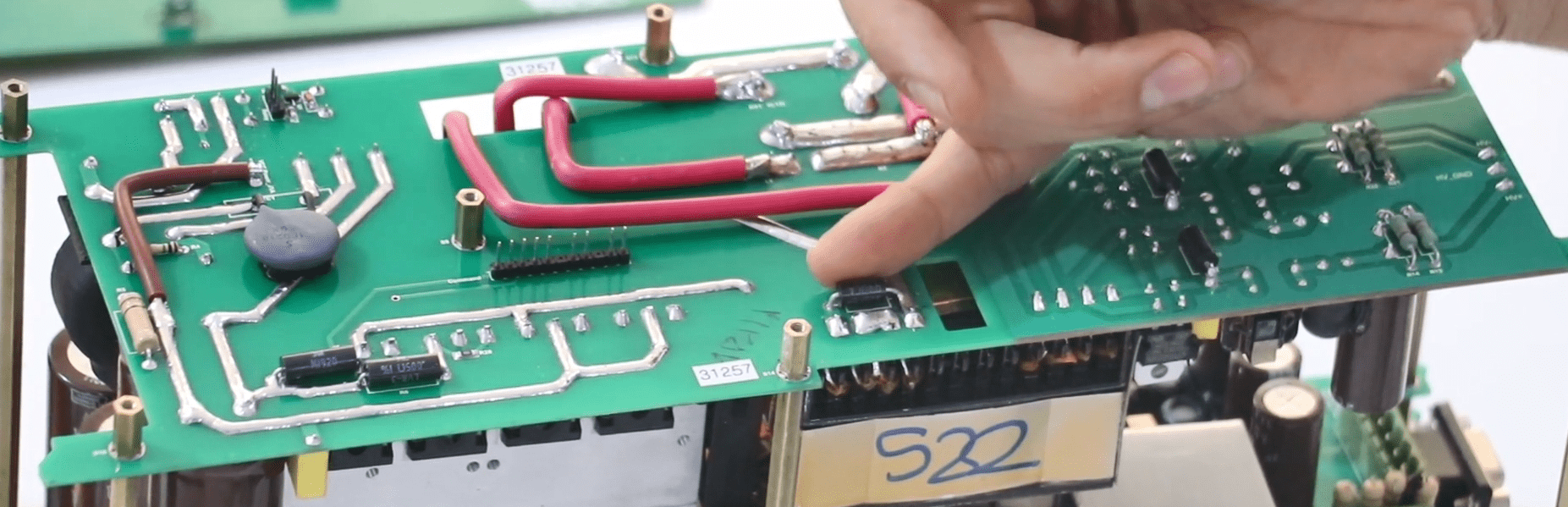

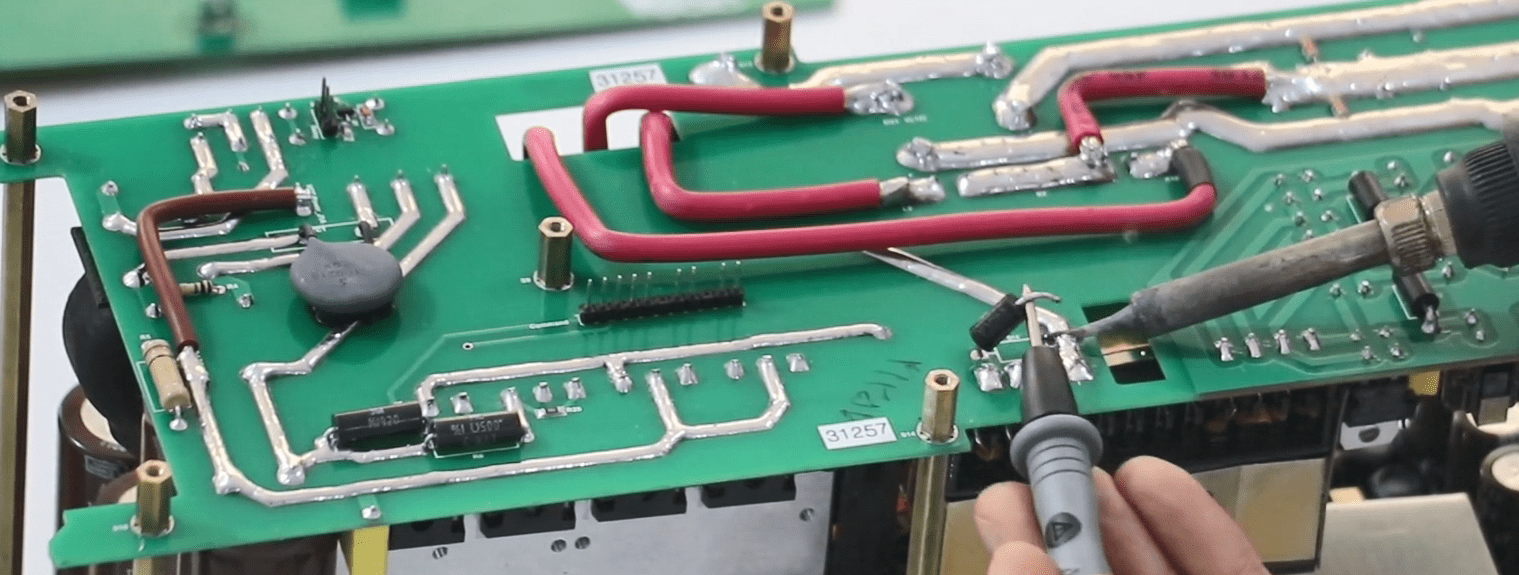

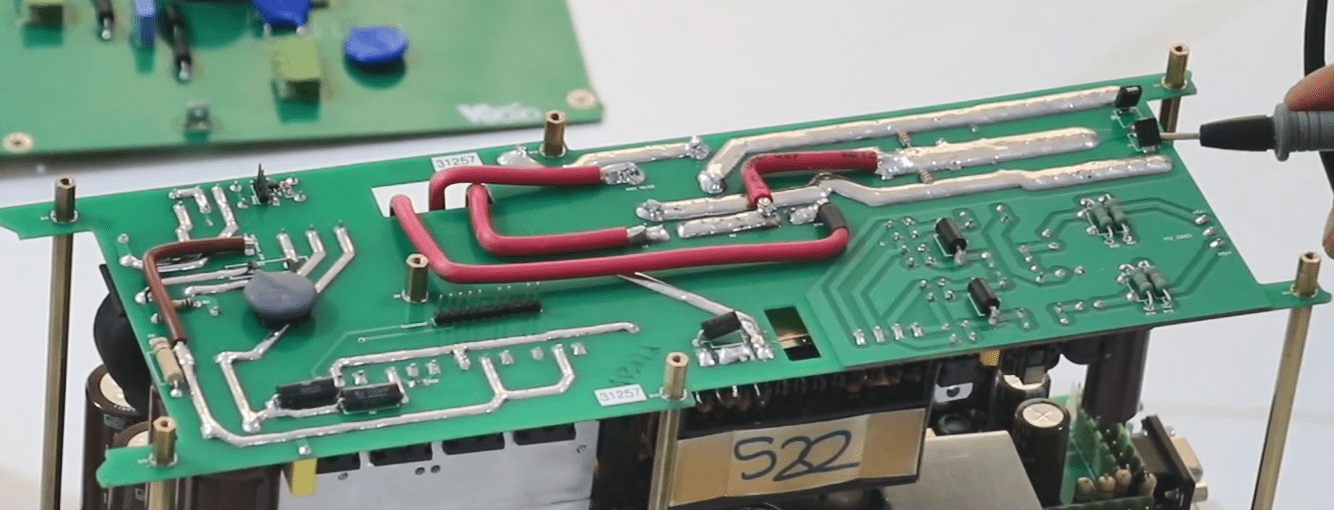

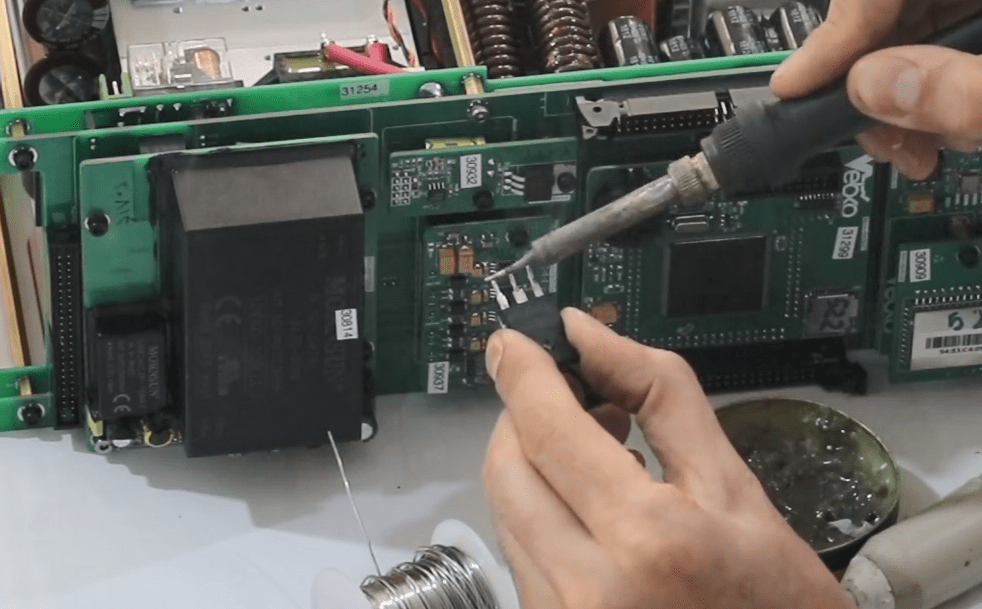

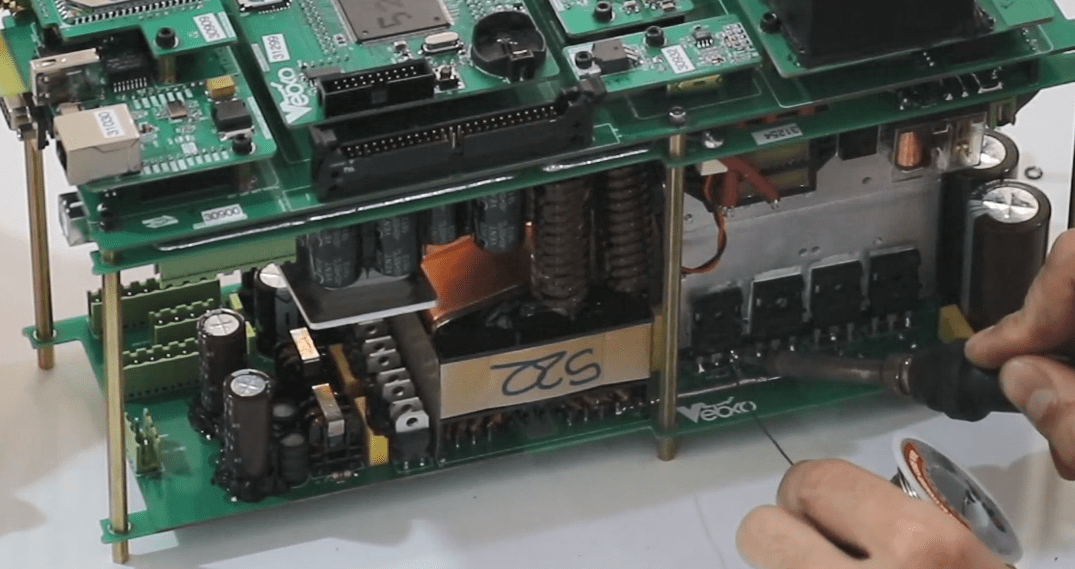

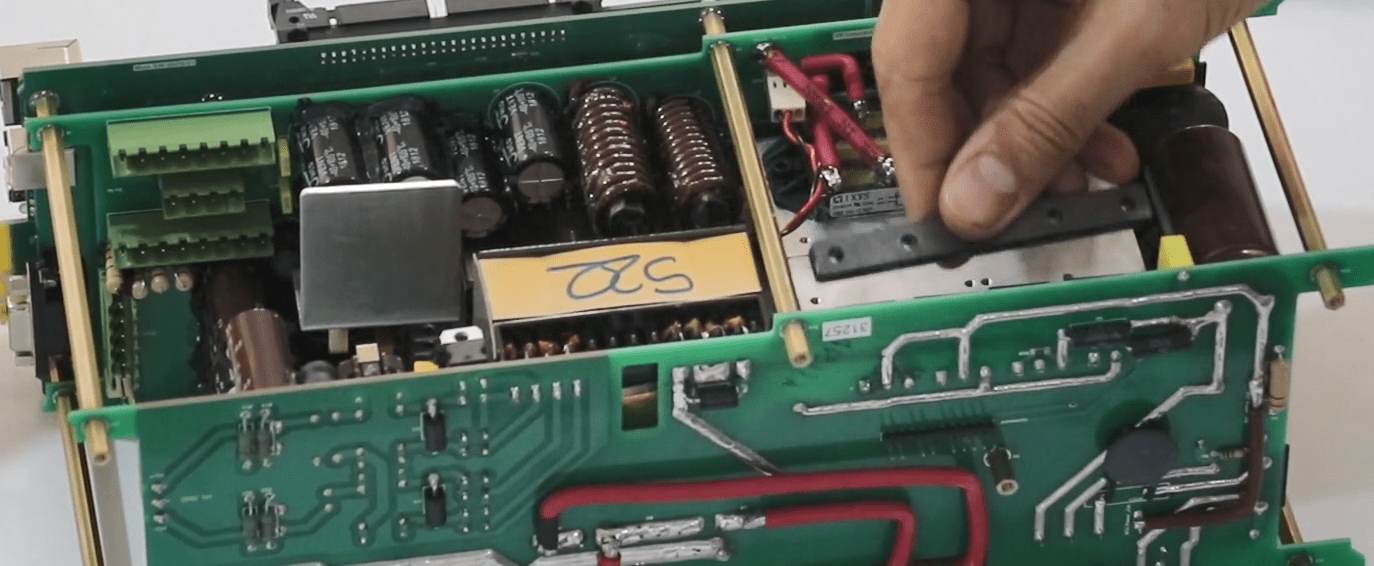

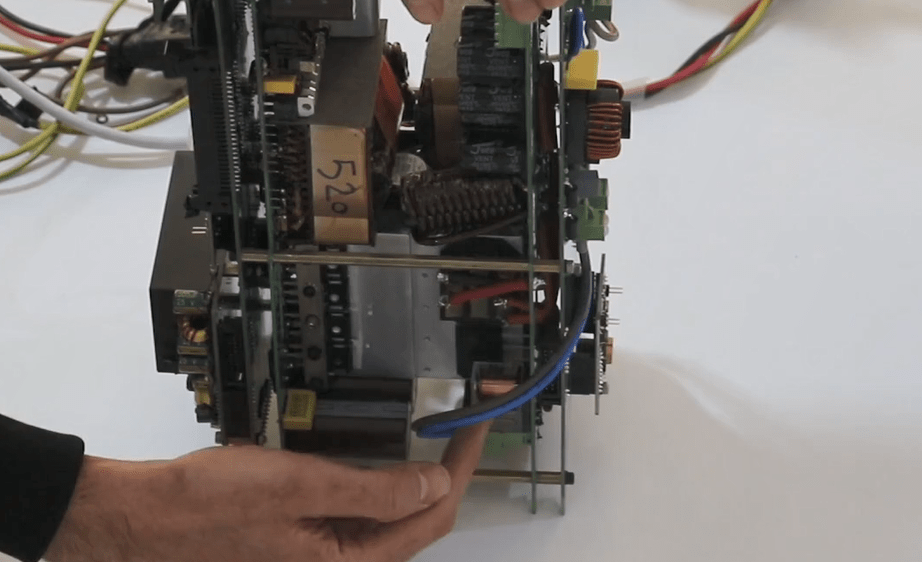

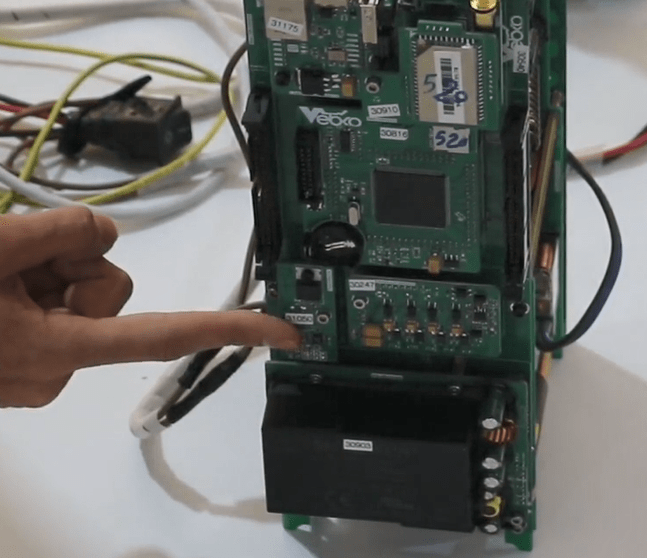

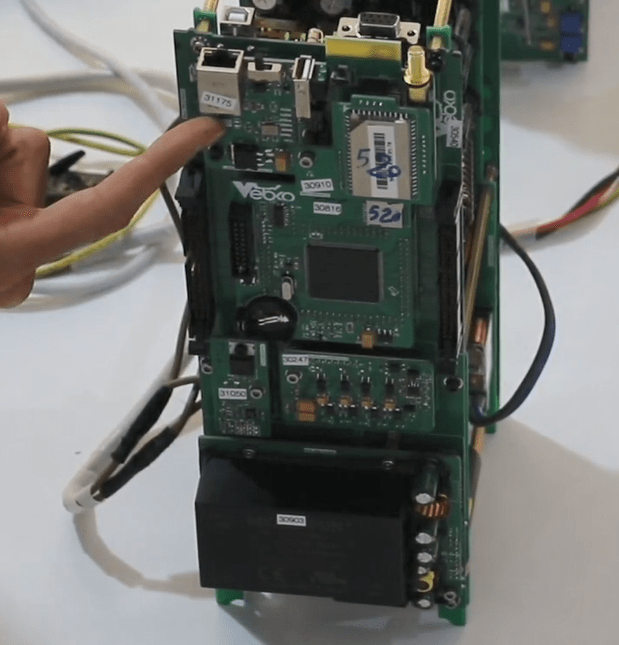

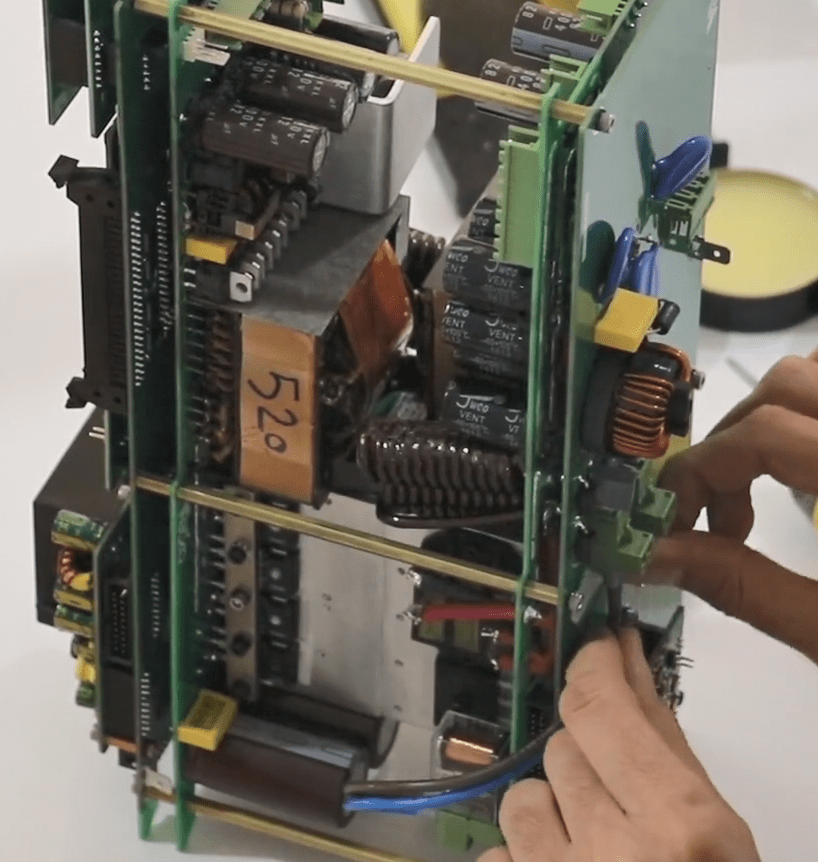

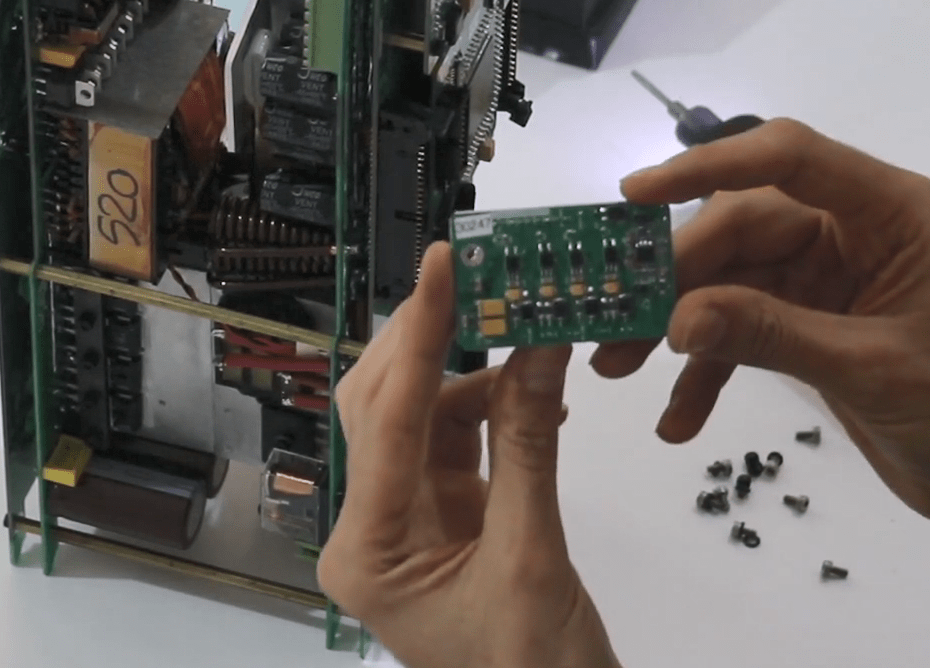

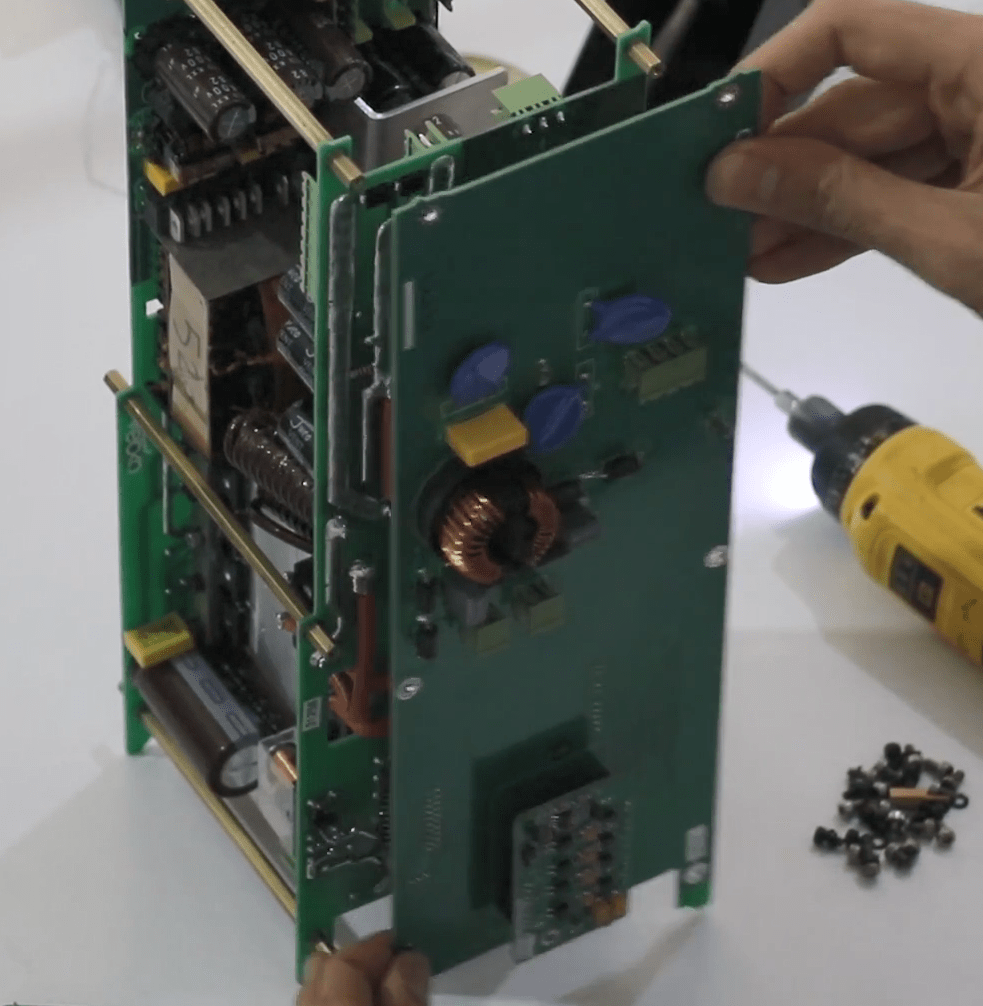

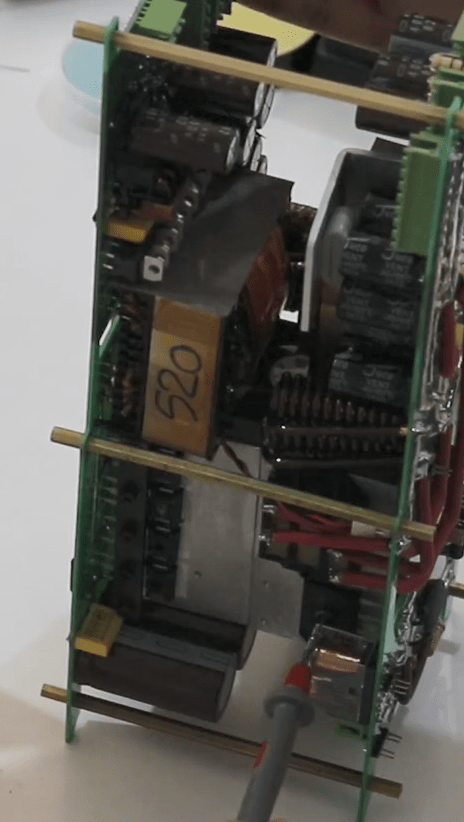

Switching module

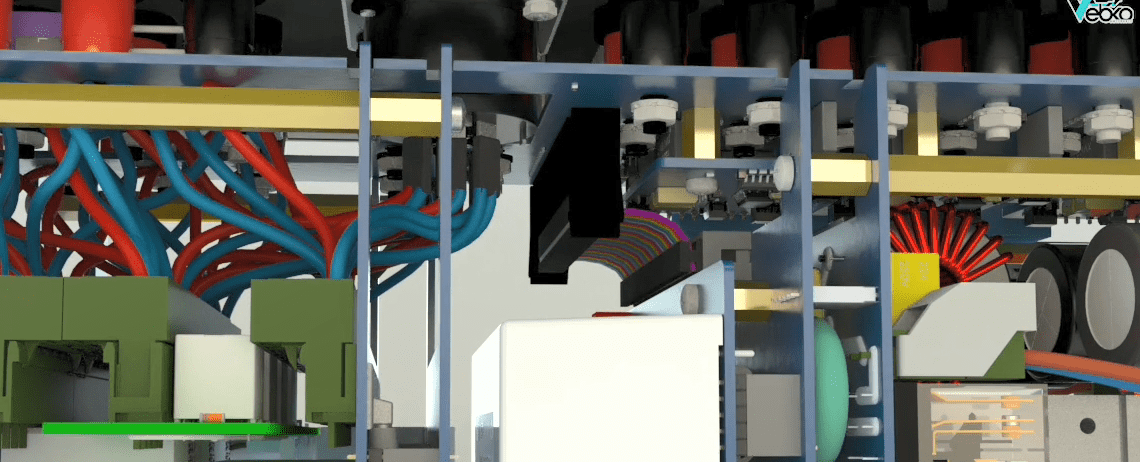

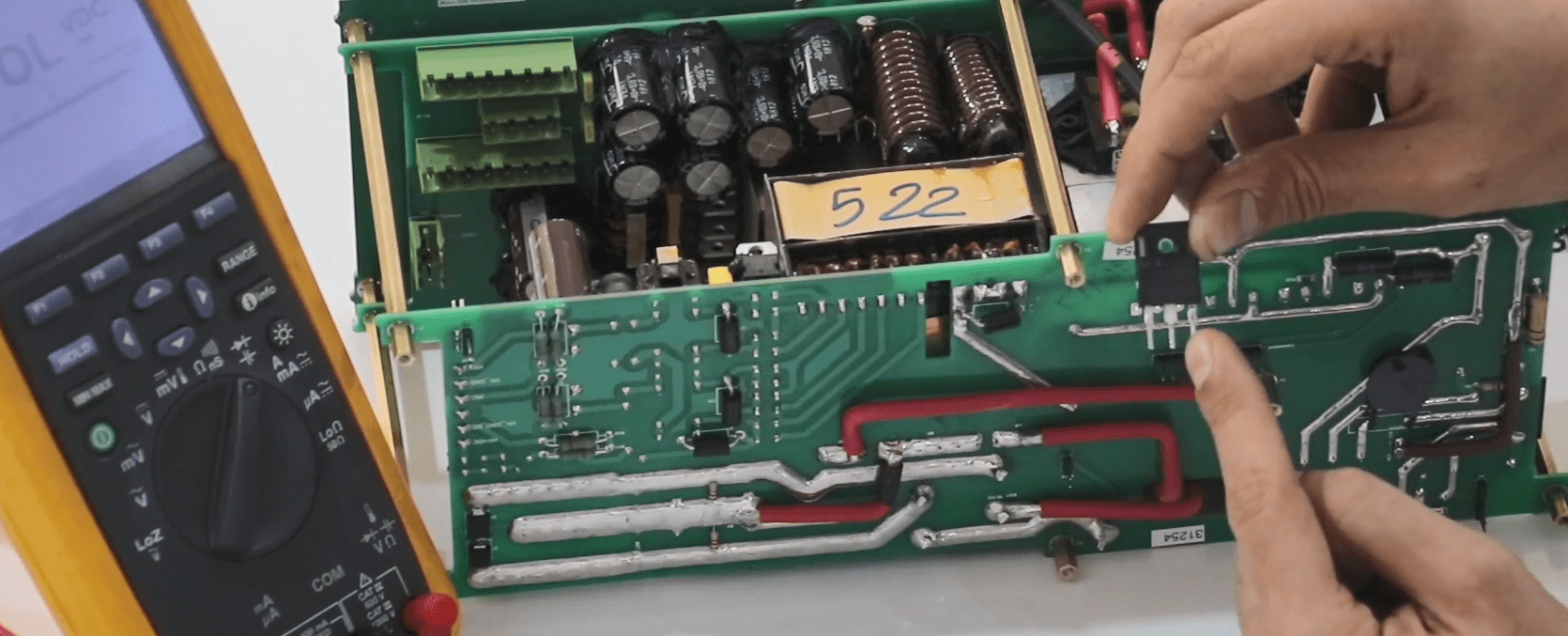

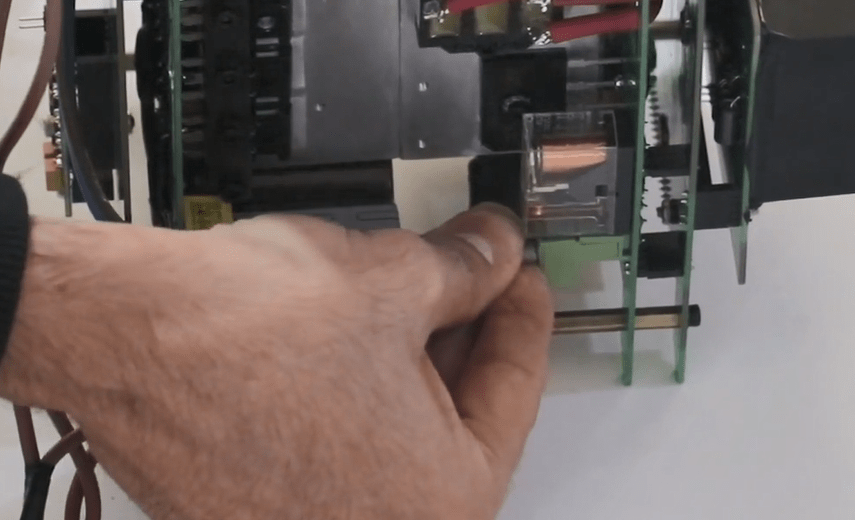

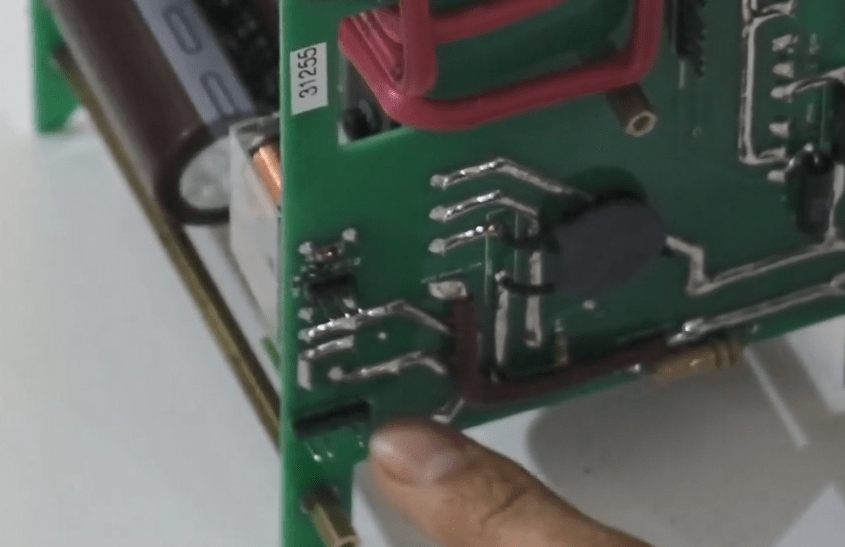

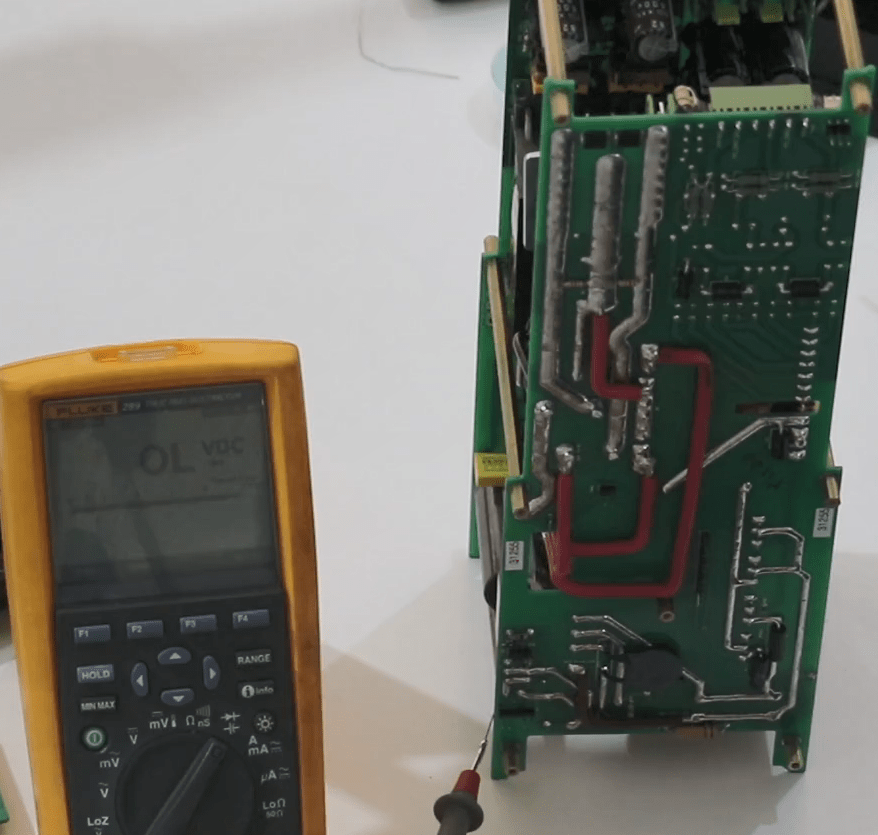

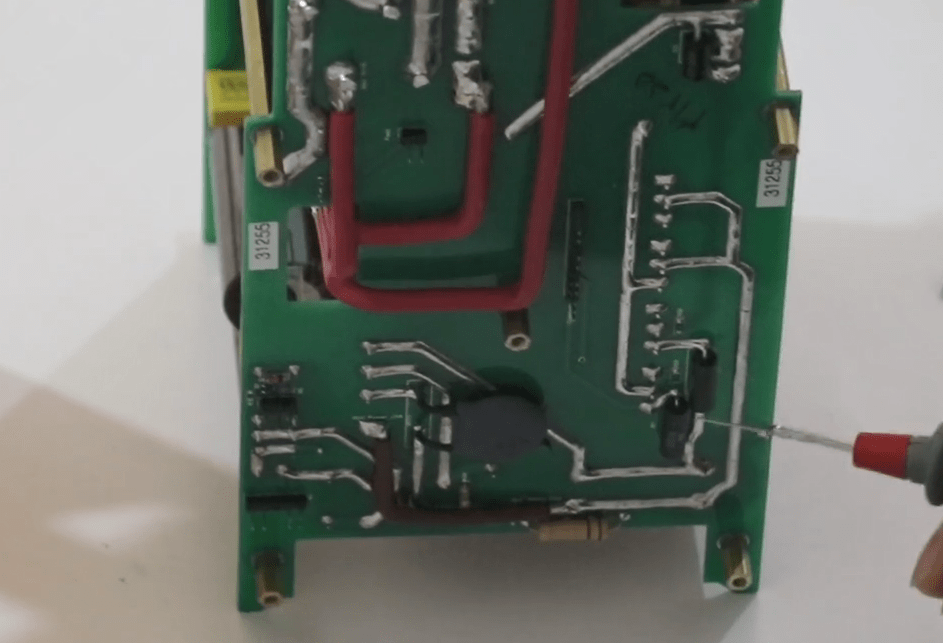

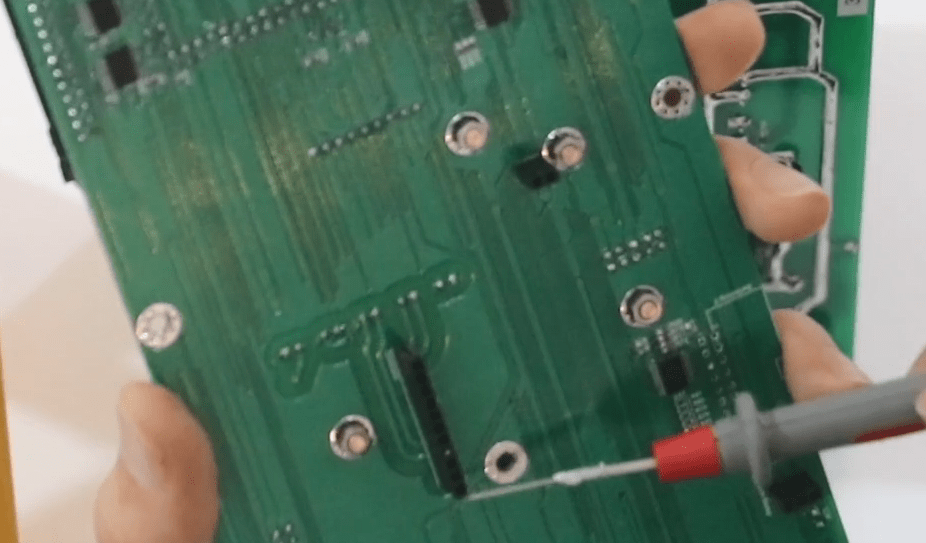

Complete side of switching module

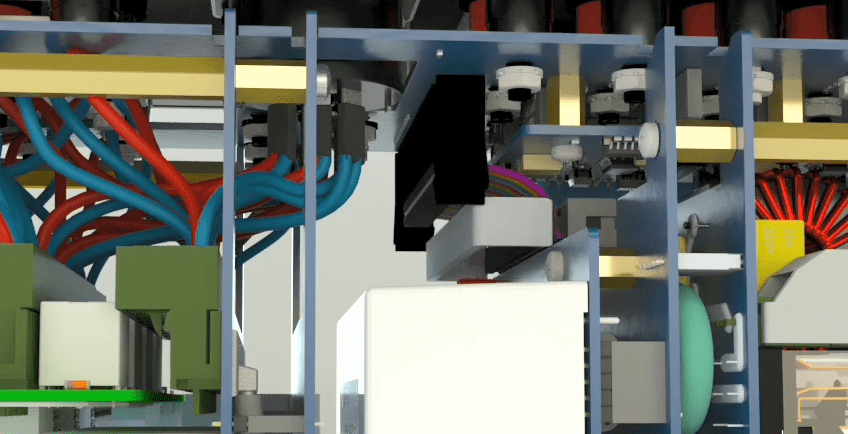

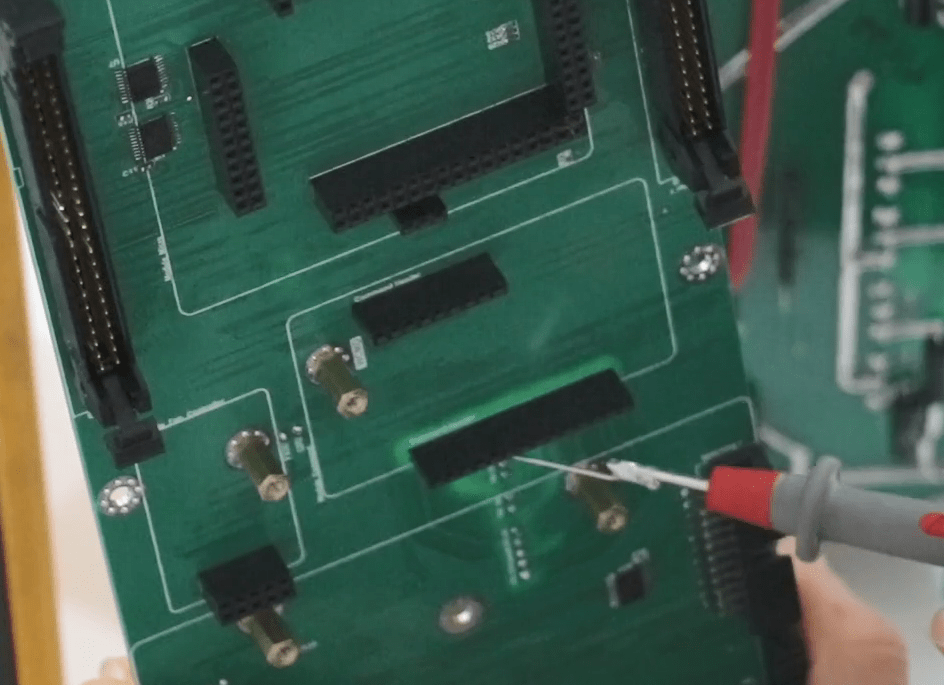

Incomplete side of switching module

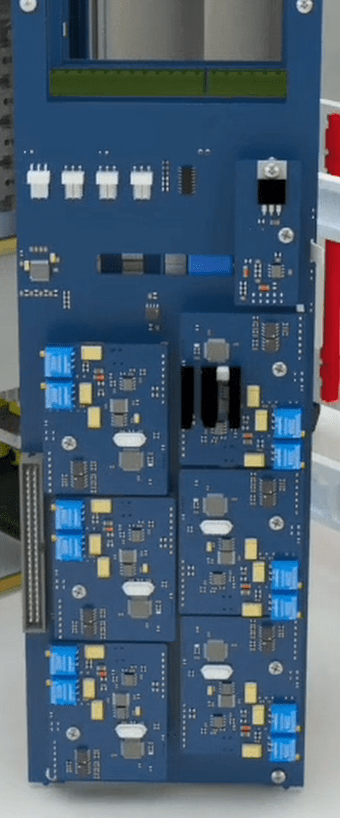

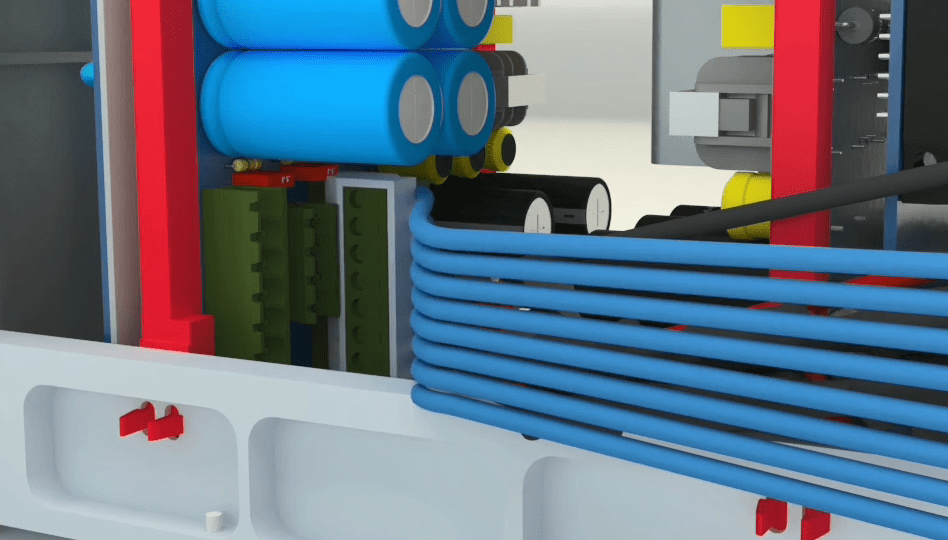

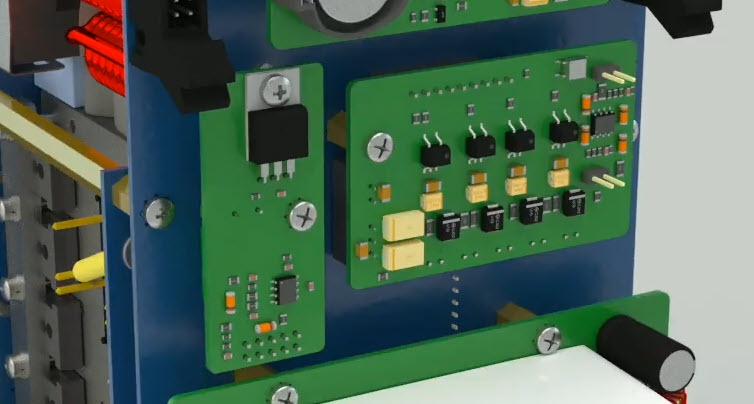

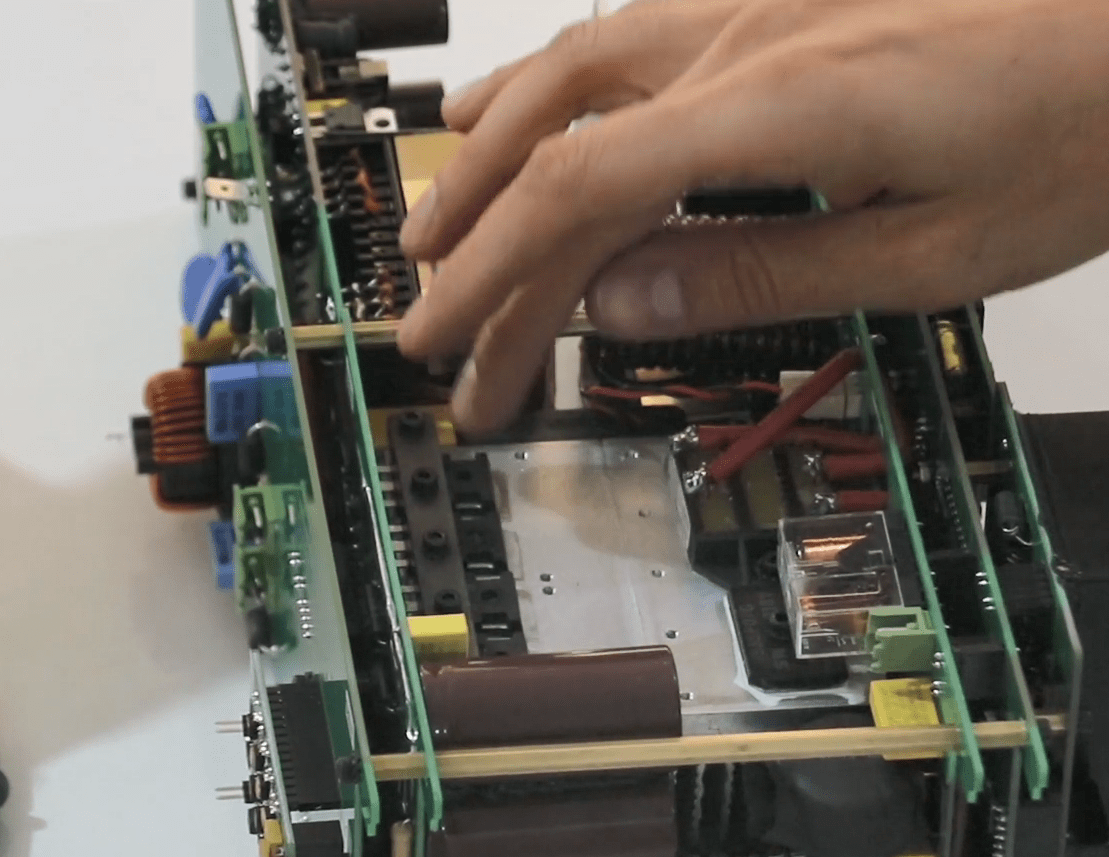

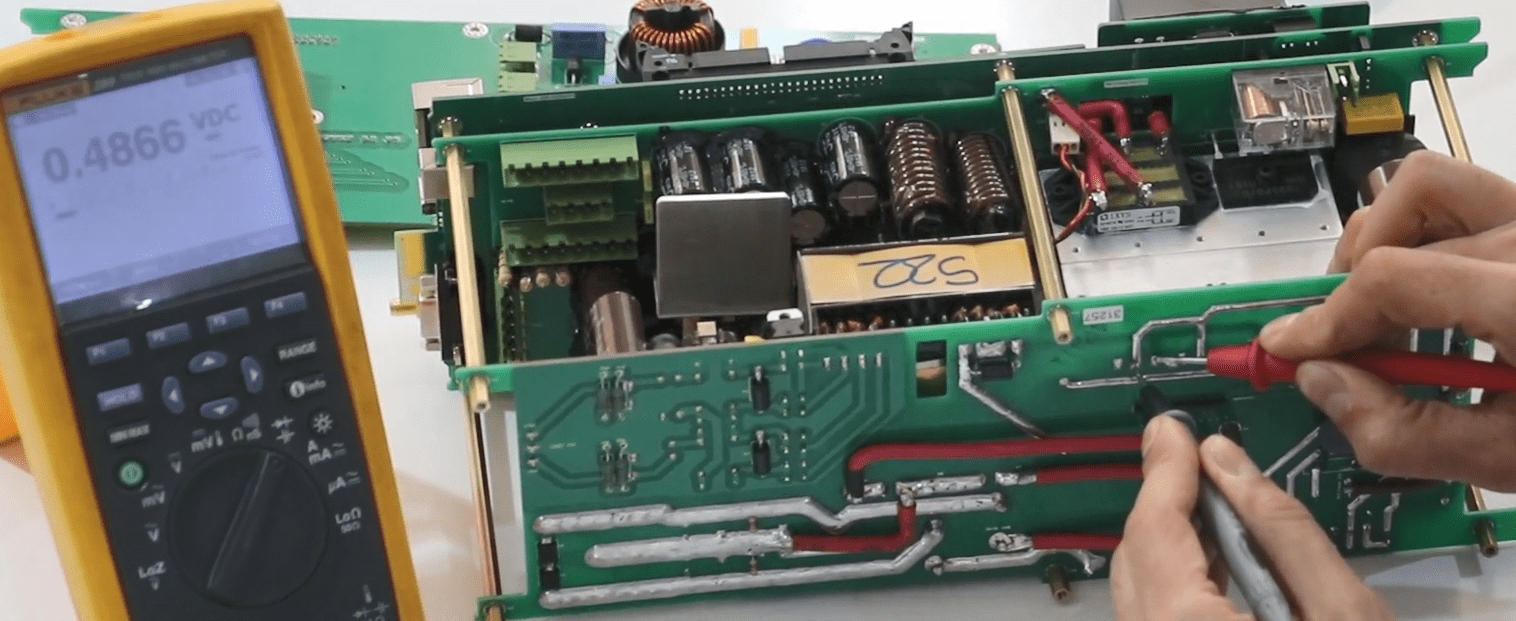

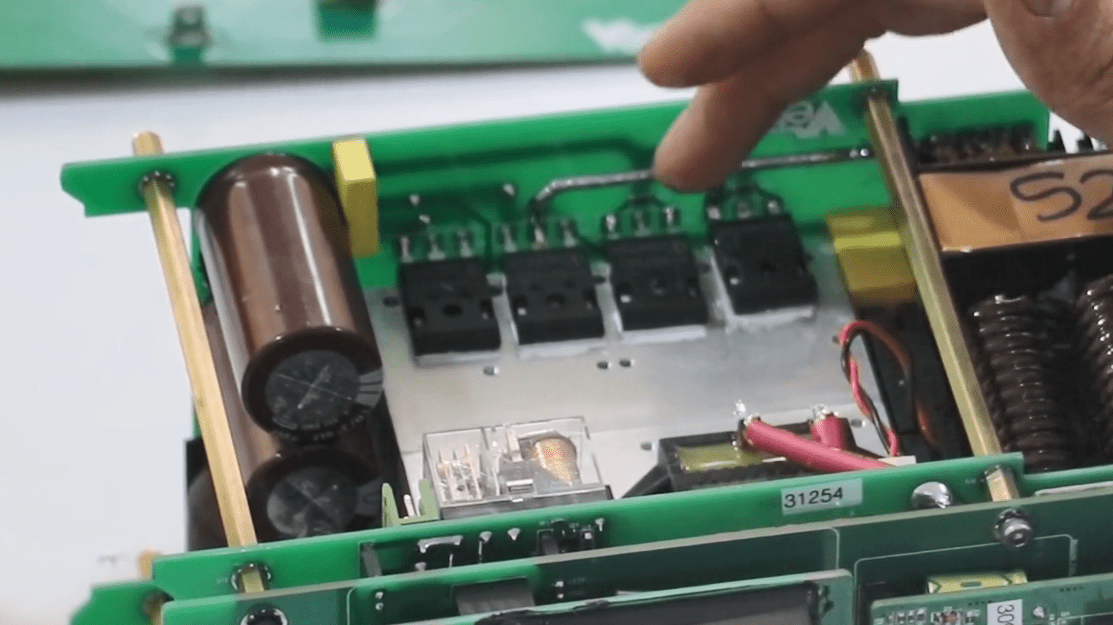

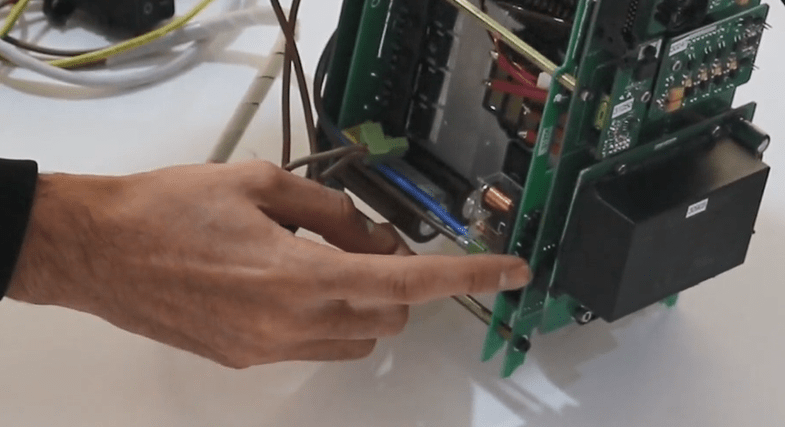

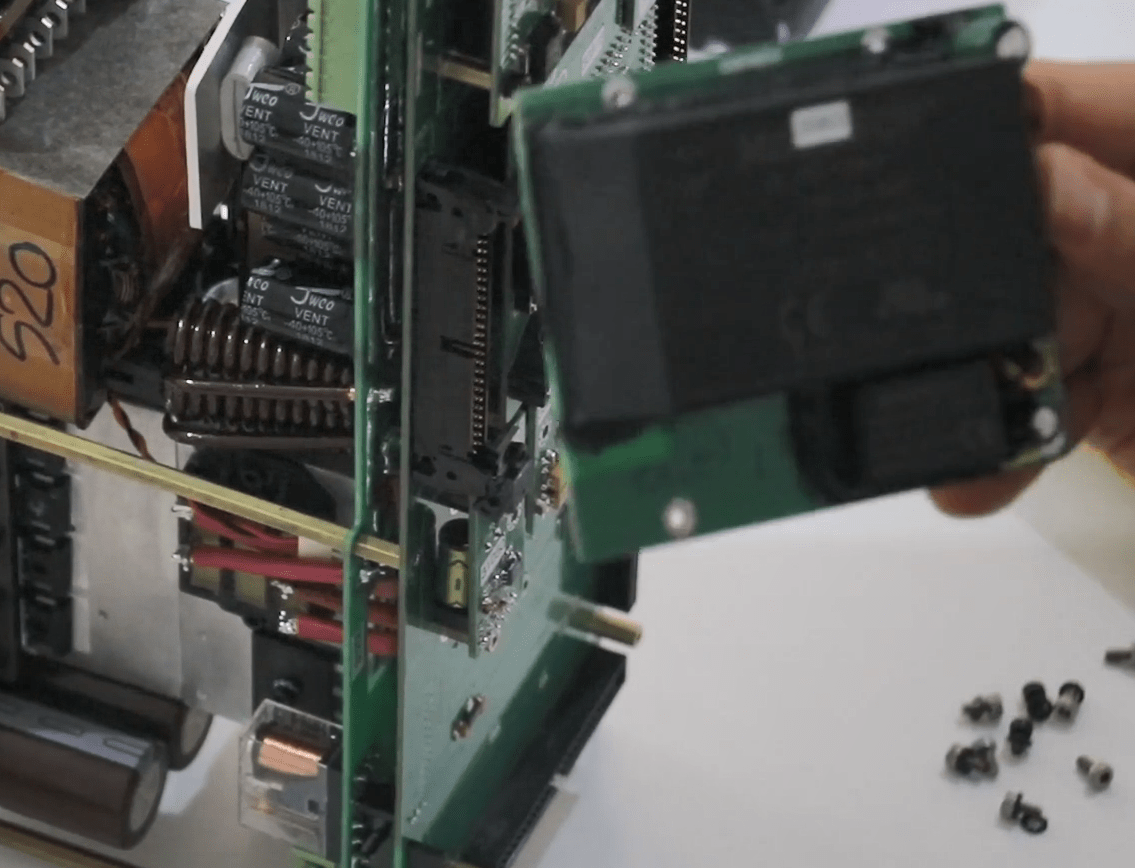

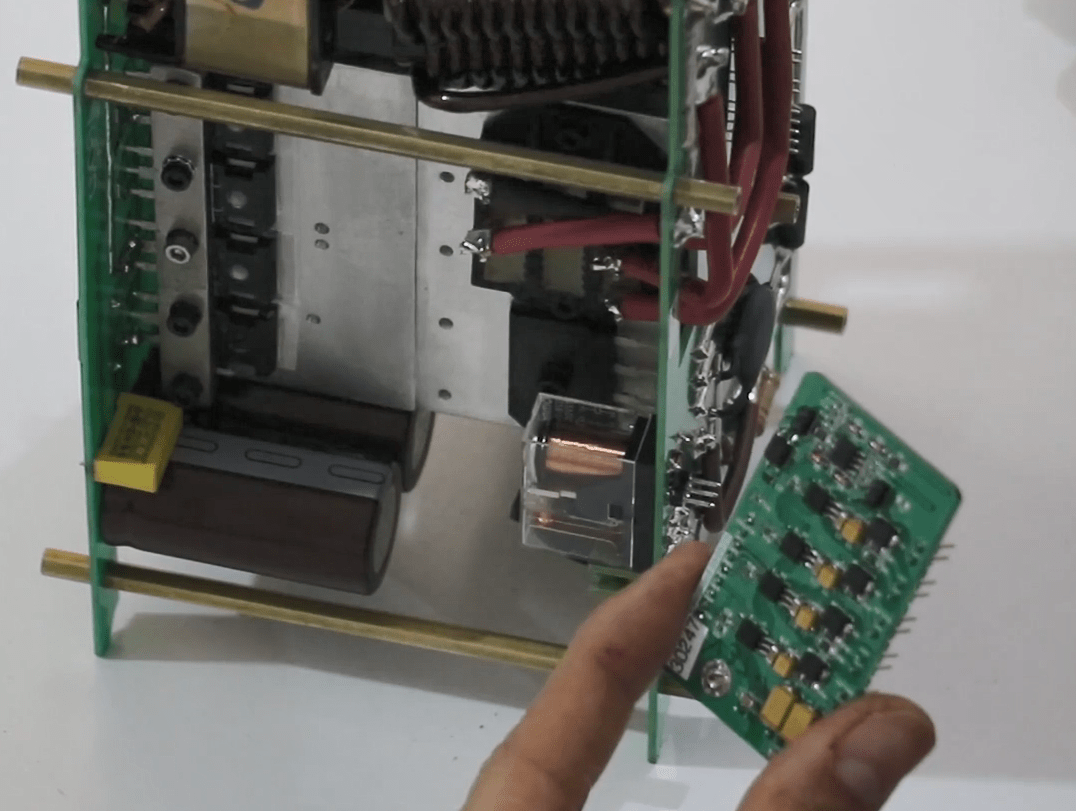

Amplifier module

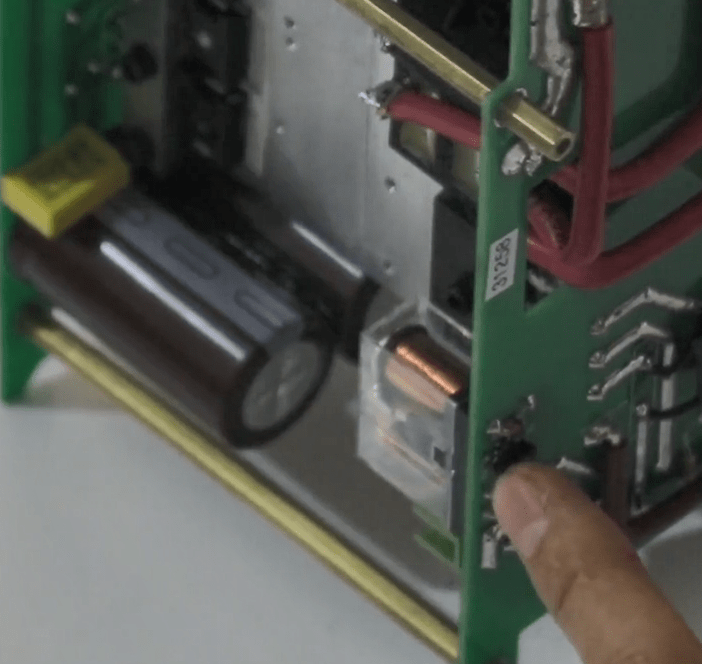

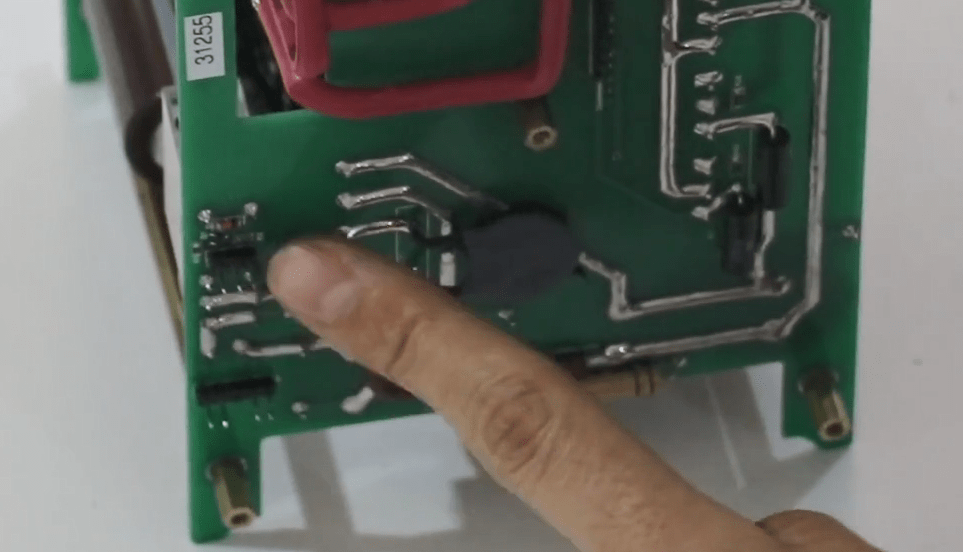

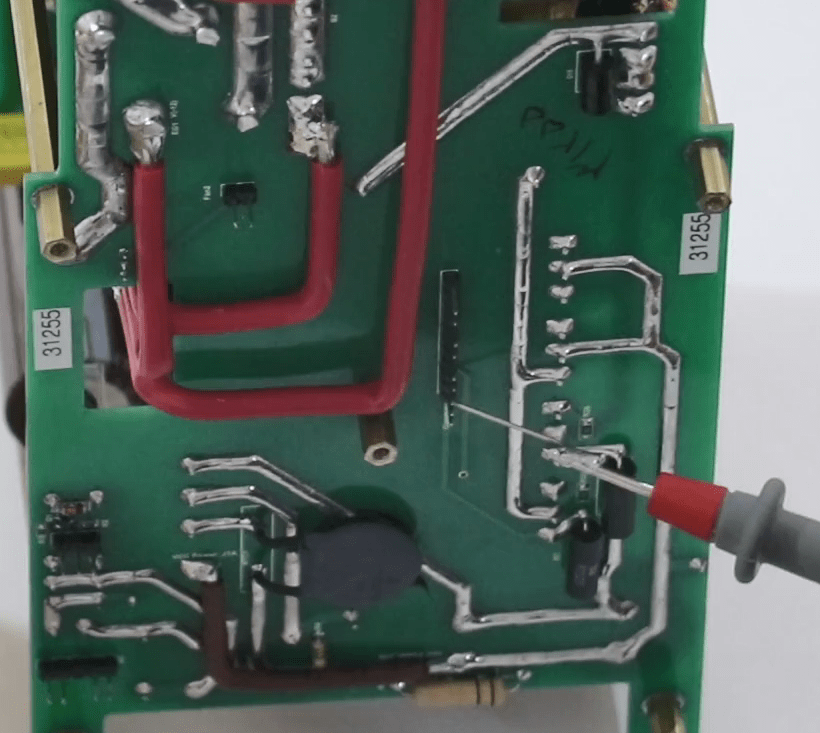

Ø Complete side of amplifier module

Incomplete side of amplifier module

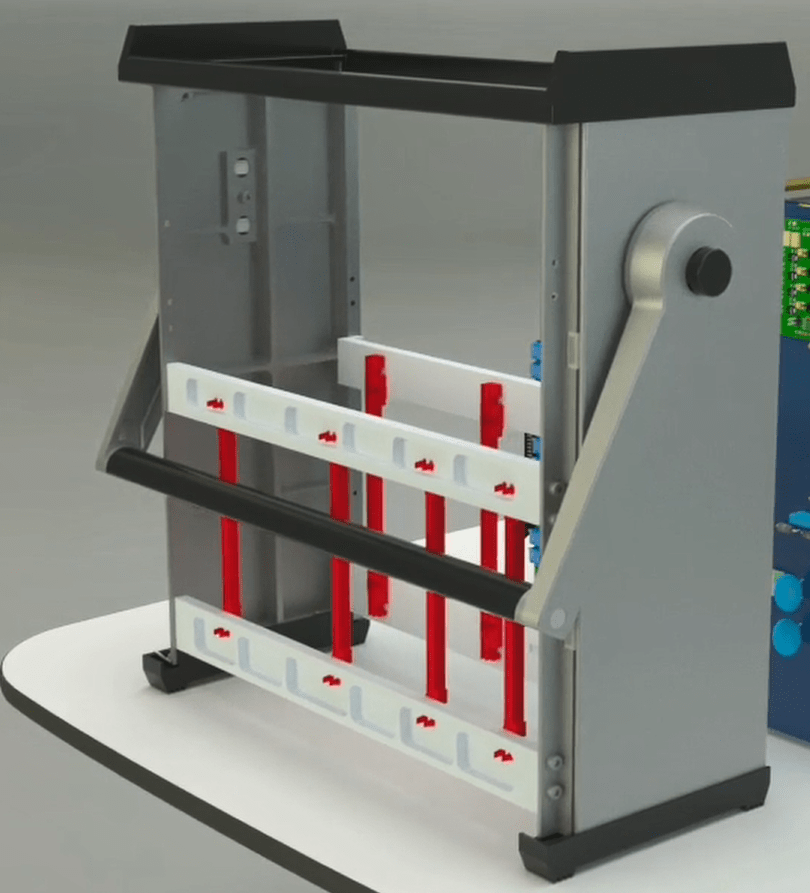

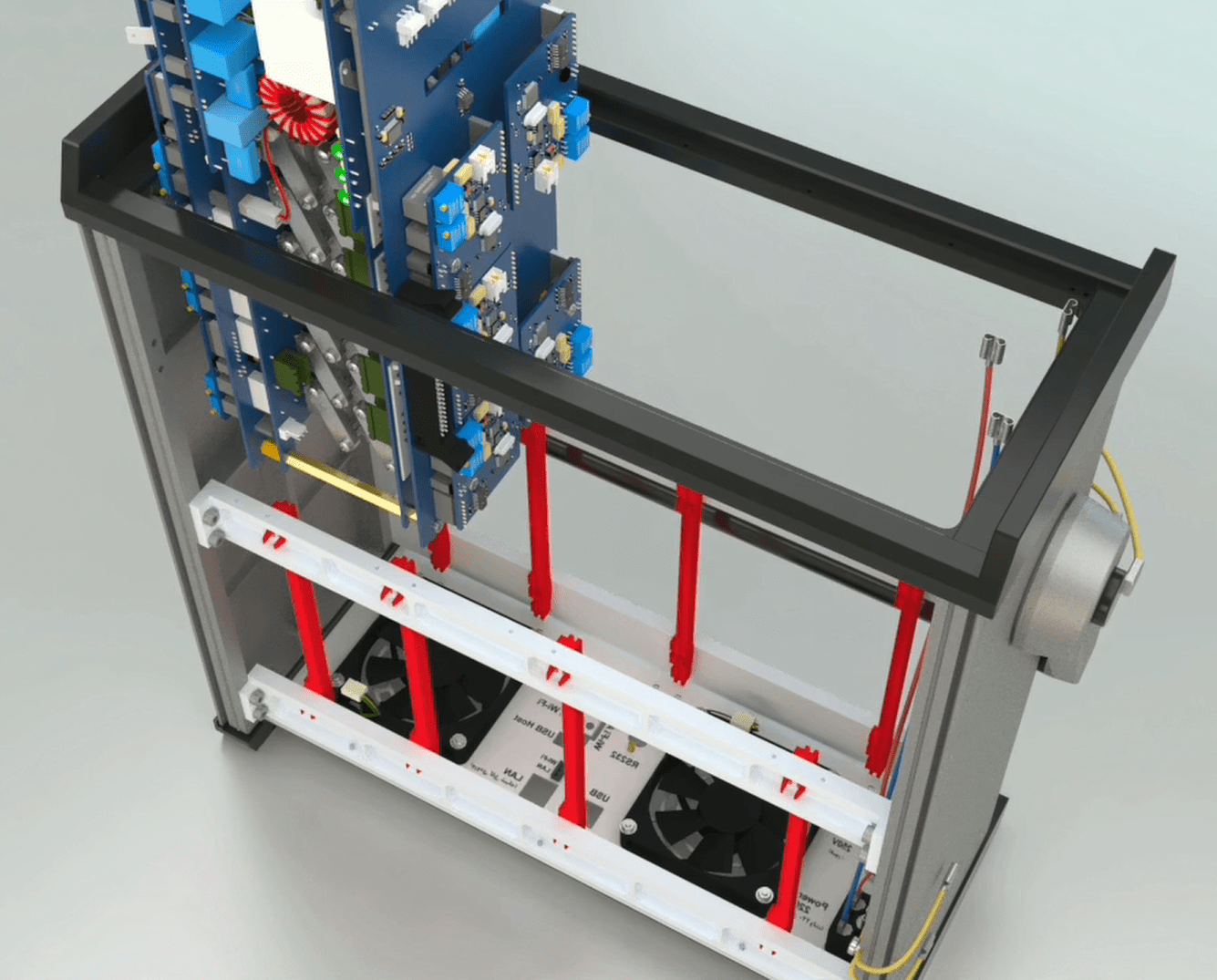

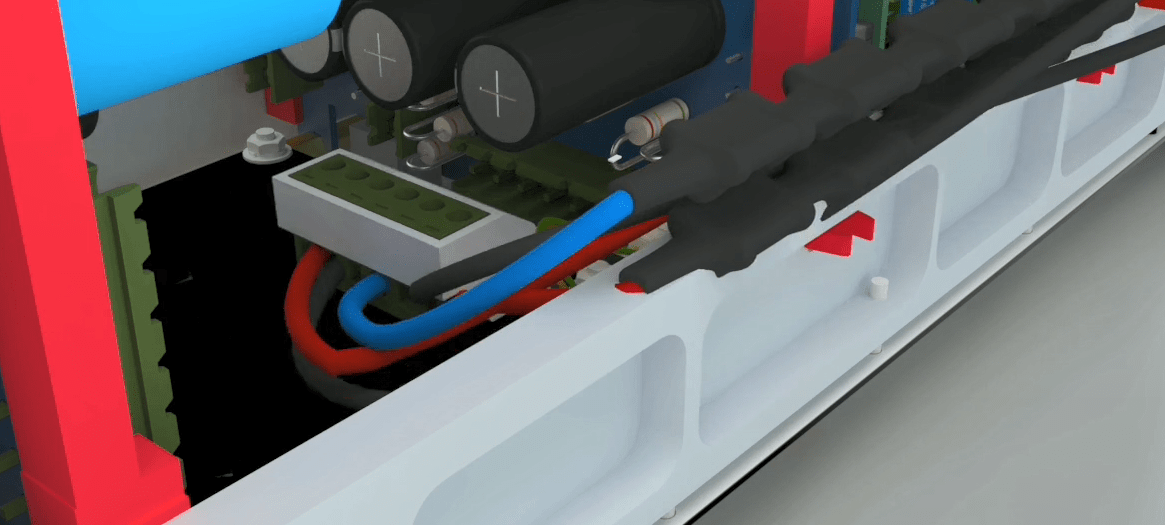

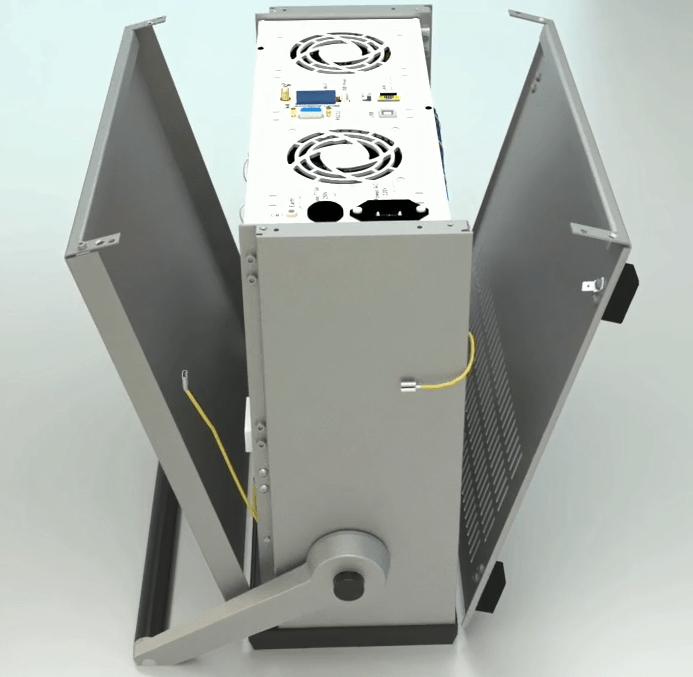

Case

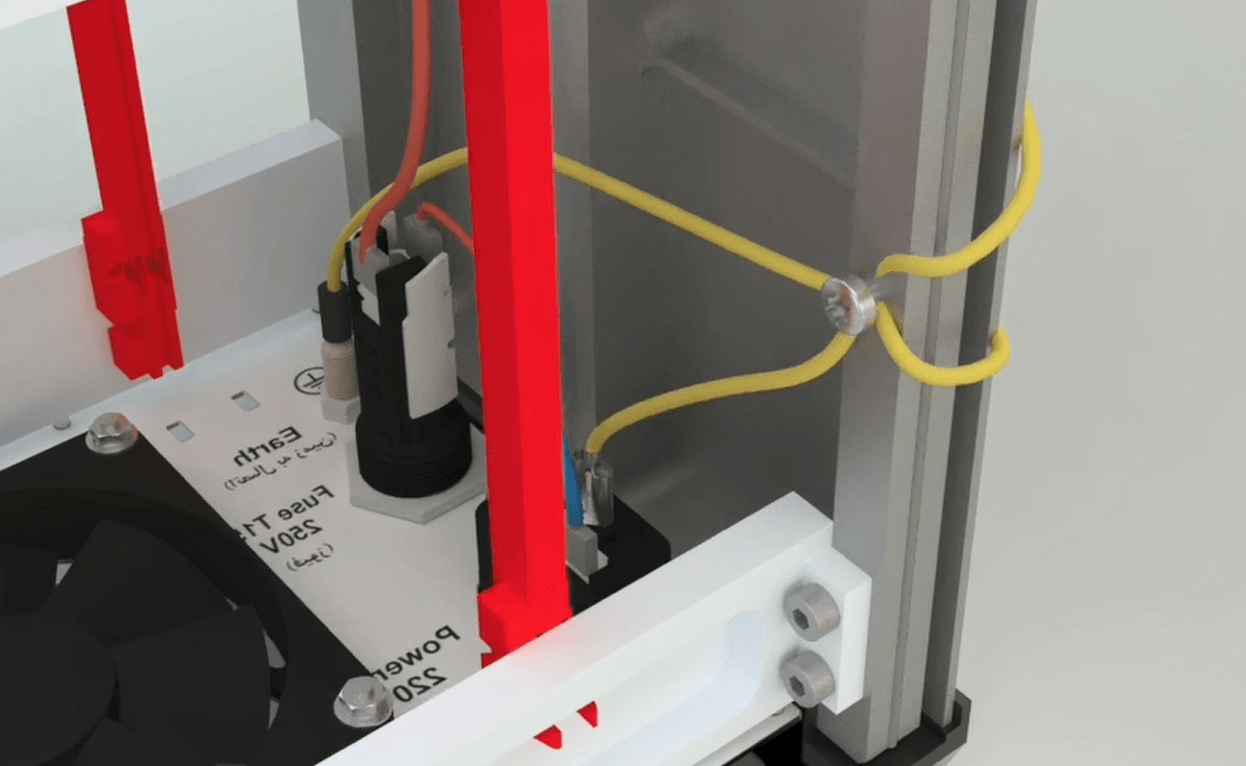

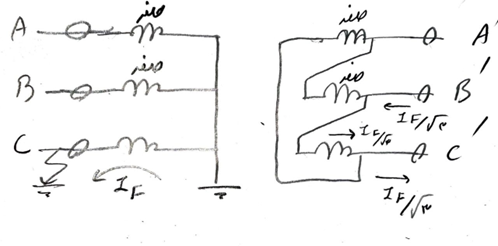

To assemble the device, you must first install the back panel on the case. Stand the case in front of you, in a way that the power socket is on your right side. Connect one of the earth wires to the power socket and the other one to the earth socket.

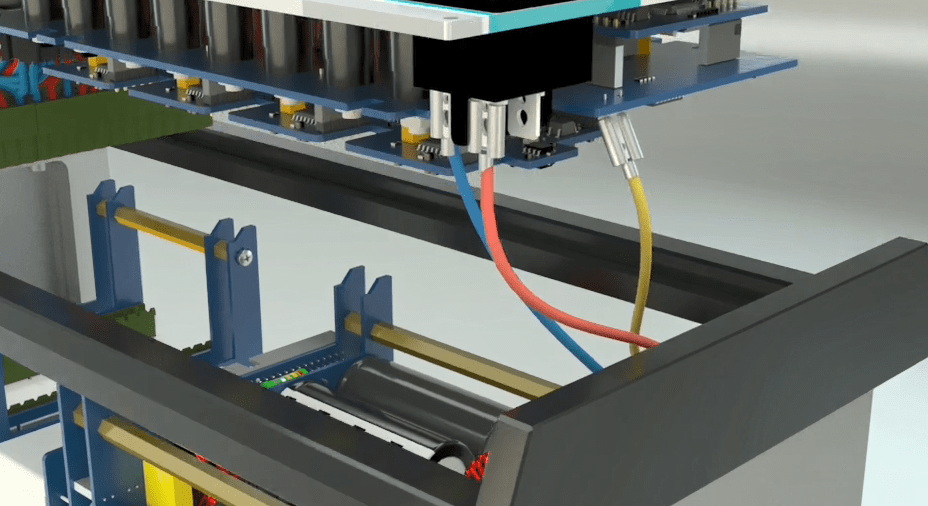

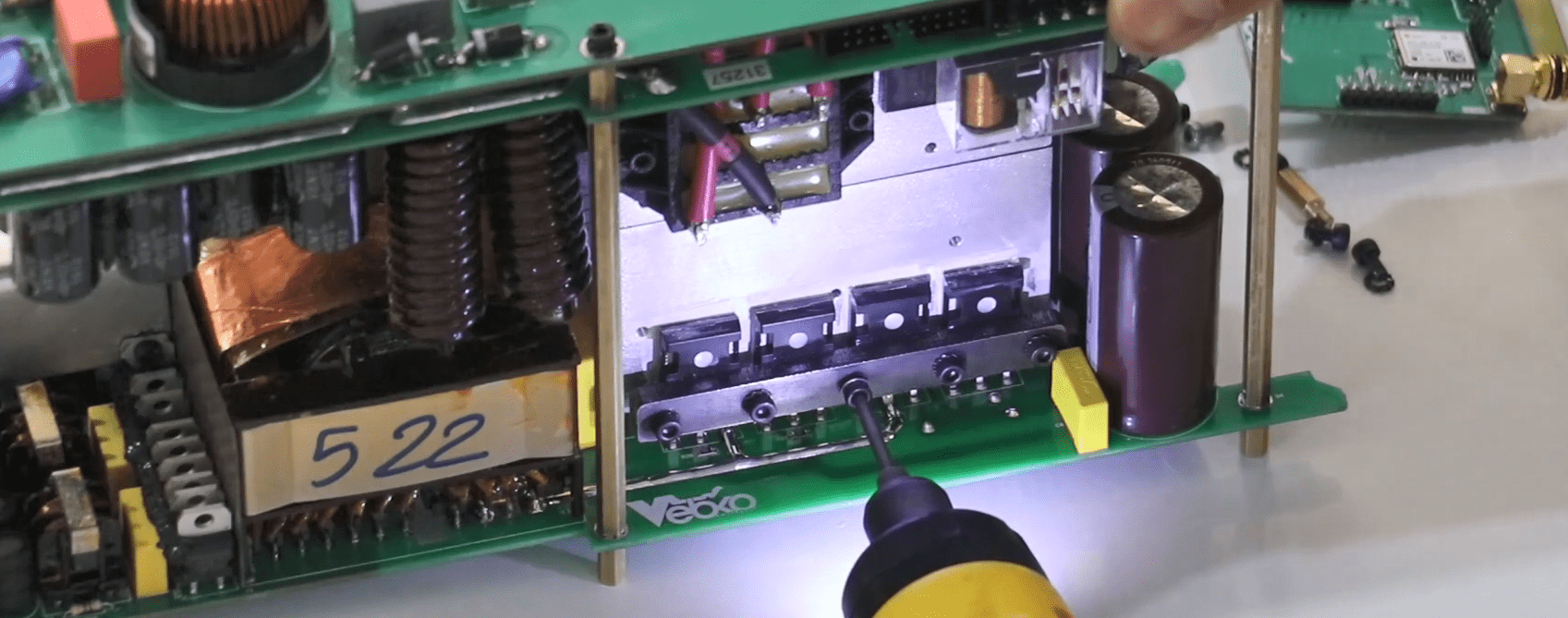

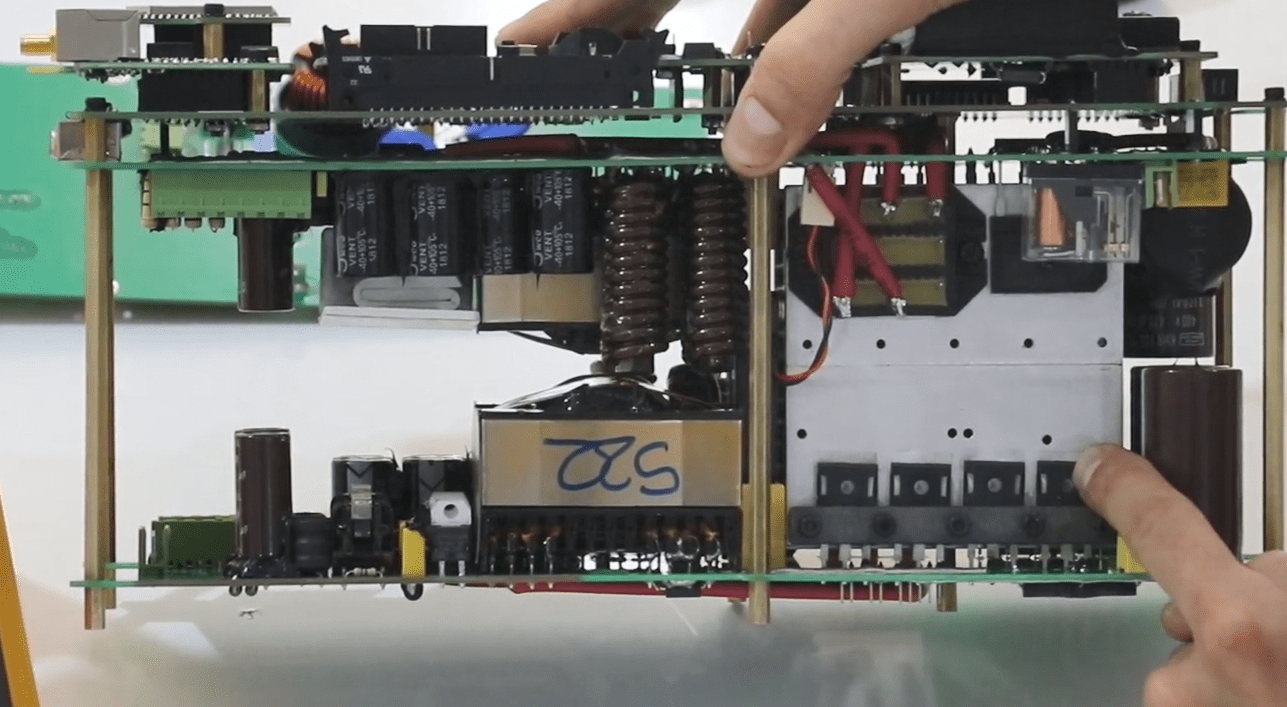

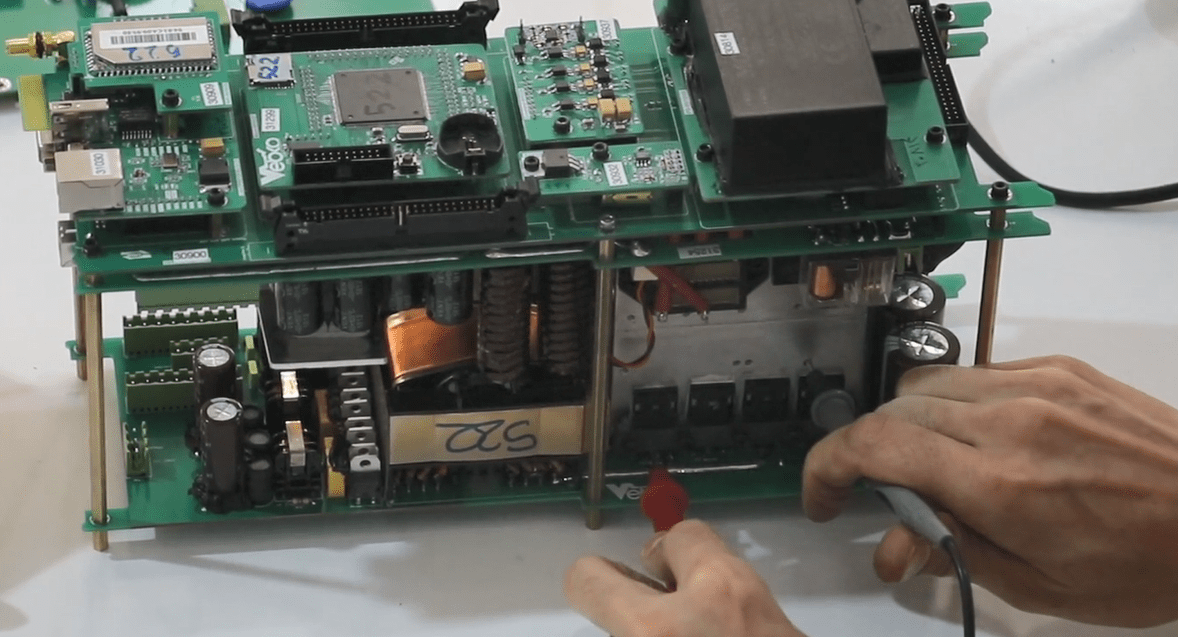

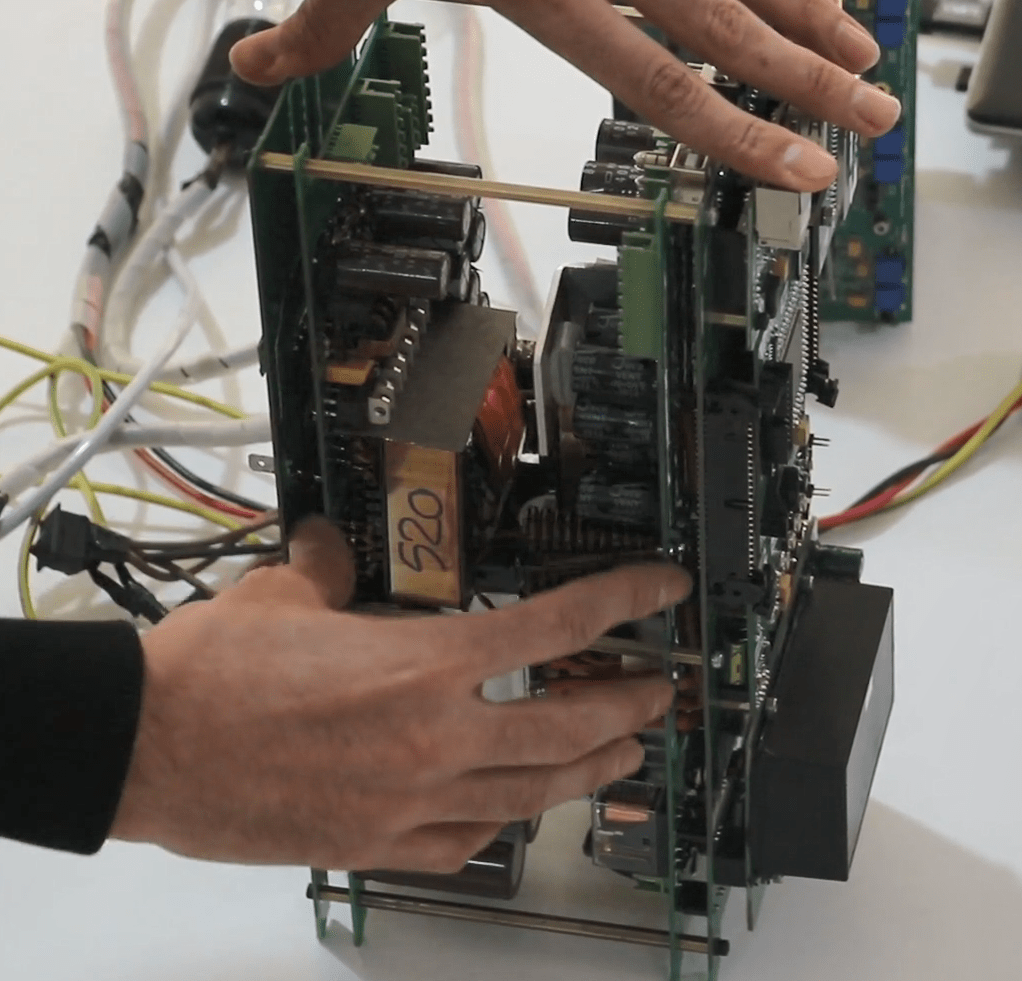

The amplifier module is placed into the case where the racks are less spaced (opposite to the input power socket).

The complete side of the amplifier goes to the case wall. The edges of the module should be placed inside the 4 racks.

Insert the module up to 5 cm to the end of the case, then take the fan wire from the back of the Spacer and connect the socket to the amplifier then push the module to the bottom of the case.

Note: make sure that the fan wire is not under any modules or inside the fan.

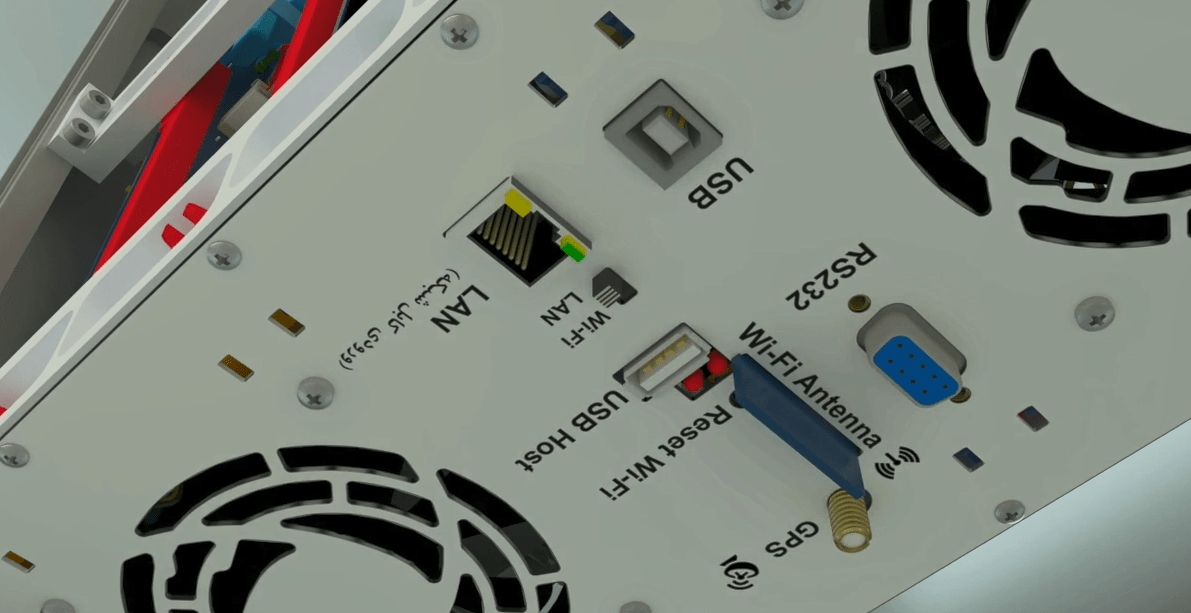

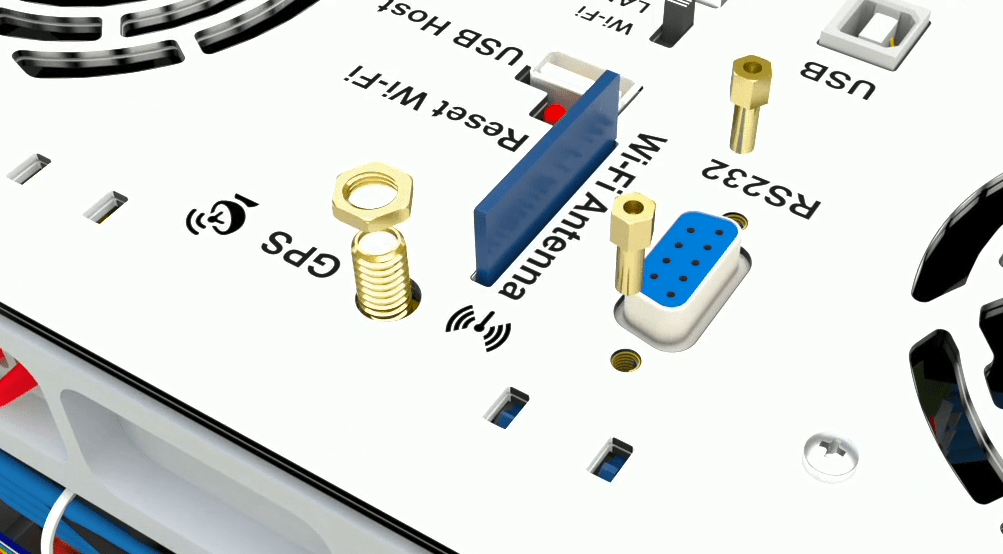

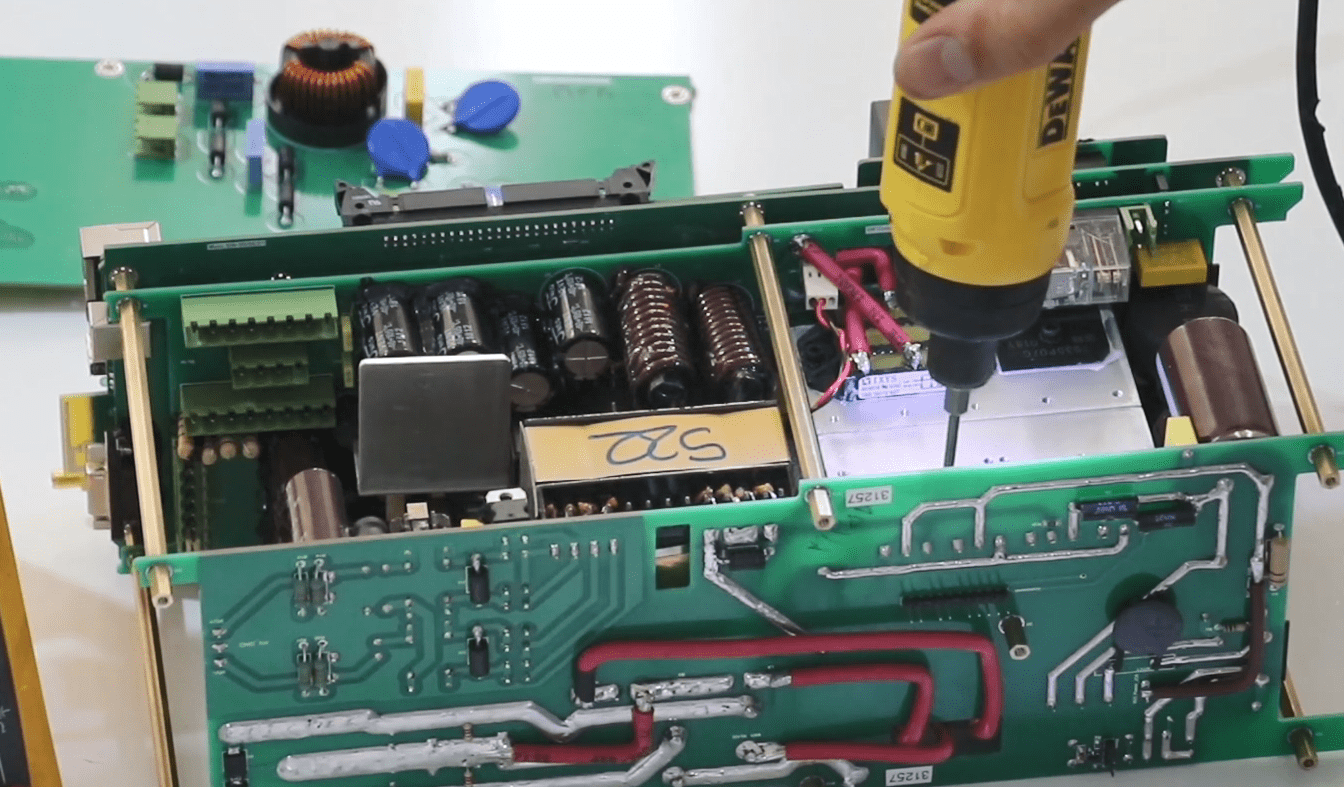

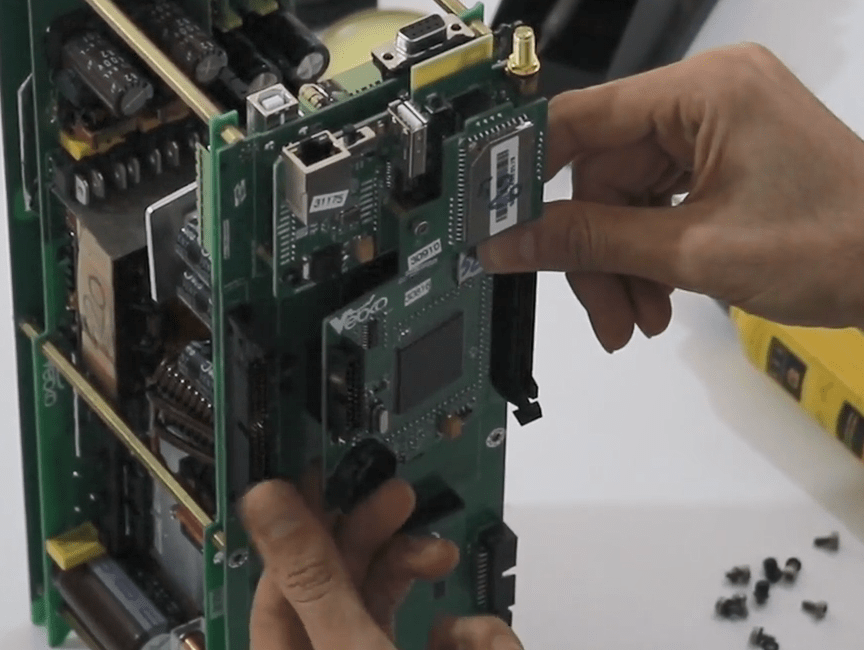

The incomplete side of the switching module (the one that only has a command board) should be on the side of the case’s wall, so that the Ethernet, USB, RS232, Wi-Fi and GPS ports are downward and placed in the rear panel.

Insert the module up to 5 cm to the end of the case, then take the fan wire from the back of the Spacer and connect the socket to the switching module finally push the module to the bottom of the case.

By shaking the GPS port, the switching module must be fully placed at the bottom of the case.

Ethernet and USB socket must be 1 to 2 mm away from the back of the case. If the socket of the Ethernet and USB are stuck, In case ports are stuck shaking them allows them to come out from the back panel.

Note: make sure that the fan wire is not under any modules or inside the fan.

Connect the two heads of wires that come from the back panel to the zero side of the power switch on the panel.

The guards must be faced outwards so that they can be easily opened.

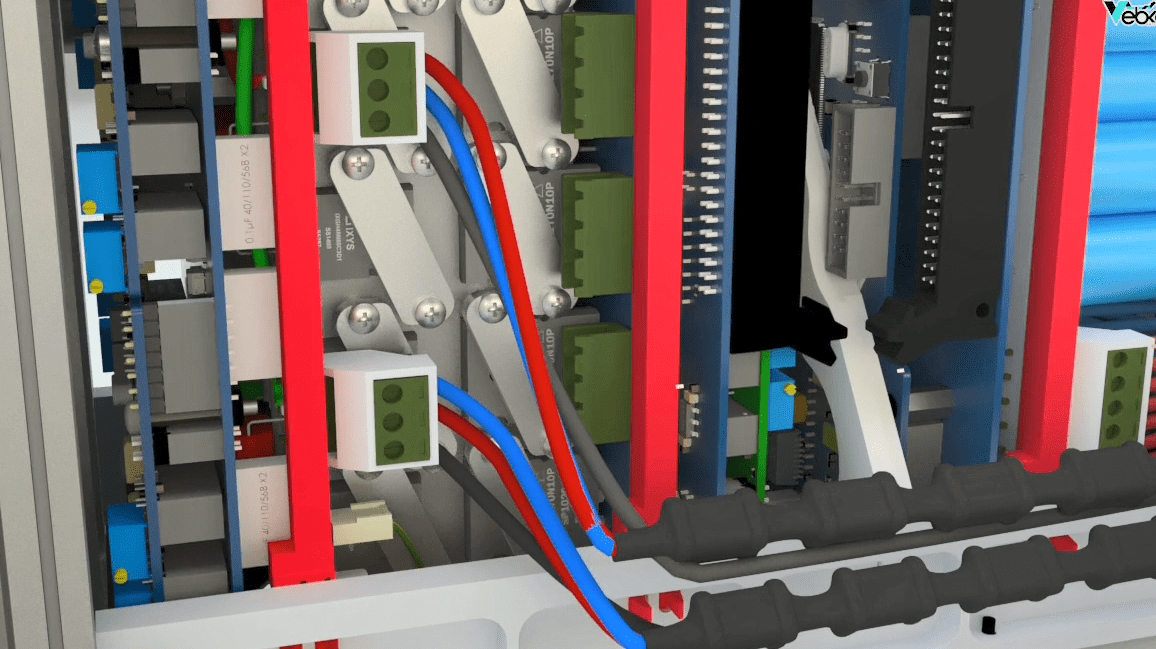

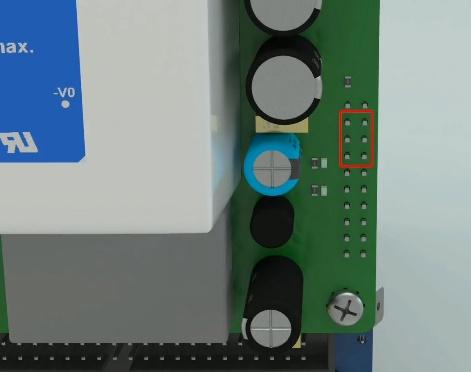

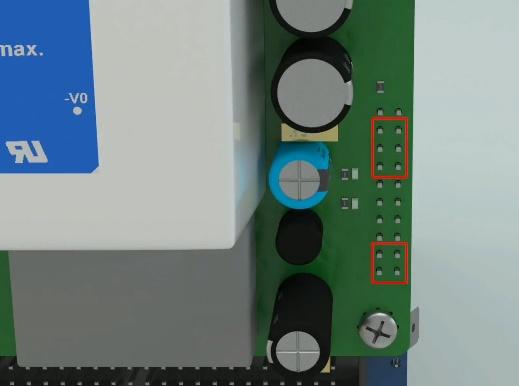

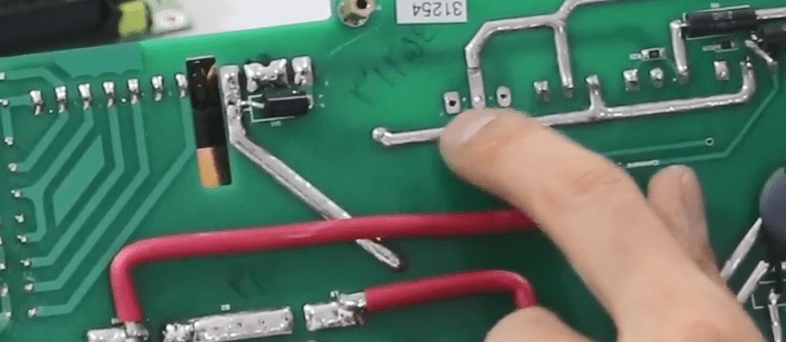

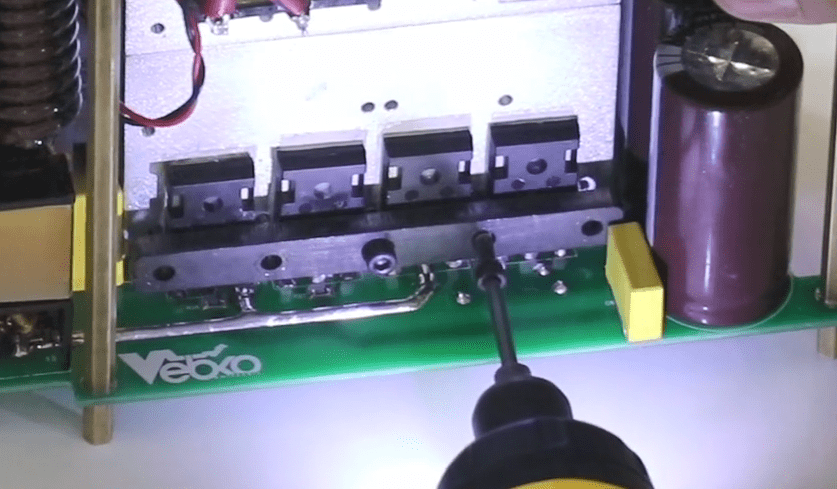

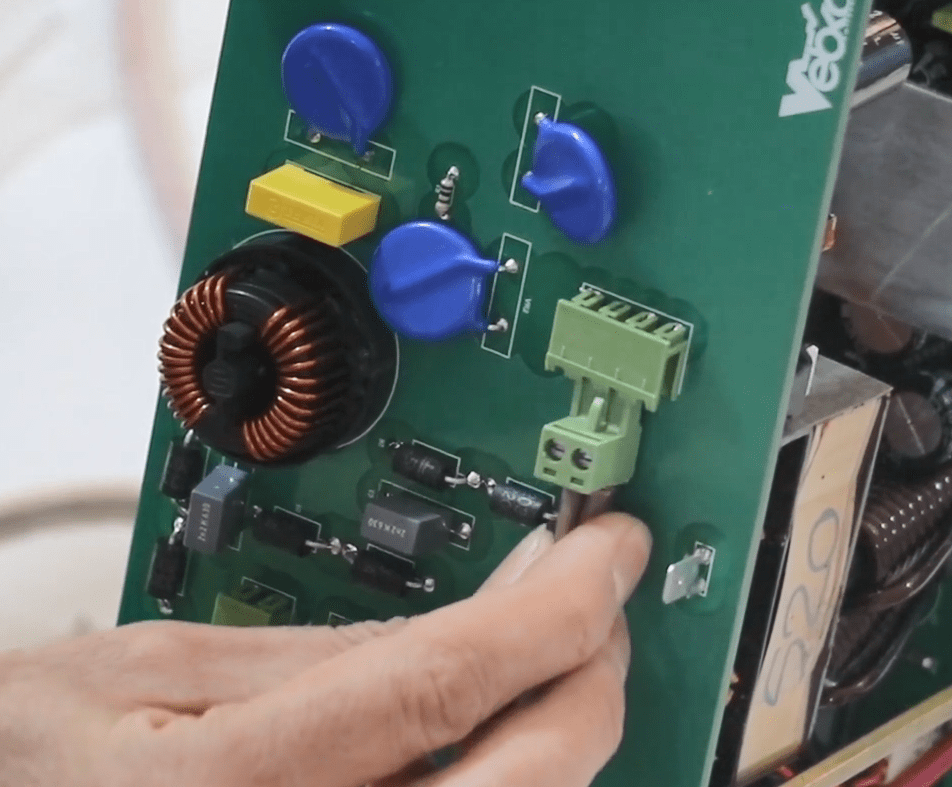

First, connect two 2 pin female Phoenix connectors to the incomplete board of the switching modules. Connect the other side to the switching modules.

Connect one side of the corresponding power cord to 1 key and connect the Phoenix side to the incomplete switching switchboard.

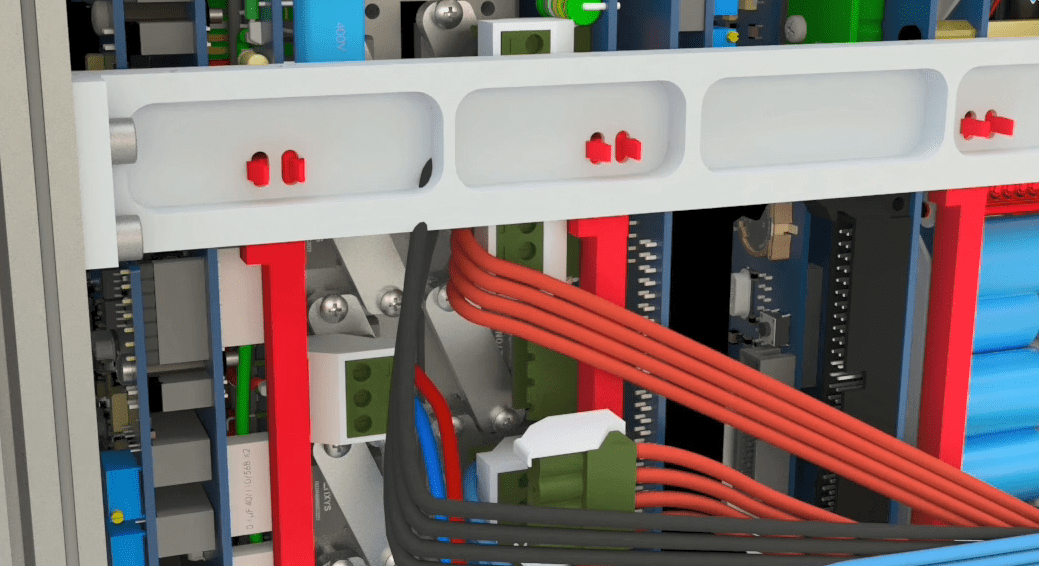

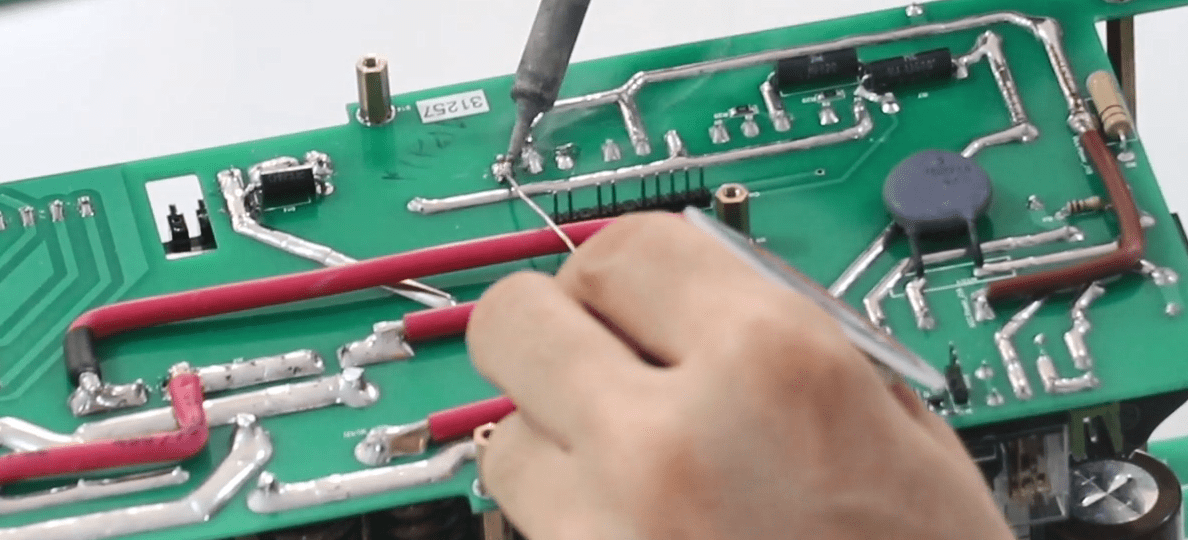

First, on the left side, connect the corresponding Phoenixes to the amplifier. You should first connect the two 16 pin Phoenixes and then connect the two 5 pin Phoenixes.

Then install the appropriate phoenixes to the right side of the amplifier.

First, turn the device in a way that its socket is to your left and the Neutrik board is placed between the amplifier phoenixes so that its socket is to your right. The socket connects to the complete board of amplifier.

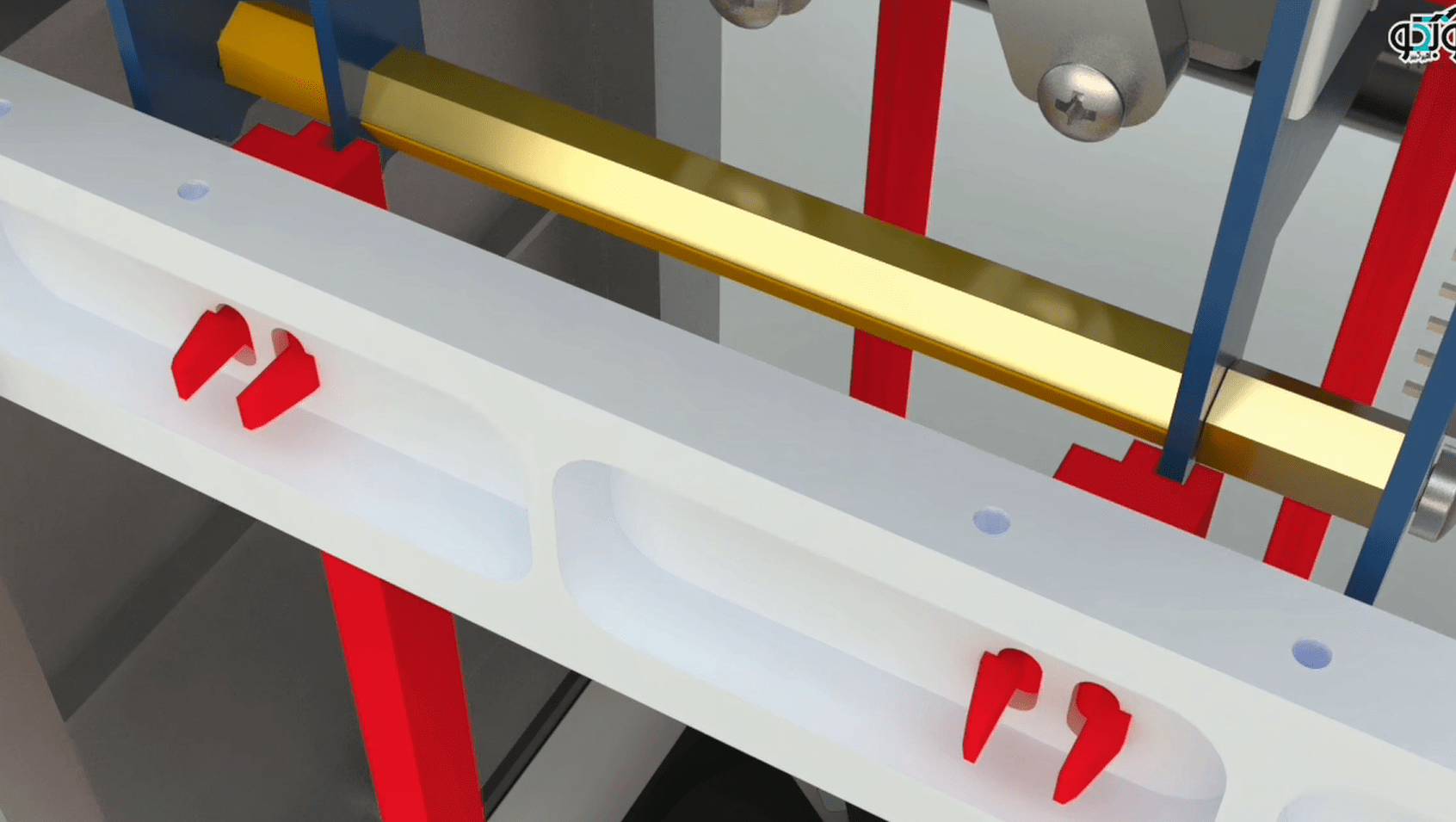

The holder is placed half way on the 6 pin Phoenix voltage connectors. Connecting the voltage 6 pin Phoenix on which the holder is placed to the switching and put the holder in place.

2 pin female Phoenix connectors with shorter wires) red and black) should be connected to the upper 2 pin male Phoenix connectors.

3 pin female Phoenix connectors with shorter wires) red, black and blue (should be connected to the lower 3 pin male Phoenix connectors.

Tip: Before placing the phoenixes on the amplifier, place the corresponding holders on phoenixes.

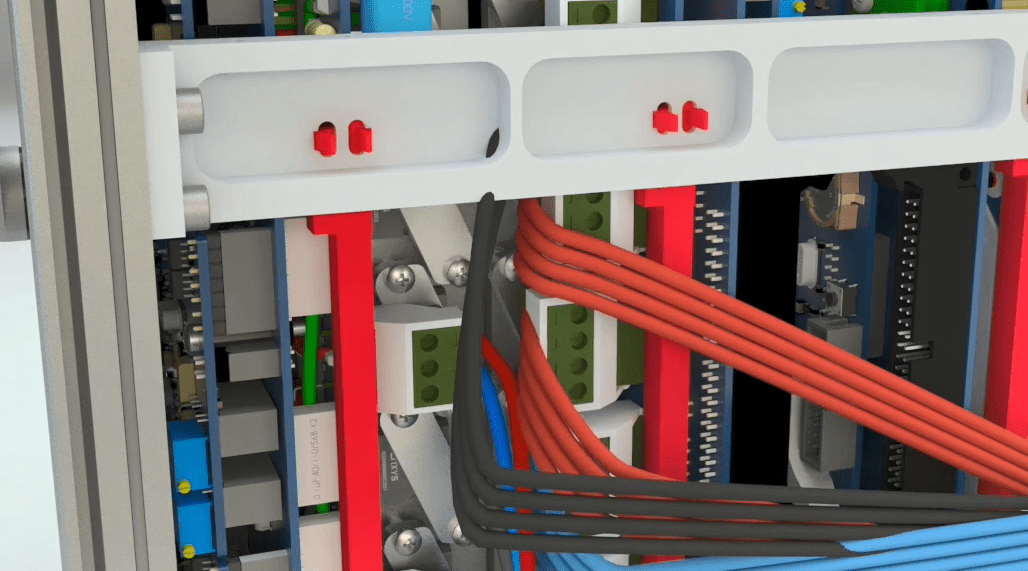

First, put a holder on the 8 pin current Phoenix (blue wire) and connect the internal 8 pin Phoenix to the incomplete switching board.

Connect the 4 pin blue longer Phoenix holder to the second male Phoenix from the bottom. Connect the 4 pin blue shorter Phoenix holder to the first male Phoenix from the bottom.

Put a holder on the 4 pin current Phoenix (black wire) and connect it to the incomplete switching board. Connect the 4 pin black male Phoenix to the first male Phoenix from the top.

Put an 8 pin Phoenix (red wire) current and connect it to the 8 pin male Phoenix of the incomplete switching board.

Connect the 4 pin female Phoenix with longer red wire holder to the second male Phoenix from the top. Connect the 4 pin female Phoenix with a shorter red wire holder to the third male Phoenix from the top. Then assemble all the current and voltage wires with a cable tie wrap.

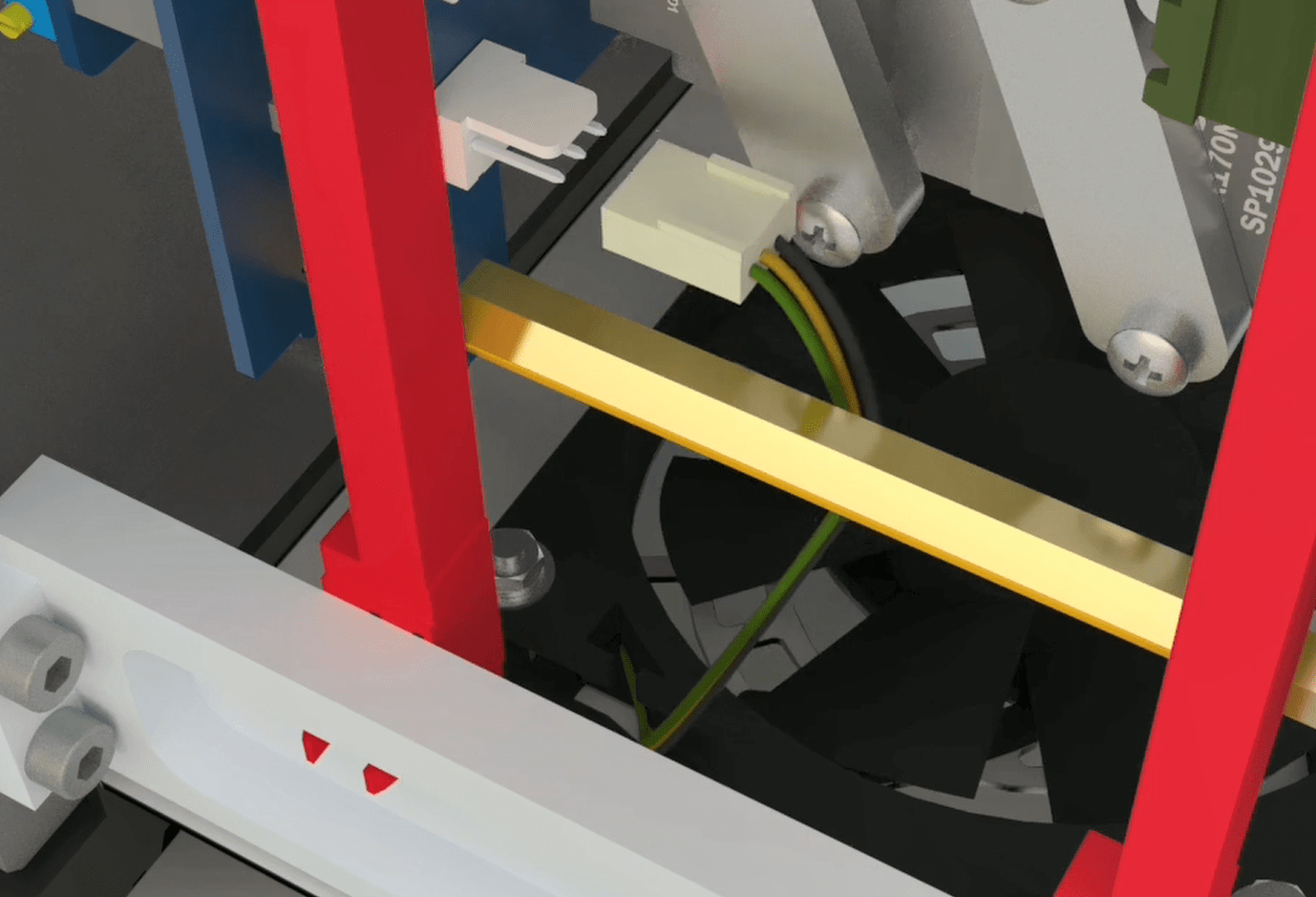

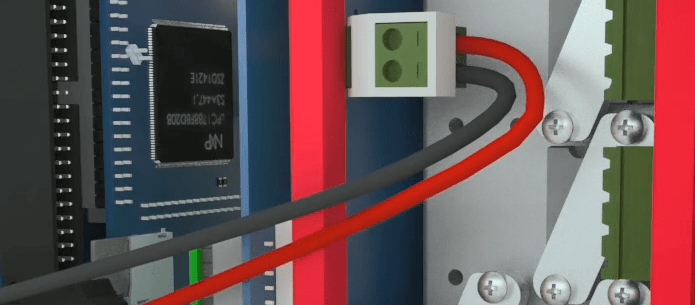

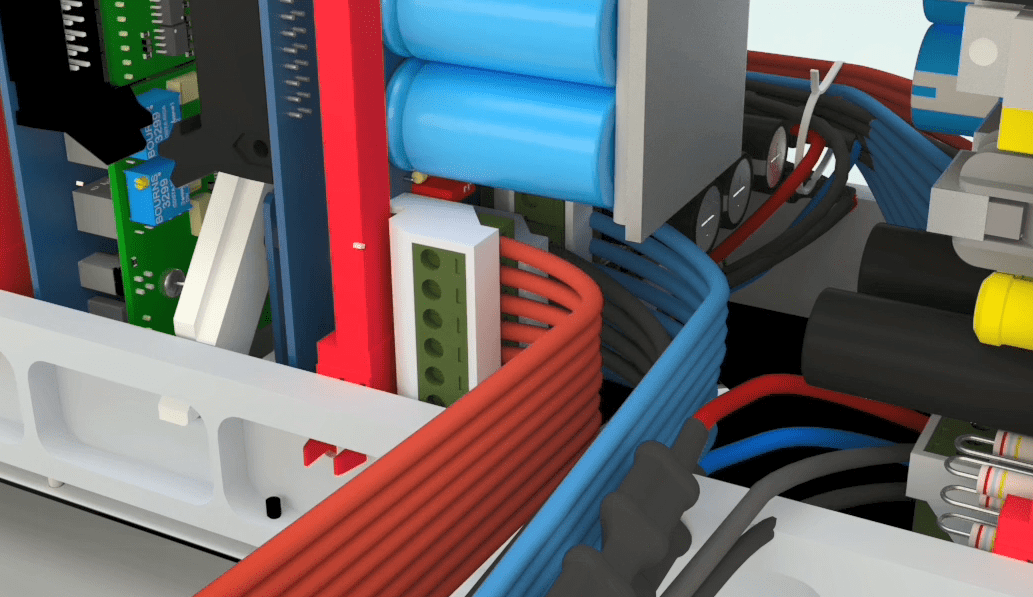

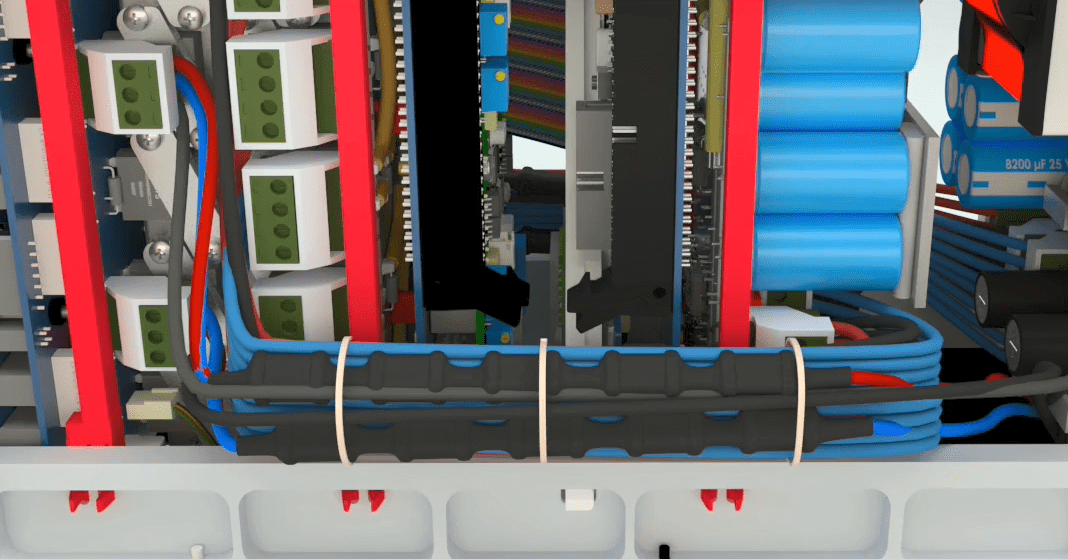

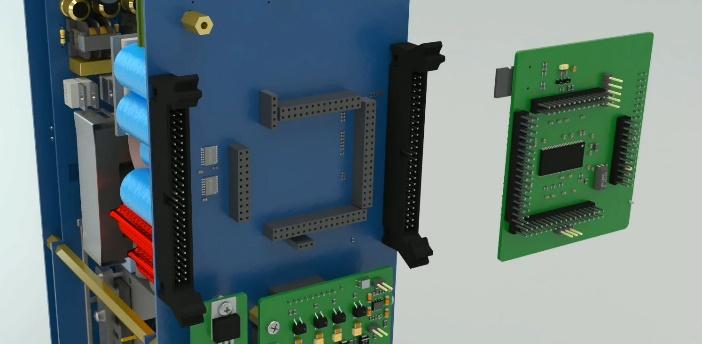

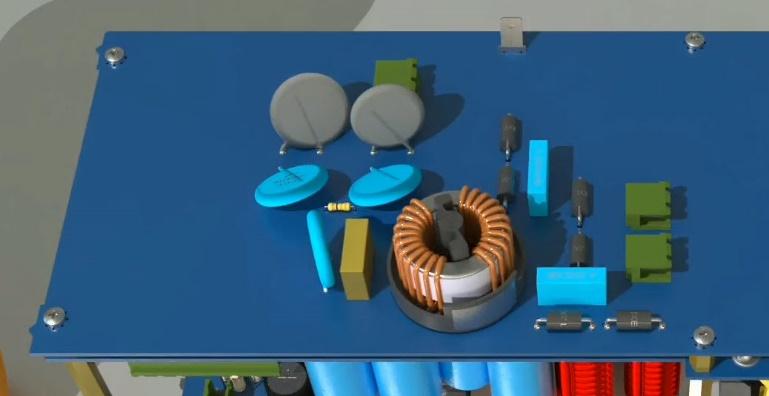

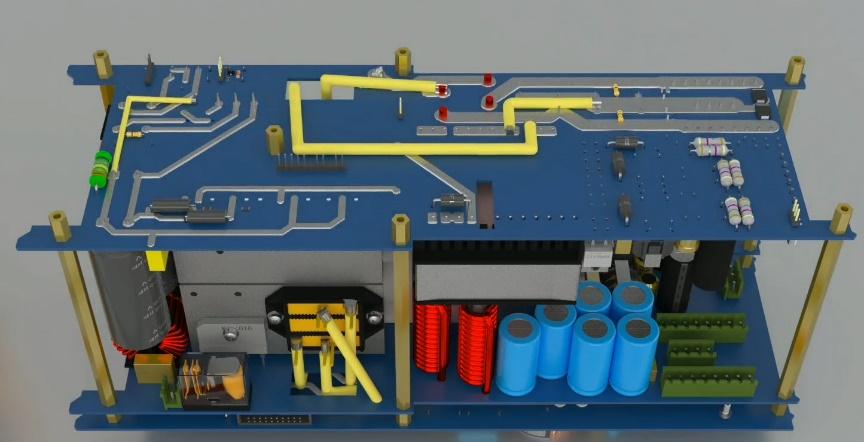

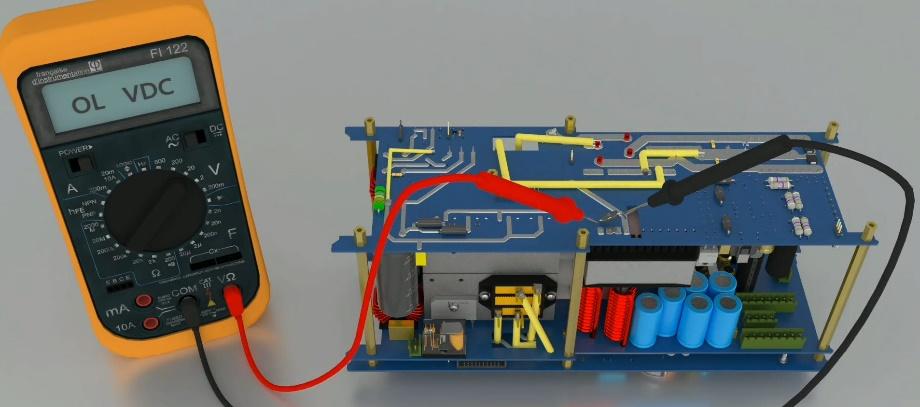

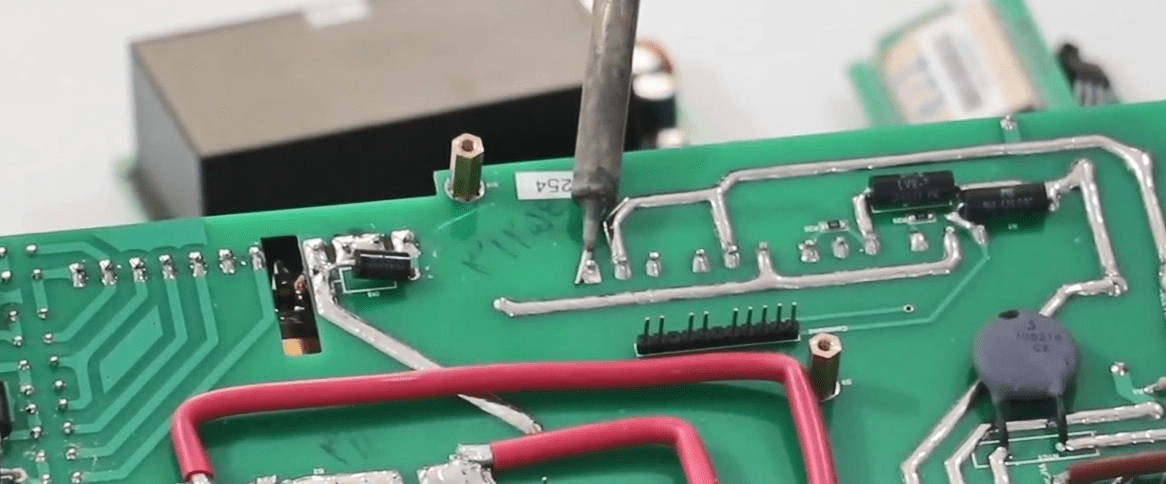

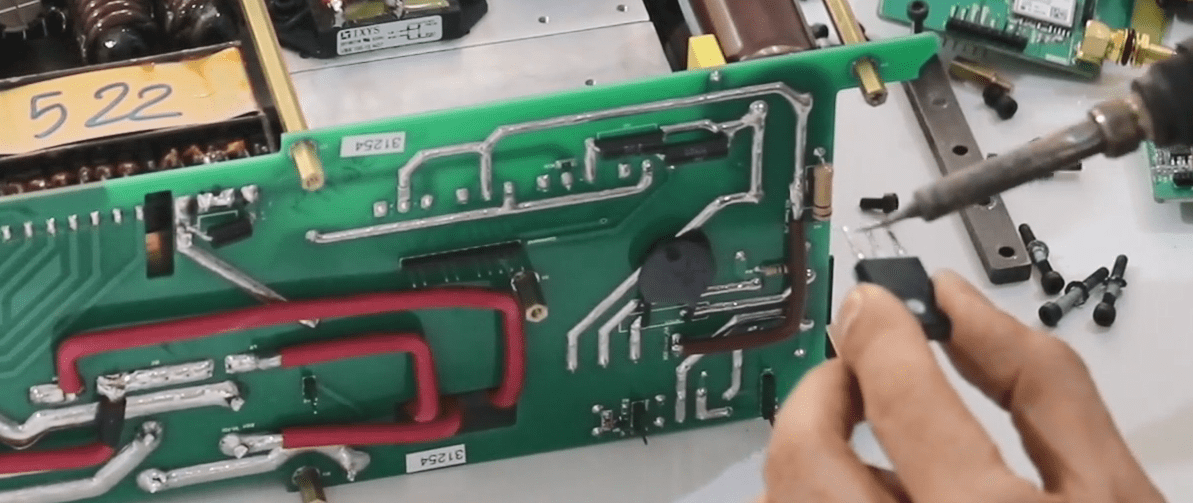

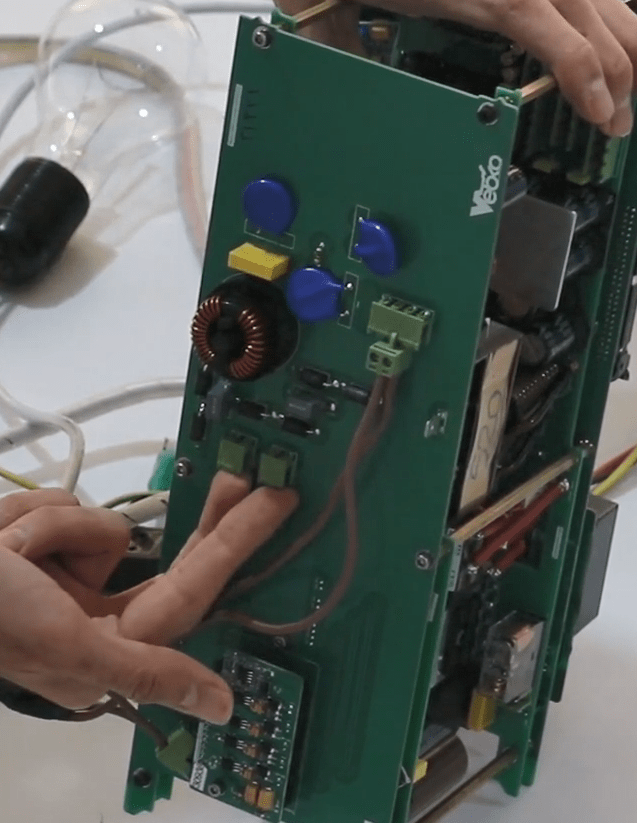

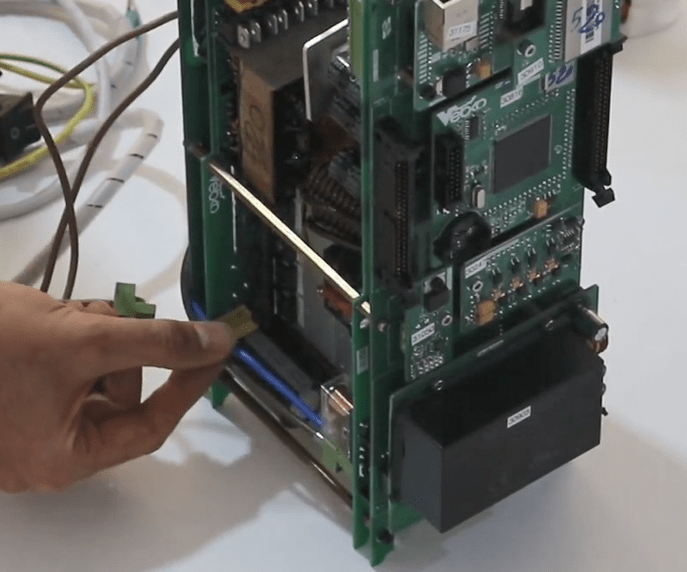

This ribbon cable connects the entire side of the switching range to the full range of the amplifier.

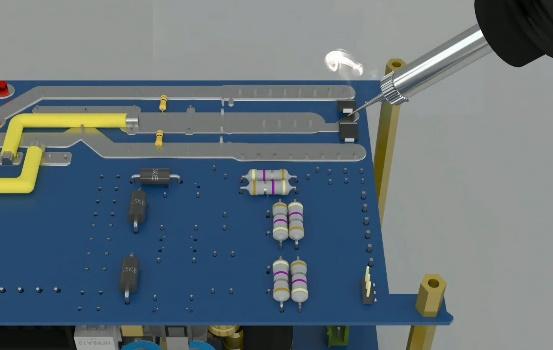

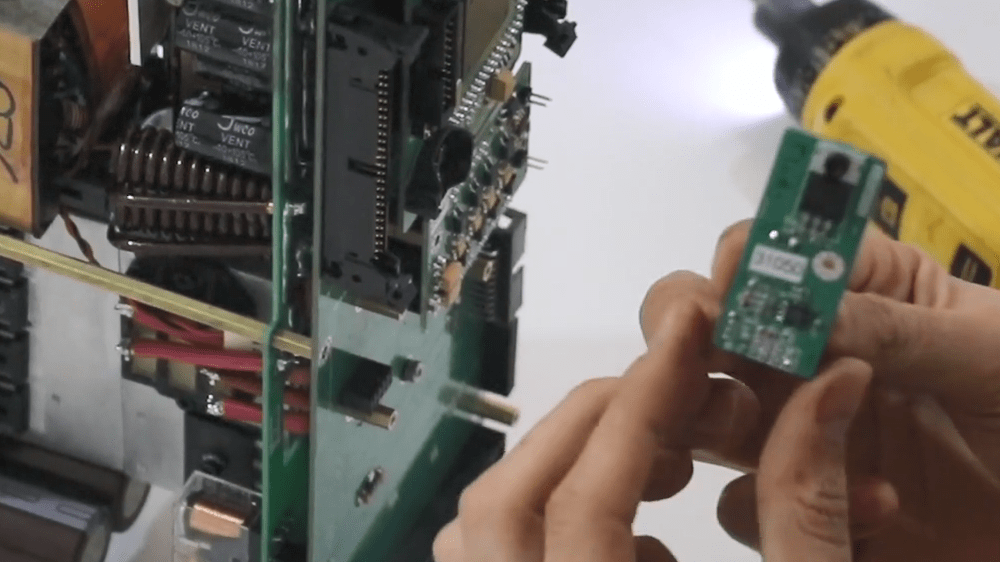

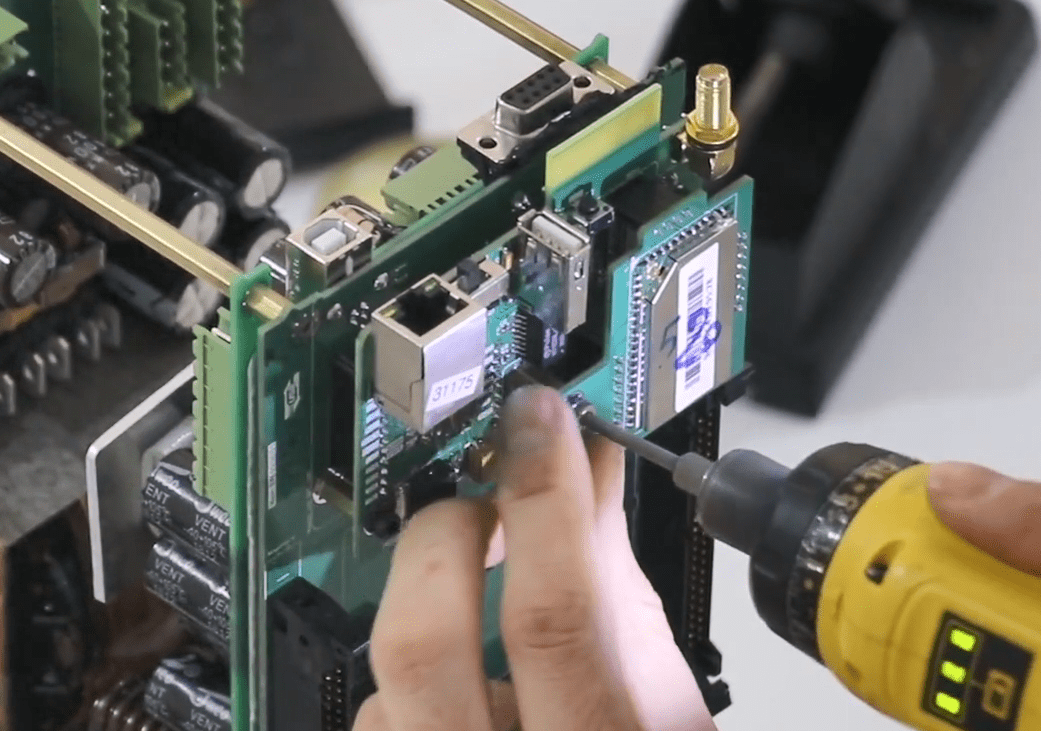

Connect the holder from one side to the IDC and connect it to the IDC by using a screwdriver or one forceps.

Holders must be placed on the rails and the two slots embedded on them should be placed on the module and the original board. Each holder is closed and tightened by 2 screws 16.5×2 soaked in a special screw along with a ribbon gasket on the holder and middle rails.

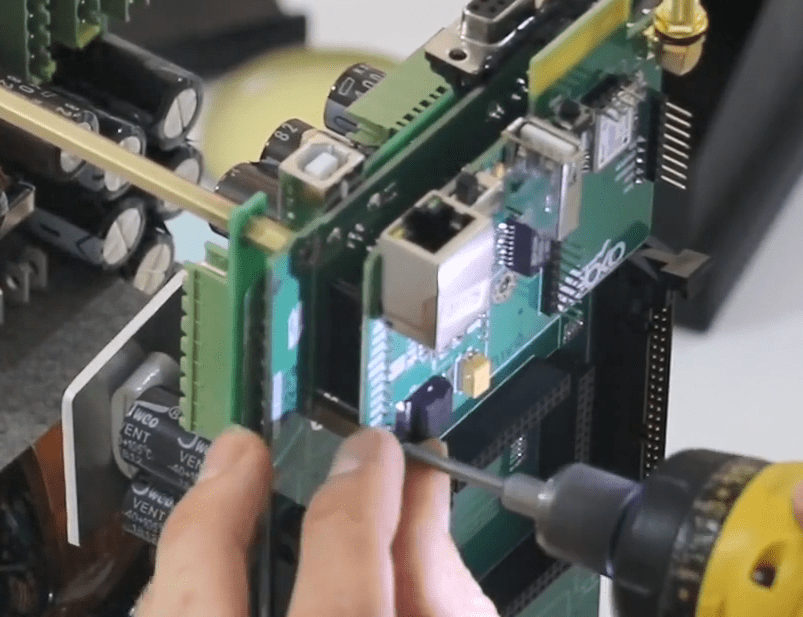

Place the micro holder on the middle rail on the one side and its two pins must be placed on the lower rails of the case on the other side.

This holder is connected to the body of the case from one side using bolts, nuts and 8×4 flat washers. The slots embedded on this holder, on the other side, are connected to the amplifier and the neutrik board. The neutrik board on this holder is fastened by a special glued 8×3nut to a bolt and a spring washer.

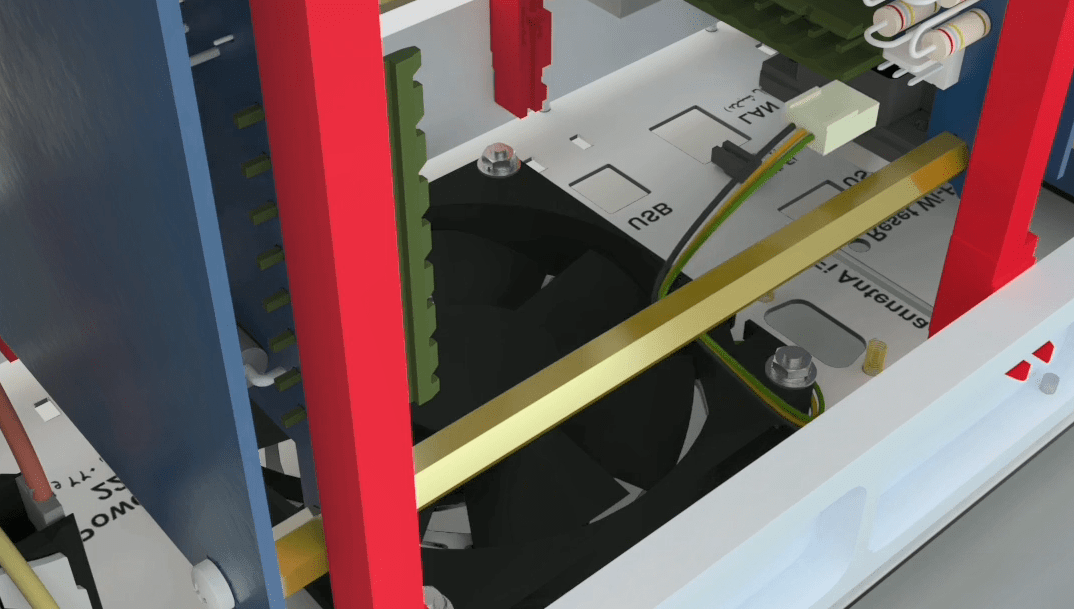

This holder is connected to the wall of the case on one side and connected to the body of the case using bolts, screw washers, and a 8×4 flat. The other side is connected to the module and main switching.

Place the 2*10 holder on a ribbon cable and push it slightly towards the IDC.

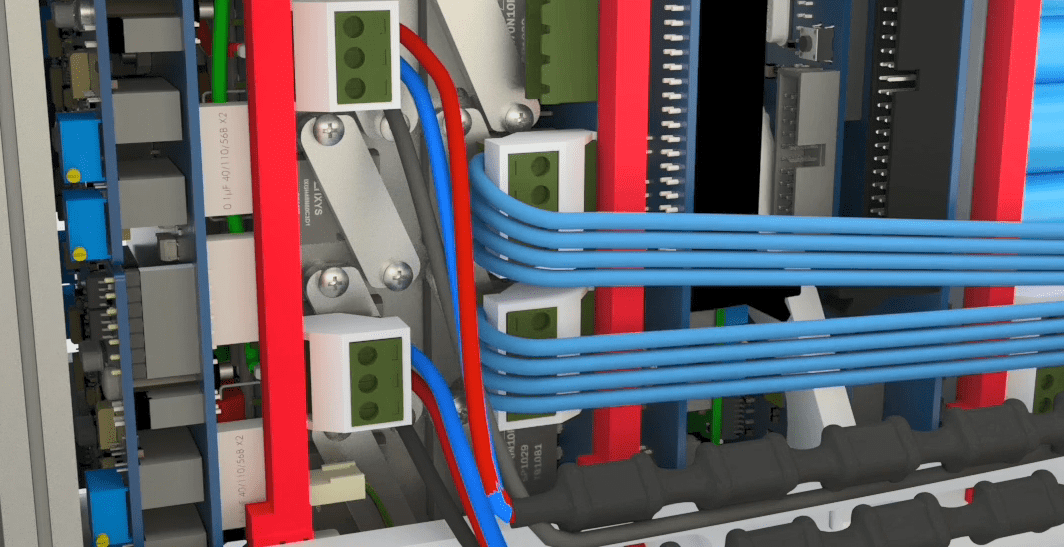

The 2 connected wires to the case must be connected to the complete switching module and the incomplete side of the amplifier module.

Connect the 6 pin Phoenix voltage cable on the holder to the switching module and put the holder in its place.

First, connect the 8 pin black Phoenix wire with its holder to the complete switching module.

Then connect the 4 pin black Phoenix wire with its holder to the complete switching module.

In the end, connect the 8 pin red Phoenix wire with its holder to the complete switching module.

The female Phoenix connector with a shorter wire on the holder should be connected to the lower 3 pin male Phoenix connector. The female Phoenix connector with a longer wire on the holder should be connected to the upper 3 pin male Phoenix connector.

First, connect the 4 pin blue female Phoenix with longer wire on the holder to the second 4 pin male Phoenix connector from the bottom. Connect the 4 pin blue female Phoenix with shorter wire on the holder to the first 4 pin male Phoenix connector from the bottom.

Connect the 4 pin black female Phoenix with shorter wire on the holder to the first 4 pin male Phoenix connector from the top. Connect the 4 pin red female Phoenix connector with longer wire on the holder to the second 4 pin male Phoenix connector from the top.

Connect the 4 pin red female Phoenix connector with shorter wire on the holder to the third 4 pin male Phoenix connector from the top.

Then assemble all the current and voltage wires with a tie wrap.

The connector of this cable is approximately in the middle and below the front panel. First, connect the switching side to the switching module, then attach the uncompressed part to the IDC Latch on the panel and close the guards.

On IDC connected to the switching module, install a high legged holder IDC and connect the two sides of the holder base to both sides of the IDC.

When connecting the ribbon cable, pay attention to the IDC cable and the groove on the IDC modules.

Holders must be placed on the rails and the two slots embedded on them should be placed on the module and the original board. Each holder is closed and tightened by 2 screws 16.5×2 soaked in a special screw glue along with a flat washer on the holder and middle rails.

This holder is connected to the wall of the case on one side and connected to the body of the case using bolts, screw and flat washers and an 8×4 flat. The other side is connected to the module and main switching.

This holder is connected to the body of the case from one side using bolts, nuts and 8×4 flat washers. The slots embedded on this holder, on the other side, are connected to the amplifier and the neutrik board. The neutrik board on this holder is fastened by a special glued 8×3nut to a bolt and a spring washer. Turnover the device on in a way that the back panel is facing upwards.

The door with four legs must be installed underneath the device and the leg-less door is installed on the top. Place the walls in the lower grooves (grooves are on the front panel frame).

On both sides of the case, two long earth wires have been attached to the body. Connect each side to its door, pull the wire a little with a small force to make sure that they are tight and steady.

Place the doors and install the legs in place; two star screws must be tightened on each side. You need a star screwdriver to tighten the screws.

First, turn the device upside down so that the base are upwards, we then open the case base using Allen wrench 3. After separating the base, separate the 4 screws connected to the case doors.

Now the case doors are released and we need to remove the earth cables that are attached to the door.

Next, put the base in its own place then open the nuts for the GPS antenna and the dongle port and return the case over.

Now open the 14 screws in the front panel then release the green connectors attached to the panel (Phoenix).

After phoenixes, it is time to release the flat panel cable and the toggle is pulled from the sides of the free cable, separated from the panel. In the next step, we release the 4 sockets attached to the key and 1 socket attached to the earth panel, now the front panel comes out of the case easily.

First, we remove the cable (earth). To remove the cables, you must first cut all belt clamps. Separate the holders attached to the phoenixes, then remove the latched flat cable by pressing the toggles.

In the next step, to separate the holder related the Neutrik, use Allen wrench 3, two screws attached to the holder, box wrench 5.5, open the nut attached to the holder and remove the screw attached to the right switch bracket. Remove the twin screws with Allen wrench 3.

The blue and brown wires are then connected to each side of the circuit, first cutting the bracket and then the phoenix 2-pin connector.

Open the 4 holders on the middle rail using allen wrench 2 and then go to the other side of the device and seprate the 2 earth cables from the device and release the holder related to the flat at the bottom of the device on the right side using a screwdriver. Seprate the other side that has a latch by releasing the latch from the device.

Cut the belt clamps, releasing cables from Phoenix using a screwdriver.

In the next step, release the flat cable holders attached to the switch, pull the flat back and separat it.

Disconnect the Neutrik board connected to the amplifier and open the 2 Neutrik holder that is attached to the case body using Allen wrench 3 and the nut under the Neutrik board with a 5.5 box wrench.

Remove the flat panel holder then release the flat, finally, open the holder that connects the switching to the case by 2 screws with Allen wrench 3 and separate it.

Open the screws for 4 holders on the middle rail using Allen wrench 2; then open the screw on the micro holder with Allen wrench 2 and remove the holder.

Finally, all the cables and screws are opened; the amplifier and switching module are freed and the fan sockets are released once ejected and easily removed from the case.

In order to remove the device from the suitcase, by pressing the push button, the handle of the device should be placed in a 45 degree angle and taken out of the case.

To change the status of handle of the device, it is necessary to press the side buttons of the device simultaneously and then the status should be changed. Once the device is positioned on the intended surface, the handle of the device can be put on the device by pressing the push button.

Also, it is possible for the handle to be positioned beneath the device so it could be used as a stand for the device. In addition, the bases that are installed under the device can be used for this purpose.

At the bottom of the device are the air conditioning grooves and it is crucial to consider that, while positioning the device, these grooves must not be blocked under any circumstances.

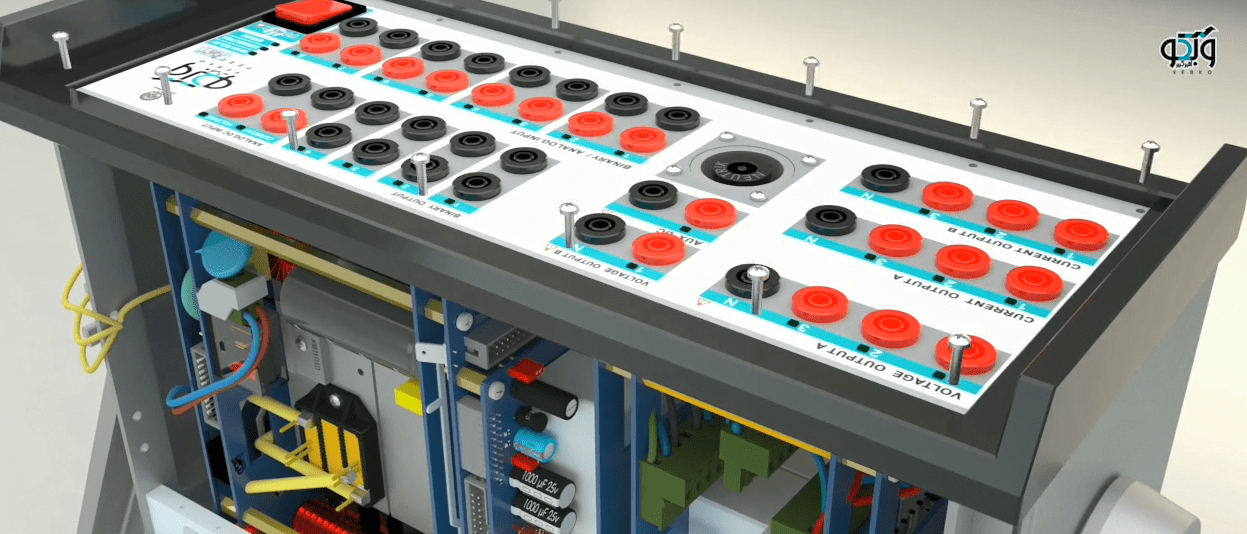

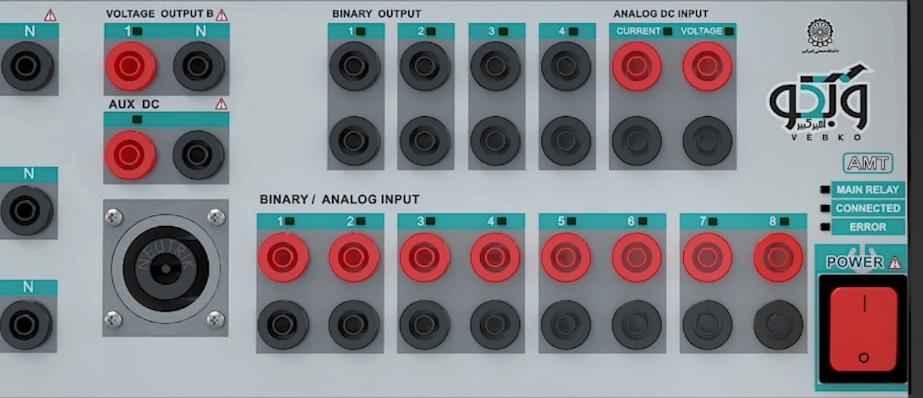

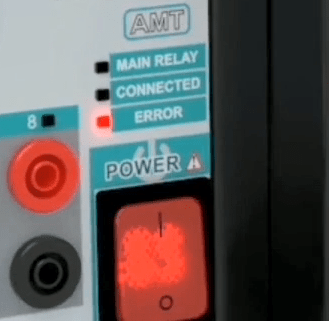

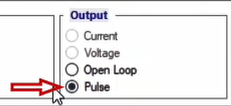

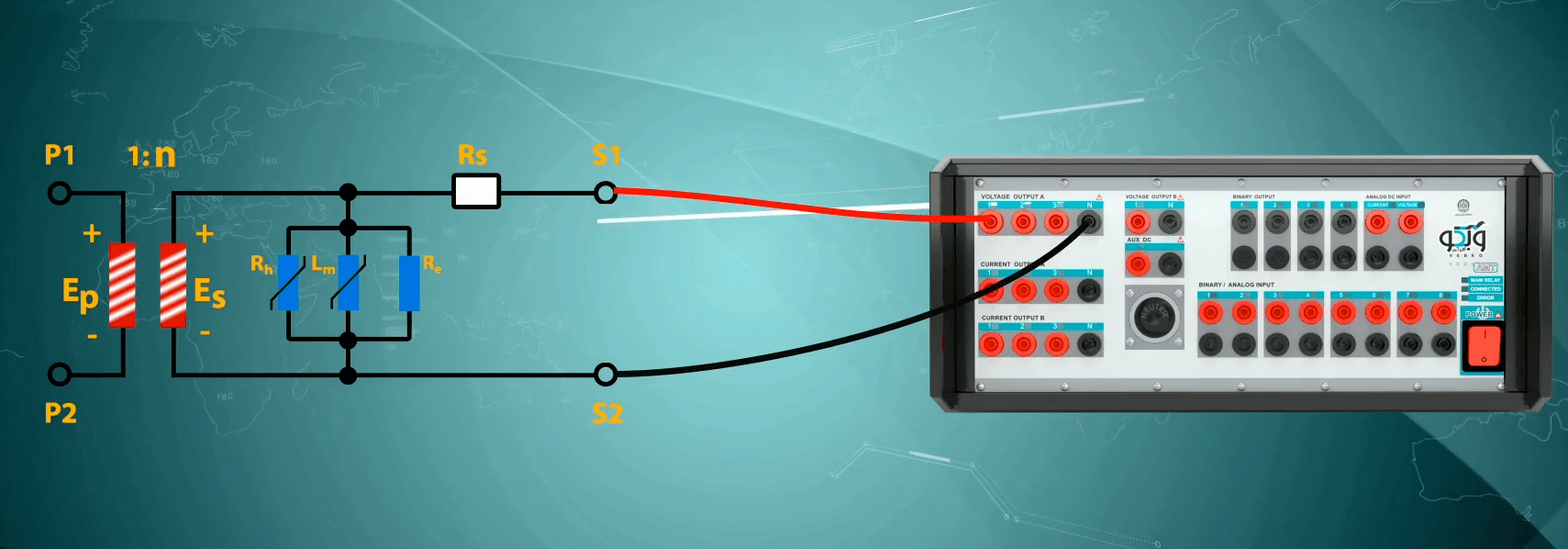

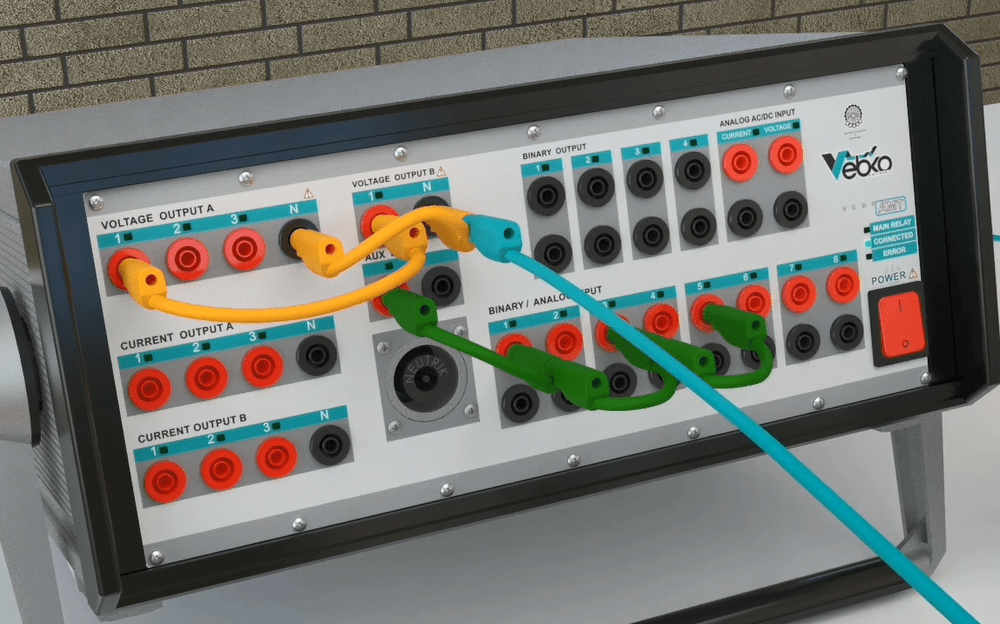

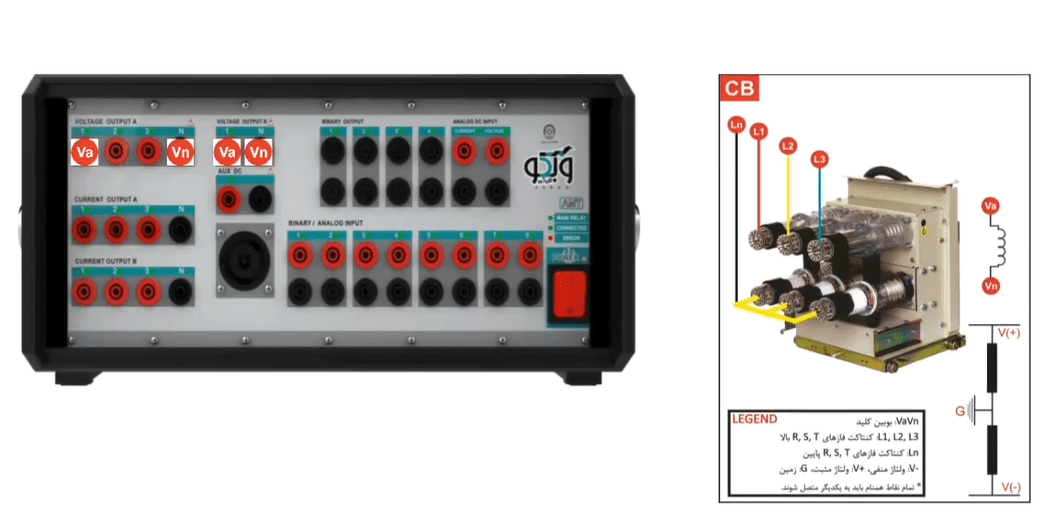

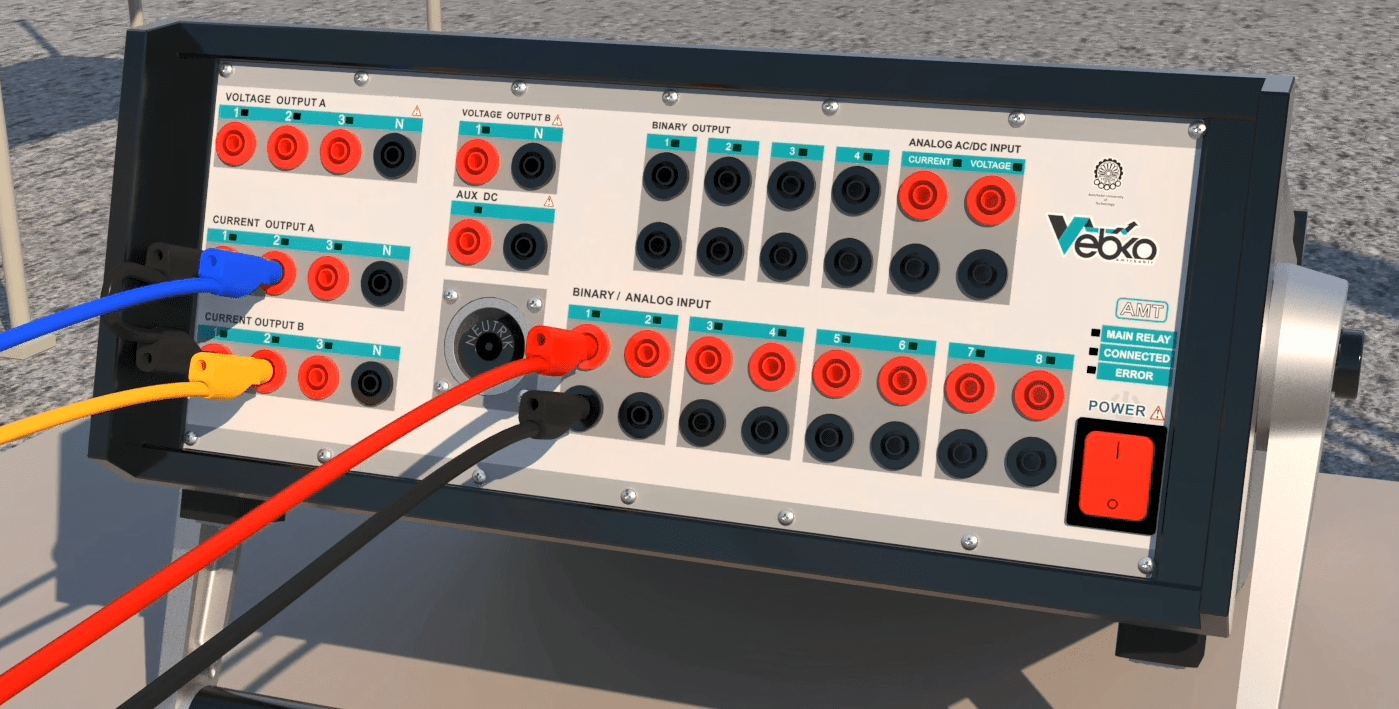

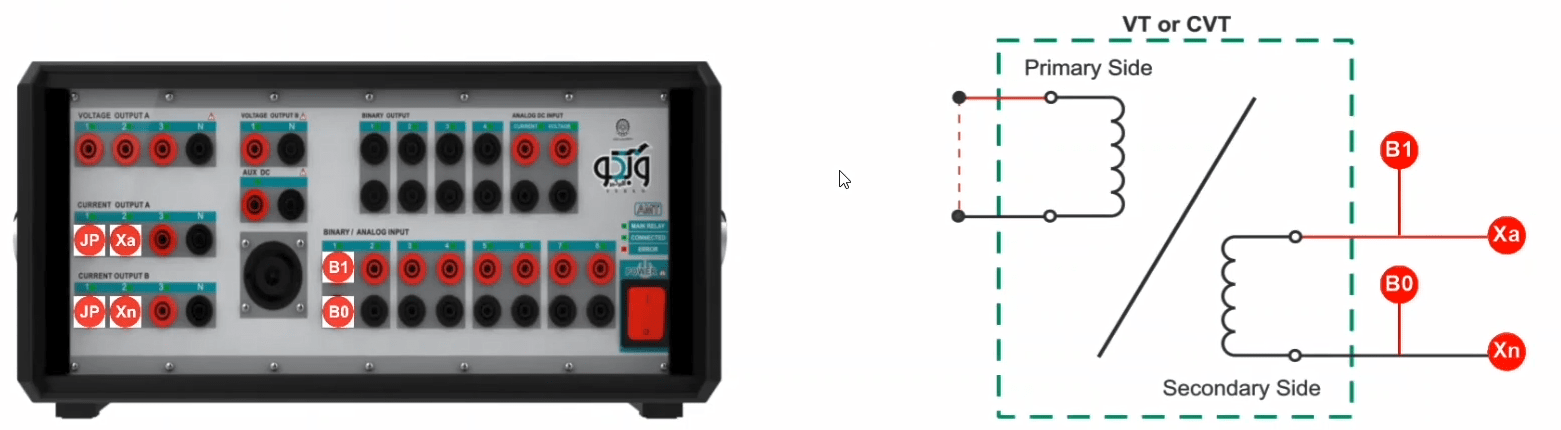

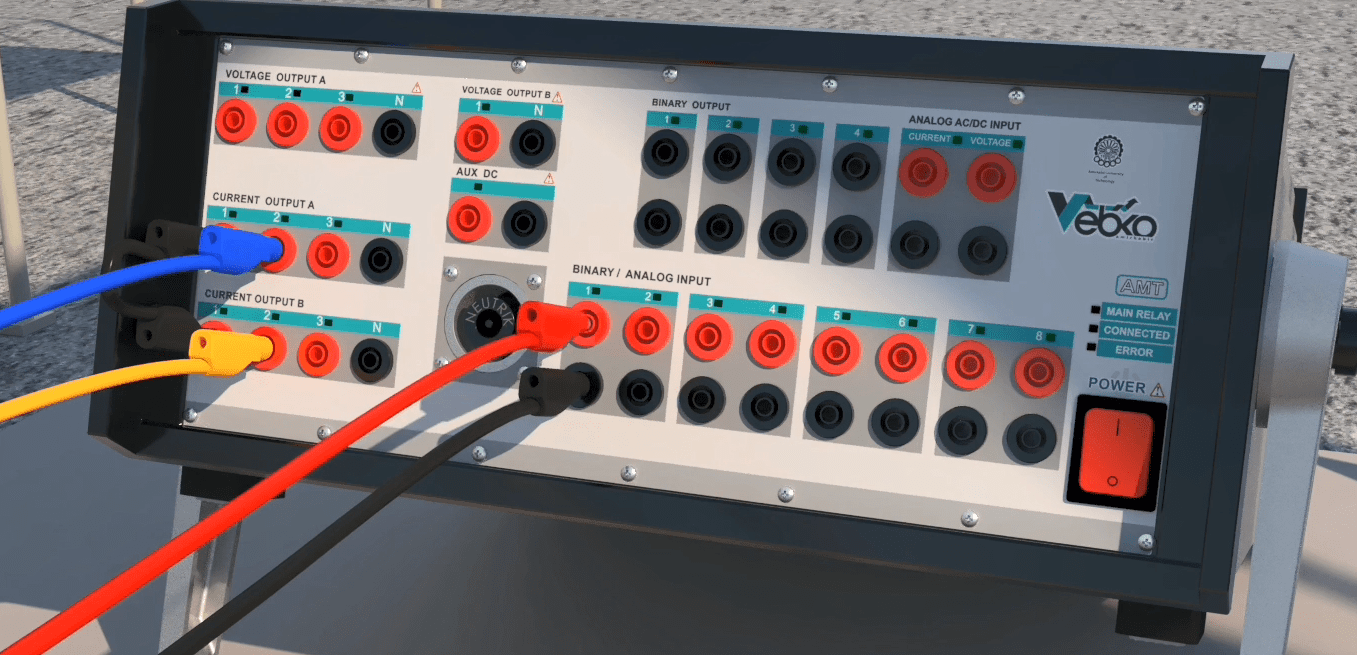

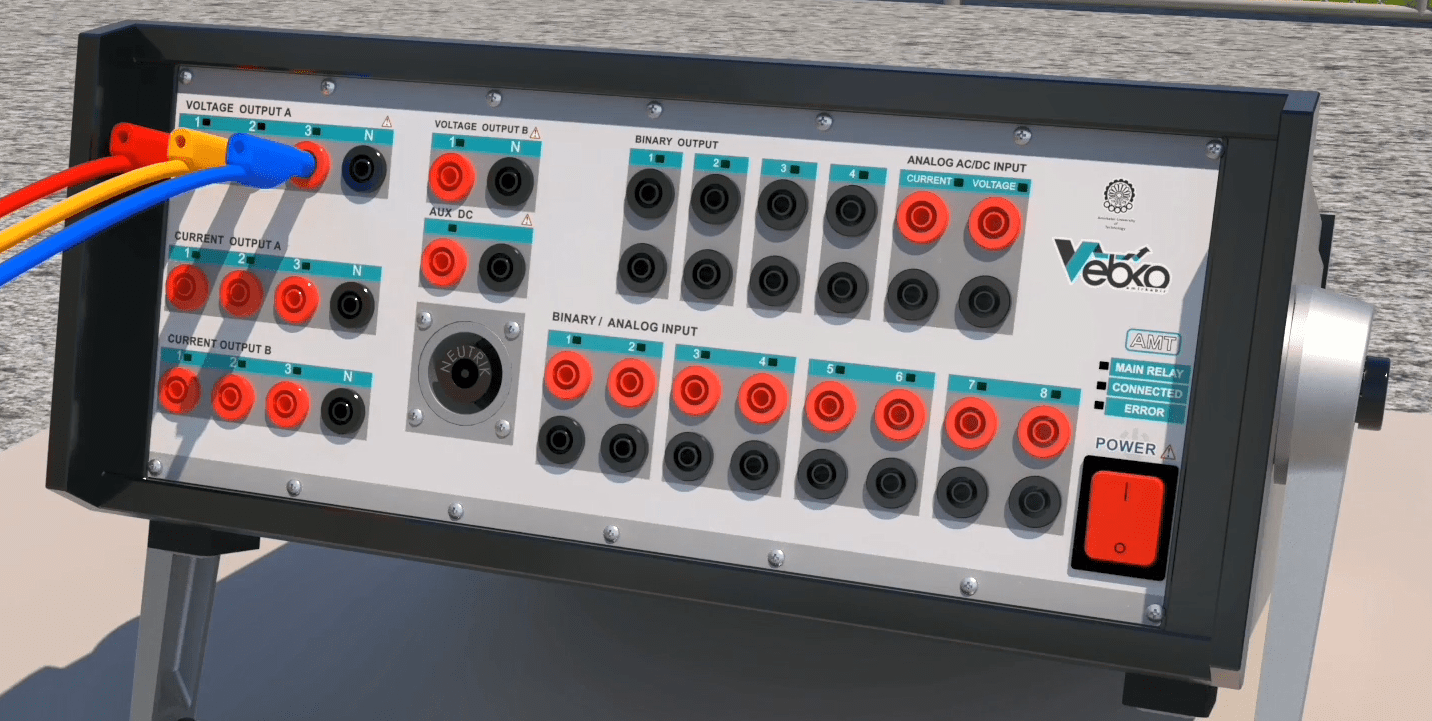

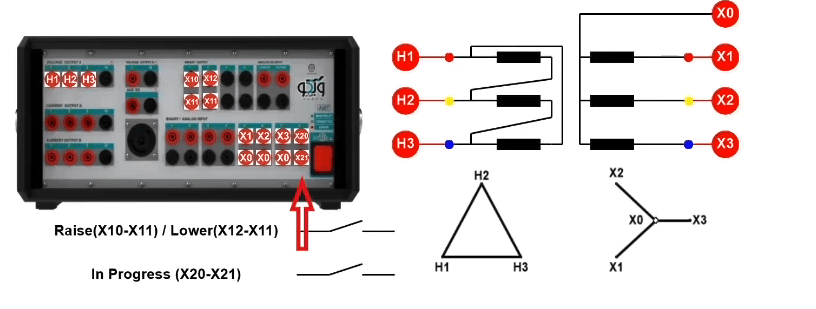

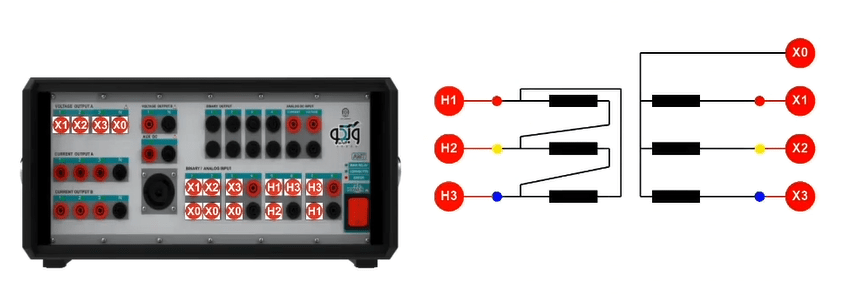

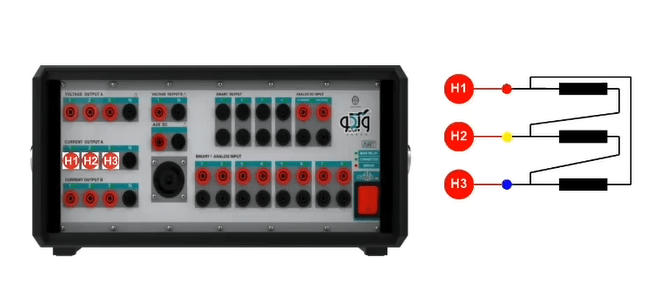

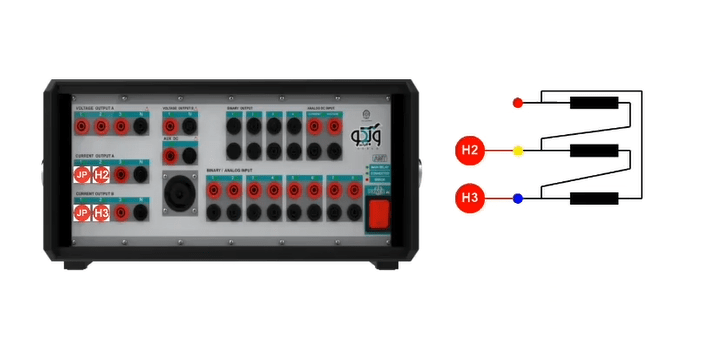

The front panel of the device consists of the outputs, inputs, device status lights, and the on/off power button.

If the green light of the main relay is on, it means that all main switches of the device are on.

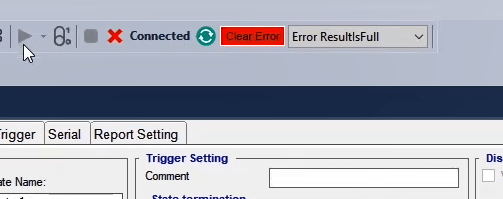

If the green light of “CONNECTED” is on, it means that the device is correctly connected to the software via PC or mobile phone.

If the red light of “ERROR” is on, it means that there is a problem with the device and it has stopped working. As long as the problem is not resolved, this light will remain on and the device will not work.

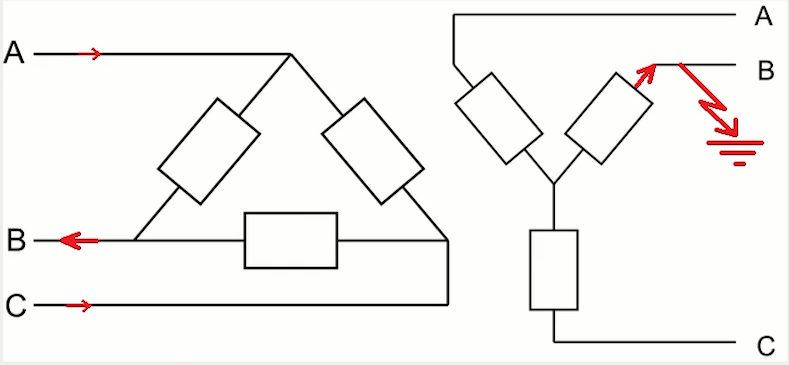

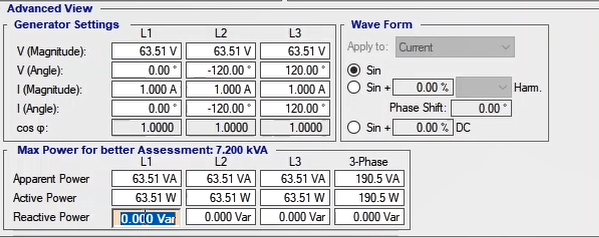

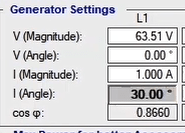

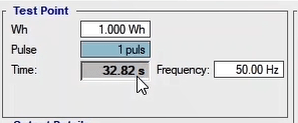

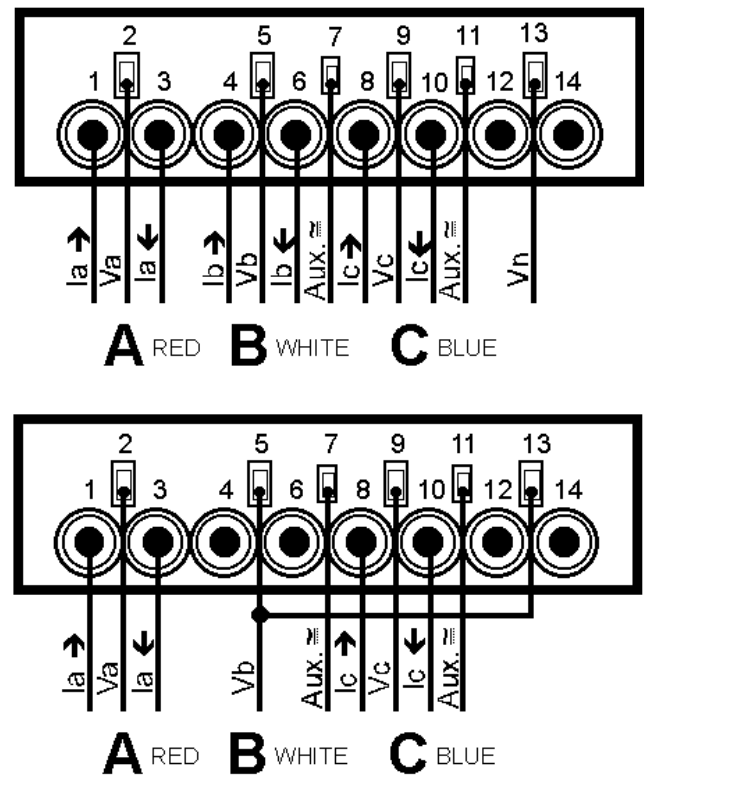

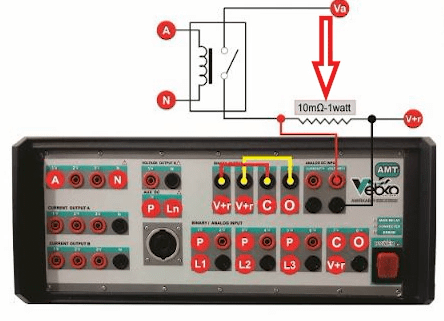

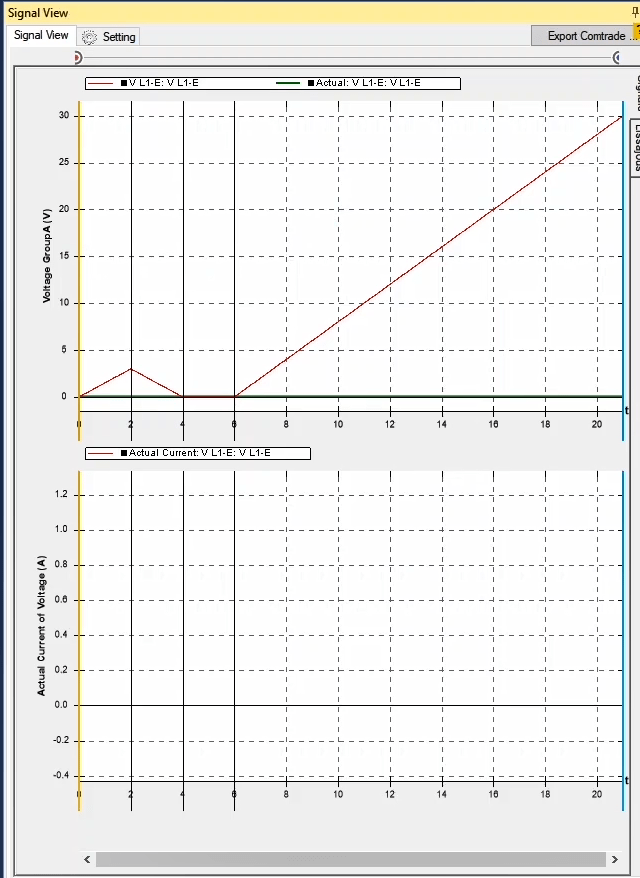

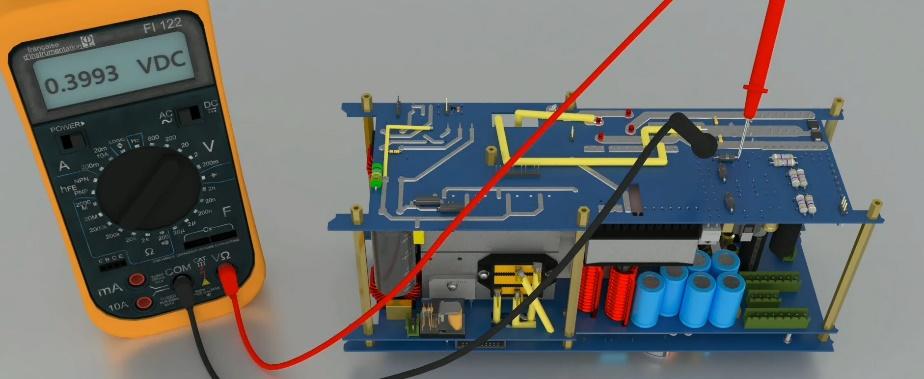

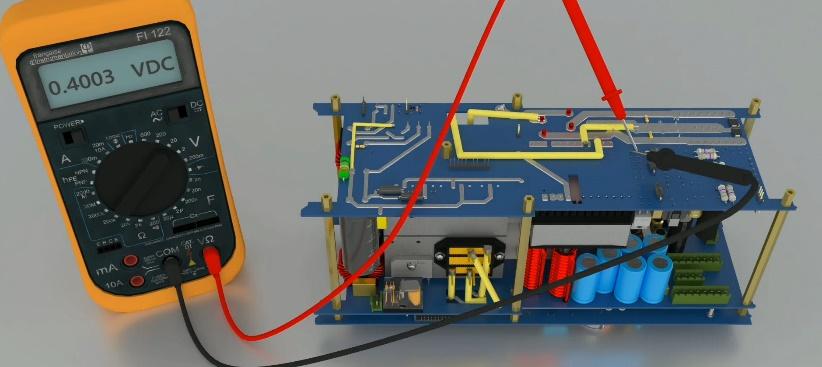

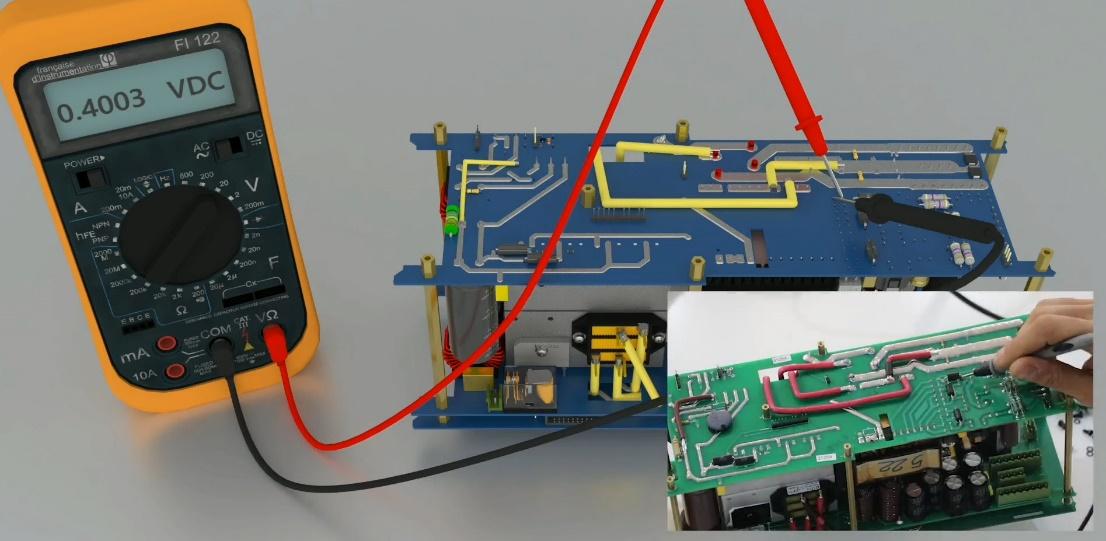

The two voltage groups A and B allow the user to receive up to 150V AC and 212V DC in all four phases simultaneously with a precision of 10mV with a maximum current of 0.4A AC and 0.6A DC as well as up to 2A in transient mode. By changing the wiring, it is possible to receive up to 450V single-phase AC from the device. Also, it is possible to increase the output voltage and provide the user with a 150V AC with a maximum current of 0.8A by changing the wiring and paralleling the two current sources.

The two current groups A and B allow the user to receive up to 32A in all six phases simultaneously or three-phase 64A. Moreover, by changing the wiring, it is possible to receive up to 128 single-phase amperes from the device.

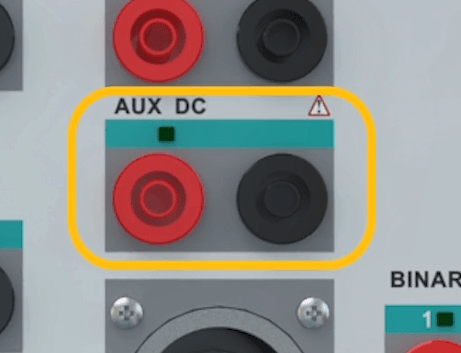

At the “Auxiliary DC” output, a DC voltage as high as 0 to 212V is permanently adjustable. This voltage is independent of the test and can be used to switch on other devices such as relays.

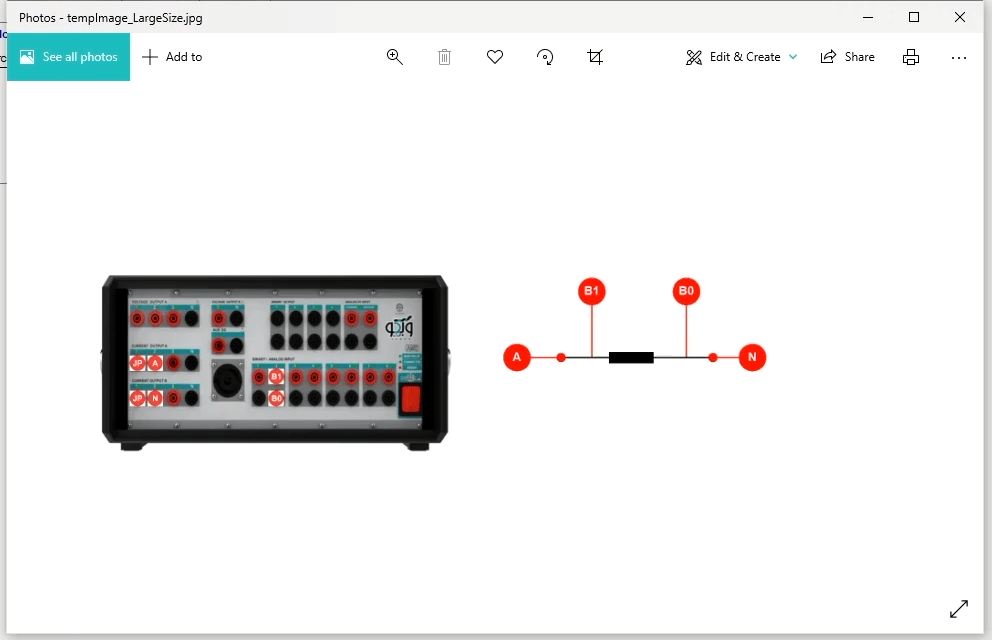

This is where the integrated cable is connected. The amount of the current and the output voltage of this port are the same as the amounts of the current and voltage ports that have been described earlier.

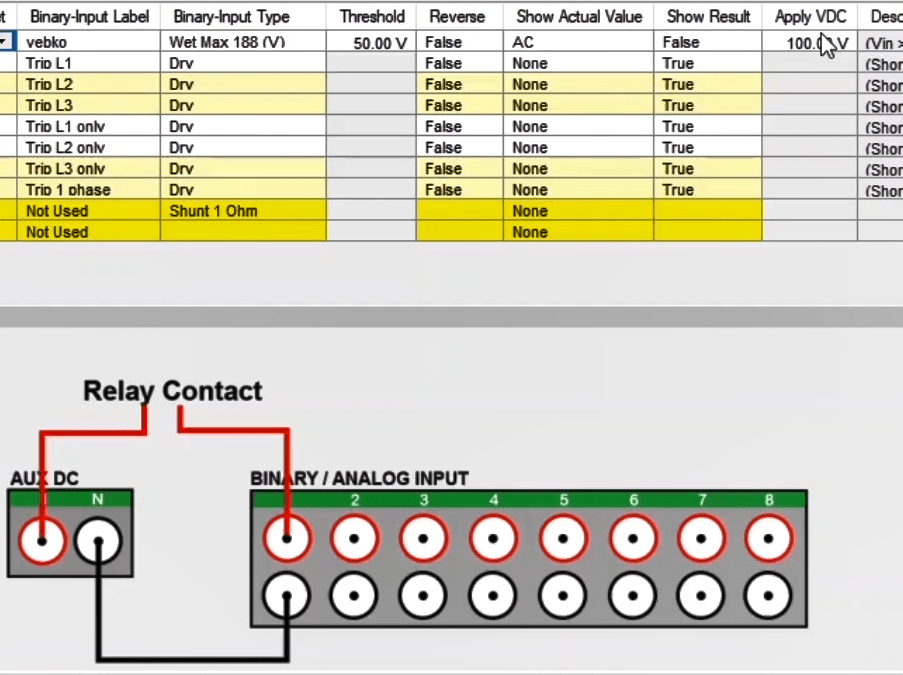

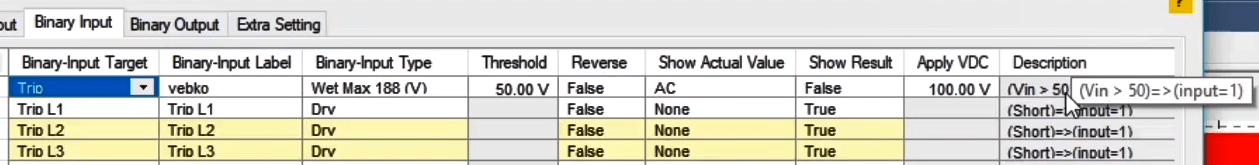

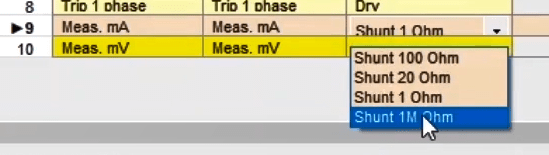

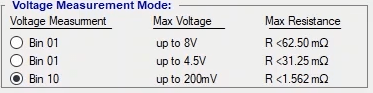

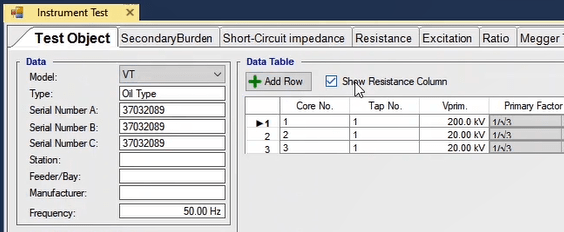

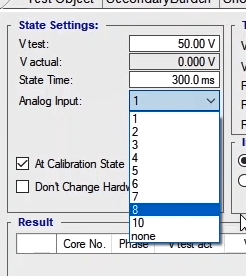

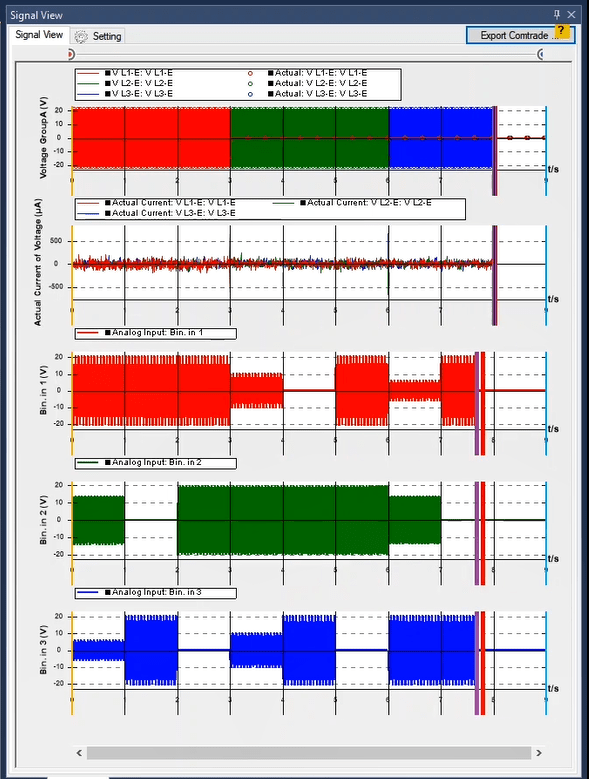

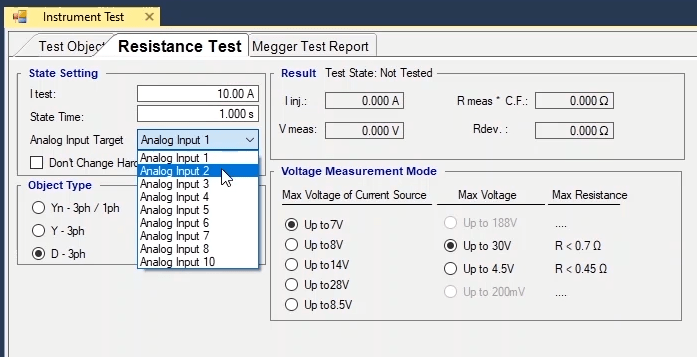

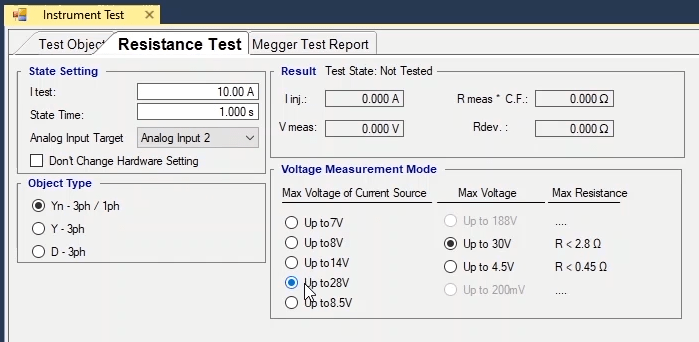

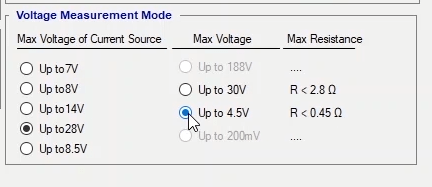

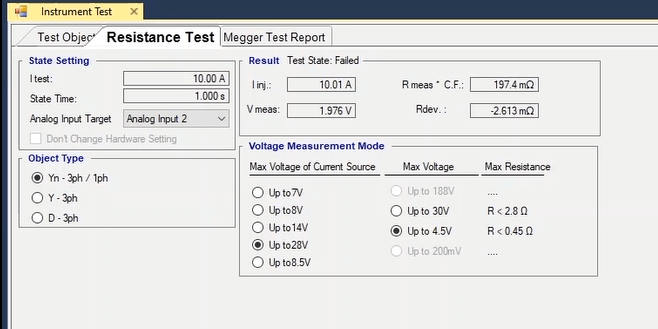

The analog inputs of the device are capable of receiving both analog and digital signals. All 8 inputs can be active simultaneously. Other than reading them, these inputs can show the waveform of voltage in three voltage levels of 4.5, 30 and 188V with the precision of 1, 3 and 10mV.

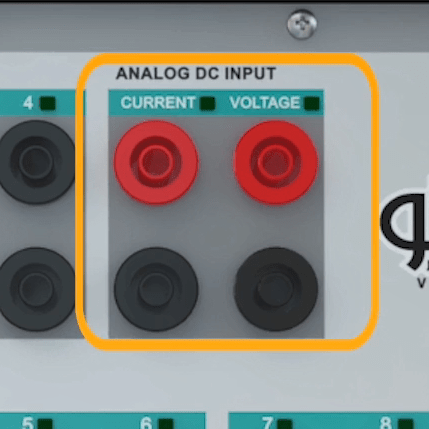

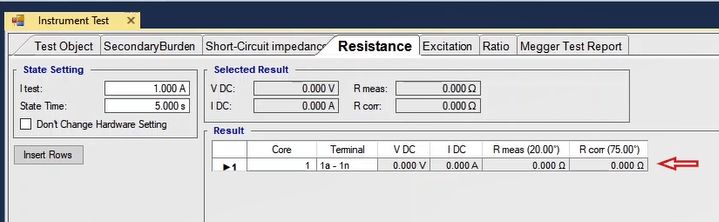

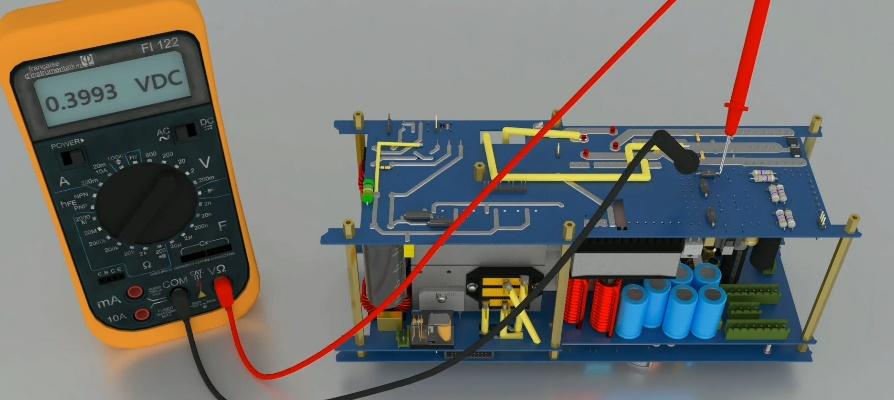

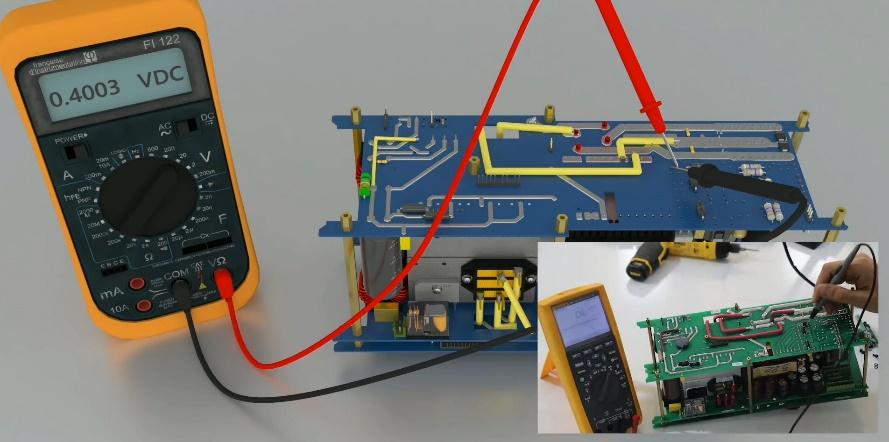

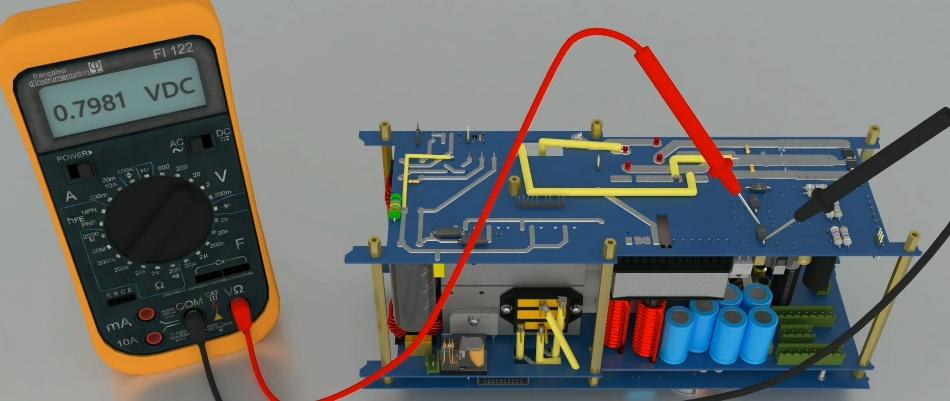

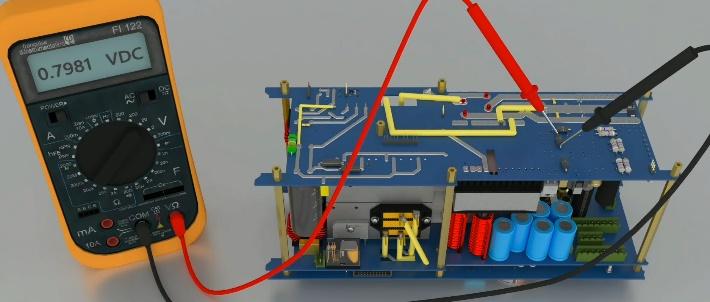

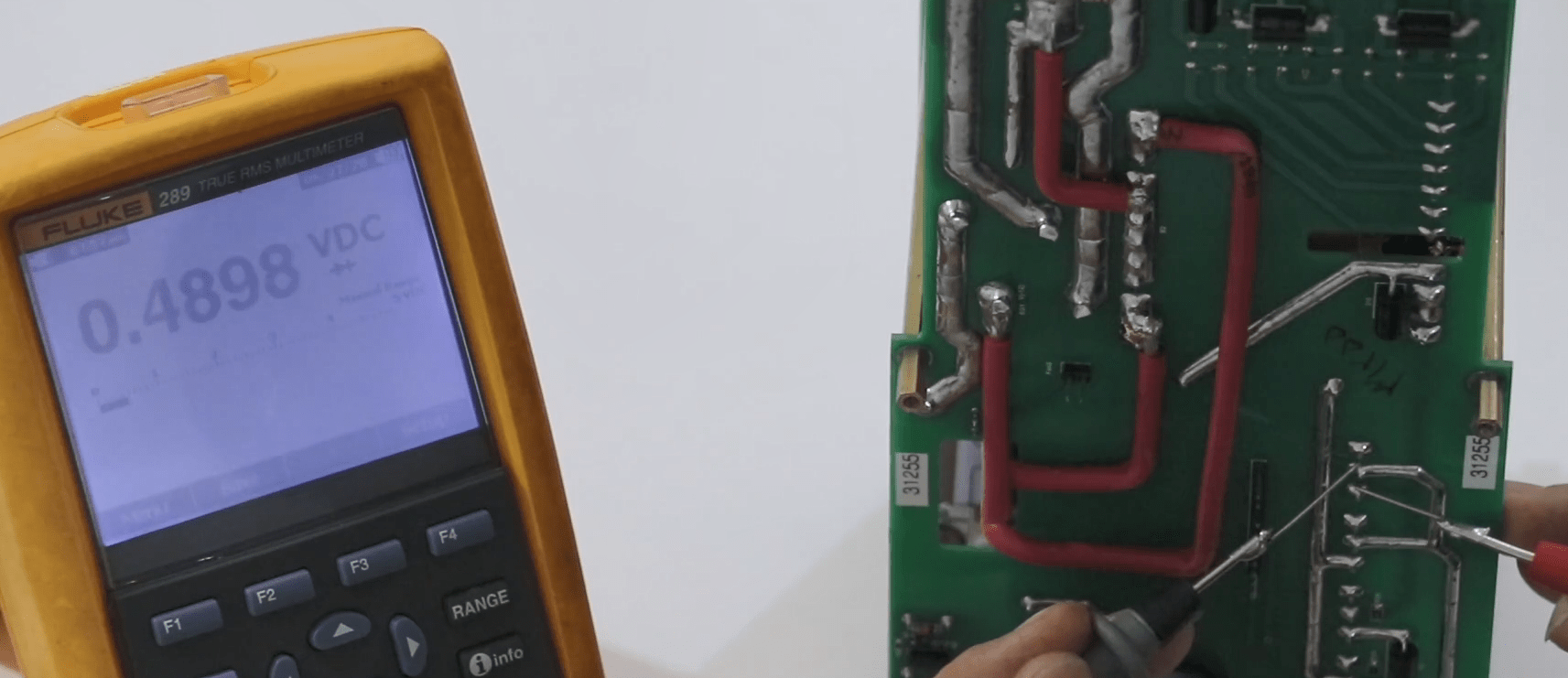

The “Analog DC Input” section is capable of measuring voltages up to 200mV with a precision of 50µV and current up to 500mA with a precision of 50µA.

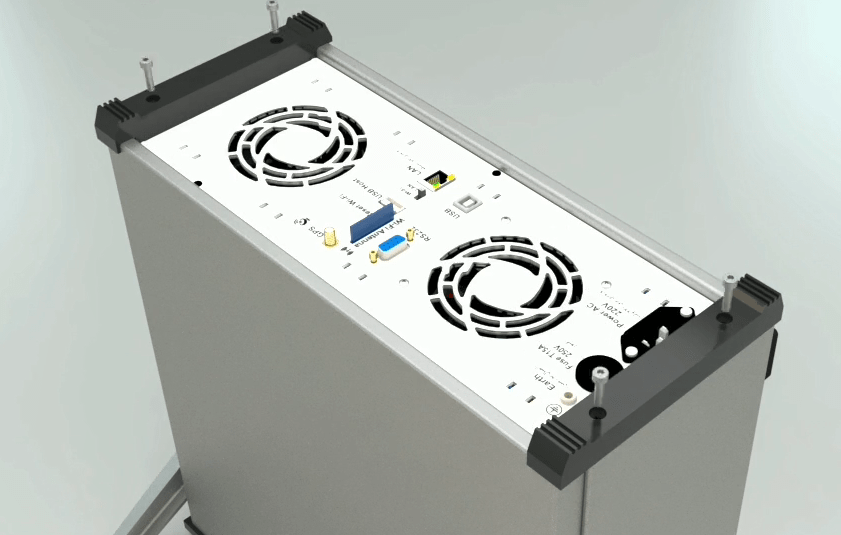

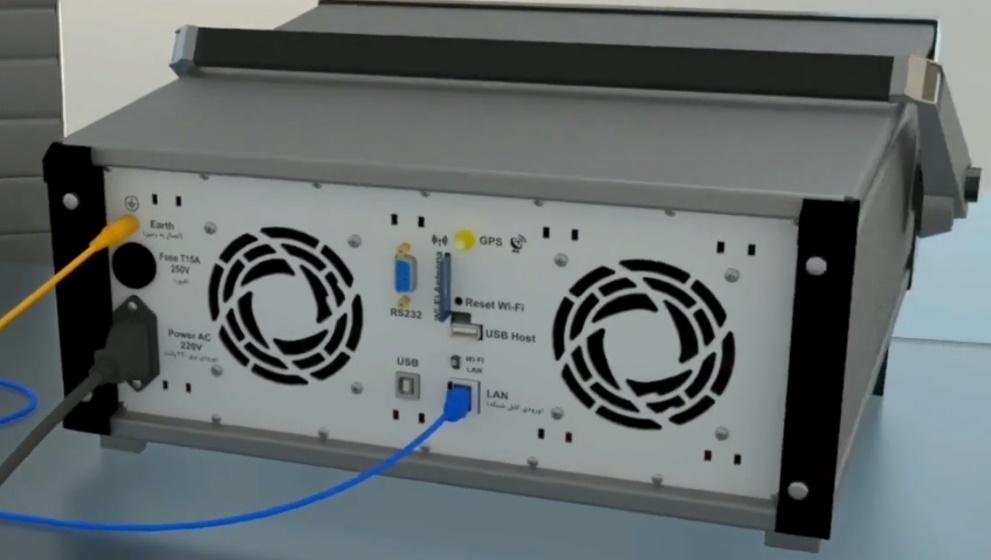

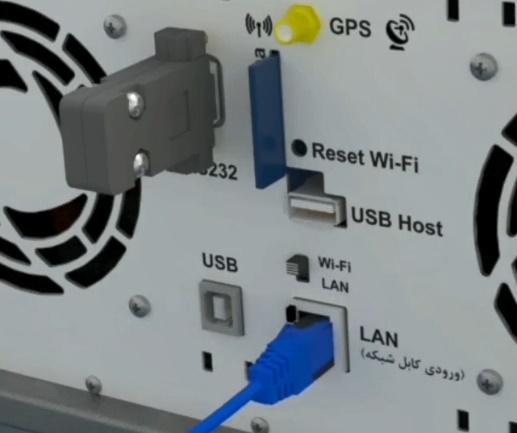

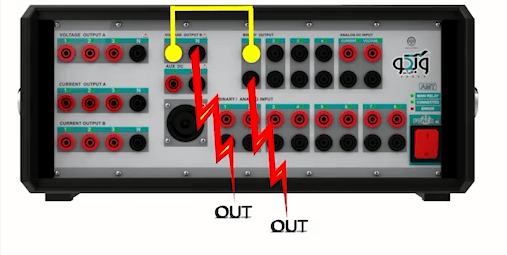

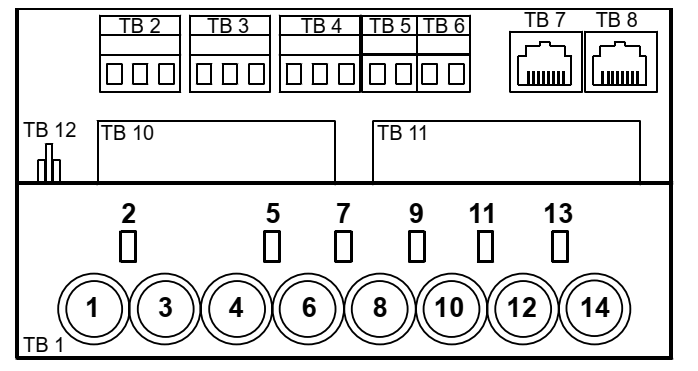

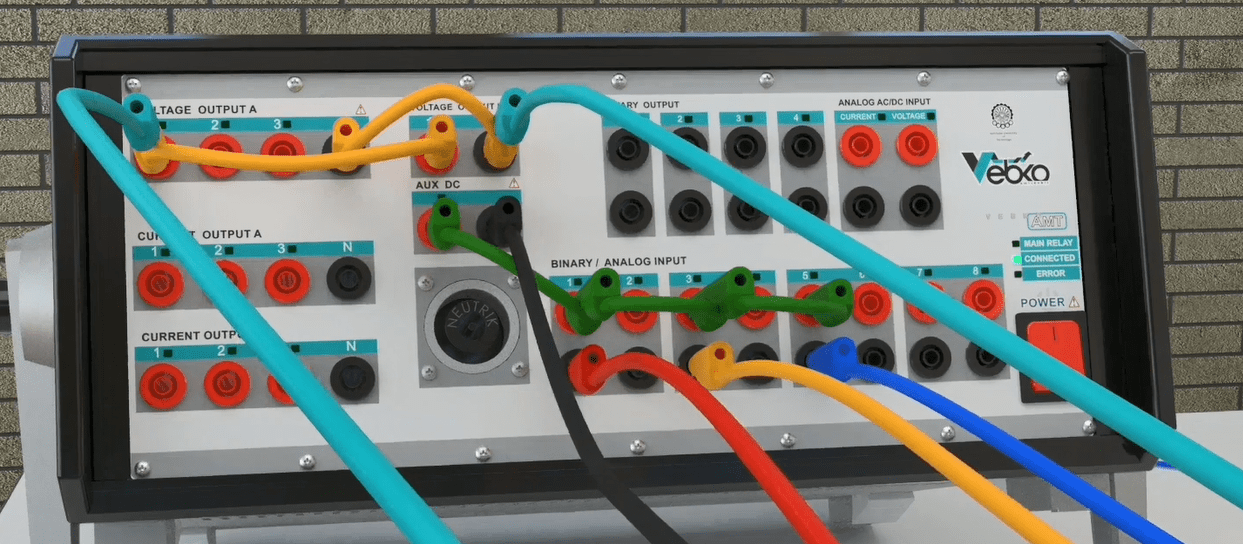

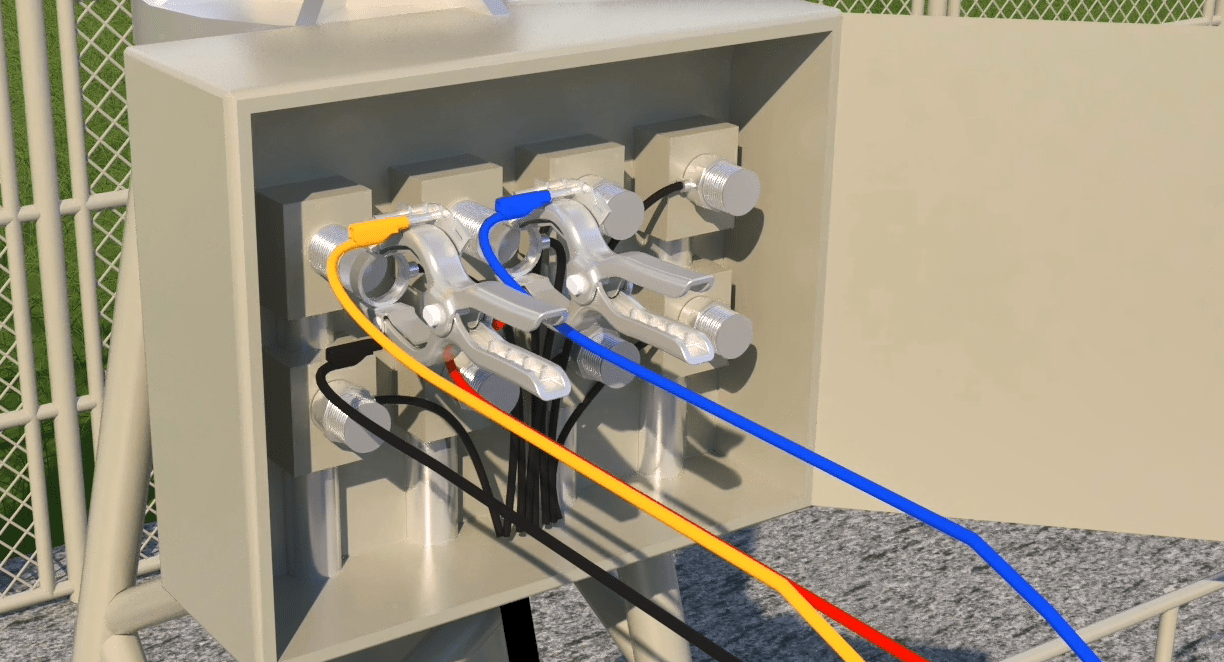

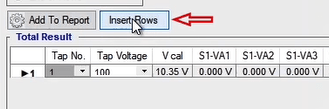

Generally, the back of the device consists of various components including:

Earth port

Fuse

Power supply

USB port type A

USB port type B

LAN and Wi-Fi switches

Ethernet port

This port is used to protect the earth connection and the earth cable of the device is connected to this port.

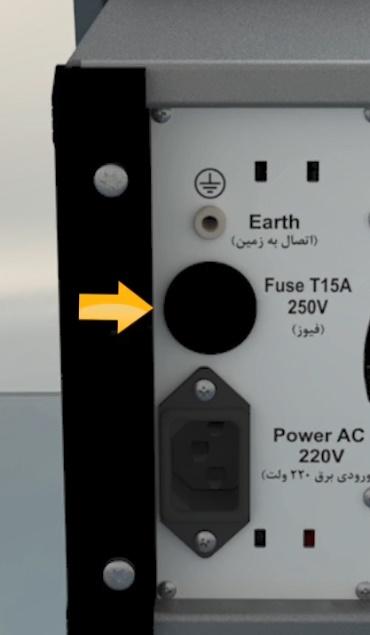

In this section, in order to protect the device, a 15A and 250V fuse is used.

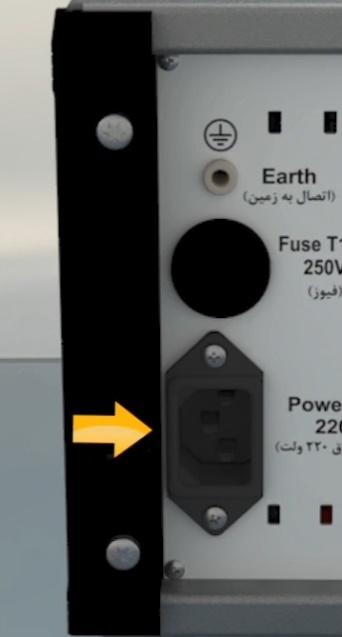

The power supply port is located here. The power cord of the device is plugged to this port.

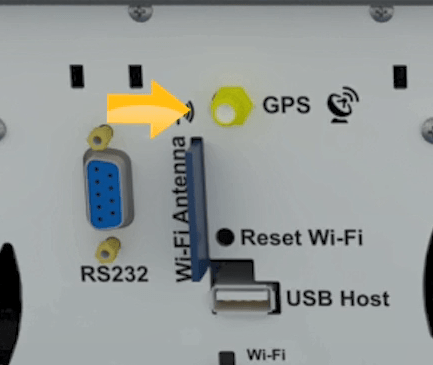

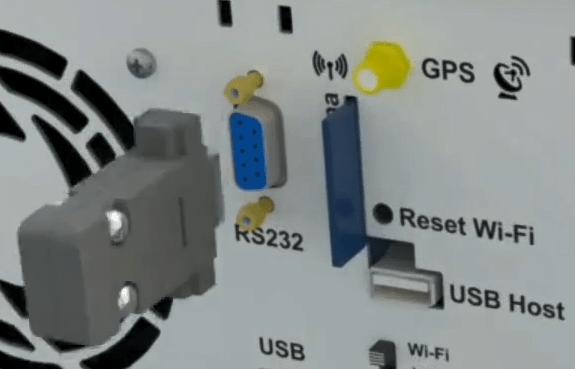

The RS232 port is mainly used for resetting the IP and updating the firmware. To do this, the RS232 dongle, which is a part of the equipment of the device, needs to be connected to this port. Then, the necessary operation, described in the following animations, needs to be performed.

In this section, by using the switch, the communication protocol between the device and laptop is selected. If the switch is up, the connection is via Wi-Fi and if the switch is down, the connection is via LAN. The LAN port located under this switch is used for the mentioned communication. The laptop settings for connecting a laptop to the device are described in the following animations.

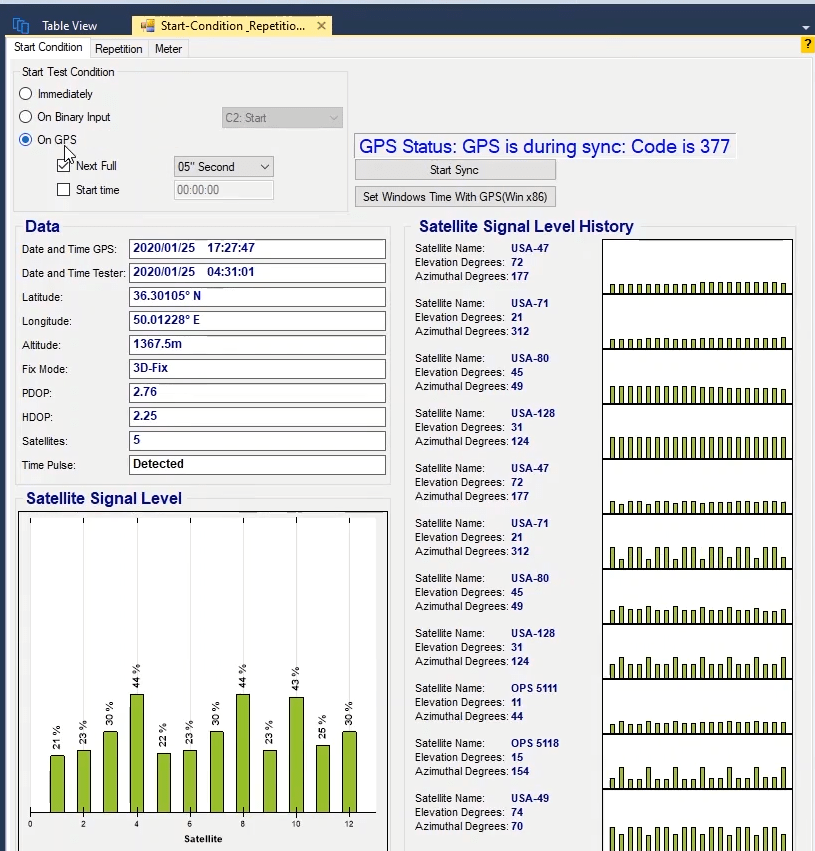

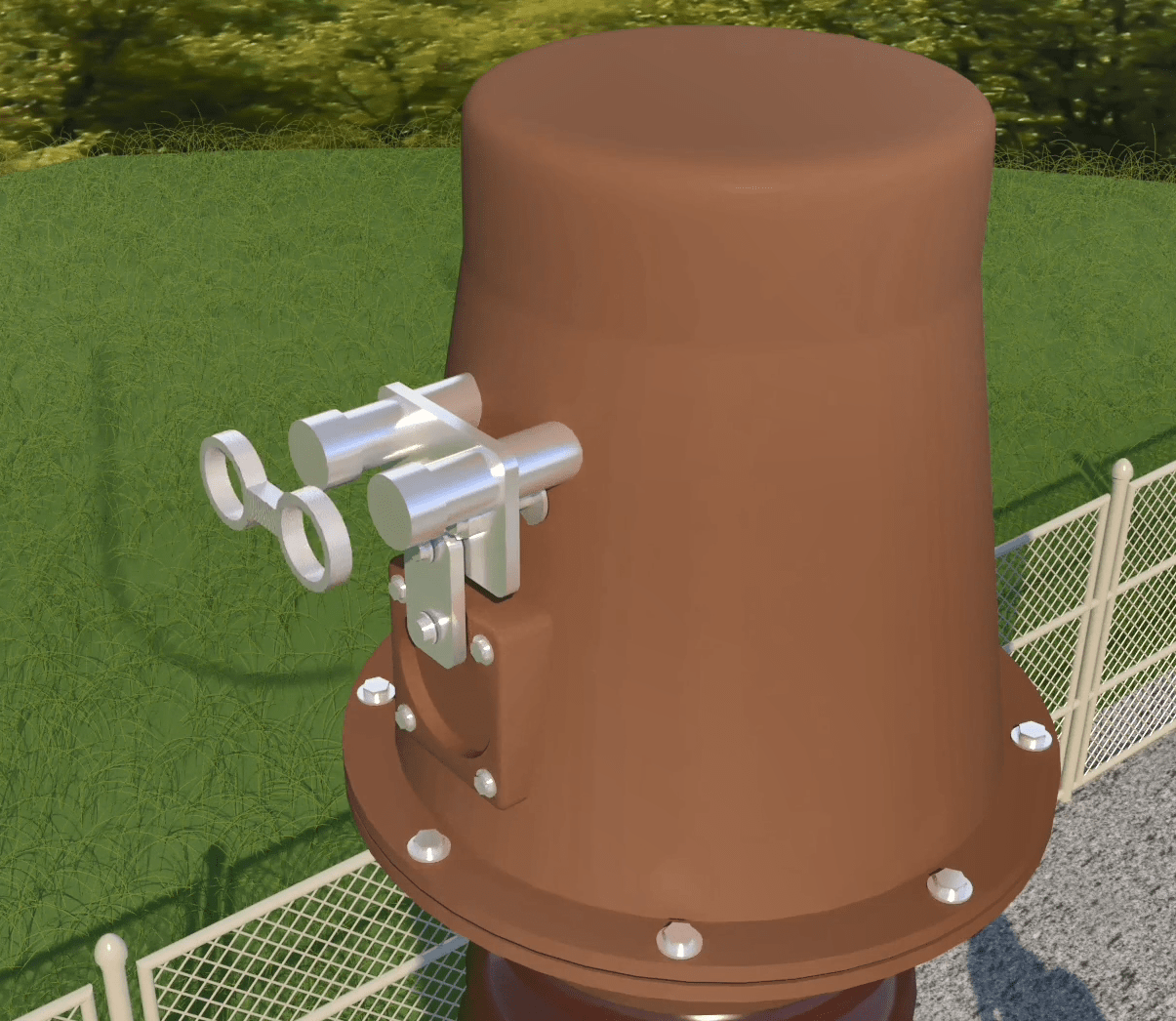

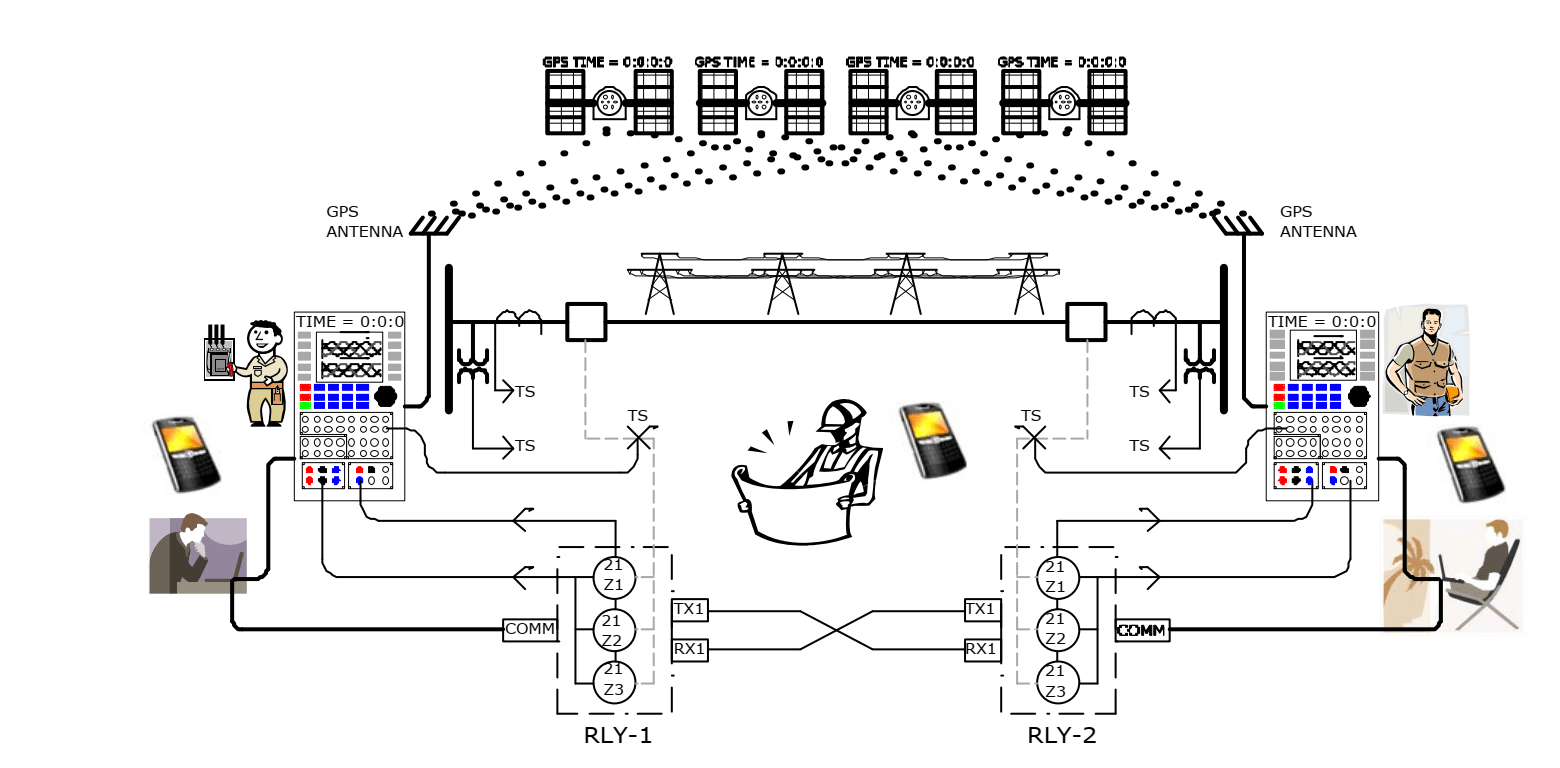

The GPS antenna, which is used for time synchronization of two devices for performing a longitudinal test, is connected to this part.

Inside the black bag comes with a one-way wire-to-female connection, a lizard clip, a 30 cm test wire, a 10 cm test wire and a 4 mm test socket, and a belt clamp and a test socket 4 mm in diameter.

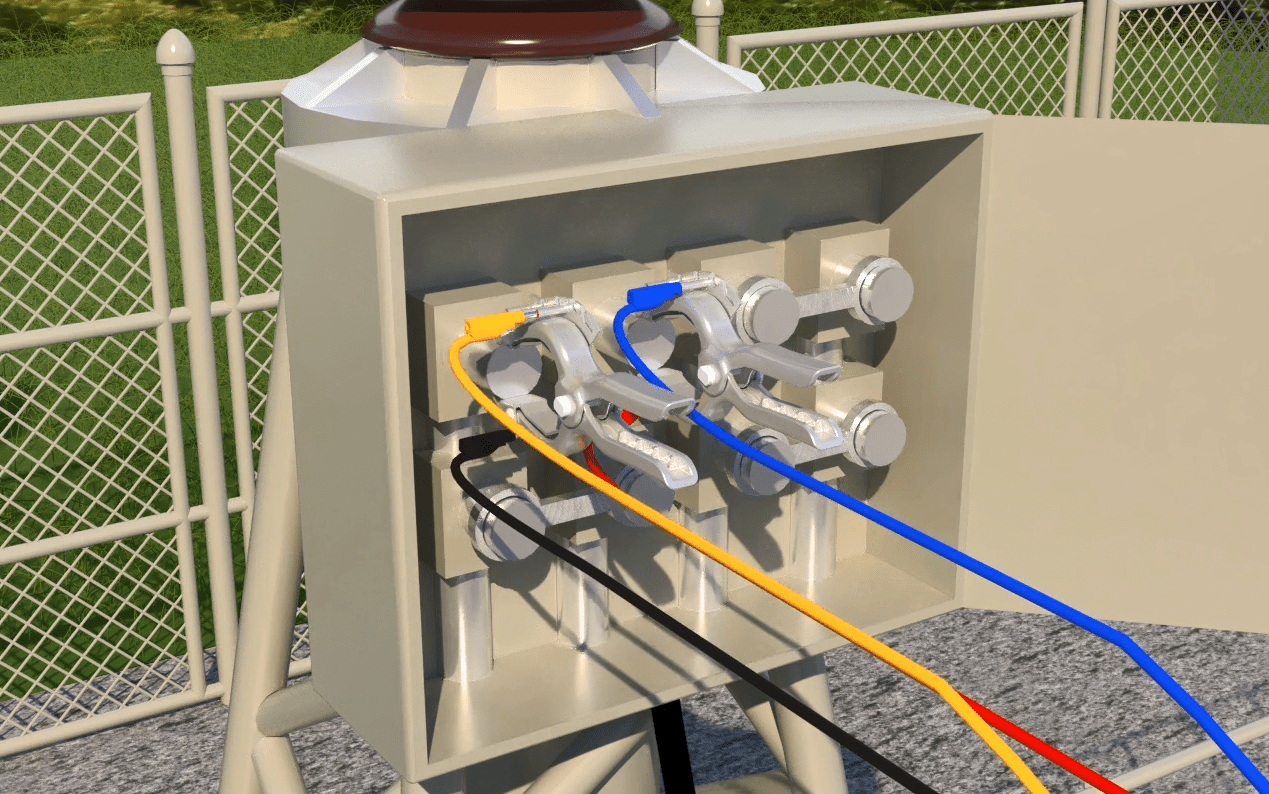

Other pieces of equipment that come with the device are communication cables which are used for communicating with the relay and injecting voltage or current. This side of the cable which has a fixed head is connected to the device and the head on the other side which has a dynamic plastic guard is connected to the equipment.

LAN cable

The blue cable, shown, is used to connect the device to a laptop.

Earth cable

The cable is the ground (earth) wire where its place of connection to the device was shown earlier. While one side of this cable is connected to the device, the other side, where the crocodile clip is attached, is connected to the location of the ground connection.

The black cable on the right is the power cable and the one on the left is the GPS antenna cable. This antenna is used for End to End tests. The GPS antenna is used for time synchronization of two devices to performe a longitudinal test.

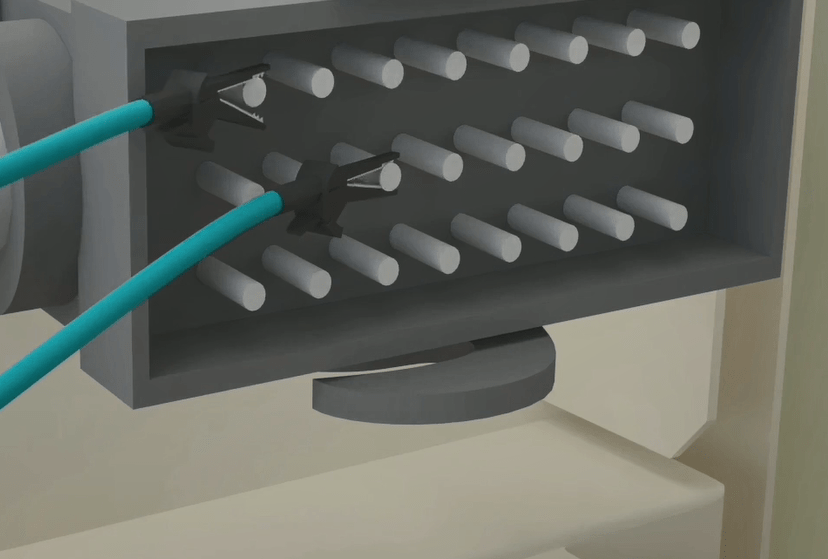

Serial Dongle:

This dongle is used to reset the device. The 2nd and 3rd pins of this dongle are interconnected, so if the dongle cannot be accessed, the device can be reset by connecting the 2nd and 3rd pins to the RS232 port located on the back of the device.

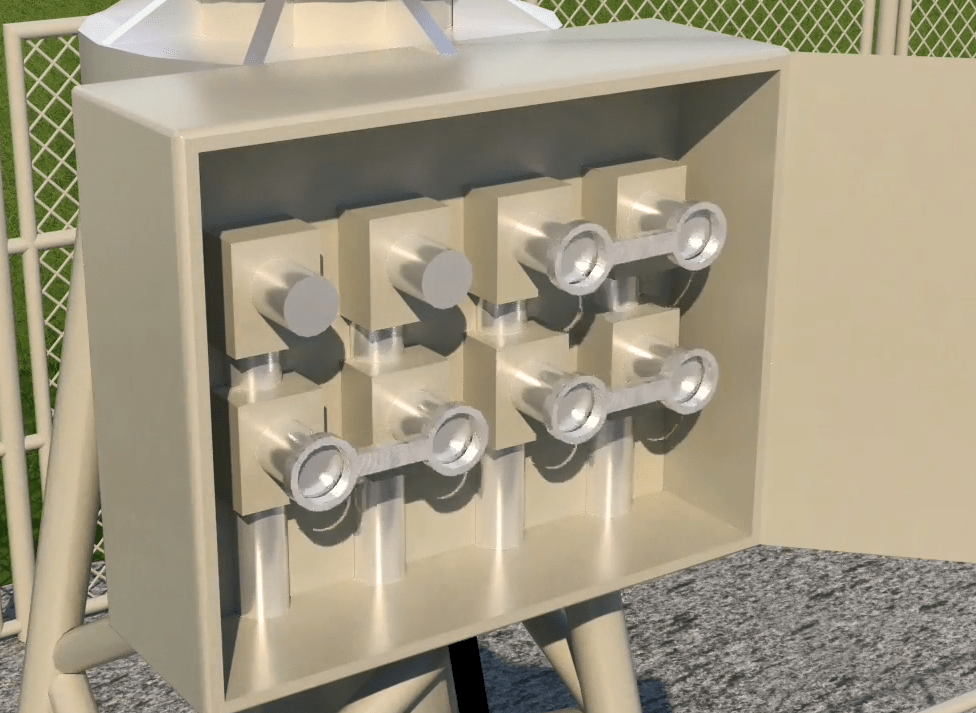

Capacitor box

In this capacitor set, there are 3 capacitors (10000μF) which are used as a filter in equipment tests.

Integrated or Neutrik cable

This cable has 6 output wires on one end and a single part on the other which is connected to the device. To plug this cable, first insert the tab of the combination cable as it is shown in the image. Then, after the Neutrik cable is inserted, spin it to the right until the metal pin fits into its place. To unplug the Neutrik cable, pull the tab and spin it to the left. After the spin is complete, it can be removed.

There are several labels attached to the sides of the device. The first label includes contact information for device support.

The second label includes the serial number and technical information of the device.

Soft bag/ Backpack

This case is designed for convenient transportation of the device.

To place it inside the case, the device must be standing perpendicular to the surface. Then it can be placed in the case and after that, the case can be closed.

At the front and back of the case, there are pockets where the equipment of the device can be placed.

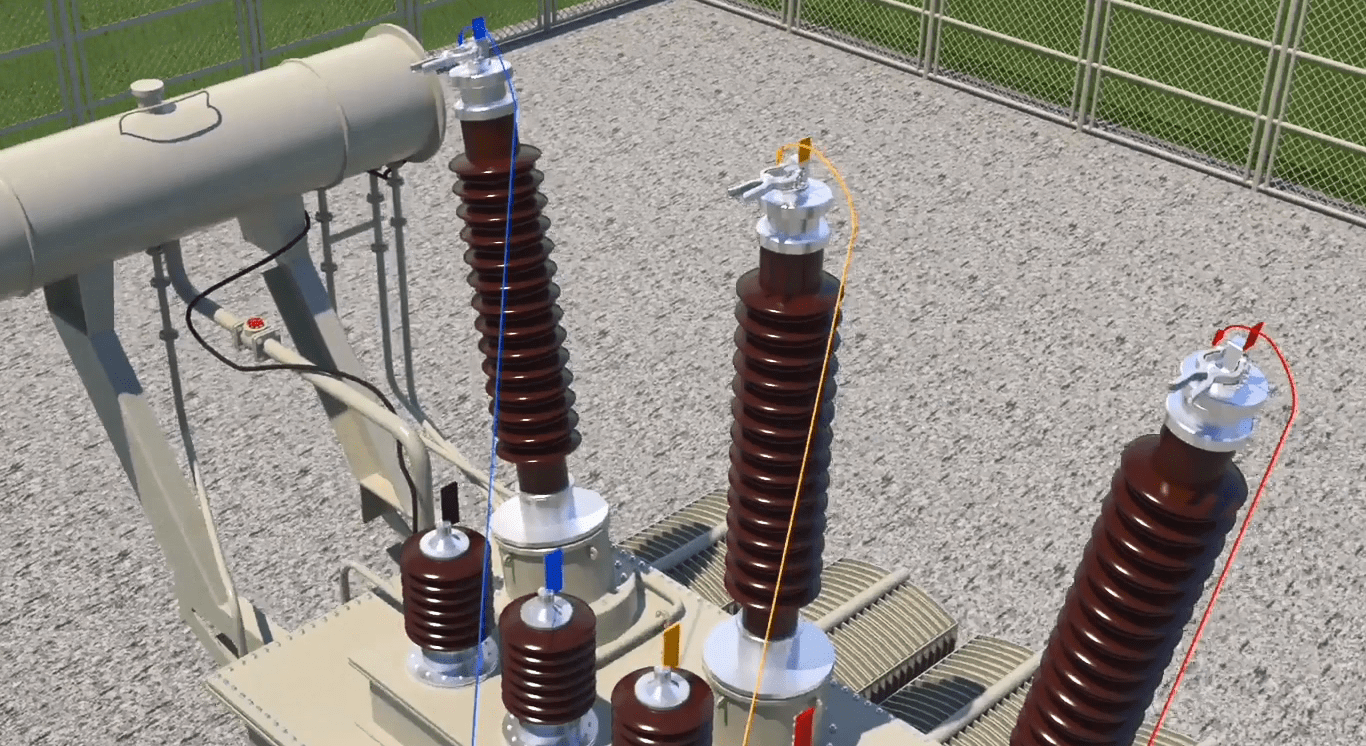

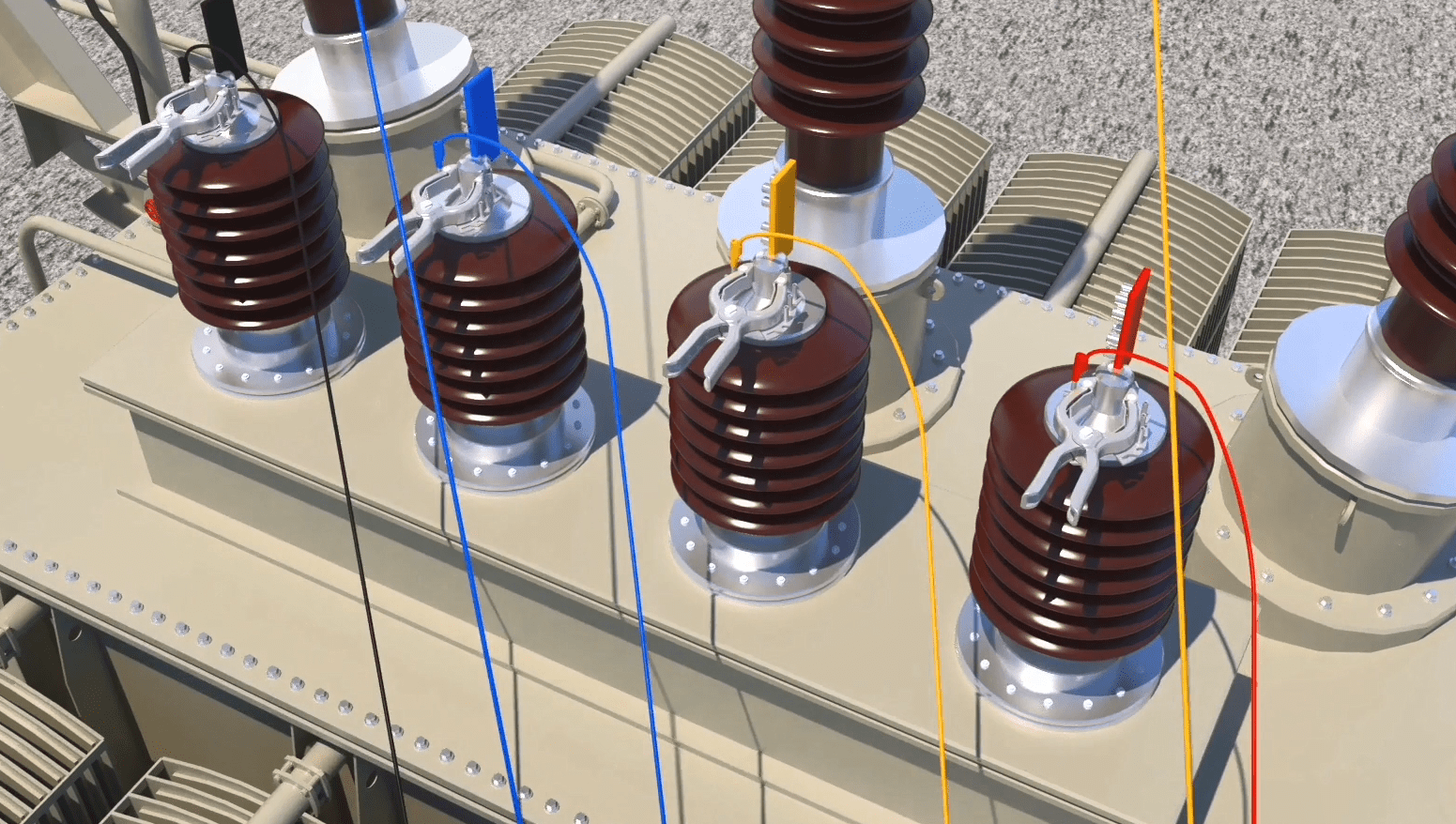

Inside the backpack, along with the device, there are three 7-meter cables and 8 clamps for testing transformers and circuit breakers, as well as several clamps to hold the connection between the cables.

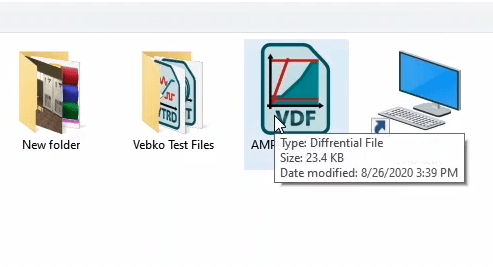

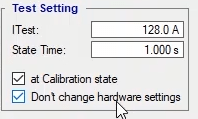

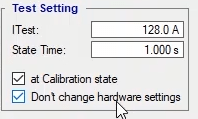

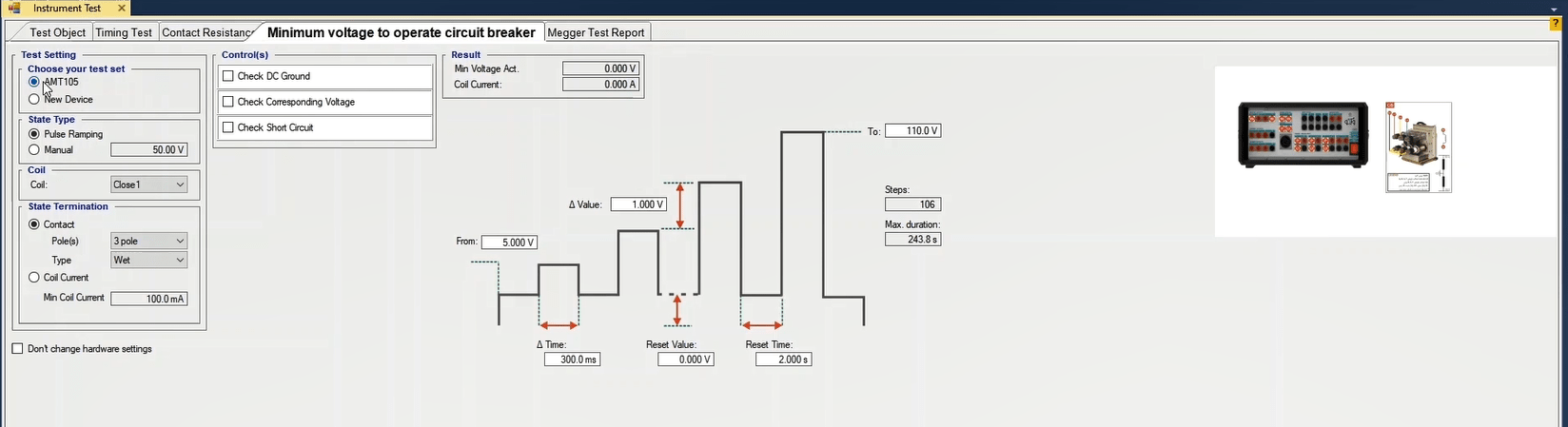

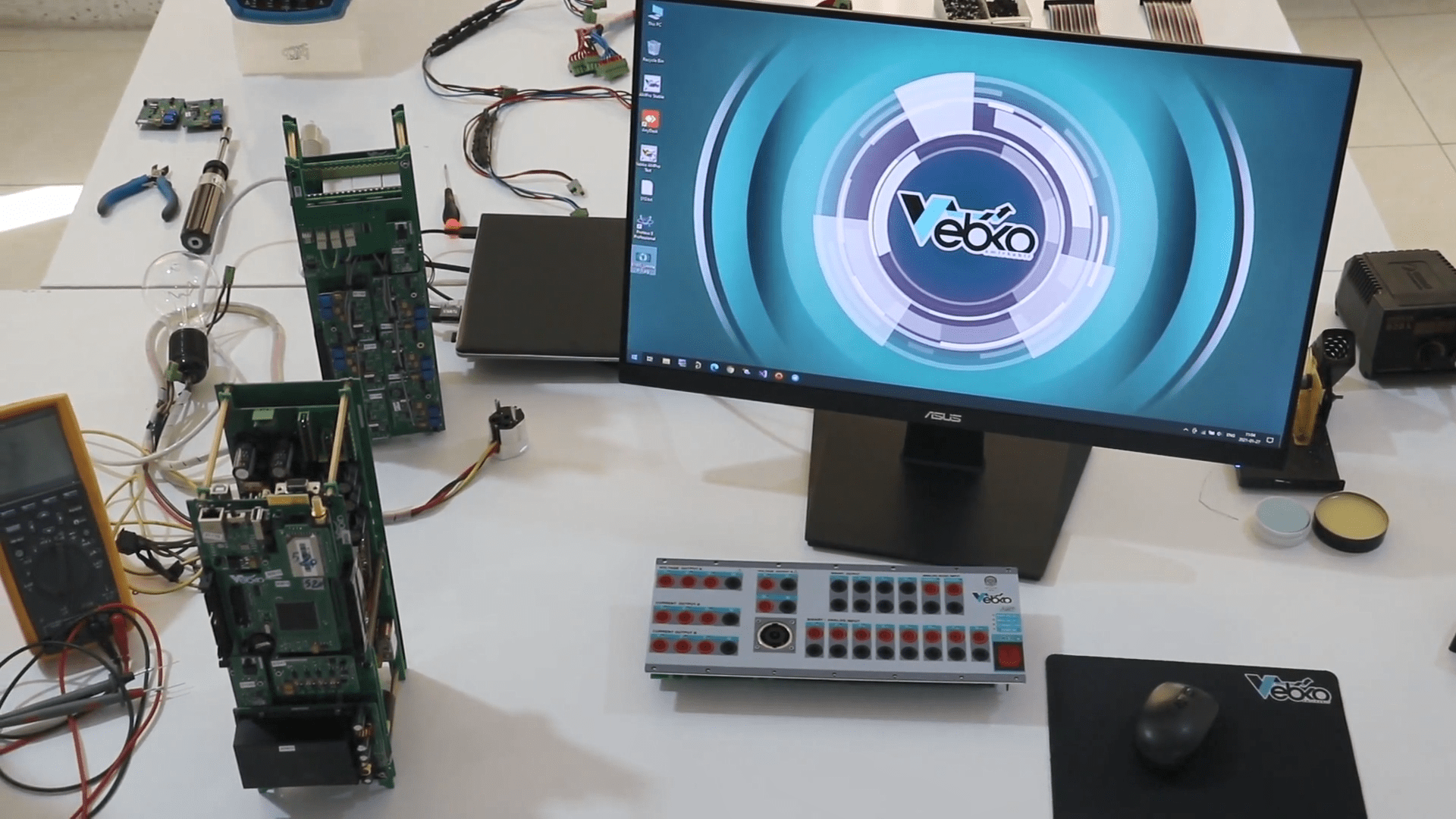

In this video, we’ll carry out a comparative analysis of the hardware features of several models from Vebco’s product line: AMT105, AMT205, AMT103, and AMT203.

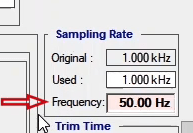

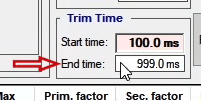

Voltage Sources: Starting with the AMT105, this device is equipped with two voltage groups: one three-phase group rated at 150 volts, and one single-phase group also rated at 150 volts. In total, it provides four 150-volt sources, each capable of delivering up to 500 milliamps per phase. The minimum sampling rate for measuring real-time values in this device is 1.2 milliseconds. This applies both to the applied voltage and the drawn current, ensuring accurate and timely data acquisition. Additionally, the AMT105 includes an independent DC voltage source with a maximum output of 212 volts. This DC source operates separately from the other voltage outputs, allowing for greater flexibility in various testing scenarios.

In contrast, the AMT205 device offers two groups of three-phase 300-volt voltage outputs, each with a maximum amplitude of 1.2 amperes. The sampling rate for measuring actual values is at least 25 microseconds, which applies to both the supplied voltage and the drawn current. These voltage sources can be converted into 1.2-ampere current sources, capable of providing up to 300 volts of electrical potential for current injection. This feature enables the device to inject extremely small currents — as low as 20 microamperes — with high precision. The device does not include a separate DC source, so if a DC source is required, the user must dedicate one of the six available phases to that purpose.

Current Sources: The AMT105 device includes two groups of 32-ampere current outputs, each capable of supplying 12 volts per phase. The sampling rate for measuring the actual values from these sources is at least 1.2 milliseconds, and it is used to monitor the drawn current.

In contrast, the AMT205 device includes two groups of 32-ampere current outputs, each capable of supplying 22 volts per phase. The sampling rate for measuring actual values from these sources is at least 25 microseconds, and is used to monitor both the injected current and the voltage supplied by the device. These current sources can be converted into 22-volt voltage sources with a maximum current of 32 amperes. This feature allows the device to apply very small voltages — as low as 40 microvolts — with high precision.

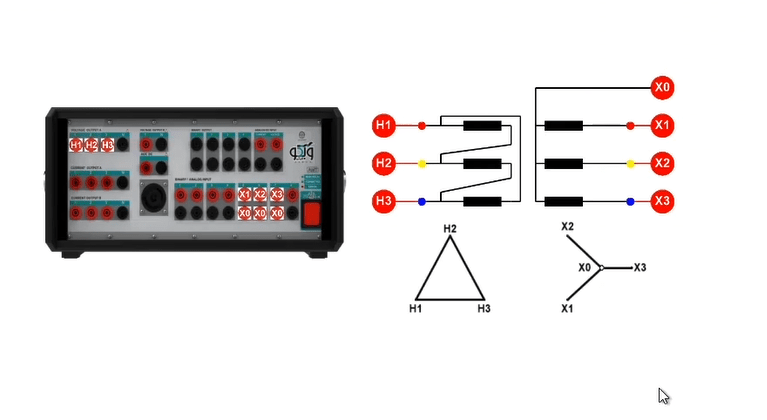

The Neutrik port on the AMT105 device provides three-phase voltage and three-phase current outputs for use in impedance and directional testing. It can also be reconfigured into six current phases for differential testing.

However, on the AMT205 device, the Neutrik port provides only three-phase voltage and three-phase current outputs for impedance and directional testing, and does not support reconfiguration.

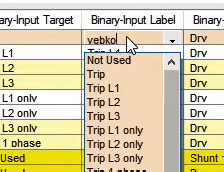

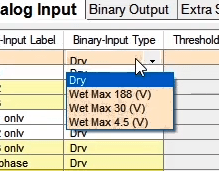

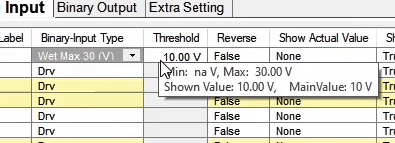

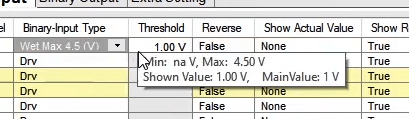

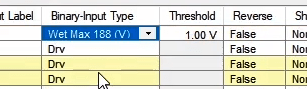

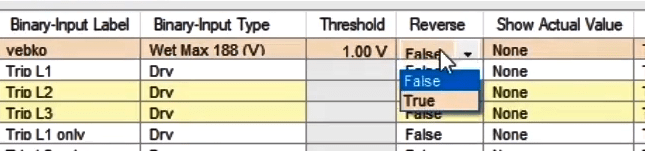

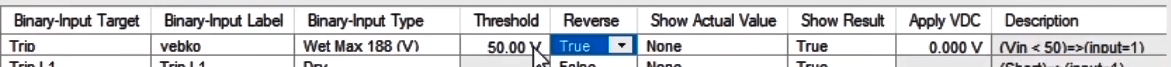

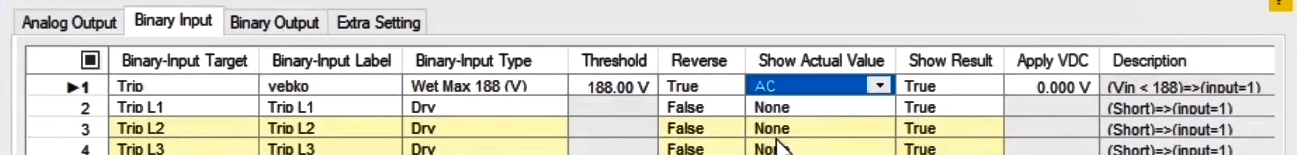

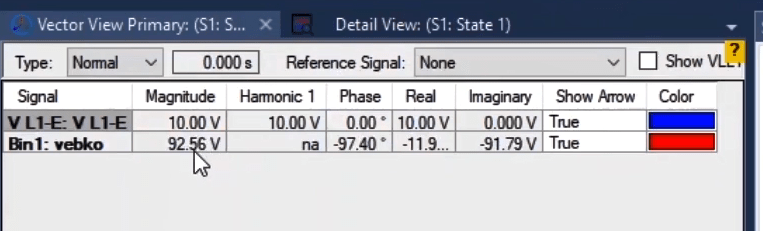

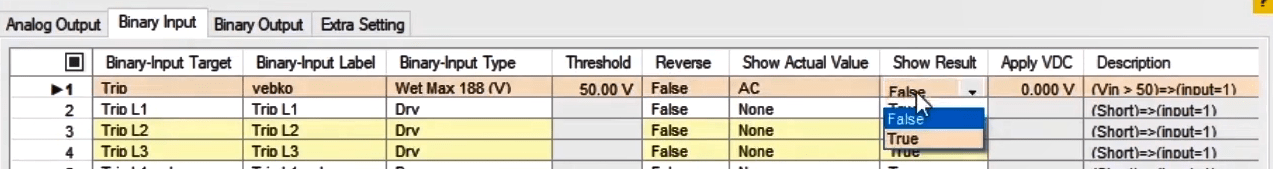

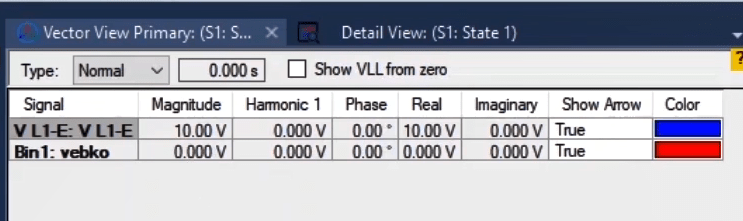

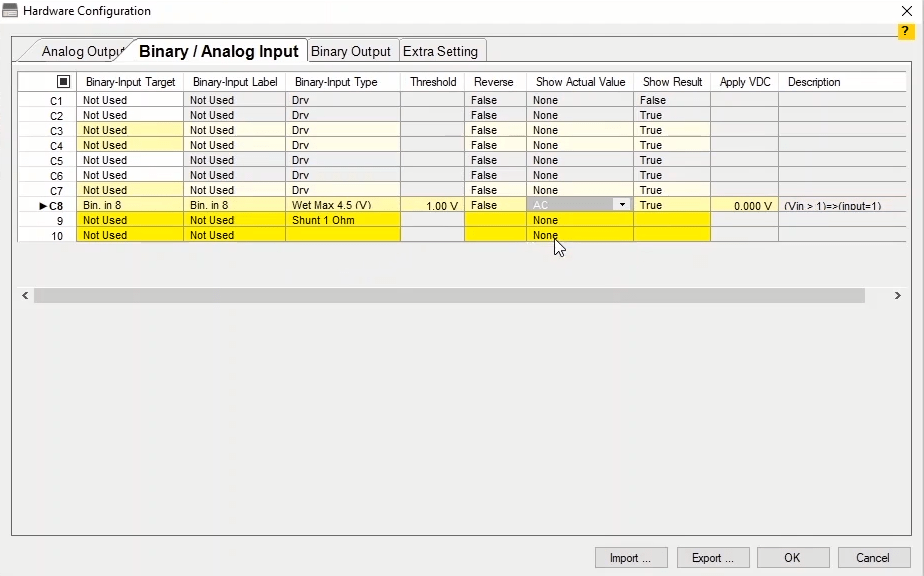

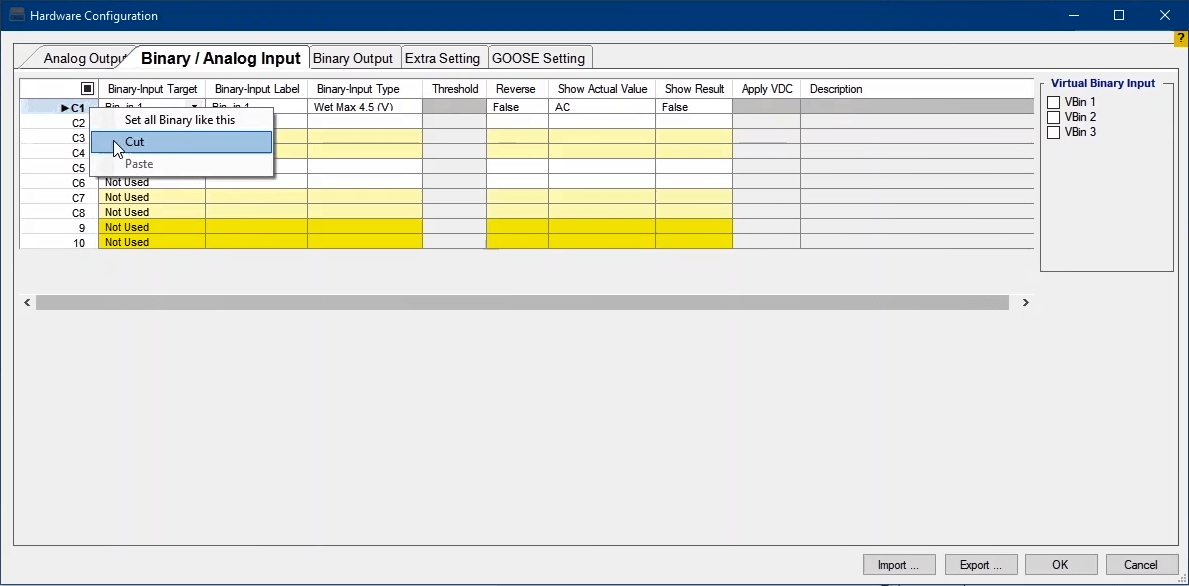

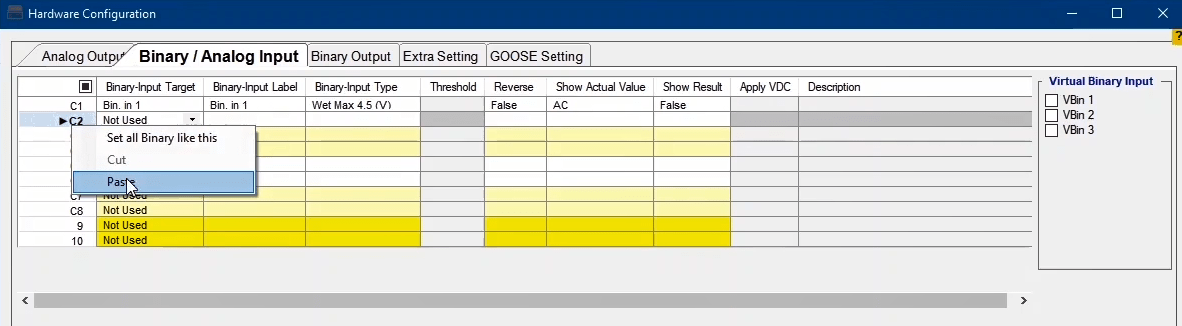

The AMT105 device includes eight binary/analog inputs, which can operate in either DRY (binary) mode or WET (analog) mode. In analog mode, the device supports three input voltage ranges: 4.5 volts, 30 volts, and 188 volts. The sampling rate for measuring values can be selected starting from 400 microseconds and higher. Naturally, as the measurement range increases, the accuracy tends to decrease.

The AMT205 device also features eight binary inputs, which can operate in both DRY (binary) and WET (analog)modes. However, unlike the AMT105, in addition to the 4.5-volt, 30-volt, and 188-volt ranges, it also includes a 500-volt range. The sampling rate for measuring values can be selected from 12.5 microseconds and above. As expected, when the measurement range increases, the accuracy of the measurement tends to decrease.

The AMT105 device includes two AC/DC analog inputs: one dedicated solely to current measurement, with a maximum range of 750 milliamperes, and the other dedicated to voltage measurement, with a maximum range of 400 millivolts. The sampling rate for measuring values can be selected from 400 microseconds and above.

The AMT205 device also includes two AC/DC analog inputs, but with extended capabilities. For current measurement, it offers four selectable ranges: 250 microamperes, 39 milliamperes, 750 milliamperes, and 10 amperes. For voltage measurement, it provides four ranges as well: 10 millivolts, 50 millivolts, 120 millivolts, and 400 millivolts. The sampling rate for measuring values can be selected from 12.5 microseconds and above. These inputs offer higher precision, especially when measuring smaller signals.

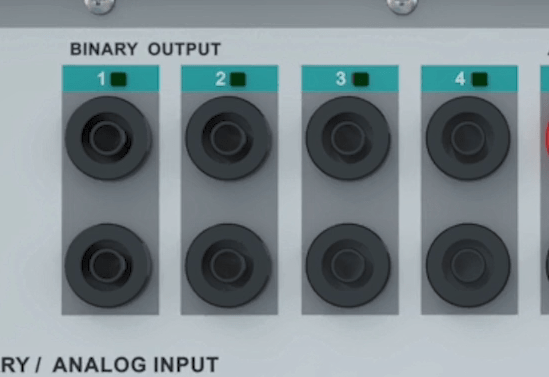

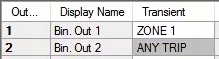

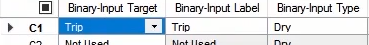

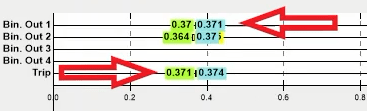

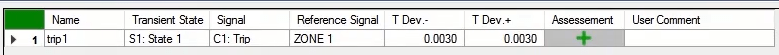

The AMT105 device features four binary outputs with relay switches, where neither the switch type nor current measurement can be changed.

In contrast, the AMT205 device also includes four binary outputs, but with the option to select between transistor-types and relay-type switches. The relay type offers higher current capacity but has a slower switching speed, while the transistor type provides very high switching speed but can handle lower current levels. A key advantage of the AMT205 is that its binary outputs can measure current, a capability not available in the AMT105.

The AMT205 device can be connected to a laptop via both LAN and Wi-Fi. Thanks to its support for IEC 61850 testing, the device is equipped with three LAN ports, which can be used to create a ring connection between the device and two other IED systems.

The AMT105 device also supports connection via LAN and Wi-Fi, but it does not support IEC 61850 testing and includes only one LAN port.

The AMT103 device shares the same technical specifications as the AMT105, with a few key differences: it includes four 150-volt voltage sources and three 32-ampere current sources, and it does not have an independent DC source. The number of binary/analog inputs has been reduced from 8 to 4, and on the Neutrik port, the number of voltage and current sources is fixed at three voltage outputs and three current outputs.

The AMT203 device shares the same technical specifications as the AMT205, with a few key differences: it includes four 300-volt voltage sources and three 32-ampere current sources. Additionally, the number of binary/analog inputs has been reduced from 8 to 4.

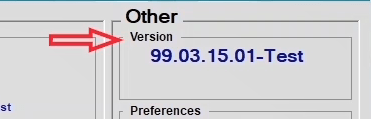

Vebko software is provided in two versions: "Stable" and "Test". The "Test" version includes the latest software changes and, as the name suggests, is an experimental version that may contain software bugs. Once these bugs are resolved, a "Stable" version is released, which addresses software issues and can be used with ease, though it may not include all features of the Test version. Note that both "Test" and "Stable" versions can be installed simultaneously without any issues. To download the latest "Test" and "Stable" versions, visit www.vebko.org and go to the Software section.

Before installing the software, it should be noted that if a version of the software is already installed on the system, there is no need to uninstall it before installing the new version, as this process will be automatically handled by the new version of the software.

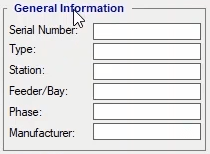

To download the software version, first enter the device's Serial Number in the Serial Number section to display the compatible version based on the microprocessor used in your device.

By clicking on the + icon, previous versions are displayed, and by clicking on the download icon, the desired version will be downloaded.

After downloading the software, to install it, run the Test.exe file.

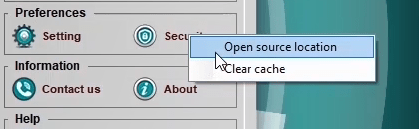

Now, in the opened window, check the "I agree" option and click "Install". Note that installing the "AMPro" software takes a few seconds. If you click "Run", the software will be executed. Before starting to work with the software and to complete the installation steps, on the main page of the software, in the "Security" section, click "Open Source Location" to open the location where the software is installed. On this page, right-click on the "AMPro Application.exe" file, select "Properties", go to the "Compatibility" tab, and check "Run this program as an administrator". Then, right-click on the "AMPro APP Launcher.exe" file, go to the "Compatibility" tab, and check "Run this program as an administrator".

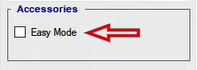

After running the software, in the Settings window, check the "Auto Detect Hardware Config" option so that the device configuration is automatically set when connecting to the device.

This translation aims to preserve the technical details and instructions while ensuring clarity and accuracy in English for power engineering field engineers who need to understand the process clearly.

In order to be able to perform various tests with the device, it is necessary to connect to it via a laptop or computer. Before starting the device, the earth wire from the back of the device needs to be connected. Note that if the outlet is grounded, there is no need to connect the ground wire from the back of the device. Then, the power cord is connected to the specified location on the back of the device. After connecting the power cord, the power button on the front of the device is pressed and the device turns on. As the device turns on, 8 binary input lights (on the bottom row) and 2 analog DC input lights (on the top right) turn on.

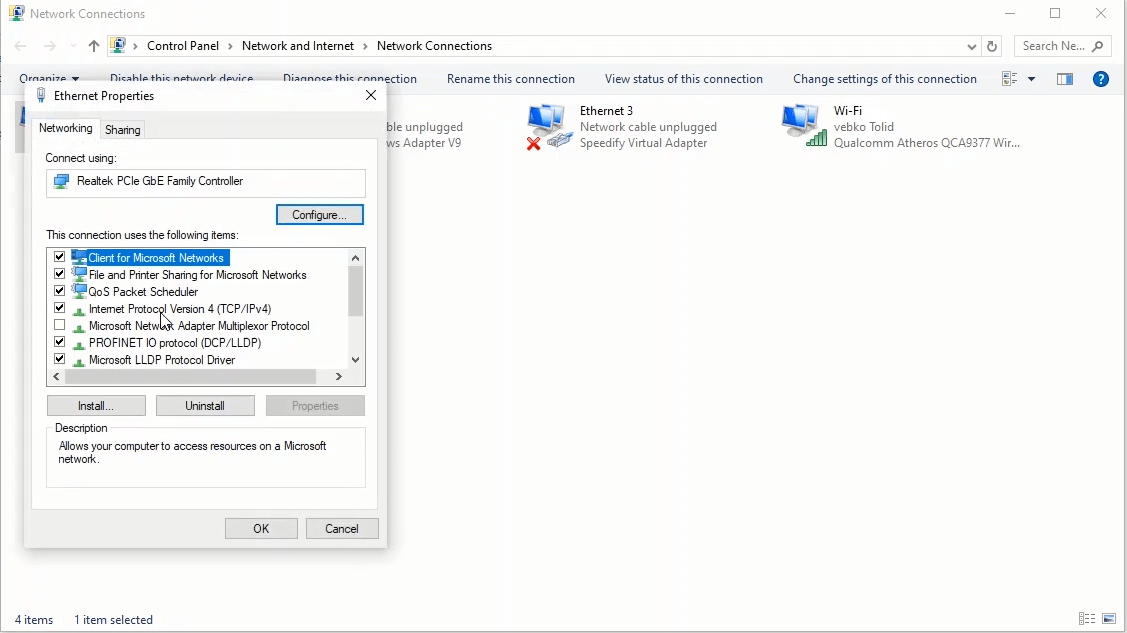

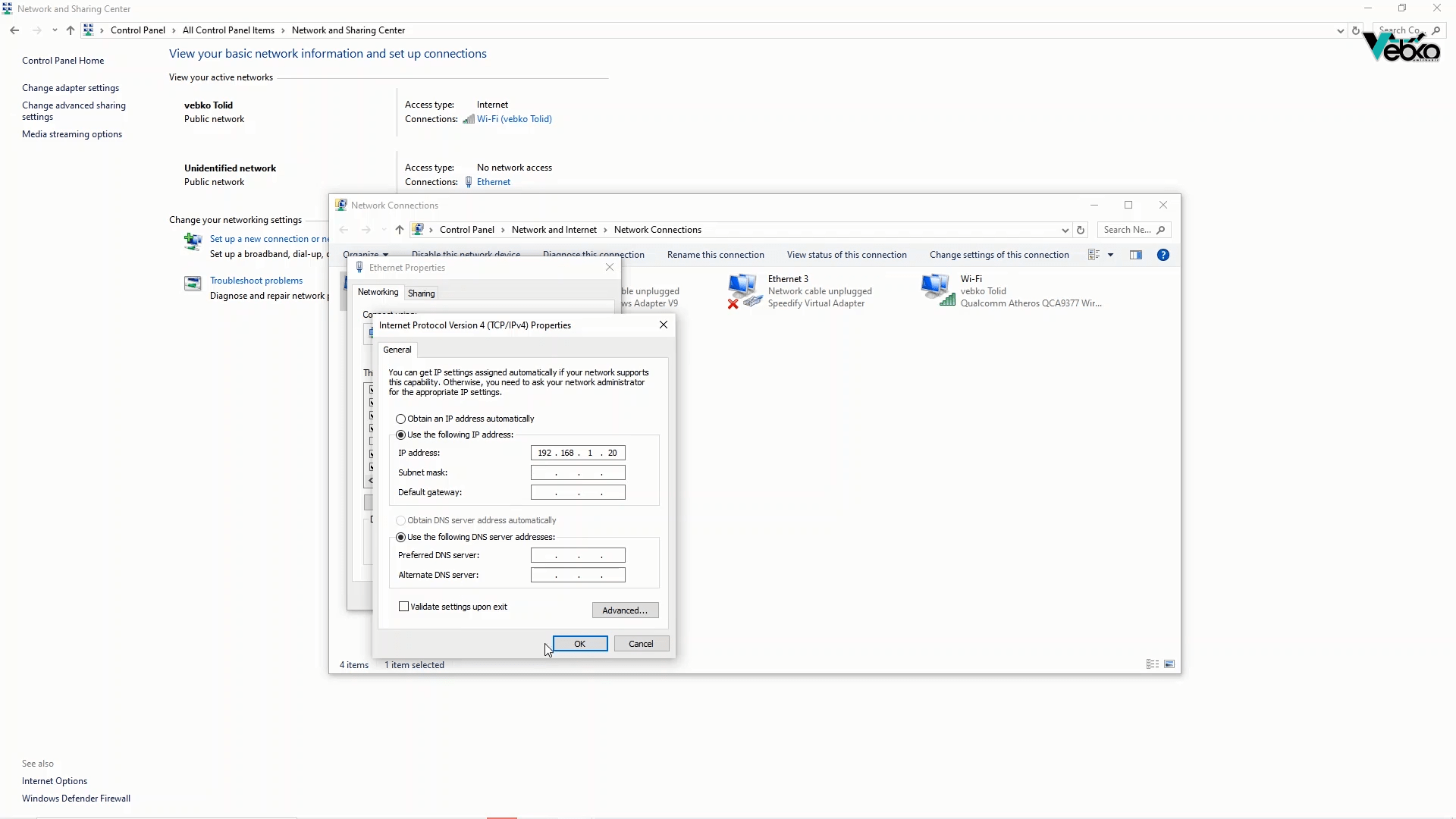

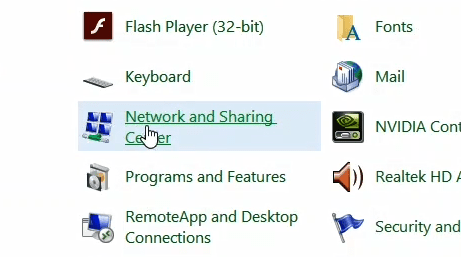

There are two ways to connect to the device: Wi-Fi and LAN. The switch on the back of the device is adjusted according to the connection type. To switch the LAN connection, one end of the LAN cable is connected to the device and the other end is connected to the laptop. When the device and the laptop are properly connected and the switch is changed from Wi-Fi to LAN, the LAN port light of the device and the laptop turn on. The setting for the connection of the LAN port is set only once for each computer before the first connection. To set these settings, go to the "Control Panel" and open "Network and Sharing Center".

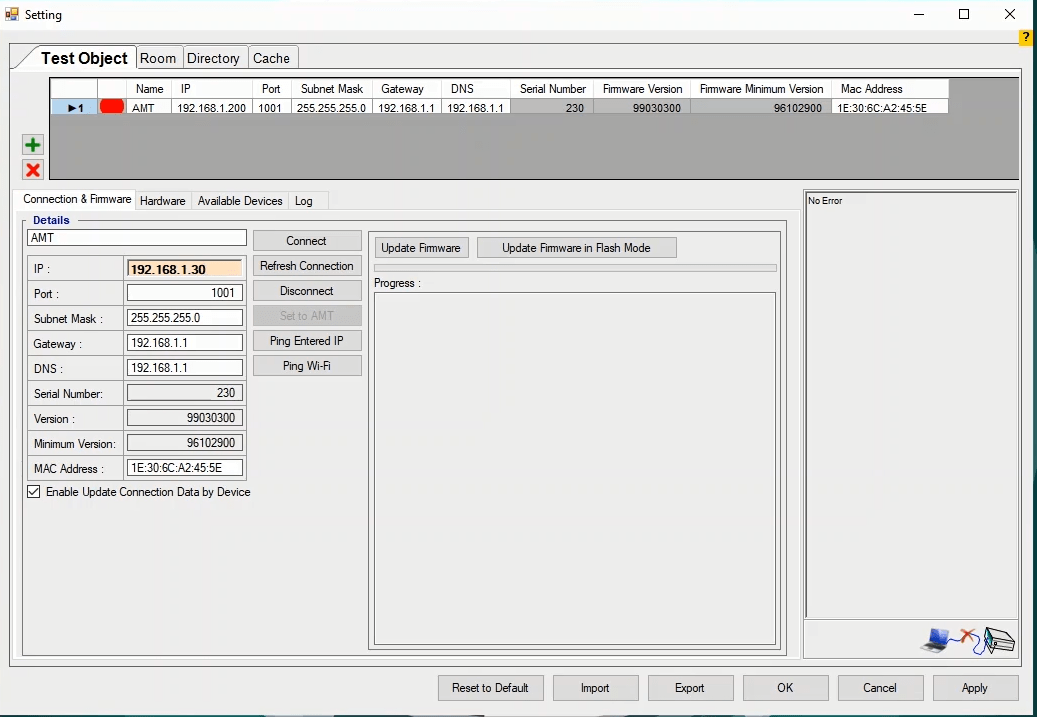

On this window, by clicking on "Change Adapter Setting" another window opens. There are several sections on this window. To change the LAN settings, double click on "Ethernet". Click on “Internet Protocol Version 4” in the opened window. On this window, enter 192.168.1.20 in the "IP Address" field and then close the window. Then, open the "AMPRO" software. By clicking on "Setting" on the start page of the software, a new window opens.

On this window, enter the last three digits of the serial number of the device in the fourth part of the IP field. To connect to the device, click on “CONNECT”. If a new version is connected to the device, the "Firmware" of the device will be updated once and after the green bar is filled, the device will be connected in a few seconds. To connect via Wi-Fi, the switch on the back of the device needs to be set on “Wi-Fi”. Then, from the "Wi-Fi" in quick launch bar on the laptop, find and select the Wi-Fi connection of the device. The password for this connection is the serial number available from the label attached to the side of the device. Once the connection is complete, click on “Setting” on the start page of the software. On this page, enter the last two digits of the serial number of the deivce in the fourth part of the "I" field. To connect to the device, click on “CONNECT”.

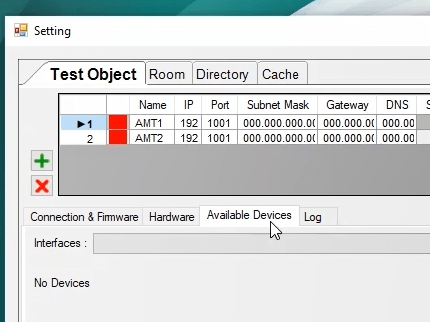

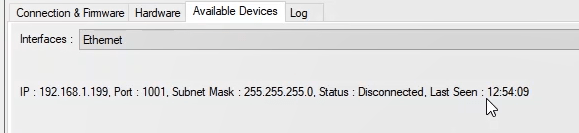

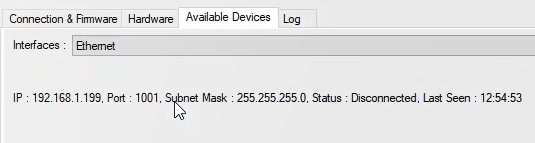

The user can view all devices that are, through different protocols, connected to the laptop on the "Available Devices" tab on the "Preferences" page. By clicking on "Start Search", after a few seconds, the list of network adaptor options of the system will appear in the "Interfaces" slider.

By clicking on any network adaptor, the list of devices connected to the laptop, as well as all their connection information, will be displayed. If the user does not know the name of their network adaptor, they should go to the "Control Panel" page and click on "Network and Sharing Center". Then, on the left side of this page, they should click on "Change Adapter Setting". If the connection cable of the device that is connected to the laptop is unstable, this instability is indicated by the connection's getting activated and deactivated on the "Network Adaptor" page.

Upon returning to the "Available Devices" page, by clicking on the currently being used "Network Adaptor", the name and IP of the device will be displayed along with its other connection information. If the user does not have access to the IP of the device, they can find it by following these steps and it will no longer be necessary for them to reset the IP of the device.

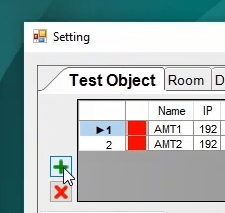

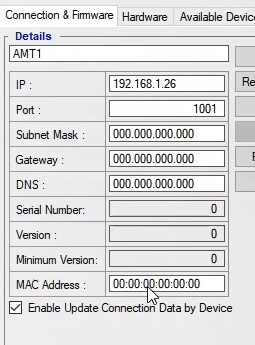

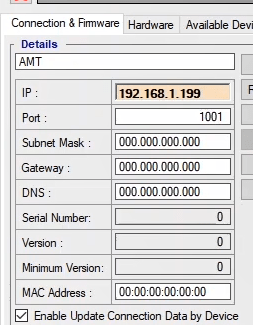

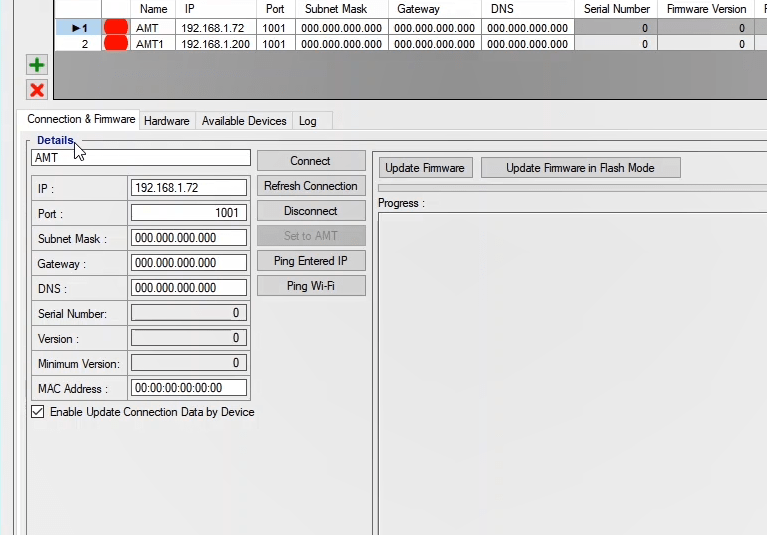

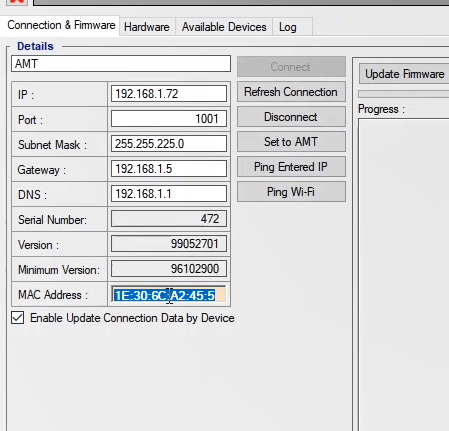

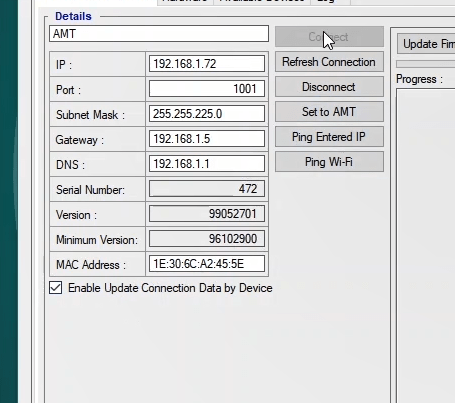

On the "Connection & Firmware" tab, the settings for the device connection, changing the IP and updating the firmware can be set. One of the features of this software is connecting to multiple devices at the same time. To do so, by clicking on the green plus button on the "AMT" tab, a new row is added to this table. On each row is the connection information which should be different from other connections.

In the case of connecting to multiple devices through one software, it should be noted that while connecting through a network adaptor", each connection must have a unique "Mac" and “IP” Address. To do this, first, you need to connect to the first device by entering its IP. Then, by clicking on the second row and entering the IP of the second device connect to it and if the "Mac" addresses are the same, make a small change in them and by clicking on "Set to AMT" apply the changes.

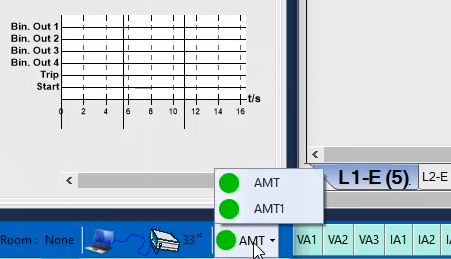

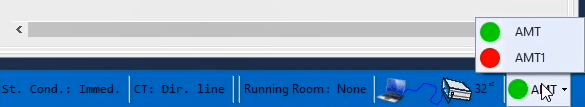

After properly connecting to multiple devices, by using them, multiple tests can be performed simultaneously. For example, if the two rooms of "AMT Sequencer" and "AMT Distance" are opened, by selecting the "AMT" connection in the "AMT Sequencer" room and "AMT1" in the "AMT Distance" room, by using two devices, two tests can be performed at the same time and two relays can be tested simultaneously.

When the LEDs of all binaries are on or you do not connect to the device according to the relevant settings, you must reset the device IP using the dongle. Before resetting the device’s IP address, it is necessary to make sure that the device is turned off. Then, the RS232 dongle is connected to its specific port on the back of the device.

Upon turning on the device, you can see that, the error lights of the device will start blinking

After blinking several times, there is a pause and then the device will start blinking again. After this process is repeated for the third time, the user should turn off the device and disconnect the RS232 dongle from the back of the device

Now, the IP address of the device is reset and its serial for connecting via Wi-Fi is changed to 199. After turning on the device, to establish the connection between the device and the laptop, enter “199” in the fourth part of the IP field on the “Setting” page.

Note that if you do not have a dongle or even an RS232 port, you can use a thin wire to do it. As can be seen, it is enough to connect pins 2 and 3 with a thin wire.

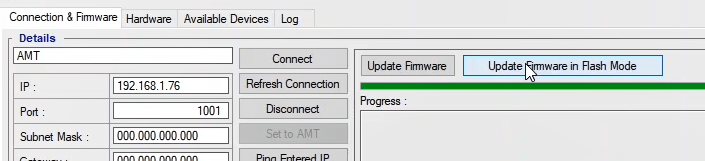

To update the "Firmware" manually, first, it is necessary for the device to be turned off.

Then click on “Disconnect” in the “Preferences” screen, so that the software will not send ping to device after the device is turned on.

To get started, the RS232 dongle needs to be connected to its specific port on the back of the device Also, the device and the laptop must be connected via LAN cable.

It can be seen that, after the device turns on, the "ERROR" light in the front panel of the device starts blinking.

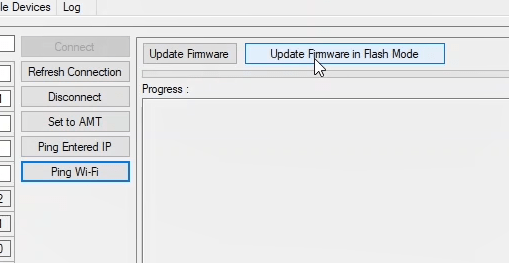

On the main page of the software, click on “Update Firmware in Flash Mode”.

Then, you have to wait for the green bar to get filled. After that, a message will be displayed. By clicking on “OK”, you can finish updating the “Firmware”.

Turn off the device and unplug the RS232 dongle.

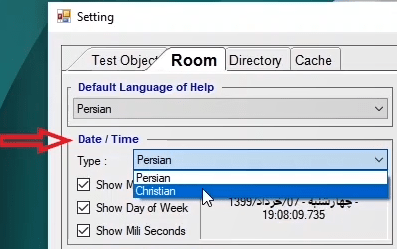

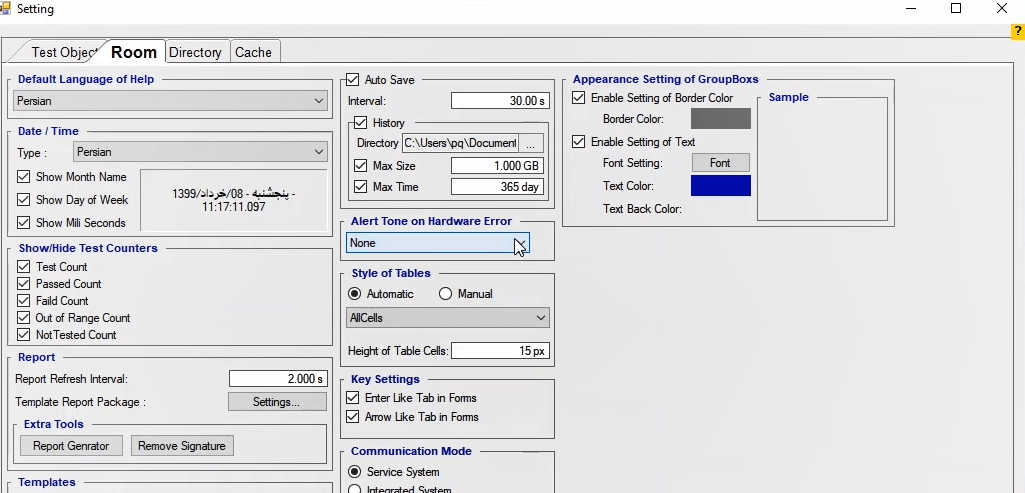

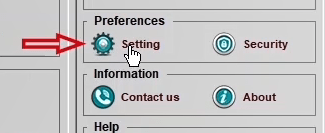

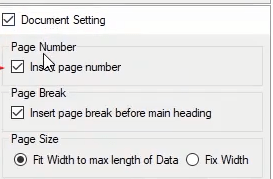

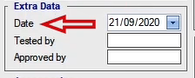

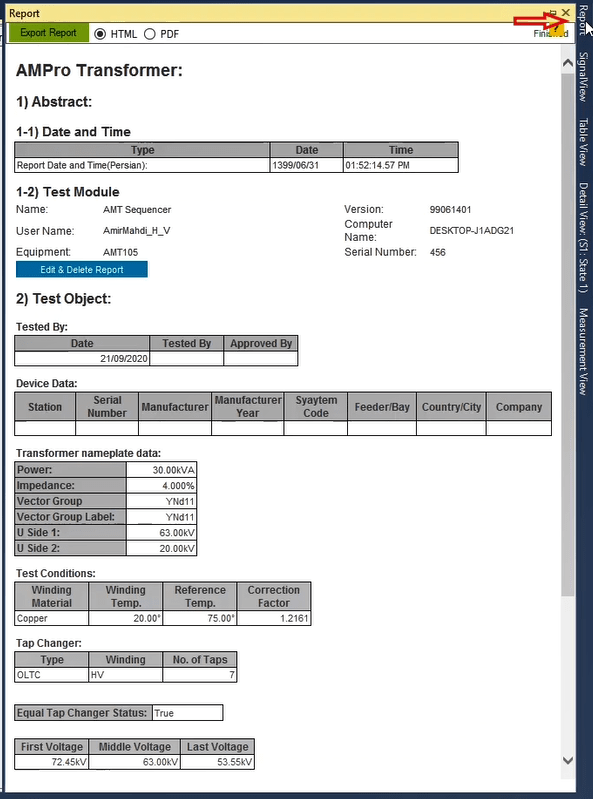

There are four main tabs in the software “setting” page. The “Room” tab provides a number of features for different rooms. In the "Date-Time" section, you can select “Persian” or “Christian” as the type of the date used in the output report. By using the other three options in this section, it is possible to show the name of the month and week and milliseconds in the report.

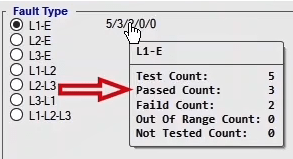

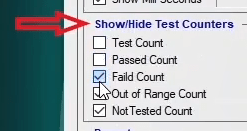

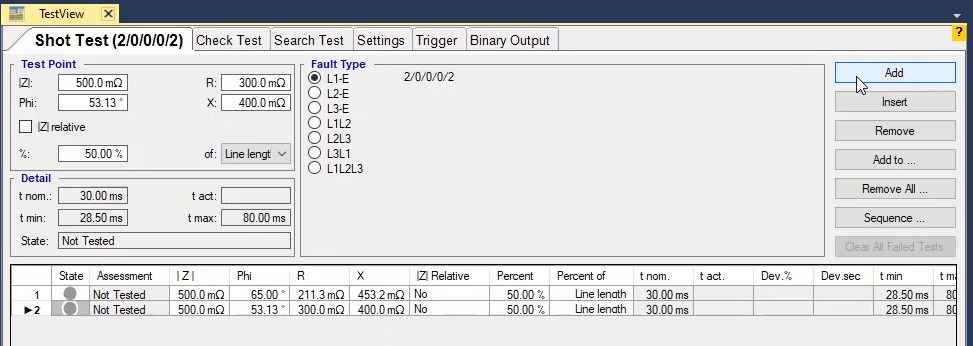

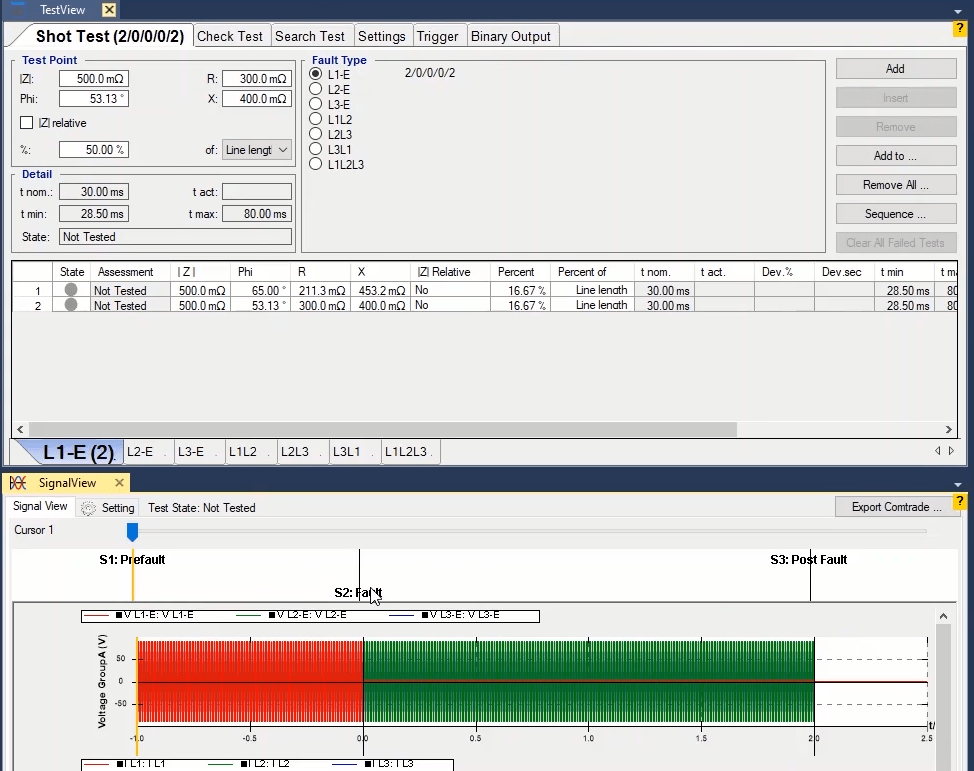

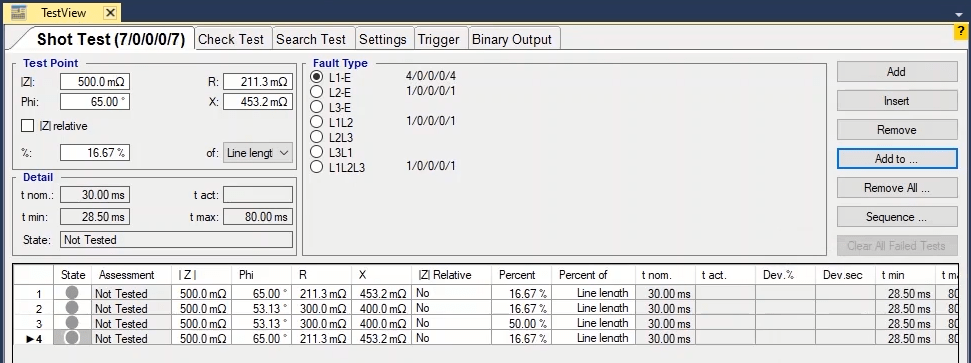

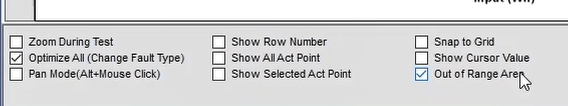

In rooms such as "AMT-Distance" and "AMT-Overcurrent", next to each of the "Fault Types" are written numbers which show the test points, the number of passed test points, the number of failed test points, the number of test points that are outside the range of the device and the number of untested test points respectively. With this explanation, unchecking each of these options in the "Show/Hide Test Counters" will cause the number of points associated with that option not to be displayed.

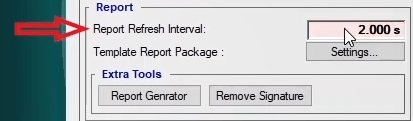

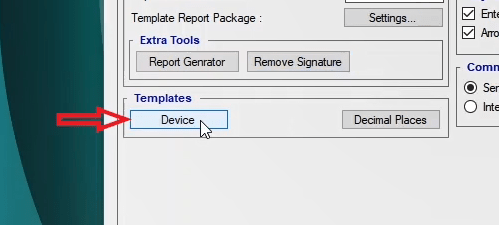

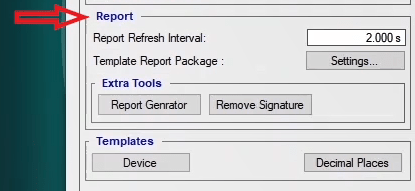

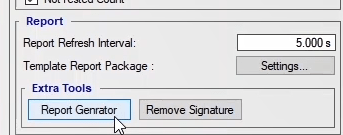

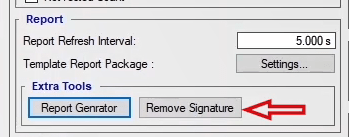

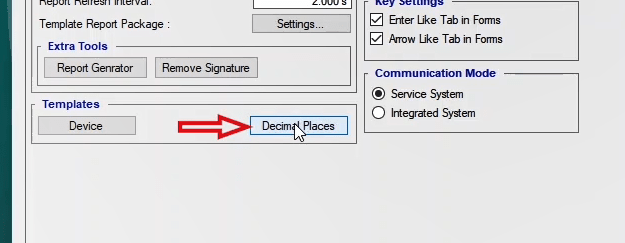

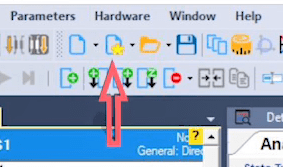

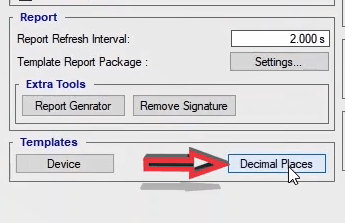

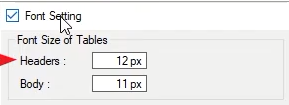

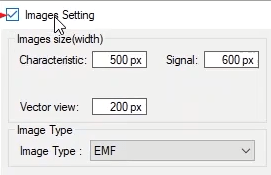

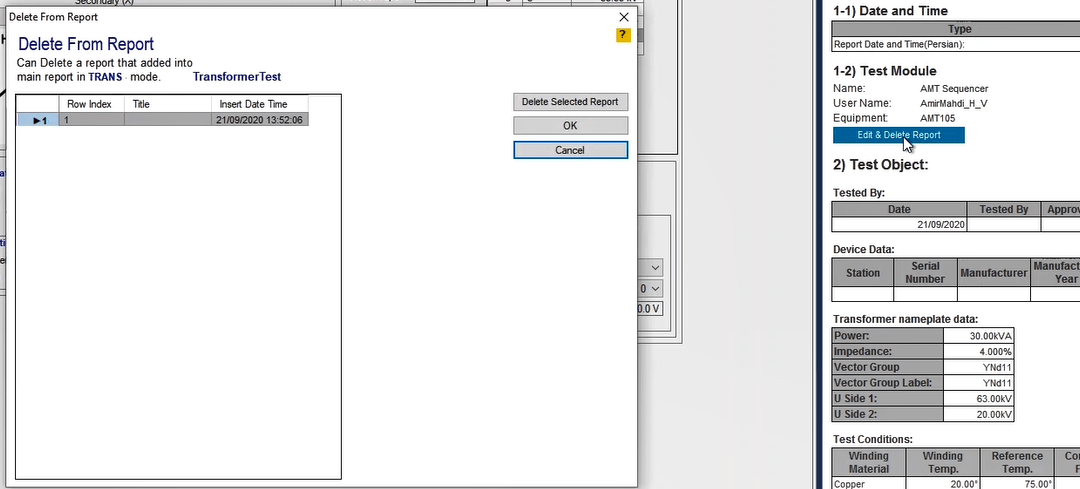

In the "Report Refresh Interval" field of the "Report" section, the update time for the report is specified. In the "Report Package" section, the default settings for the "Reports" are adjusted. In the "Extra Tools" section, clicking on the " Template Report Generator", opens the "PDF Report Creator" page where the desired test files can be imported to get a report. By clicking on "Remove Signature", the "Remove Signature from Report" page opens where, without needing to open the test files, the added signatures to the reports can be removed. In the "Template" section, the settings of the "Test Object" of the device as well as the settings related to displaying numbers in the "Decimal Places" are adjusted.

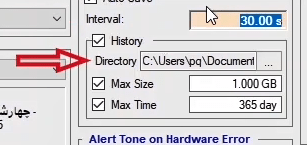

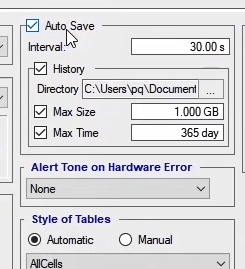

By checking the "Auto Save" option, the software saves the last changes made to the test page according to the time specified in the "Interval" field. These files are also saved in the location specified in the “Directory” box in “History” section.The maximum reserved size for these files and the maximum duration of time that these files are kept in the system is specified in the “Max Size” and “Max Time” filed, respectively,and the user is able to change these values. By unchecking any of these options, the limitation is removed as well. By doing this, if the software crashes for any reason, the test page and the user information will remain safe.

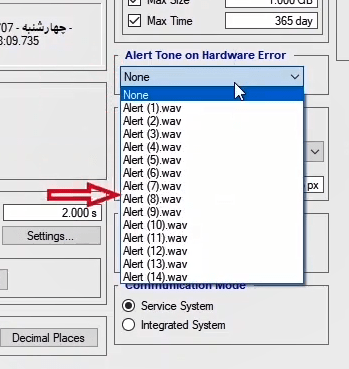

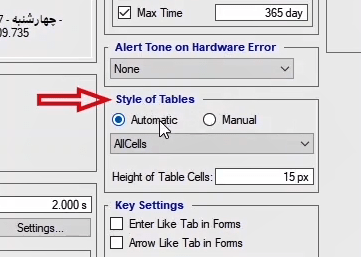

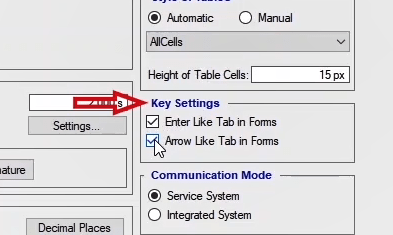

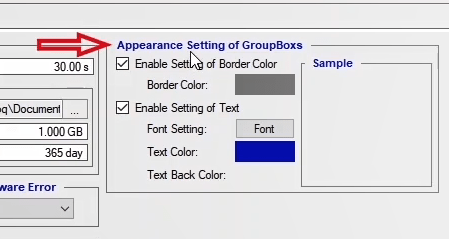

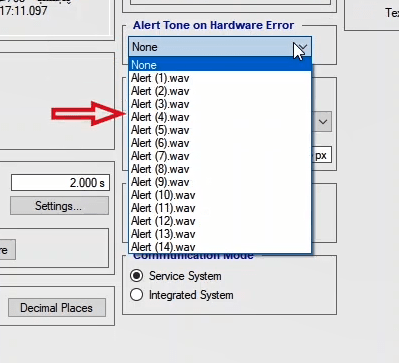

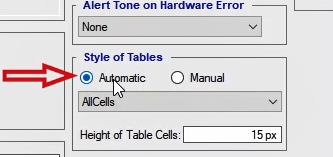

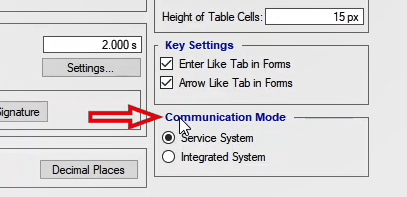

In the "Alert-Tone on Hardware Error" dropdown field, you can select an alert sound for when there is a hardware error in the device. The settings for specifying and changing the sizes of the tables of the rooms such as "Distance" and "Differential" are adjusted in the "Styles of Tables" section. You can customize the "Key Setting" section to be able to use the "Enter" key and the arrow keys to move in the cells of a table. In the "Communication Mode" section, you can choose between "Service System" and "Integrated System" for the connection between different rooms and pages of the software. "Appearance Setting of Groupbox" is designed for personalizing user interface. This setting is divided to two categories of “text” and “border”, which are used to personalizing the borders , color and text’s fonts. In the following tutorials, all of the above will be stated in detail as well as how to adjust the settings.

To Improve or modify the translation of the Vebko company's website, first, go to the address

79.127.52.162, after selecting the desired language (in this tutorial, French is used), download the corresponding Excel file. Without changing the file name, make the desired

changes and then drag and drop the file back to the main page of the website. After entering

the Username and Password provided by the support team, the modification process will be

completed.

Please note that each section on the website has a unique ID. If you are looking for a

specific section in the Excel file and cannot find its location on the site, simply click on the

section's ID, and it will be highlighted in green for you.

Additionally, by adding ?resx=true to the end of the address, you can view the IDs related to each section.

For example, you can find 61Resx in the Default sheet of the Excel file.

It is important to note that the downloaded Excel file is organized into sheets corresponding to the site's tabs.

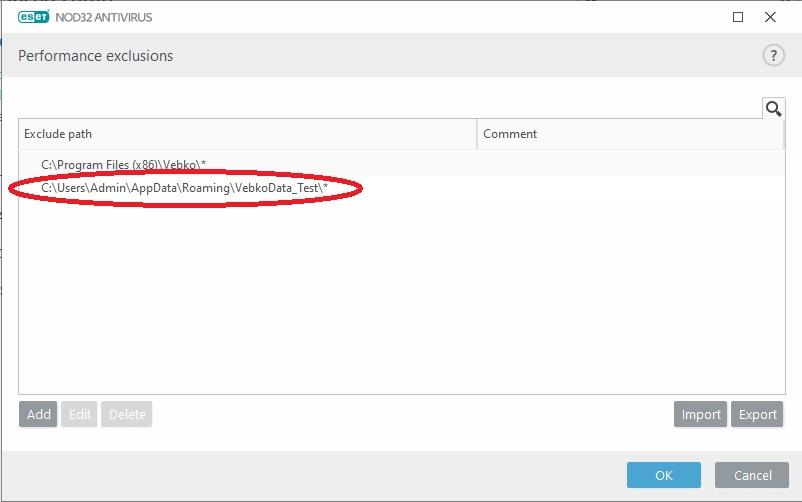

First, from the software's start page, go to the "Setting" window, select the "Cache" tab, and

click on "Open Roaming Directory" to be directed to the file storage window.

In the "Language" folder, open the Excel file where you can make the desired changes to the respective language. Finally, save the file with the CSV extension.

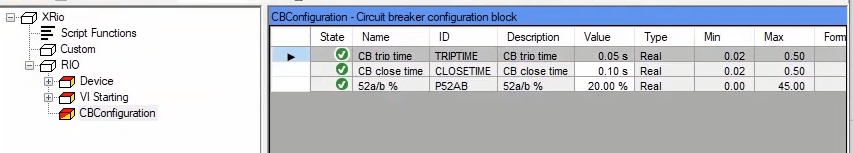

For example, in the "Circuit Breaker" room, the "Object Test" window, to change Test (s) in English, open the Excel file, make the desired changes, save the Excel file with the CSV extension, close and reopen the "Circuit Breaker" room to see the changes.

It should be noted that in the Excel file, the rows indicate the name of the respective section,

and the columns indicate the language.

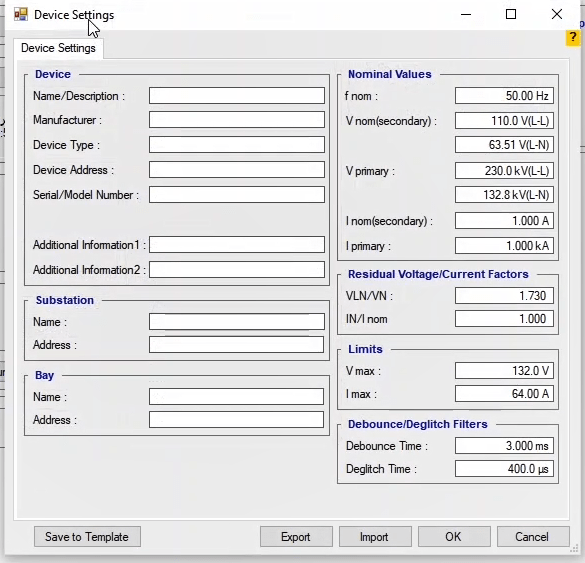

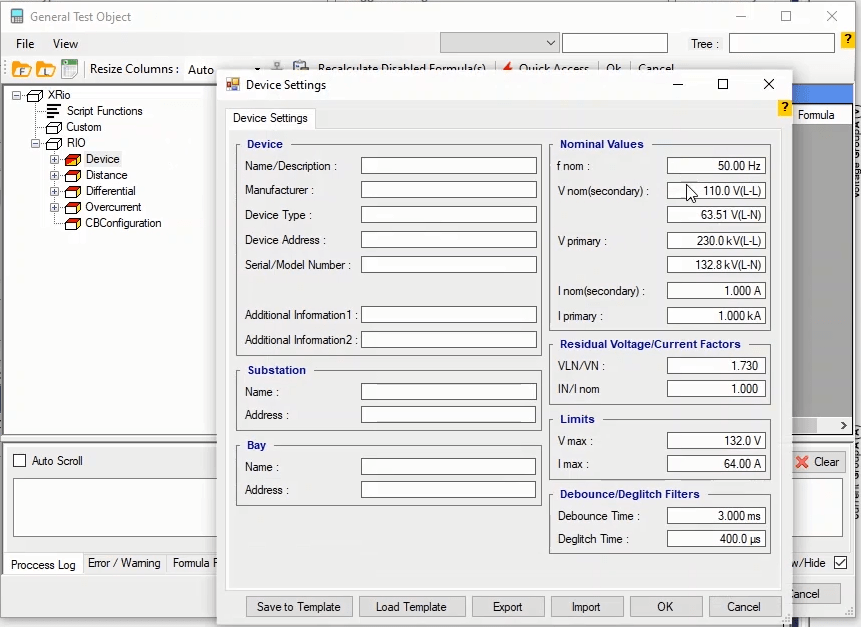

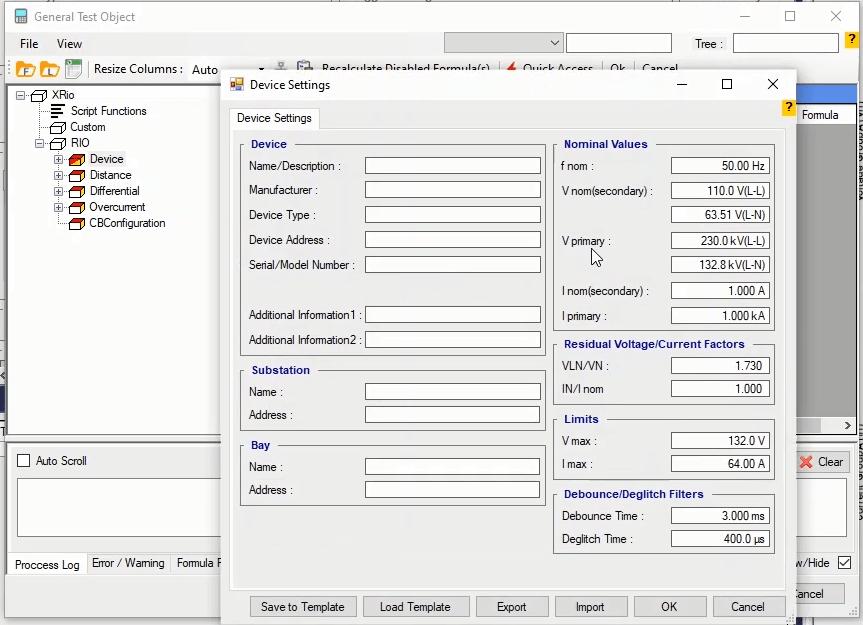

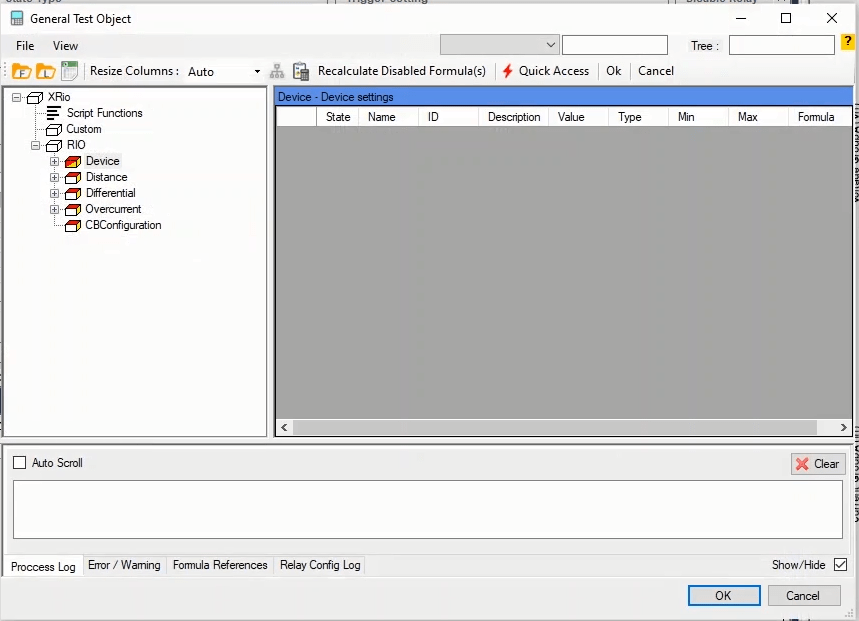

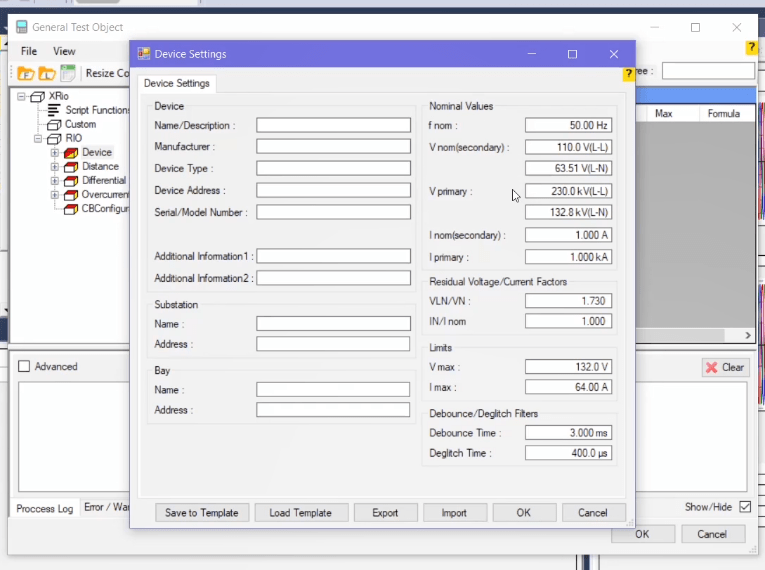

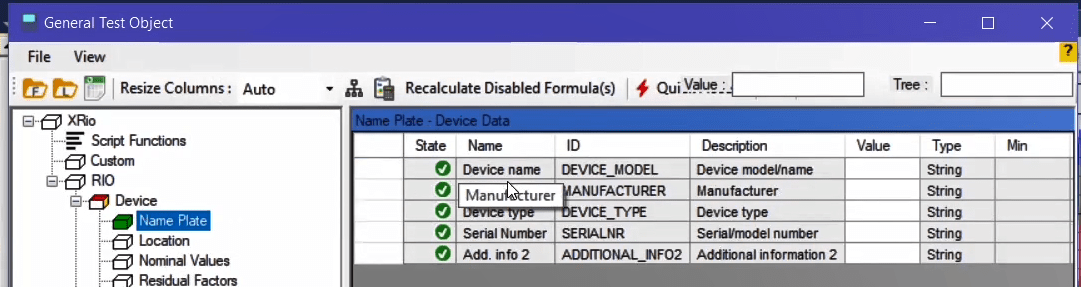

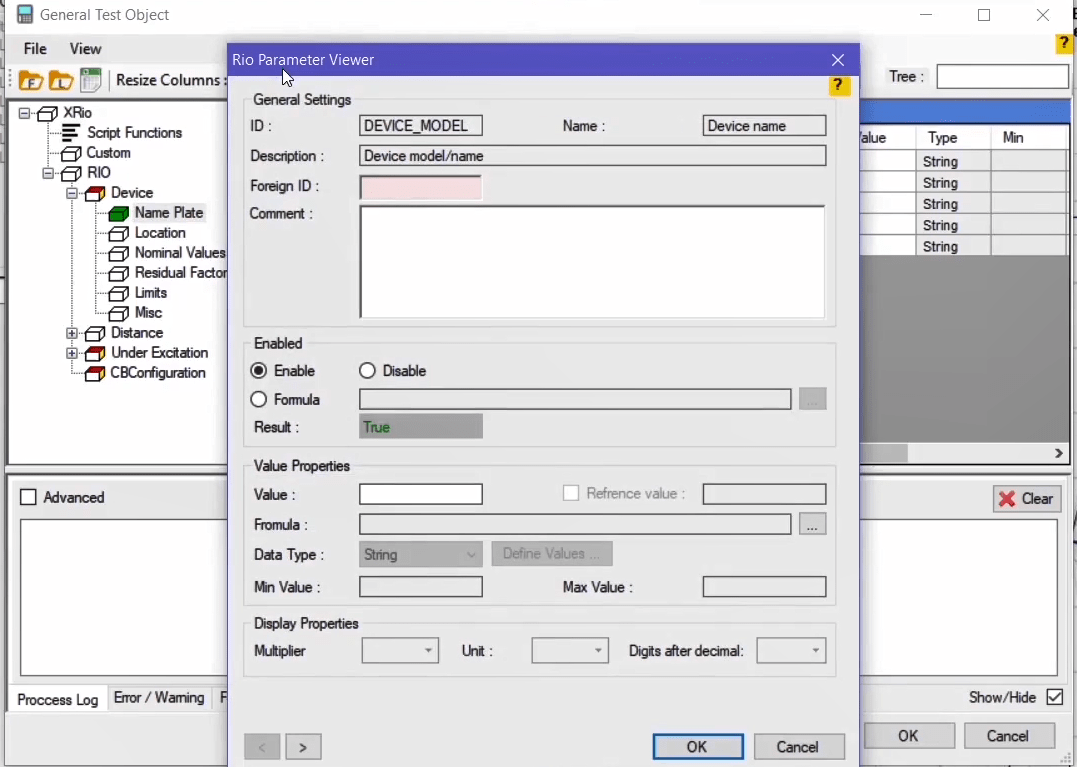

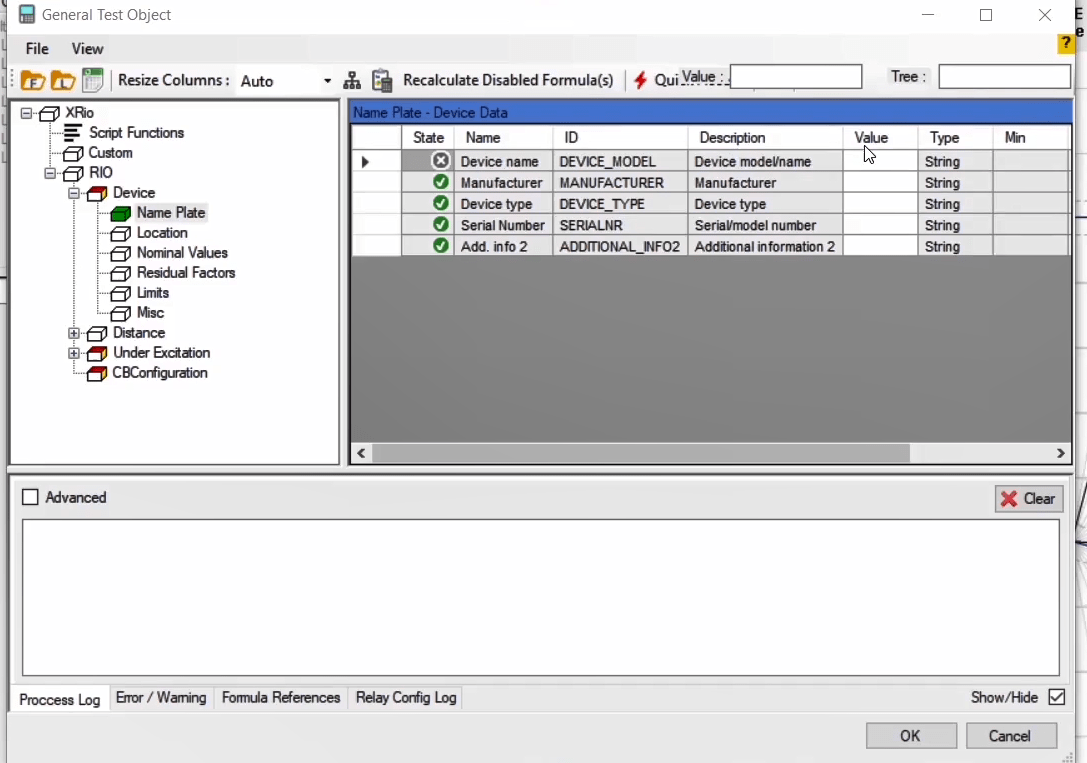

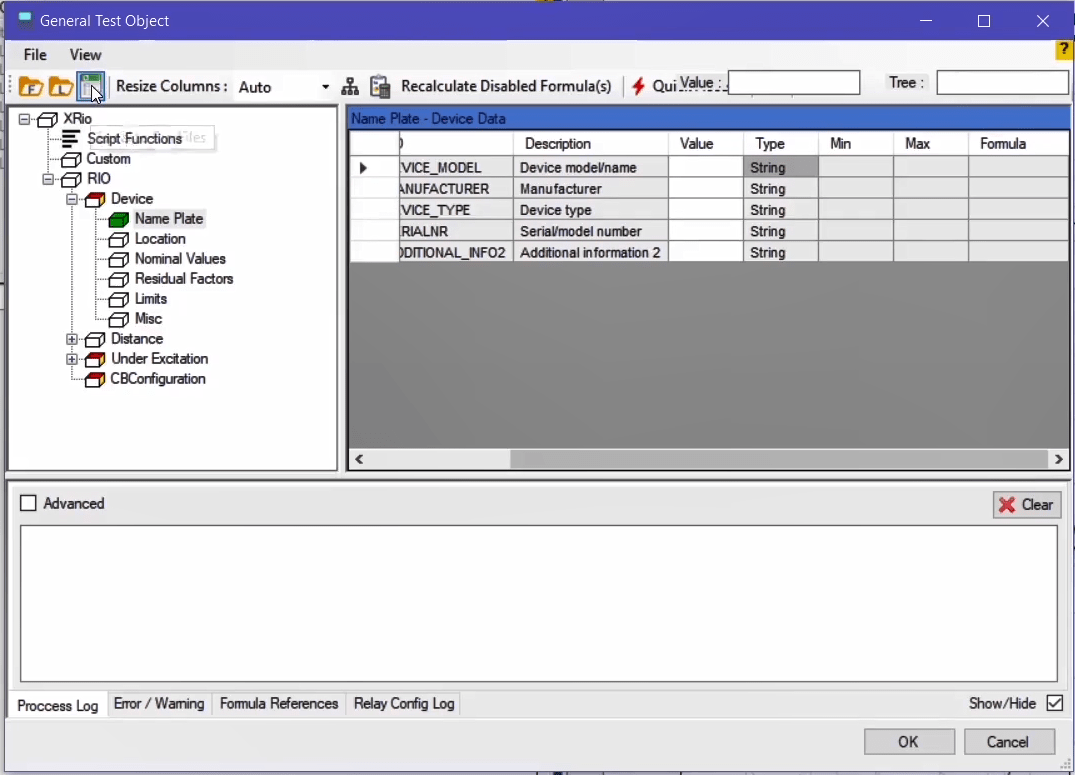

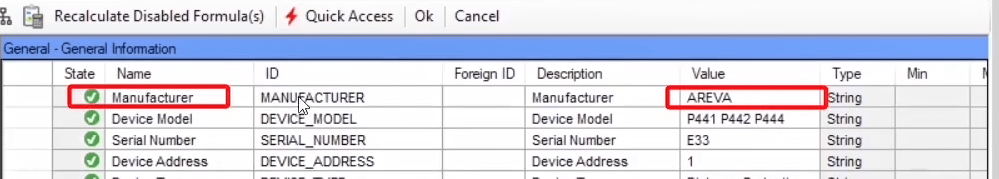

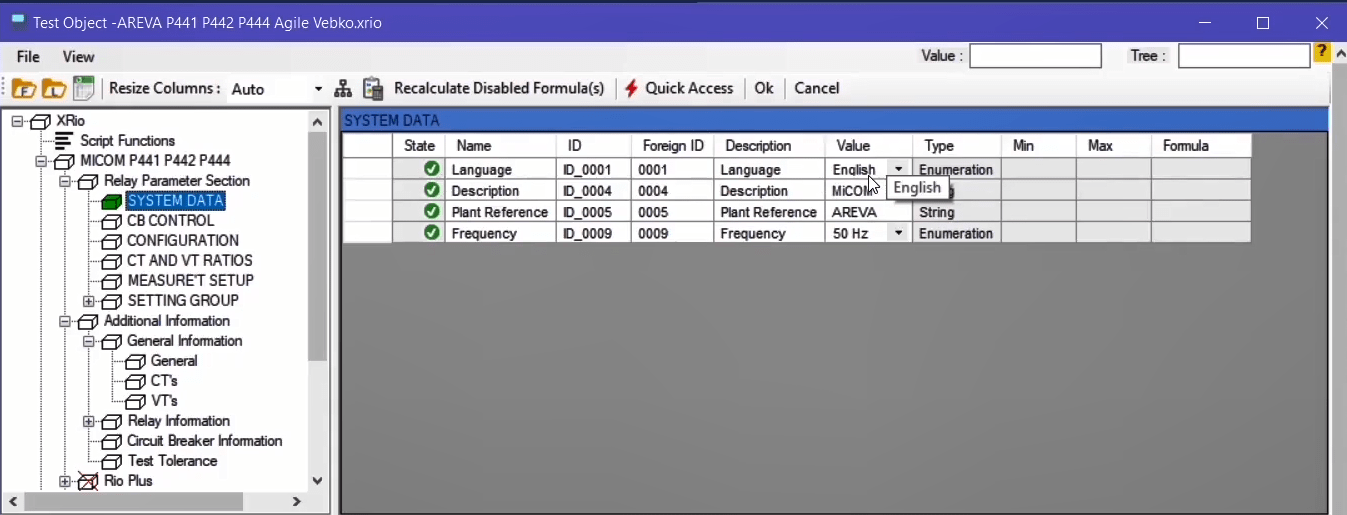

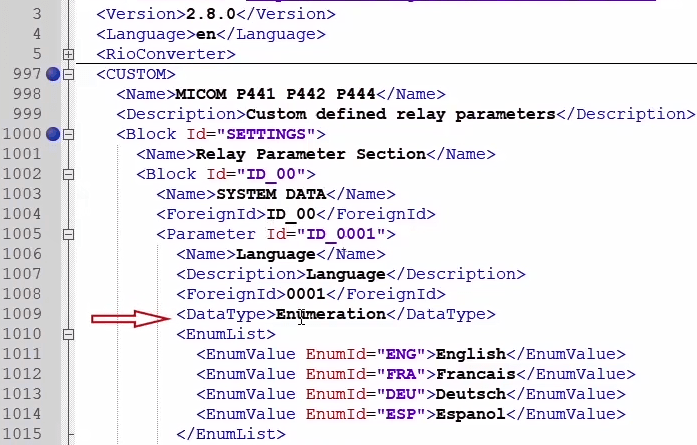

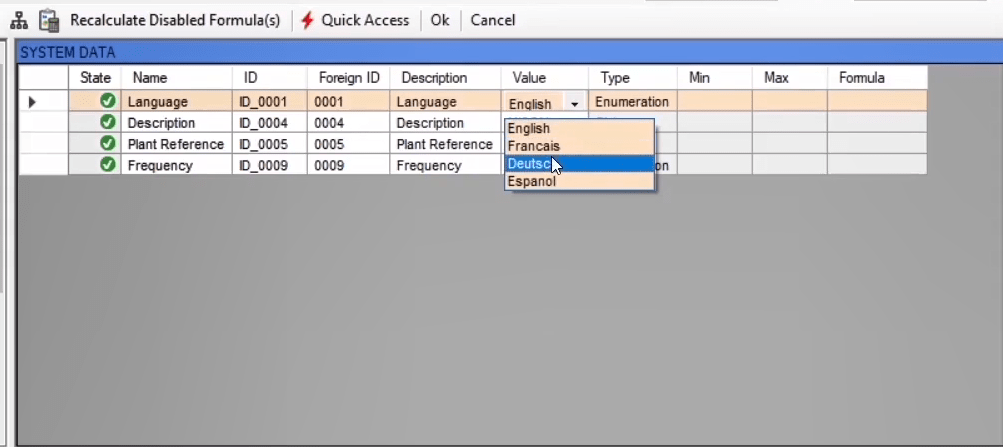

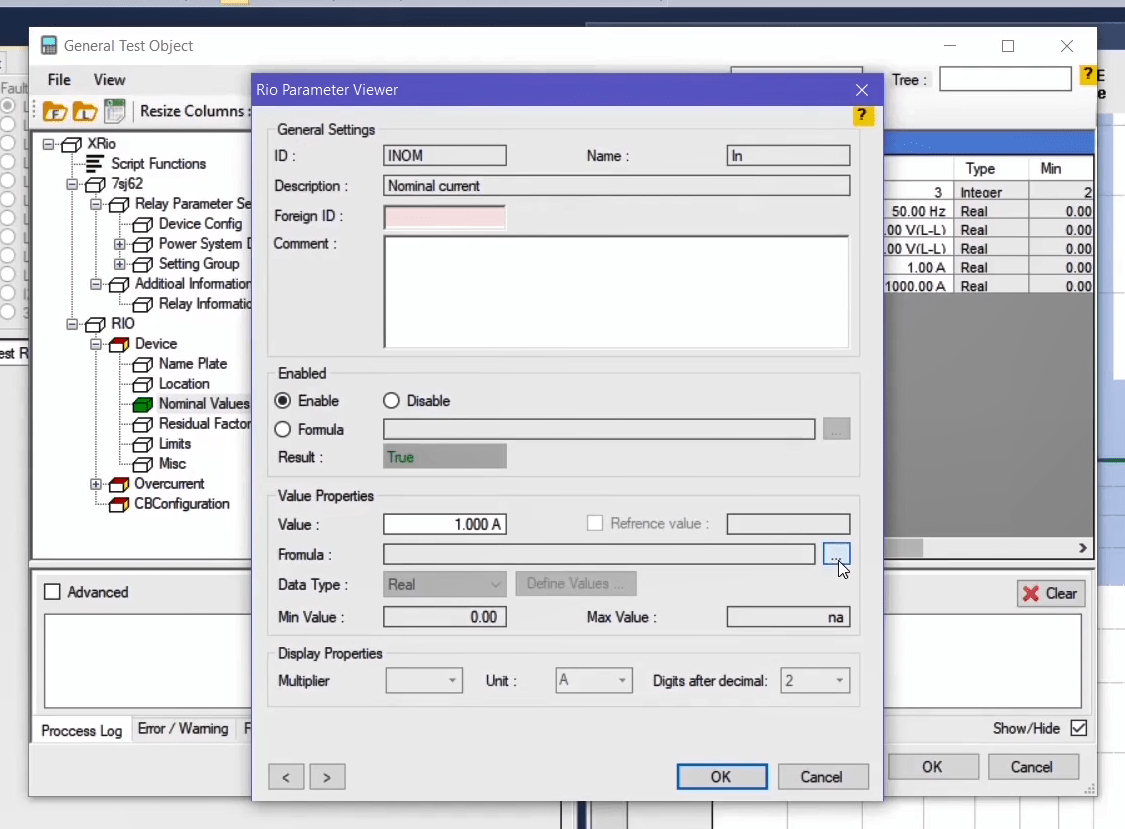

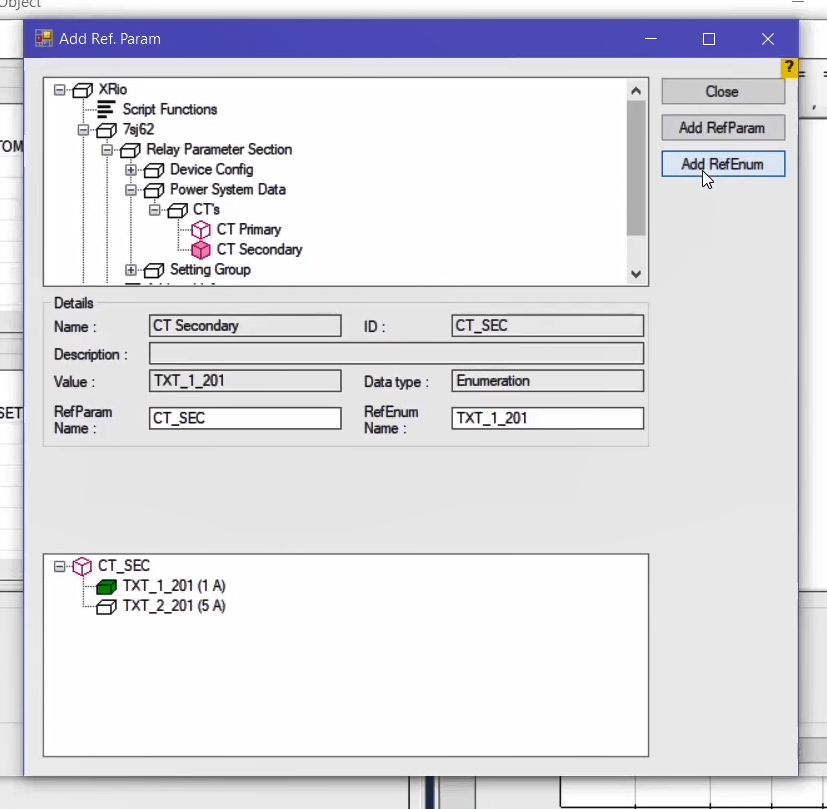

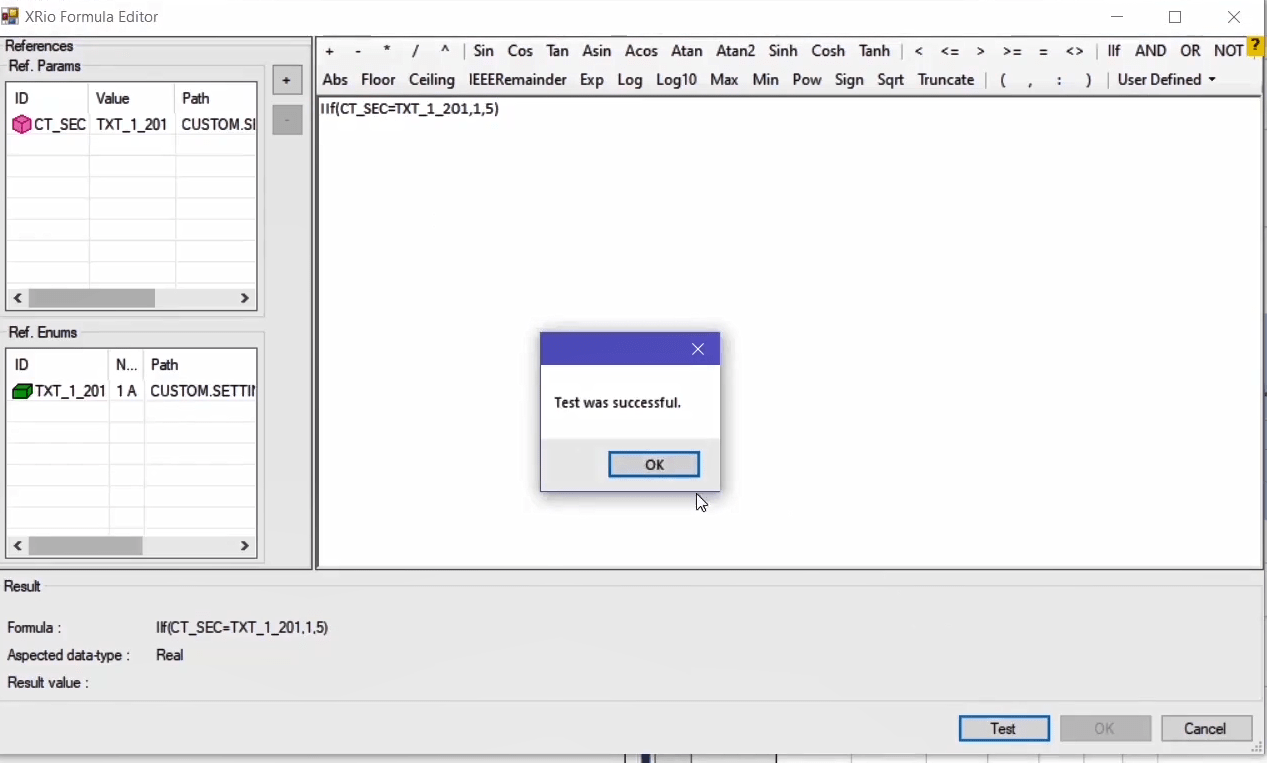

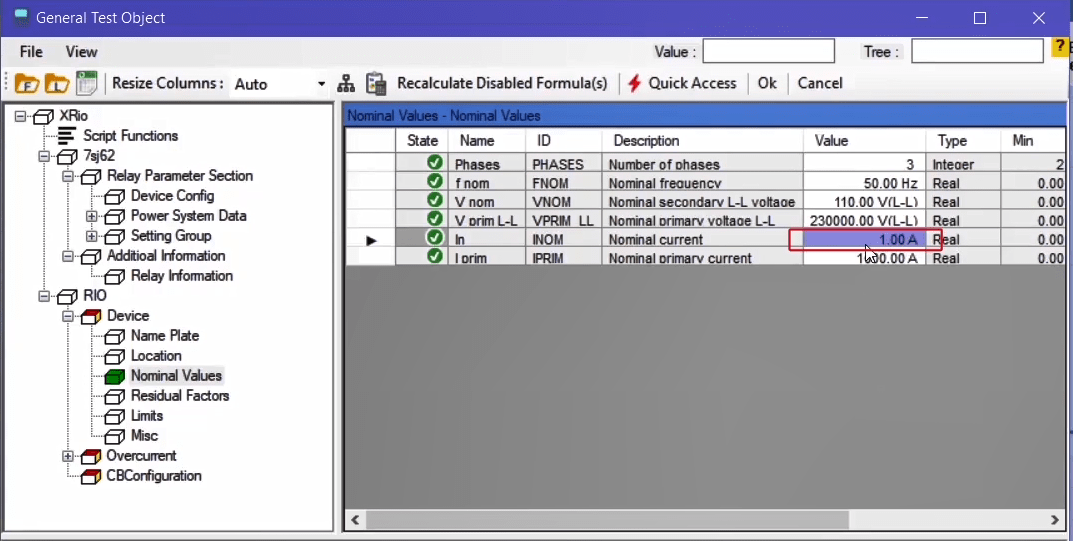

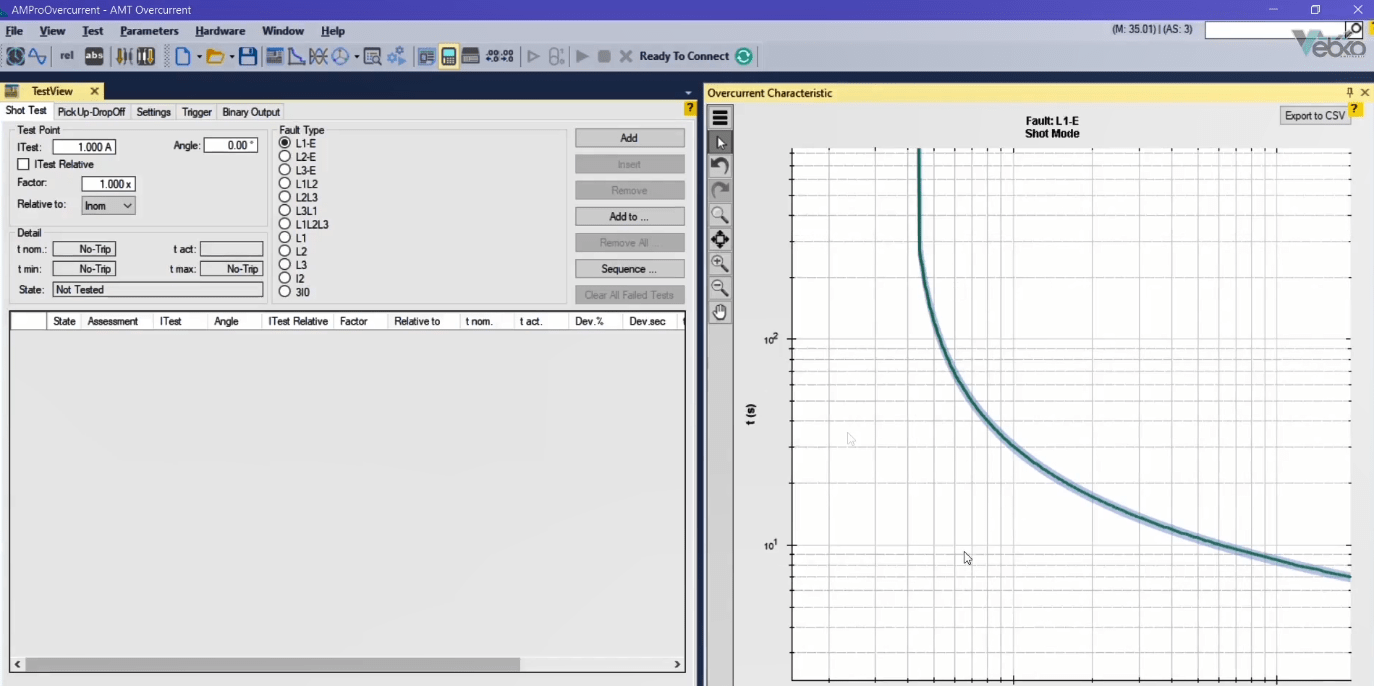

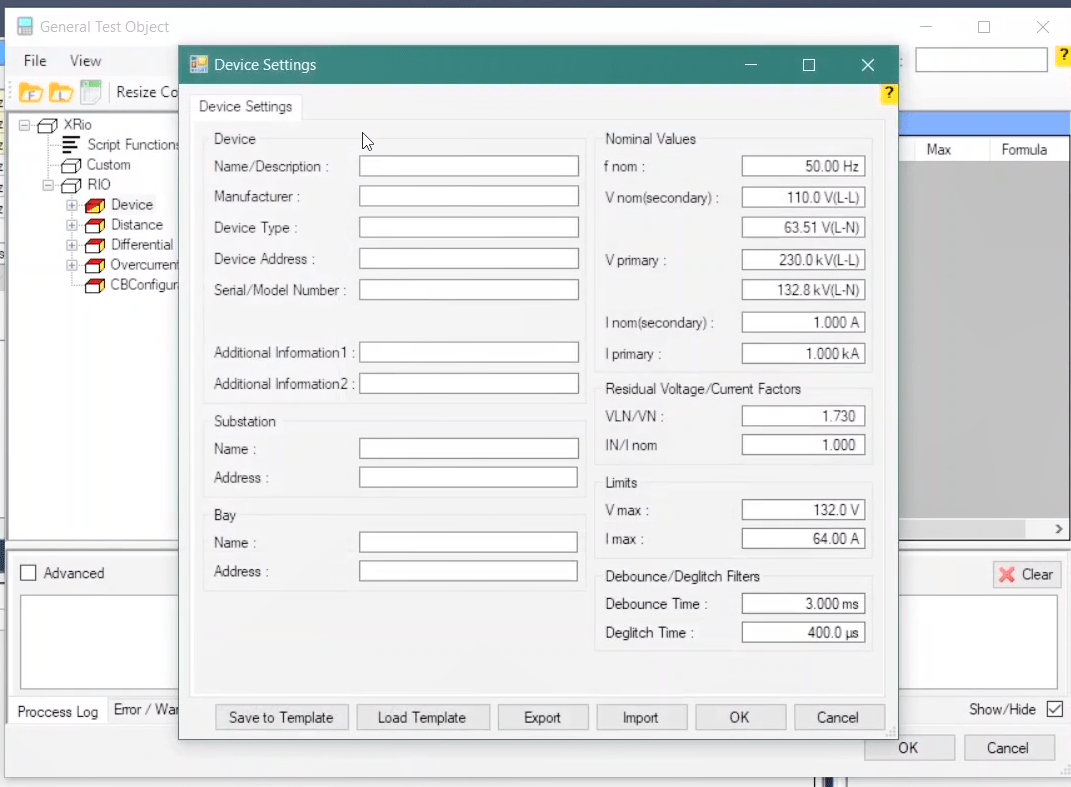

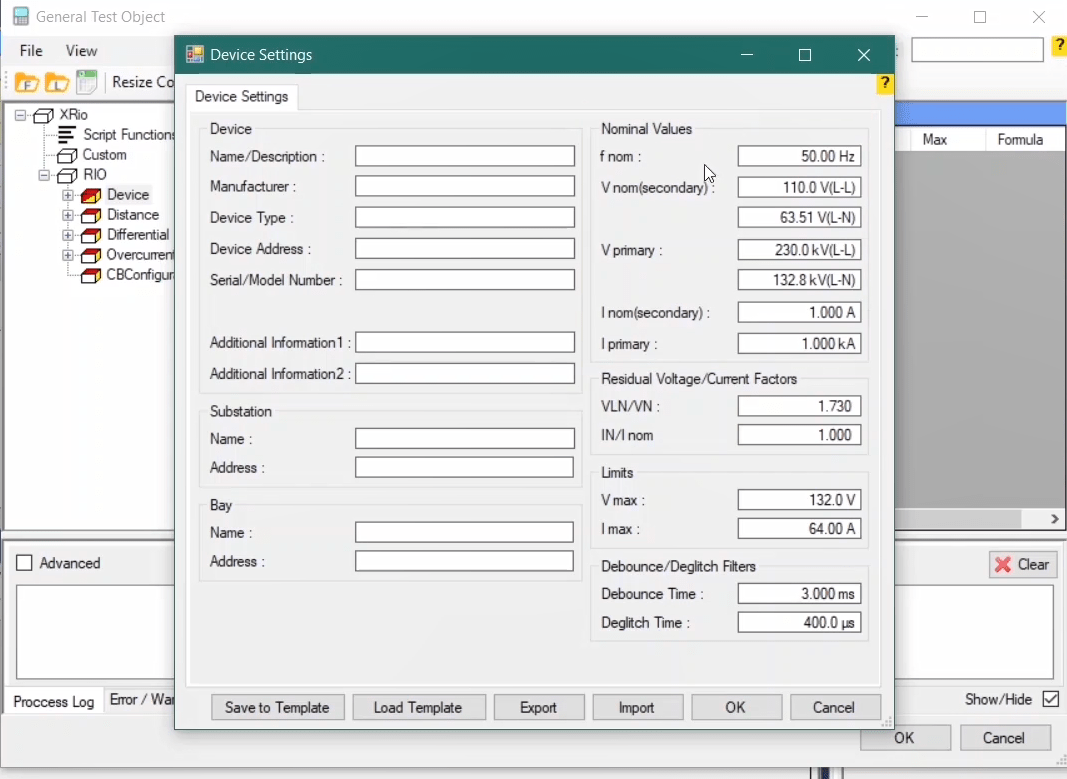

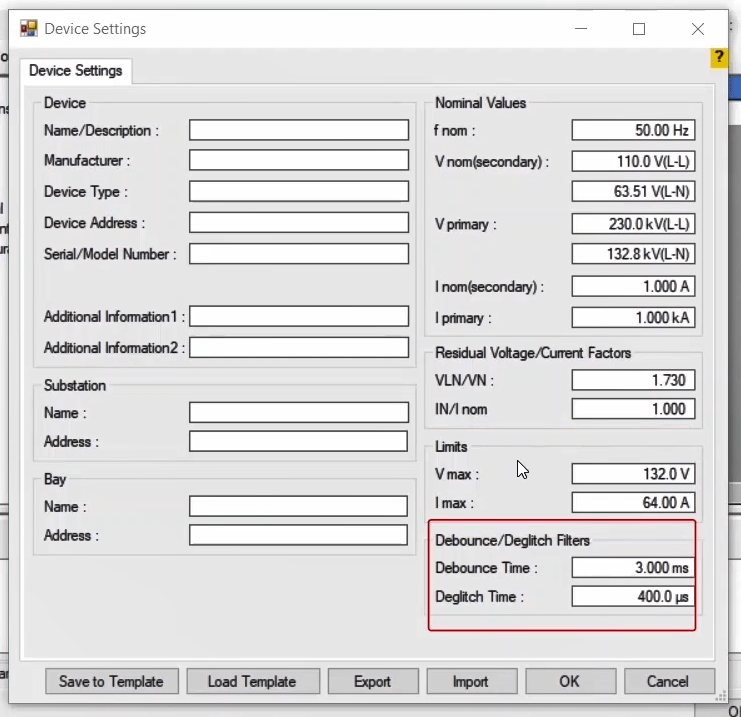

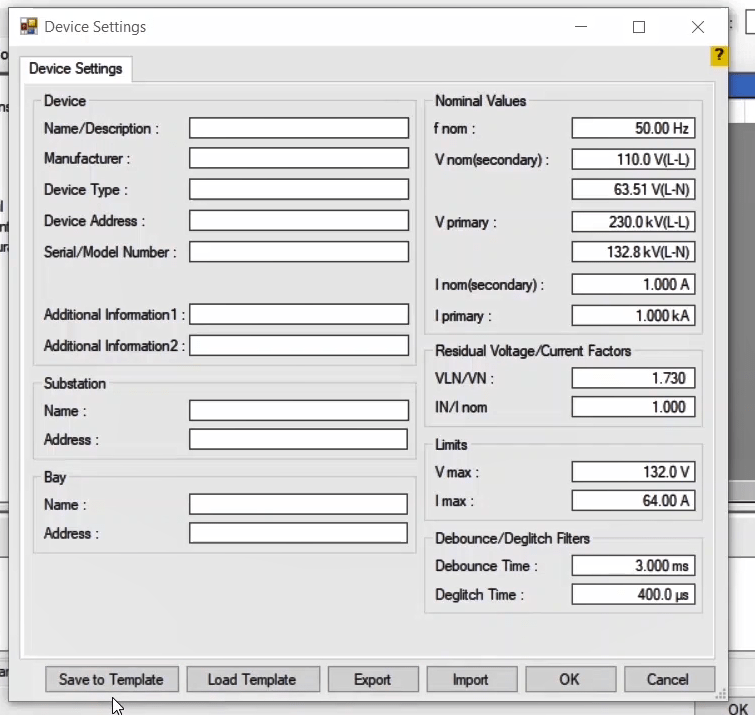

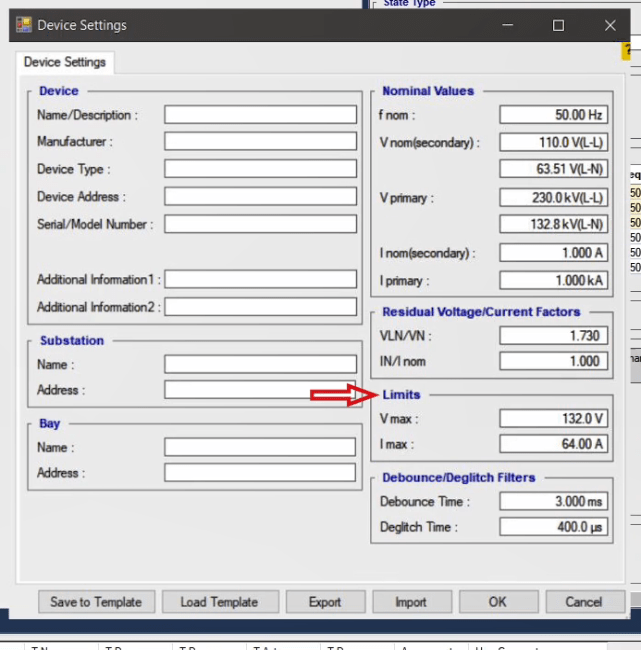

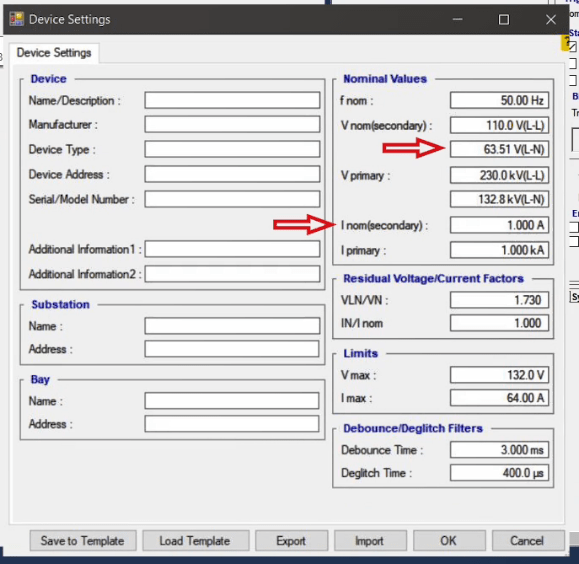

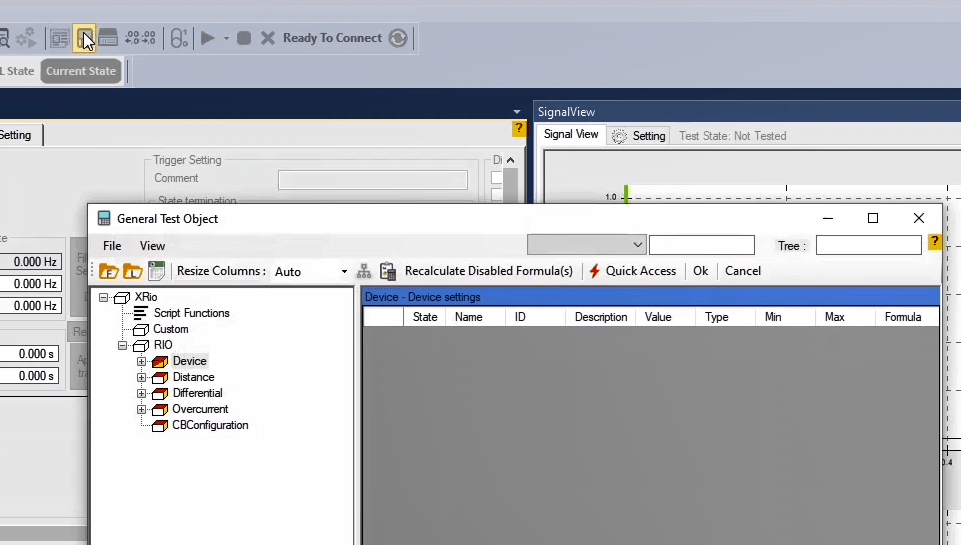

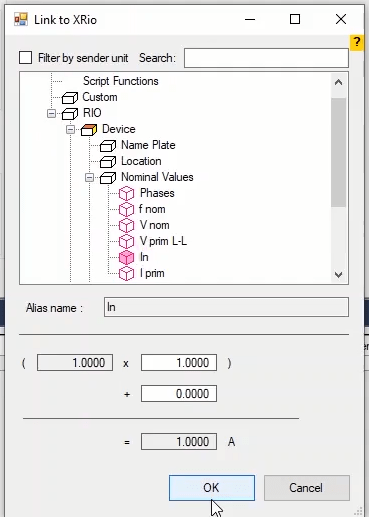

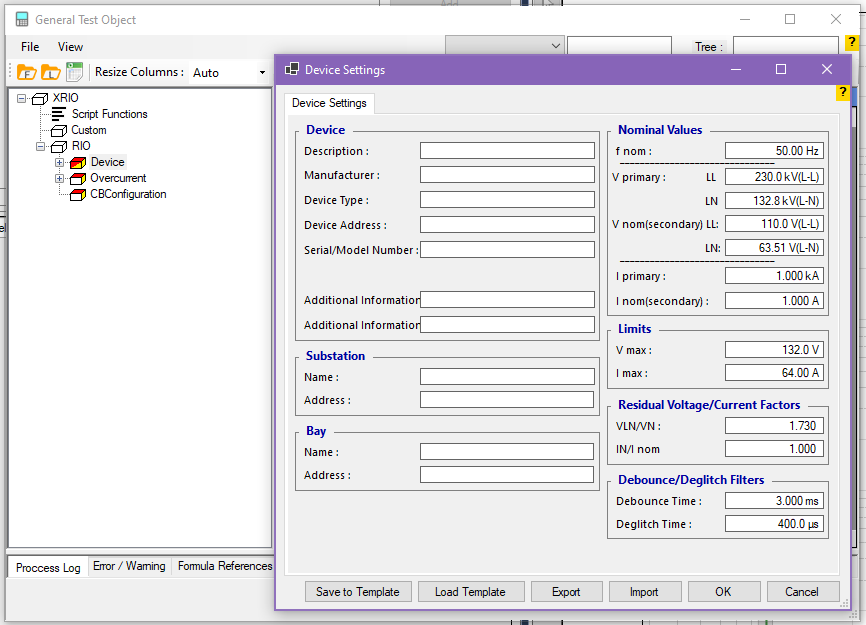

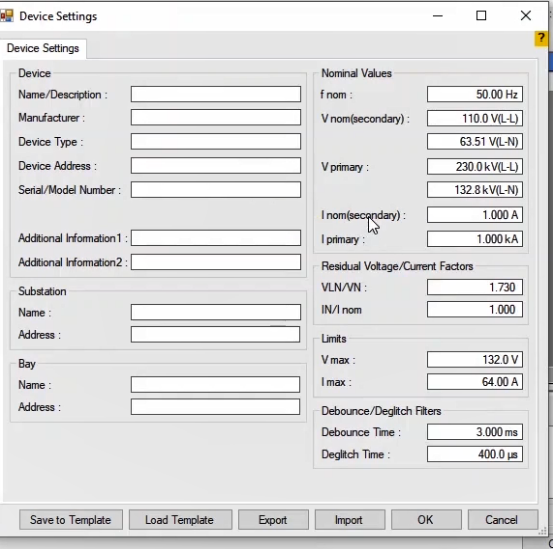

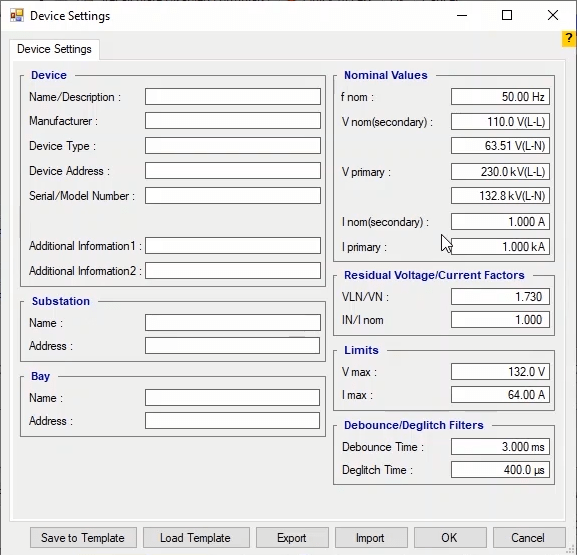

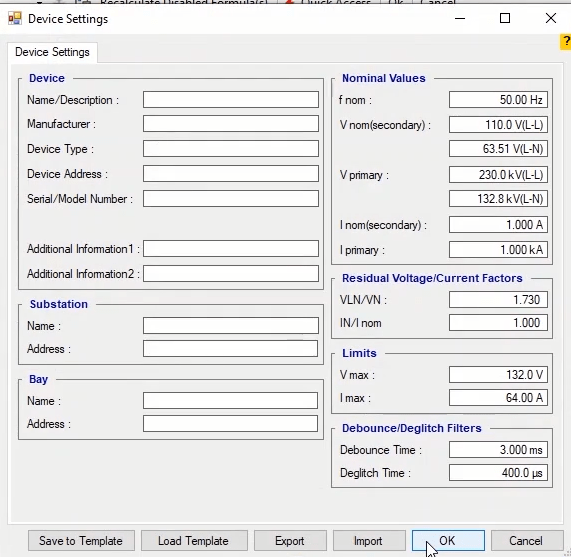

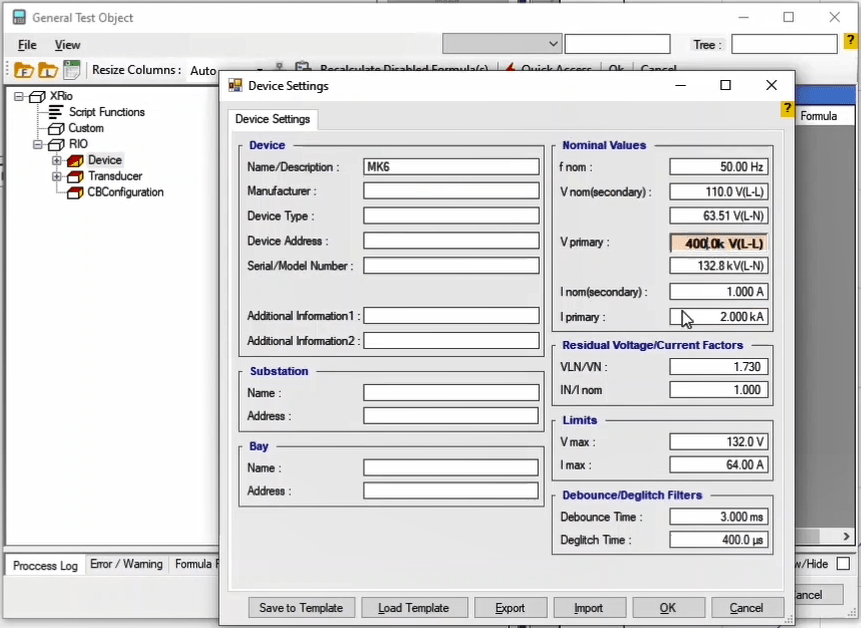

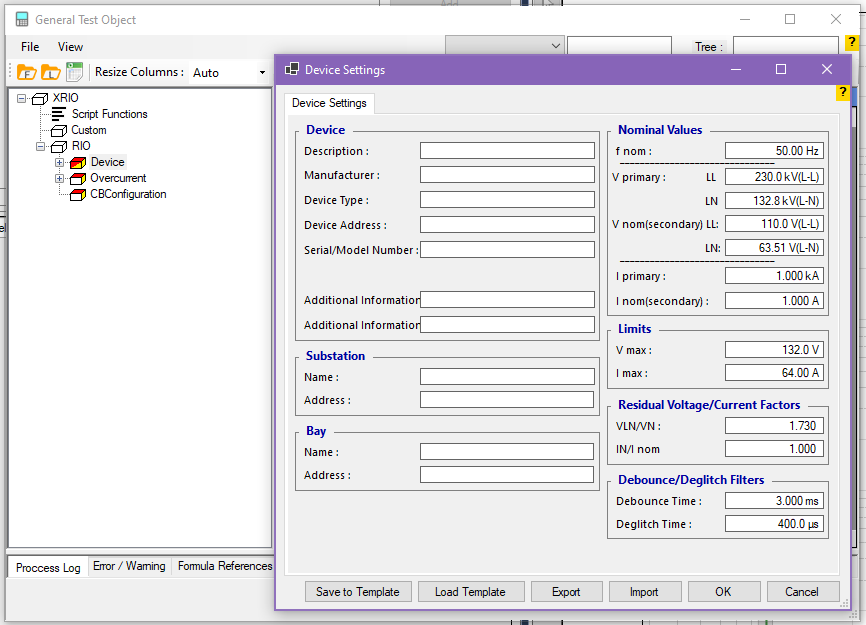

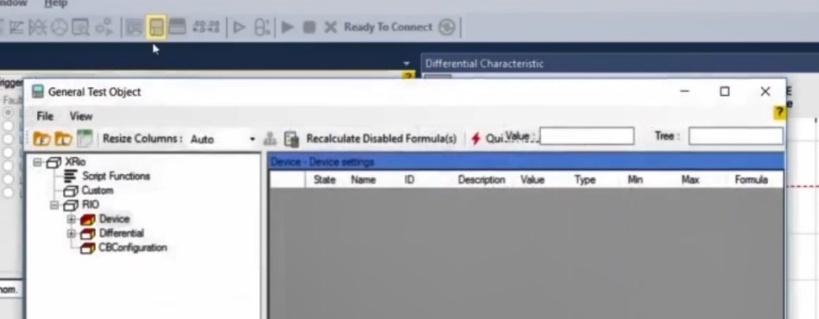

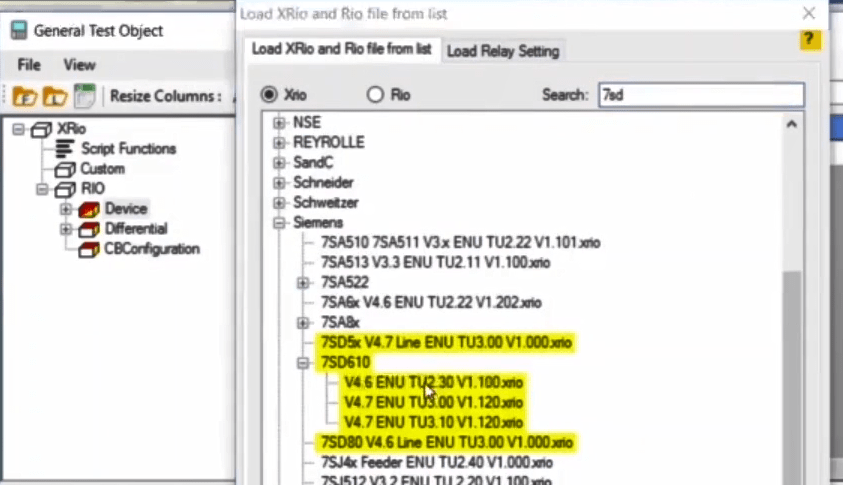

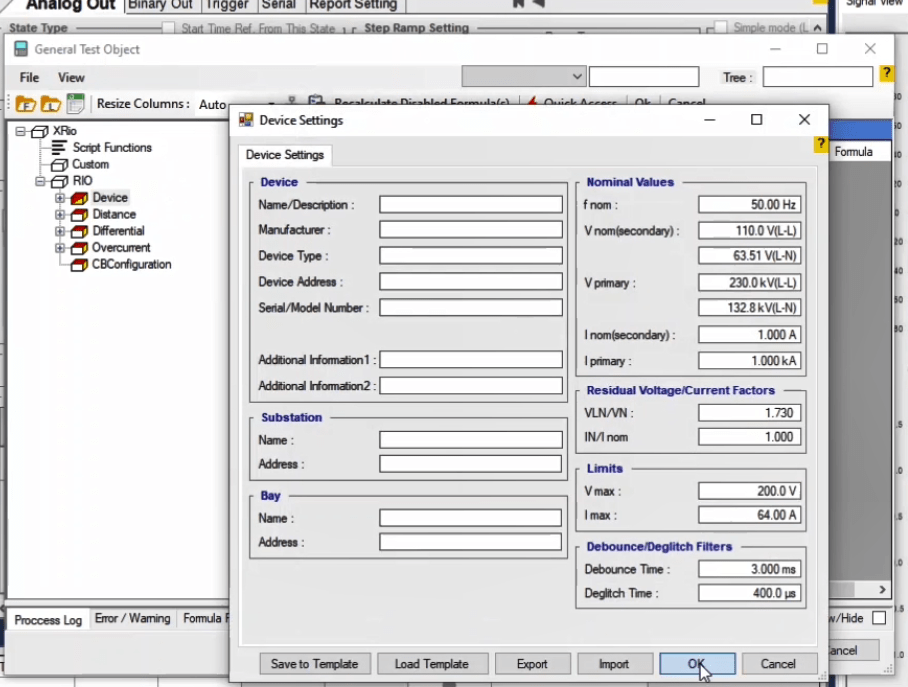

In the “Templates” section, by clicking on the “Device” button, a new screen named"Device Settings" appears in which the default settings for the Device are set. If changes are made to this section, clicking on the "Save to Template" button will save these changes as a template. After confirming the setting, The user can reset the settings saved as the template, by visiting the “General Test Object” in any of the rooms and clicking on “Load Template” in ”Device Setting” screen.

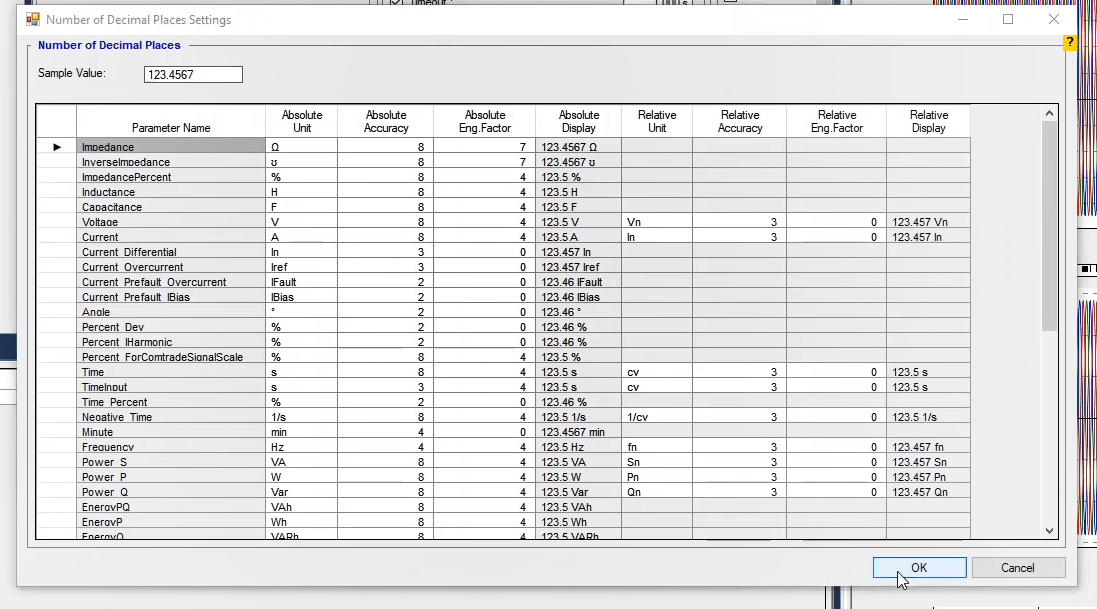

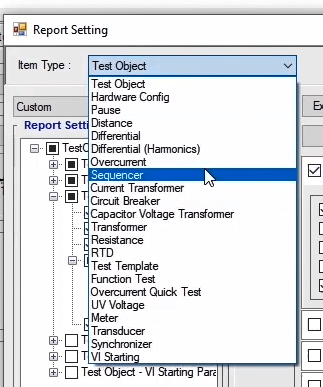

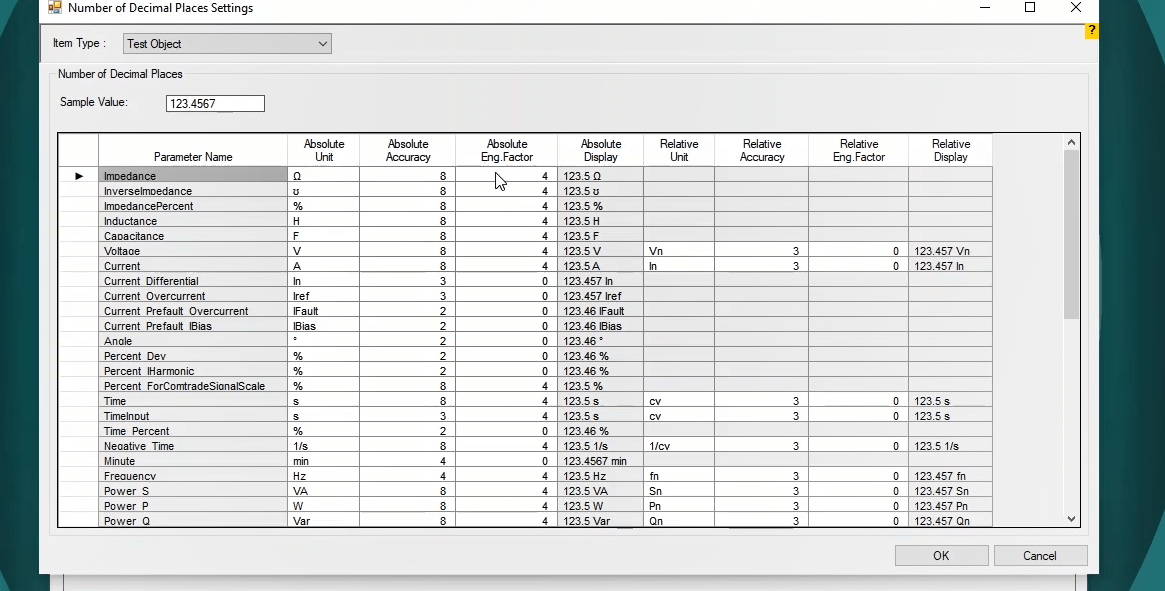

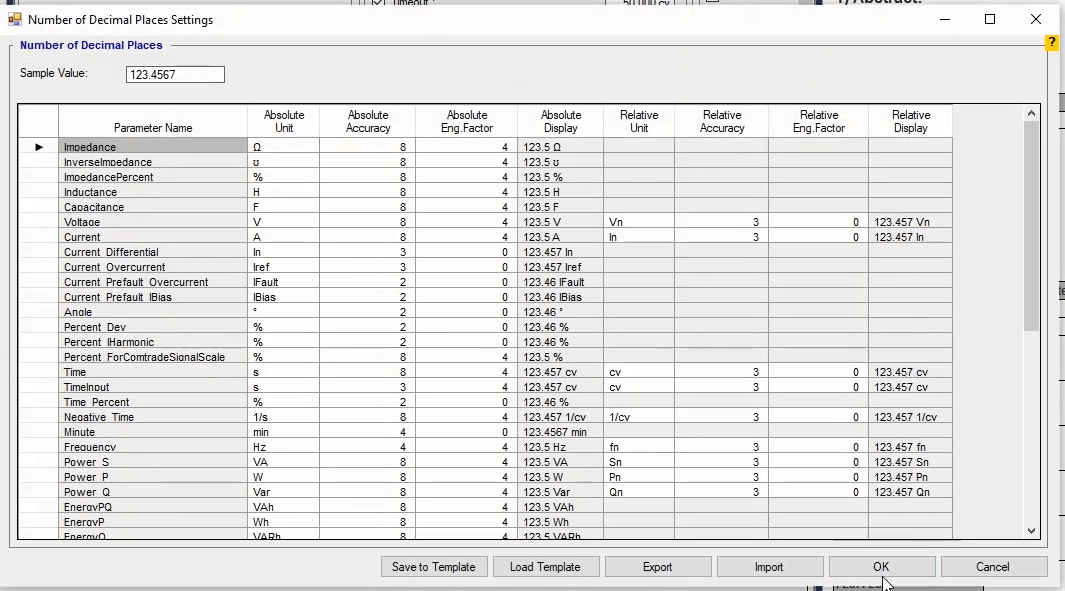

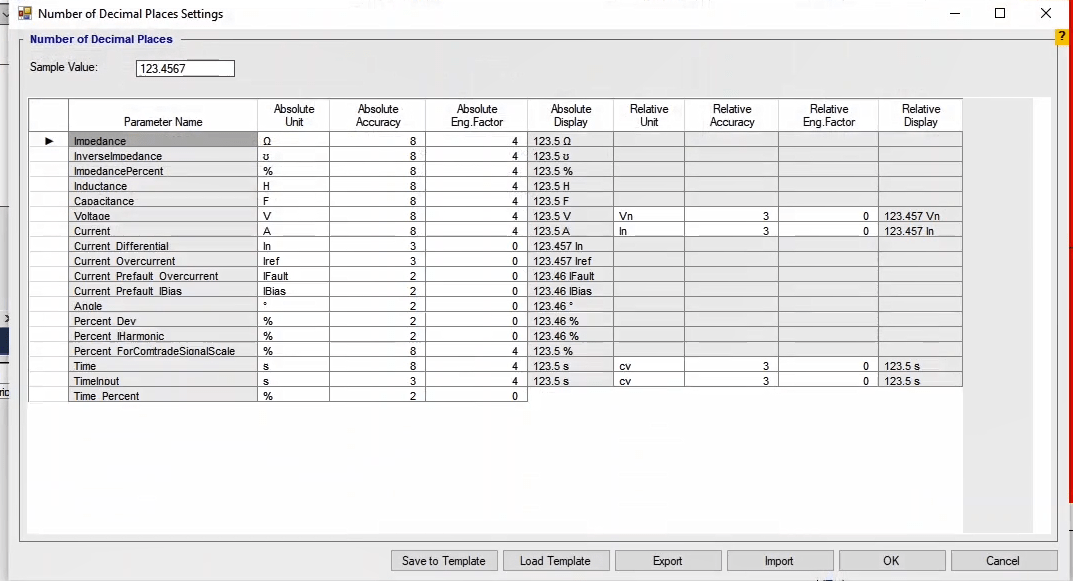

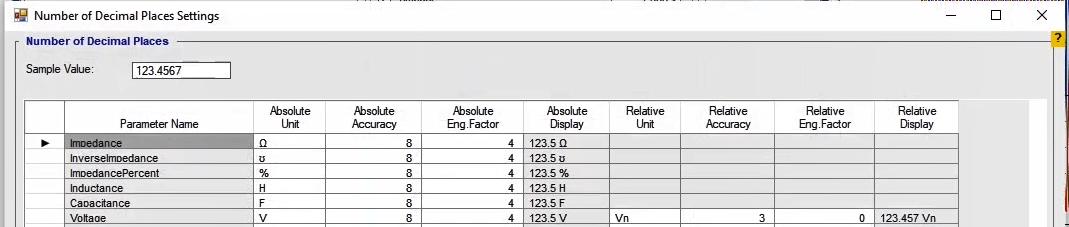

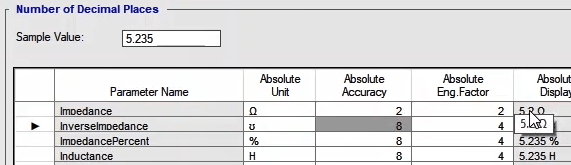

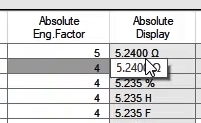

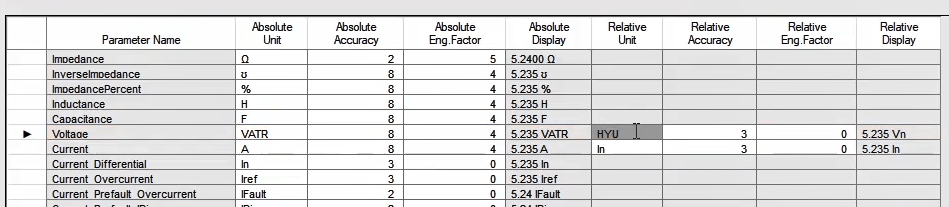

Clicking on the “Decimal Places” button opens a screen named “Number of Decimal Places Settings” where the accuracy of the numbers and the number of digits visible for every parameter are determined. In the “Item Type” field, the desired section or room is selected and in the “Sample Value” field a number has been inserted as an example. The name and unit of the parameter are seen in the “Parameter Name” and “Absolute Unit” columns respectively. In the “Absolute Eng. Factor” column, the number of digits displayed is specified. For example, if number 7 is entered in this column, 7 digits of the number entered in the “Sample Value” are displayed.

All changes made on this screen are considered as default for this section in the software and applied to different rooms. For example, if "Sequencer" is selected in "Item Type" field, by making and confirming some changes in this screen, via opening “Sequencer" room and checking "Decimal Places", it can be seen that done setting considered as default. There are several audio files available in the “Alert Tone on Hardware Error” section in the “Preferences” screen which can be used as the alarm tone in case of a hardware error.

By activating the “Automatic” option in the “Style of Tables”, dimensions of table cells will be set by the software automatically. By activating the “Manual” option, the user can modify the dimensions of the cells of the tables. In this drop-down list, user chooses how table cells dimensions be set. In the “height of table cells” the height of each cell is adjusted by pixels. For example by selecting and confirming "All Cells", If you visit the “Distance” room and shot several points, you see the width of each column is equal to the title of its header and due to selecting "Manual" state its dimensions is changeable by the user. In the “Key Setting” section, by activating the “Enter like Tab in Forms” option, the user chooses “Enter” as the “Tab” key to move between the cells. By activating the “Arrow like Tab in Forms” option, the user chooses to move between the cells in the tables by using the arrow keys.

By selecting “Service System” in the “Communication Mode” section, each of the rooms on the first screen of the software, if opened, will launch as a separate exe file and each window will be used independently from the windows of other rooms which will reduce the use of system resources; however, by selecting the “Integrated System” option, if several rooms are running simultaneously, all of them will be running in the same exe file. In this case, in addition to using more system resources, if a window is running in one of the rooms, the other rooms and screens of the software will not be usable.

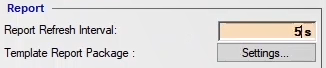

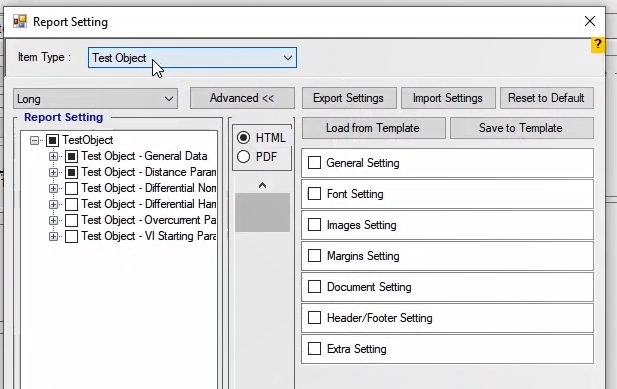

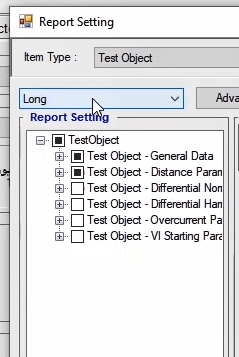

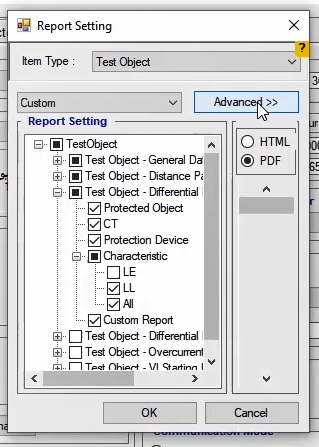

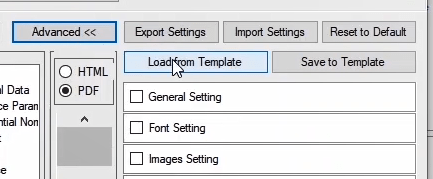

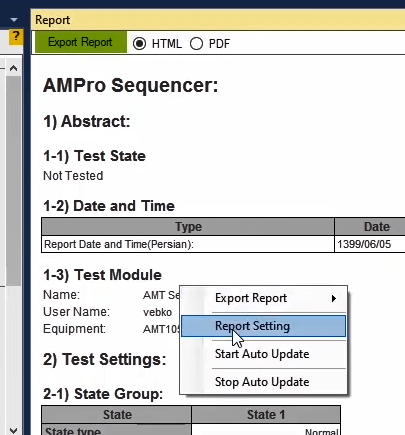

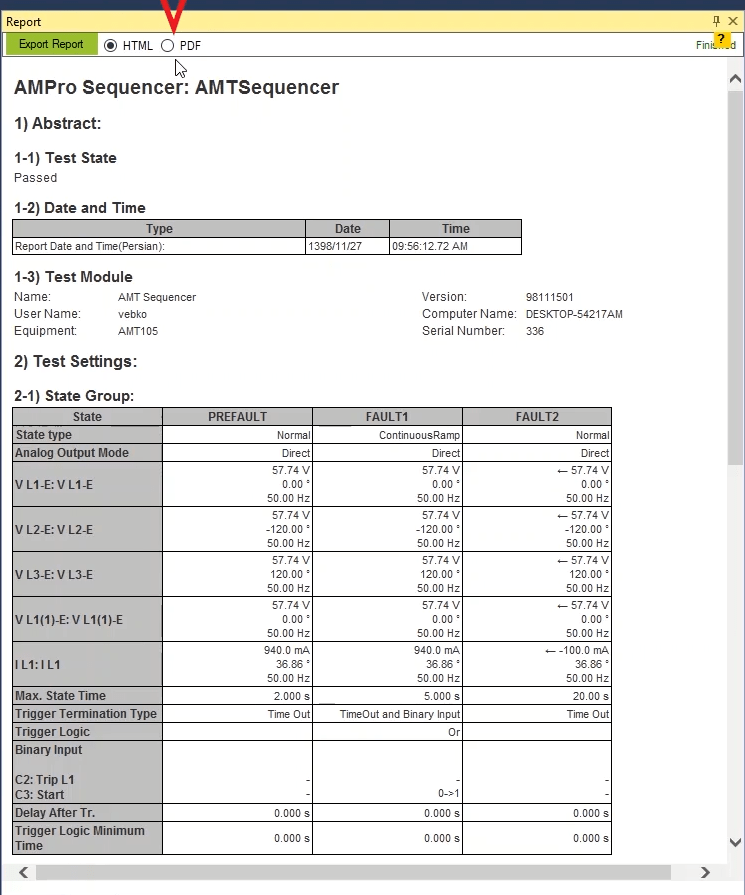

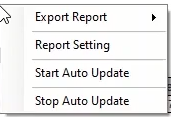

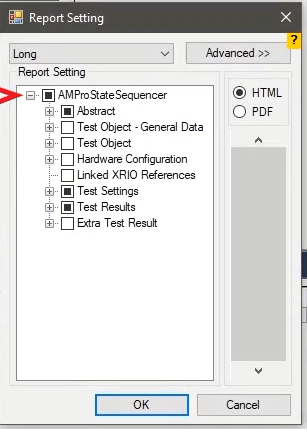

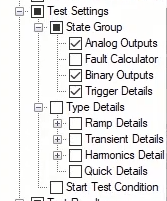

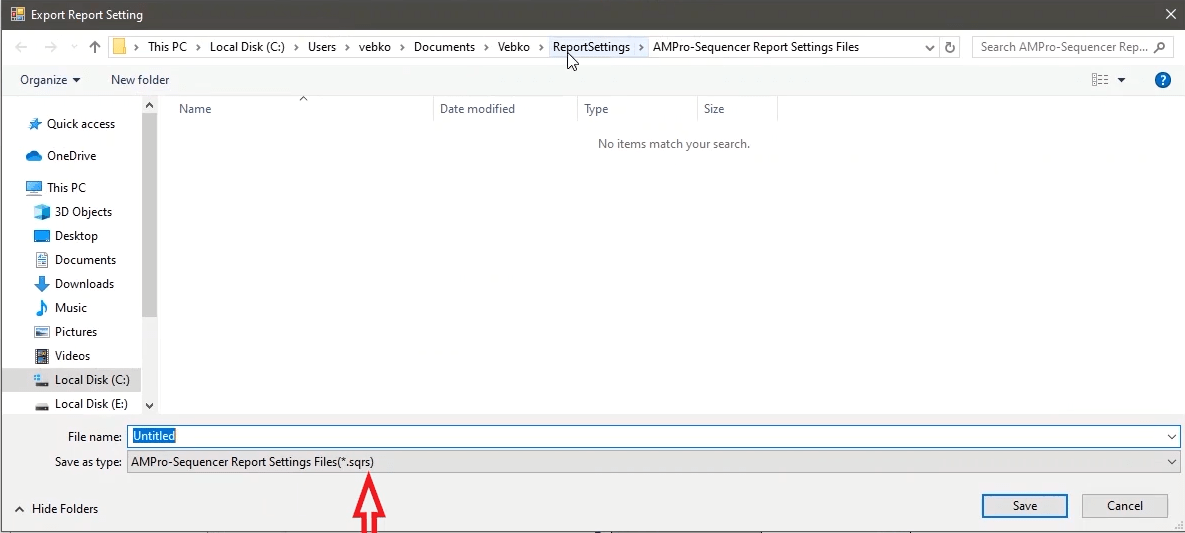

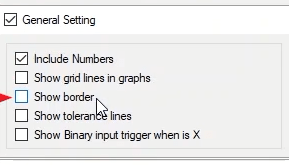

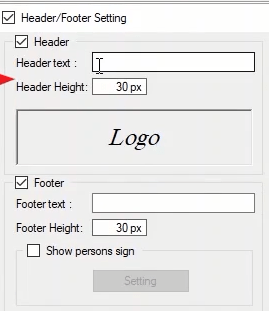

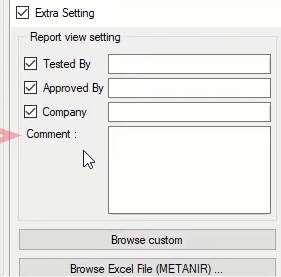

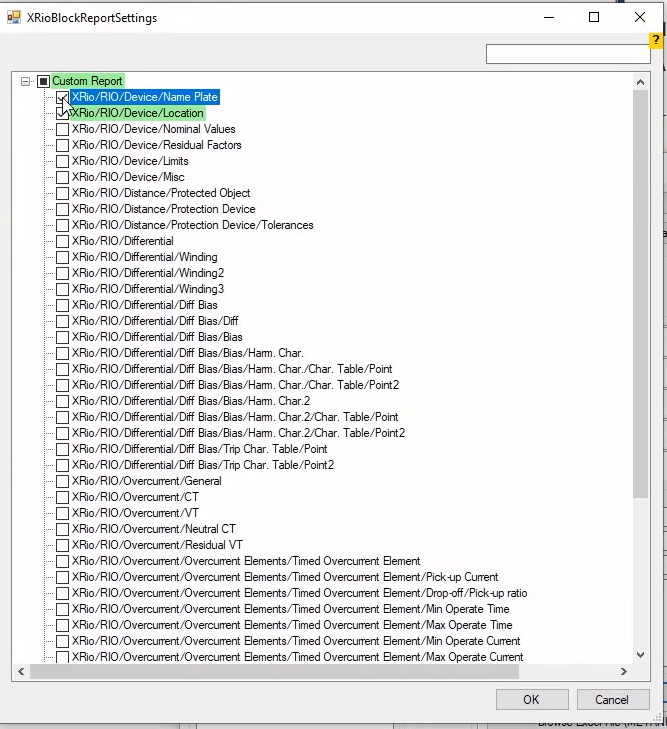

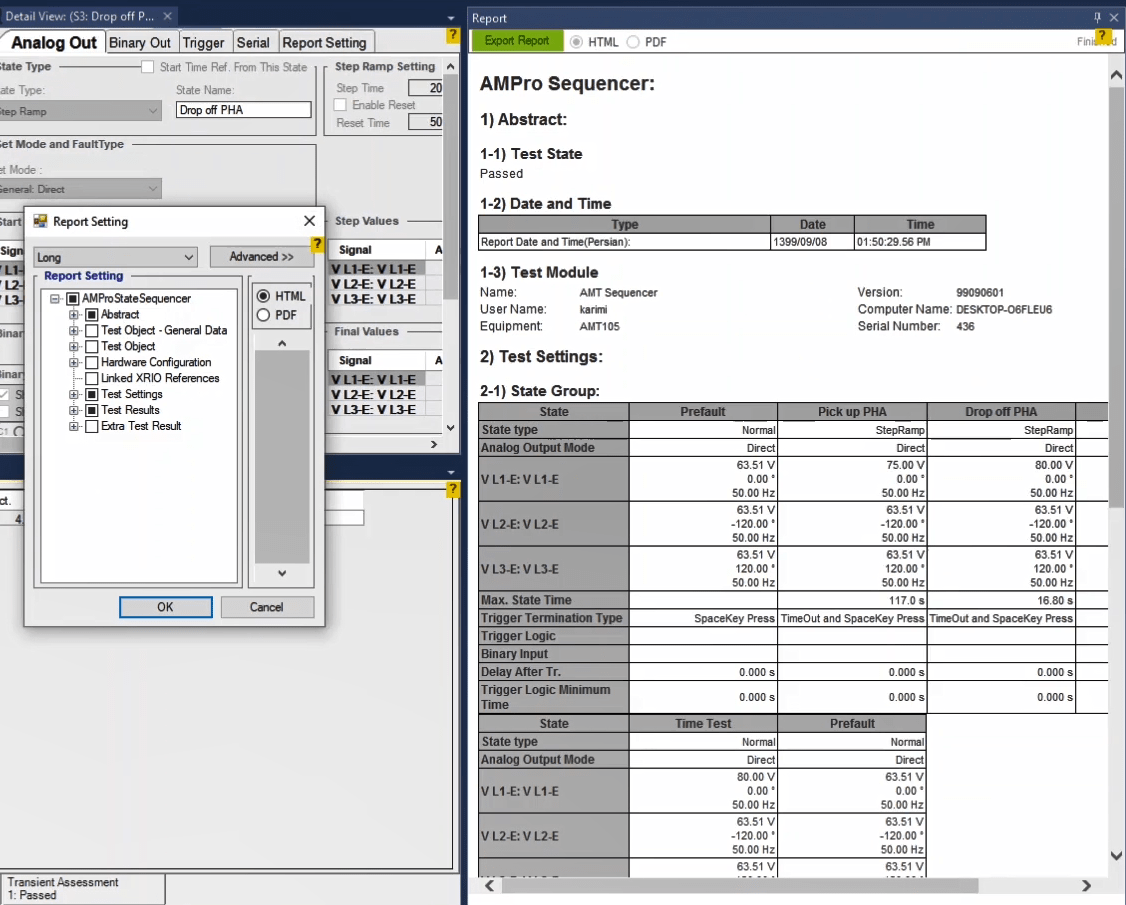

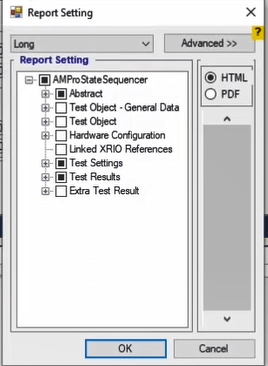

In the “Room” tab and in the “Report” section, the time of updating the reports in the rooms, if any changes happen, it indicates in the “Report Refresh Interval” field. For example, the test information is checked every five seconds and if there is any change the report is updated. In this section, by clicking on the “Setting” button a new window named “Report Setting” is opened. In “Item Type” the default settings can be specified to get the report from a specific room or screen.

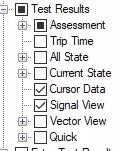

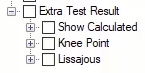

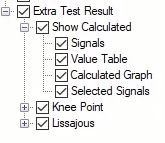

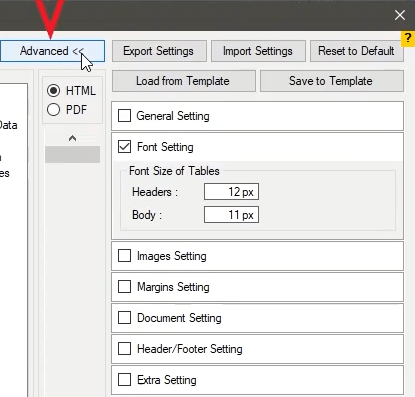

The elements that can be added to the report by the user are located in the “Report Setting” section of this window. By checking the main option, the user can add all the subsets to their output report. If the user chooses only some of the subsets of the main option, the square sign next to the main option will be displayed as a half-filled square. In the column next to the "Report Setting" section, the user can select HTML or PDF as the format of the report preview.

By clicking on the "Advance" button, the screen is displayed more extensively, and more settings can be applied to the report. By checking each of these categories, their subcategory is opened and the needed settings can be applied. At the top of this screen, there are options used for saving the applied settings and using them again later.

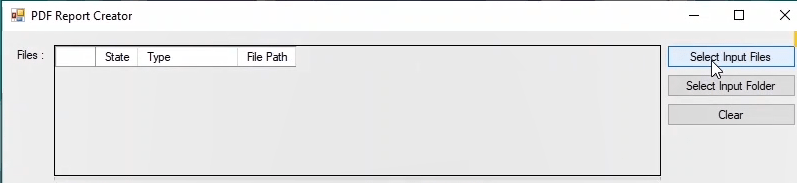

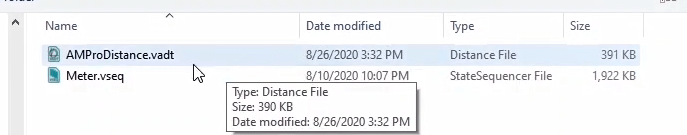

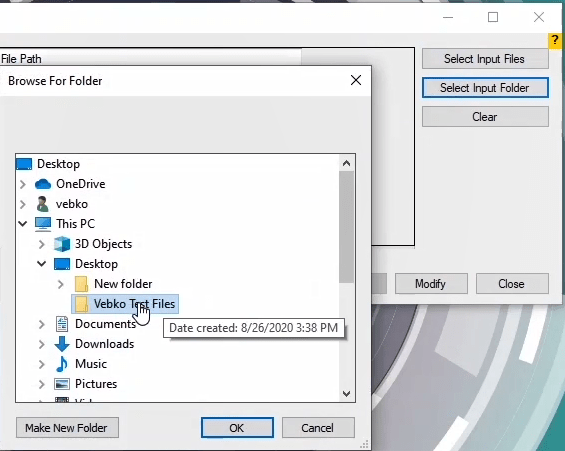

For instance, if “Sequencer” is selected in the “Item Type” and some specific settings are set at default and confirmed, after entering the “Sequencer” room, selecting the “Report View” option from “View” menu and reviewing the “Report Setting” section and then selecting “Load from Template” option, you will see that the same settings are set at default for this section as well. In the "Extra Tools" section, the user is allowed to click on the "Report Generator" button and get a report on the saved test files without needing to open them. After clicking on this button, a screen called "PDF Report Creator" opens. On this screen, the user can select their test files to get a report on by clicking on the “Select Input Files” button. For example, the first two files are selected. The user can, also, by clicking on the “Select Input Folders”, select a folder including several test files. and insert them into the “Files” section. For example, “Vebko Test Files” folder is selected. By clicking on the “Clear” button, the files inserted for getting a report can be removed from the list.

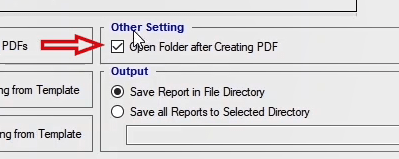

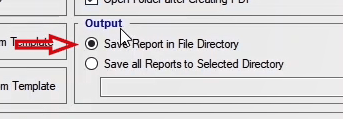

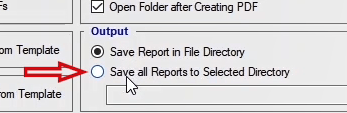

By selecting the “Open Folder after Creating PDF” option in the “Other Setting” section, the folder where the file is saved will be displayed right after the report is made. In the “Output” section, by selecting the “Save Report in File Directory” option, the report files can be saved at the same directory as where the files are imported from. If the “Save all Report to Selected Directory” option is selected, the user can select a specific directory and save all their reports in that directory.

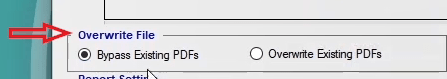

There are two options available in the “Overwrite File” section. In order to clarify this issue with an example, a file is imported for getting a report. By selecting the “Bypass Existing PDFs” option, if they’re already exists a report on a file in the selected directory, the software does not make another report on that file. The appearance of this screen is due to the prior selection of the “Open Folder after Creating PDF” option which can be disabled. By selecting the “Overwrite Existing PDFs”, the new report replaces the previous one.

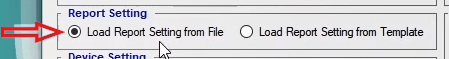

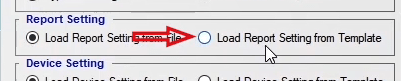

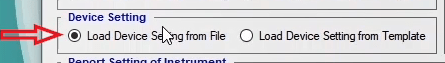

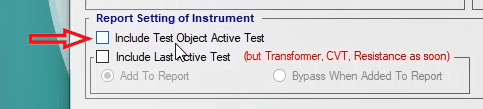

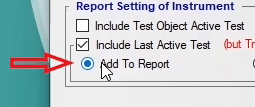

In the “Report Setting” section, by selecting the “Load Report Setting from File” option, it is specified that for making the reports, the setting from the loaded files should be used. By selecting the “Load Report Setting From Template” option, the settings which are saved in the Template file will be used for making the reports. In the “Device Setting” section, by selecting the “Load Device Setting from File” option, it is specified that for making the reports, the Device setting from the loaded files will be used, while in the same section, by selecting the “Load Device Setting from Template” option the settings which are saved in the Template file will be used for making the reports. By selecting the “Include Test Object Active Test” option in the “Report Setting of Instrument” section, if a report is made on the Instrument test files, the information existing in the “Test Object” tab will be included in the report under any circumstances.

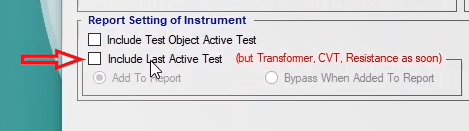

By selecting “Include Last Active Test” option, the previously saved equipment test files and the last performed test which has not been cleared by the user, by selecting “Add to Report” radio-button the report of that test is added to the report as well but if the user has added the test result to the output report, by selecting “Bypass When Added To Report” radio-button, the software does not add the test result to the output report again.

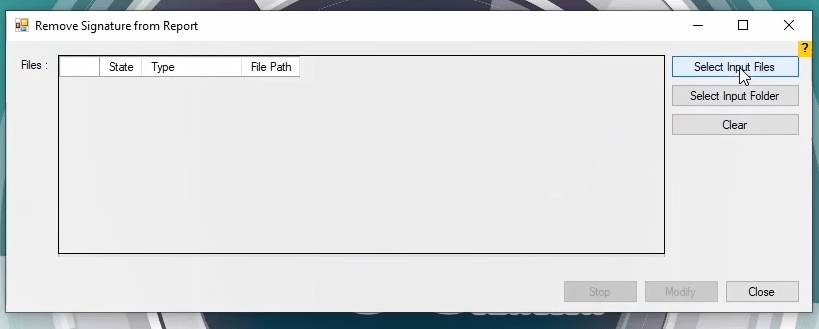

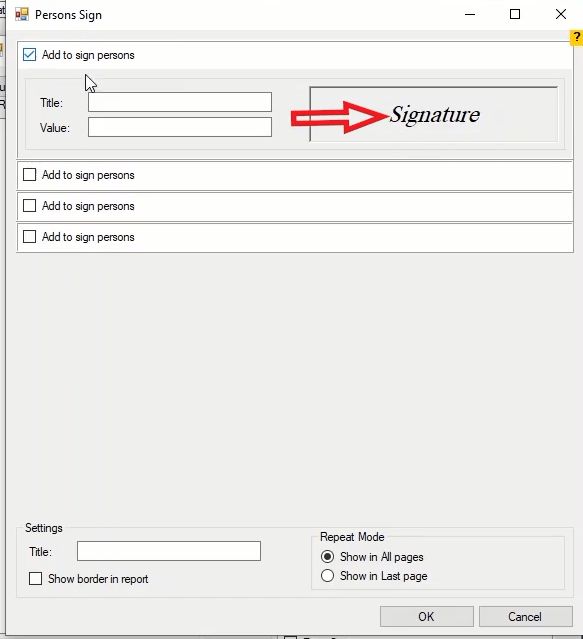

By clicking on the “Remove Signature” button in the “Extra Tools” section on the “Preferences” screen, a new screen named “Remove Signature from Report” appears in which the user can remove the existing signatures from the reports on their desired files. On this screen, by clicking on the “Select Input Files” button, the user selects their files for removing the signature. By clicking on the “Select Input Folder” button, the user can select a folder containing several report files and import all of these files into this list altogether. After the report files have been added to the list, by clicking on the “Modify” button, the existing signatures in the report will be deleted along with the framework around the report as well as the added names to the signature.

In the "Directory" tab, the default paths for saving files are specified. By clicking on any of the file formats, this default path can be changed. For example, by double-click on "AMPro-Distance Report Files", its path can be changed to desktop. To save the existing report file, open "Report View" in the "Distance” room and click on the “Export Report”. It is seen that the saving path is located on the desktop.

By checking the squares in the “Remember Last Location” column, it is specified that if the user chooses another path while storing the file, the software should remember that path. For example, if you open the “Distance” room, and set the report file saving path on drive “C” and save the file and then if you try to save the file again you can see that the saving path has been changed to that folder.

By clicking on the “Restore Selected to Defaults” button in the “Preferences” tab, the changes made to the squares in the “Remember Last Location” column are restored and reset to the default settings. For example if three squares become unchecked and two of them be selected. By clicking on "Restore Selected to Defaults" it's seen that these squares are gotten back to default state.

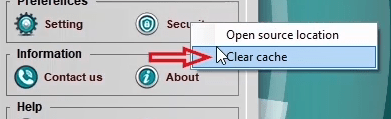

By clicking on the “Reset to Default” button, all settings are reset to the default values. It is possible to save the changes made to the settings of this section in a file by clicking on the “Export” button. When necessary, this file can be imported and applied to other screens. Settings related to different sections of the software are saved in the paths stored in the “Cache” tab. In order to prevent software slowdown in the long run, the software cache must be cleared. For clearing the cache of the software, the “Clear” button should be used. The “Open Roaming Directory” button opens the path where the cache is stored. In this folder, cache files can be viewed or cleared. For clearing, select all of the folders then press the delete button on keyboard.

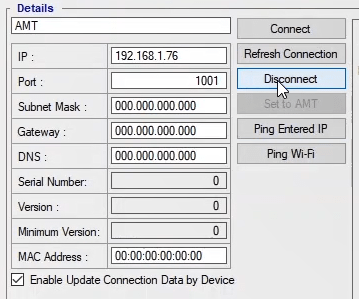

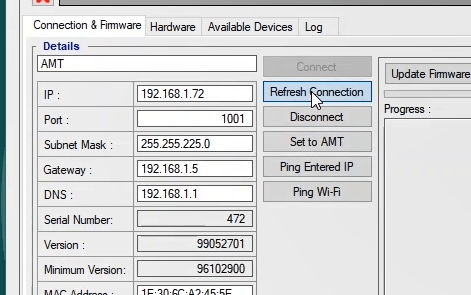

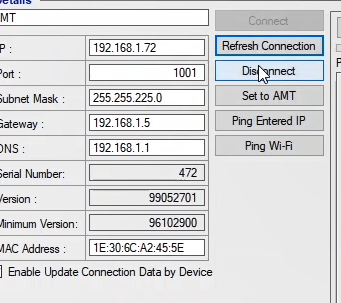

In the "Connection & Firmware" tab on the "Setting" page, the settings for the device connection and "Firmware Update" can be adjusted. Also, the settings for the connection can be adjusted in the "Details" section. The "IP" field is used to connect to the device. In the past, the last three digits of the device's serial number were used for the fourth part of this field, but as of 15/07/2019, the last two digits of the device's serial number are used for this purpose. The "DNS", "Gateway", 'Subset Mask" and "Port" fields are used for network connections. Once connected to the device, you can change these elements and then by selecting the "Set to ATM" option the changes can be saved.

The "Serial Number" is not changeable by a user and after connecting to the device, the last three digits of the device's serial is written in this part. The "Version" field displays the current version of the device and the "Minimum Version" field displays the minimum version that allows updating the “Firmware". In the "MAC Address" field, users can use the same software to connect to two devices. If the "MAC Address" of both devices is the same, it is necessary to change one of them. "MAC Address" of a device consists of 6 2-character parts. Enabling the "Enable Update Connection Date by Device" option causes the information of this part to be refreshed continually. If the user wishes to make and apply some changes in this section, they should uncheck the mentioned option and by clicking on the "Set to AMT" option, apply the changes.

The “Connect” button is used to connect to the device,

the “Refresh Connection” button is used to connect and disconnect the device once,

the “Disconnect” button is used to disconnect the device,

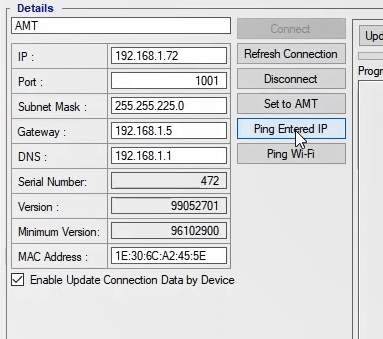

the “Ping Entered IP” button is used to check the authenticity of the connection to the device via LAN.

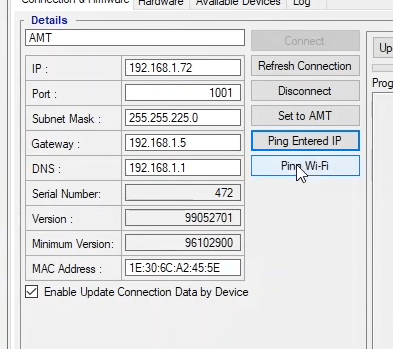

and, finally, the “Ping Wi-Fi” botton is used to check the authenticity of the connection to the device via "Wi-Fi".

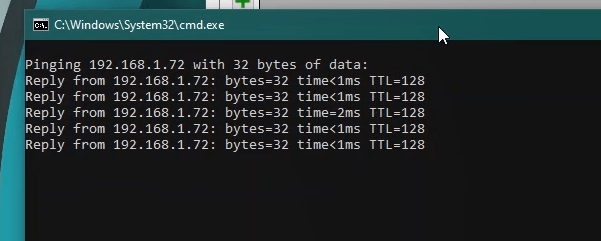

If the connection is made via LAN, by clicking on the “Ping Entered IP”, the IP which is entered in this section will be pinged.

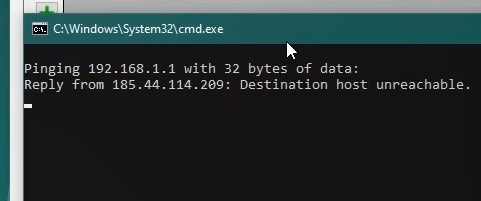

If the connection is made via Wi-Fi, by clicking on “Ping Wi-Fi”, this IP (192.168.1.1), which is specified for the Wi-Fi of all devices, will be pinged.

“Update Firmware” is used to update the firmware of the device which is, usually, done automatically after connecting to the device. If it didn’t happen automatically, the “Update Firmware in Flash Mode” must be used. How to use this option is explained in the related animation.

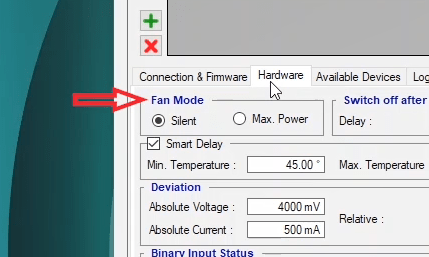

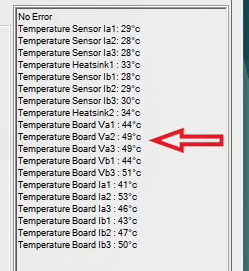

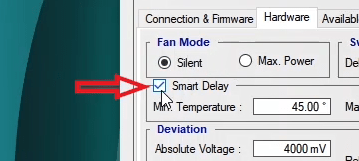

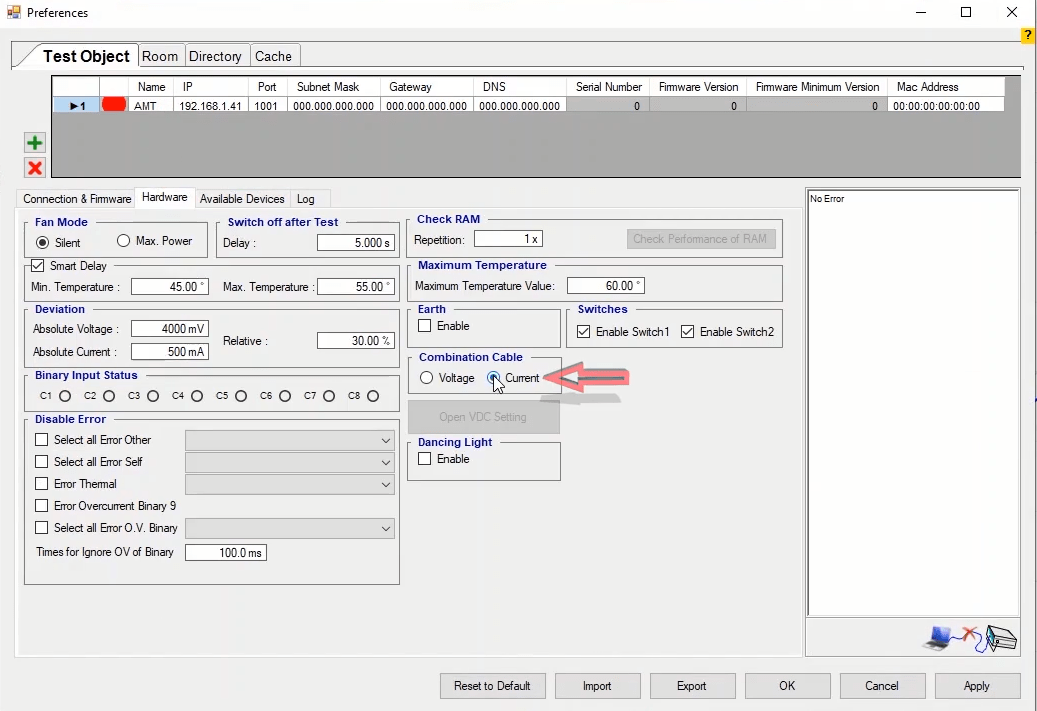

The general settings of the device are adjusted in the “Hardware” tab on the “Preferences” page. In the “Fan mode” section, selecting "Silent" will change the speed of the "Fan" depending on the temperature of the switches or heatsinks of the device which is displayed on this page. But, if the "Max.Power" option is selected, the fan of the device will work at its maximum power constantly.

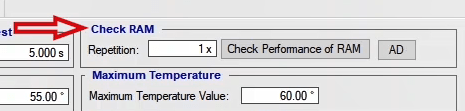

By activating the "Smart Delay" option, if the temperature of the device reaches 55 degrees, in the rooms such as "Distance" and "OverCurrent" where points are used for the test, the test will automatically pause and a message saying "Cooling" will be displayed on the bottom bar of the test screen. The test will not resume until the temperature reaches 45 degrees. The maximum operating temperature of the device is specified in the "Maximum Temperature" section. If the temperature of the device exceeds this value, the device will stop working completely. This value can be changed up to 70 degrees but, except for certain conditions, the user must not set the temperature above 60 degrees.

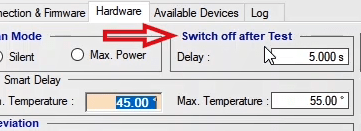

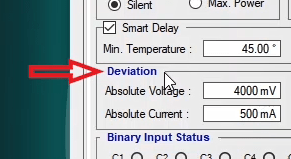

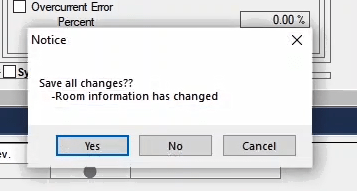

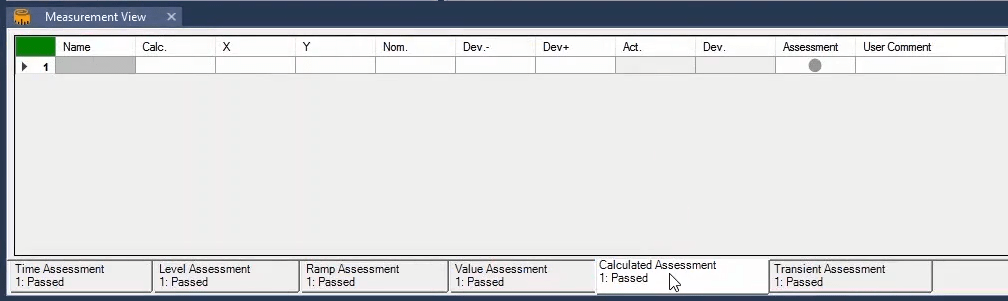

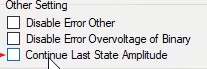

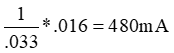

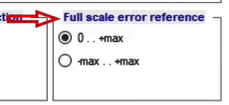

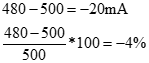

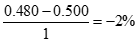

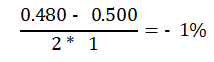

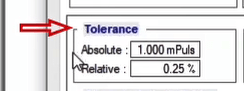

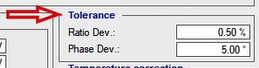

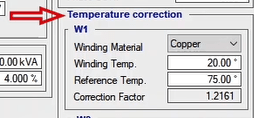

In the "Switch Off After Test" section, the user can specify how many seconds after the test is finished, the current and voltage switches should be opened. This number is set to 5 seconds by default but it can be increased up to 10 seconds.In the "Deviation" section, the reporting conditions for “Other” errors can be specified. By default, it is specified in the software that if there is a difference between actual voltage of the device and value specified in the software exceed 4 volts or the current difference goes over 500 mA, the “Other” error should be displayed. In the "Relative" section, this value is specified as a percentage of the value specified in the test. In the actual operating mode, the device uses the lowest value among these two for the error message.

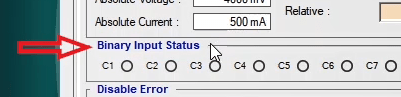

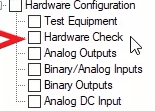

In the "Binary Input Status" section, it is specified which binary is connected and which binary is not.

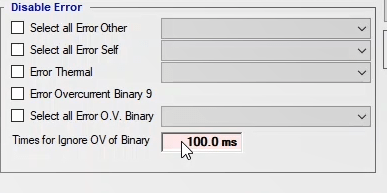

In the "Disable Error" section, a list of possible errors of the device is available and you can disable them.

"Select All Error Other": this error is displayed when the device is unable to produce the current and voltage asked by the user. The cause for this error can be the voltage outputs' short circuting or the current outputs' open-circuting. By opening the drop-down of each errors’ fields, any error can be disabled for a number of voltage and current outputs.

"Select All Error Self": every time before running the test, the device checks its internal hardware to determine whether it is capable of generating +50V or -50V of voltage and +5A and -5A of current. If there is a problem, the device displays a "Self" error.

"Error Thermal": this error is displayed when the temperature of the device's sensors is increased. Occasionally, the thermal sensor of one of the switches has a problem, indicating irrational temperatures such as 800 degrees. In this case, in the slider of this section, it is possible to deactivate the thermal error to continue working with the device.

"Error Over Current Binary 9": the binary 9 of the device can measure the current up to 500mA. If the input current of this binary exceeds this value, this error is displayed.

"Select All Error Over Voltage Binary": depending on the duration specified for them, if their input voltage exceeds the specified limit, the binary inputs of the device will display this error. For instance, in the 4.5V mode, if the input voltage of any of the binaries exceeds 4.5V, the device will display this error.

In the "Times For ignoring Over Voltage Binary" field, the maximum time allowed to ignore the "Over Voltage" error of the binary is specified. By default, it is set that if the time for the "Over Voltage" error is not shorter than 100 milliseconds, the device will not display any error about this matter.

This should be noted that, since "Thermal Error" and "Error Over Current Binary 9" are among the fatal "Errors" of the device, their deactivation setting will not be saved by the software and will be disabled each time the software is run, then if this "Error" needs to be disabled, the user must do this manually. The "Check RAM" section is used for testing the RAM that is used in the “AMT”. In the "Repetition" field, the number of times that a series of data are written in the RAM and erased is specified. This section can be used in case of uncertainty about the performance of the device's RAM. Since the writing and reading operations are performed on the RAM multiple times, eventually, if there is a problem in this process, the error light on the panel of the device will turn on.

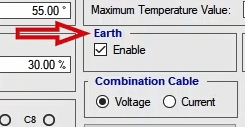

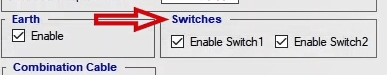

In the "Earth" section, it is possible to enable or disable the "Earth" error of the device. If the "Enable" option is checked, it is necessary to connect the "Earth" cable to perform the test. Otherwise, an “Earth” error will be displayed and the device will stop working. This error can be deactivated by unchecking the “Enable” option. But, it is vital to note that, doing so during the test can be lethal and as it is ,also, stated in the displayed message, Vebko company will not be responsible.

It is possible to activate or deactivate the main hardware switches of the device in the “Switches” section. The switch number 1 is related to the voltages and currents of the group A output. The switch number 2 is related to the voltages and currents of the group B and VDC. By deactivating every switch, all outputs of that switch will be deactivated.

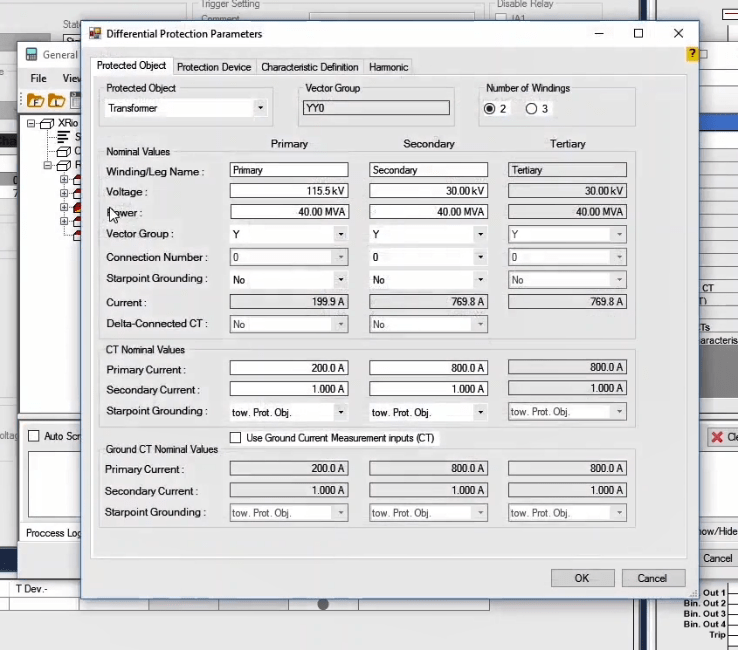

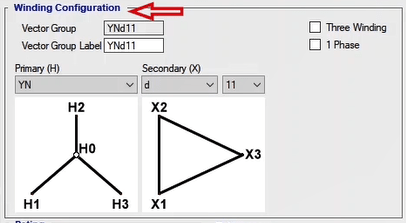

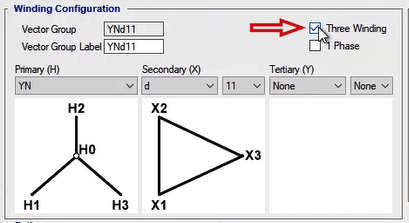

In the "Combination Cable" section, if the "Voltage" option is selected, the outputs of the Neutrik cable will include three current and three voltage phases. But if the "Current" option is selected, the output of the cable will consist of two three-phase current groups which are used for various tests such as differential test.

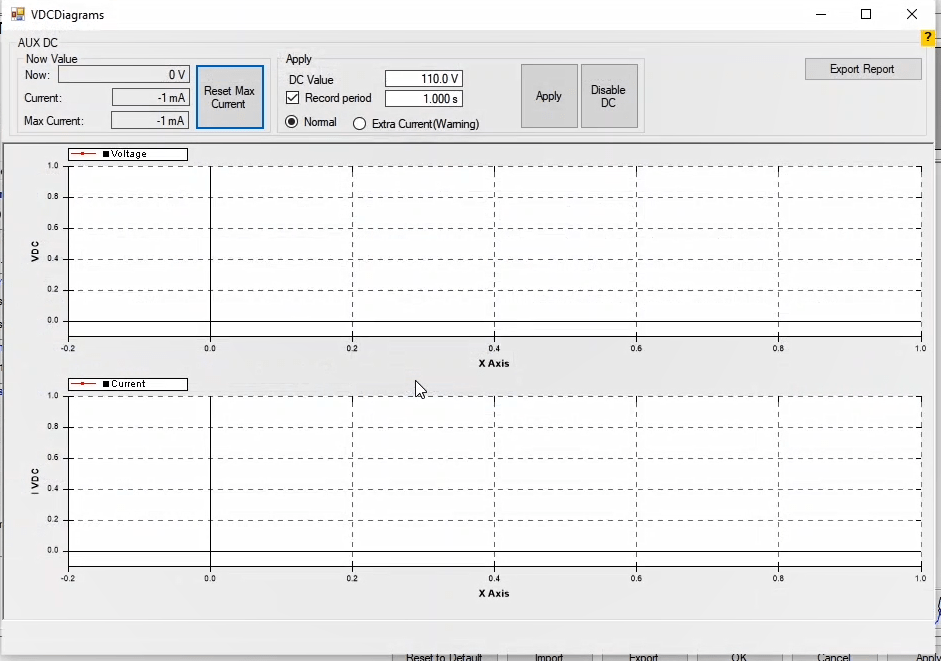

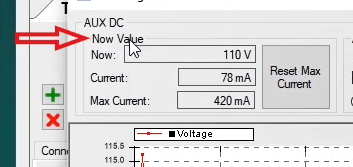

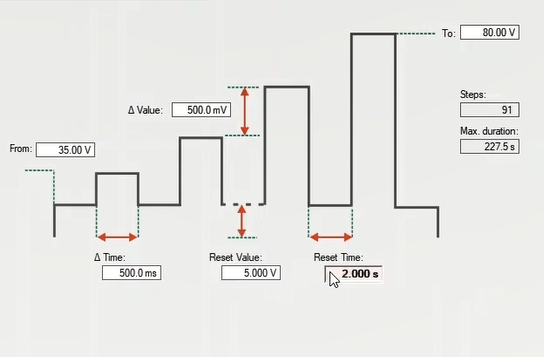

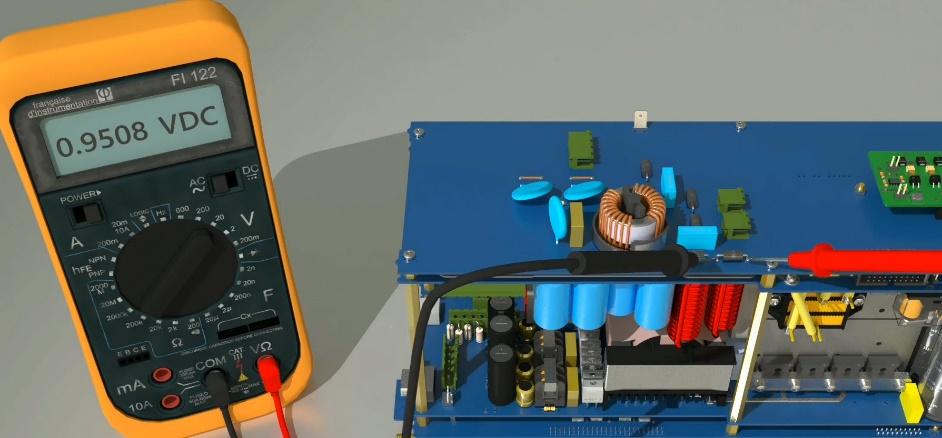

The "Open VDC Setting" option is used to enable the DC output voltage of the device. By clicking on this option, the "VCD Diagrams" page opens. On this page, in the "DC Value" field of the "Apply" section, the output DC value of this port is specified. This value can be set up to a maximum of 212V DC. By clicking on the "Apply" option, the "AUX DC" port of the device will inject the amount that is specified in the "DC Value" field. The "AUX DC" output can be disabled by clicking on the "Disable DC" option. By activating the "Record Period" option in the next field, a duration of time is specified for recording the output signal of this port.

In the "Now Value" section, the amount of current and voltage produced by the "AUX DC" port is displayed. The "Max Current" field shows the maximum current pulled from this port. In the following two diagrams, the instantaneous amounts of voltage and DC current of this port are indicated. It is also possible to save the settings set on this page as a PDF file by clicking on the "Export Report" option. To reset and update the amount of the current displayed in the "Max Current" section, you can click on the "Reset Max Current" option.

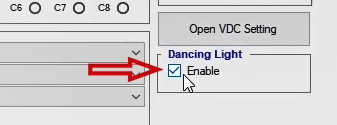

By checking the "Dancing Light" option, the LEDs in front of the device will turn on in a dancing manner. This operation is to test the healthy "LED" binary inputs of the device.

The "Start" page of the software is the first page that the you face when the software is opened. At the top right is the version name of the software ("Stable", "Test") as well as its version number. If a new version of the software is provided by Vebko, when you are connected to the internet, an option, saying "New Version is Available" will appear at the top right. By clicking on this option, you can download and install the latest version of the software. Clicking on the "What's New" option opens a page in which the fixes or the features added to different versions of the software are displayed. For preparing these versions, first, Vebko experts present the software problems and suggestions to the software group. Then, after evaluating and correcting this group, the new features are displayed in detail on this page.

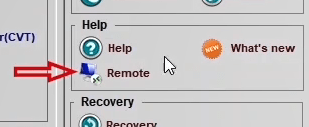

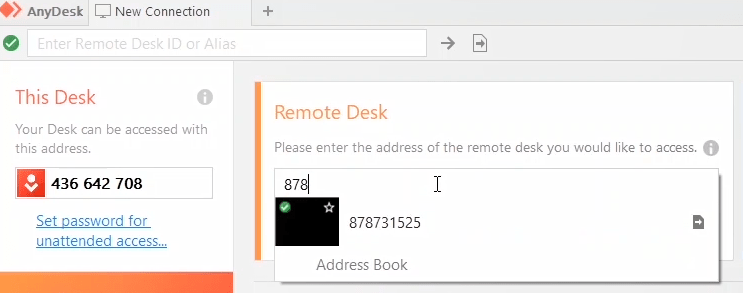

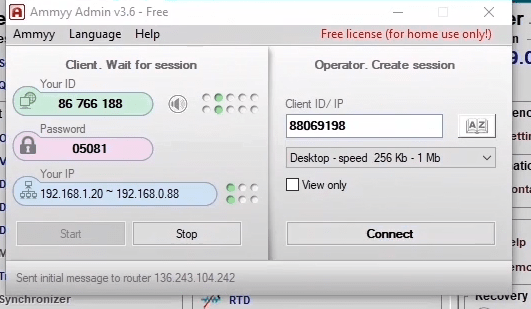

By clicking on the "Launch Remote Help" option, you can connect to the online software support via one of the two available methods of "AnyDesk" or "Ammyy Admin". For using AnyDesk, first, the user needs to give the 9-digit number called AnyDesk ID, which is available at the top left of the "New Connection" page, to the supporter. Then, the supporter will enter the code in the "Remote Desk" section and press "Connect" to connect to the user's "Desktop" page.

Also, by clicking on "Ammyy Admin", the "Ammyy Admin-Free" page opens. Then, the user needs to give their "ID" and "Password" to the supporter. After that, the supporter will enter this information and connect to the user's desktop.

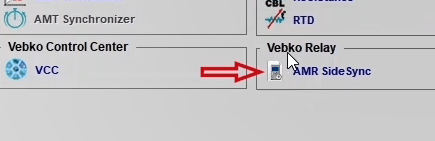

The "Relay Modules" section contains the special software for Vebko’s relay. In the "Tester Modules" section, different relay test rooms are on the left while equipment test rooms are on the right.

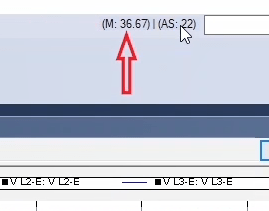

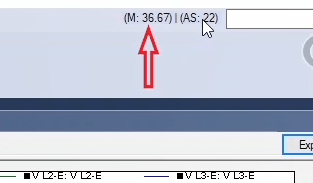

You can adjust the settings for all test pages by clicking on the "Preferences" option. In all rooms, you can see two letters and numbers at the top right of the screen:

1- "M" means that how many megabytes of the ram is occupied by this page.

2- "AS" which is "Auto Save" means that if you make a change to the file, after passing the time that is specified in front of this option, the software automatically saves the status of the file and if there is a previous file, the new file replaces the existing one. After the filed is saved, a message saying "Auto Save Done" will be displayed at the bottom of the page.

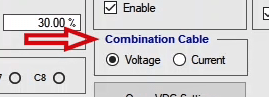

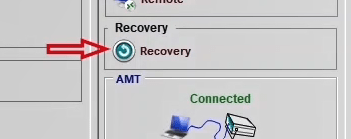

The software repeats this saving process every 30 seconds which can be changed in the “Auto Save” section in the "Room" tab on the "Preferences" page. This saved file is displayed in the "Recovery" option. If the software crashes for any reason, by clicking on the "Recovery" option, you can recover and view the last saved version of your file. This is an advantage for the software because the "Ctrl+Z" key combination recovers the changes based on this 30 seconds and if the software crashes, the test file will not be destroyed.

By clicking on the "Security", two options open. "Clear Cache" option which is used to clear the cache of the software.

When you install the software for the first time, you should click on the "Open Source Location" option to run both "AMPro Application" and "AMPro APP Launcher" files as an administrator. To do this, right-click on the mentioned files, then select "Properties" and in the "Compatibility" tab, check the "Run this program as an administrator" option. After that, you can close the window.

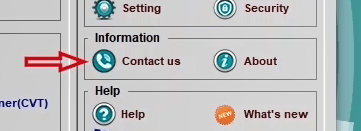

The "Contact us" option provides you with ways to connect with experts at Vebko.

The "About" option, provides the user with information about Vebko company.

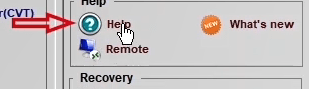

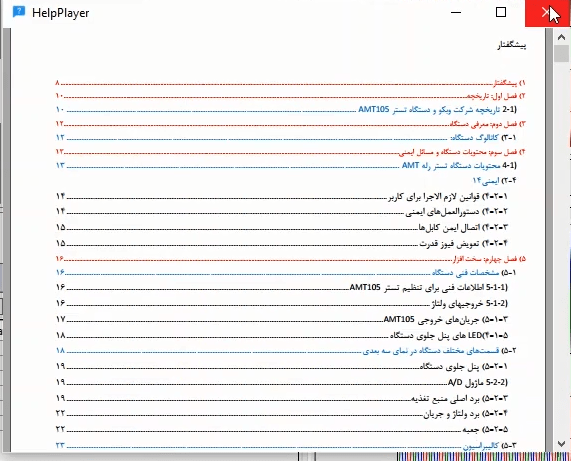

By clicking the "Help" option, provides the user with the reference manual and of the tester and the software.

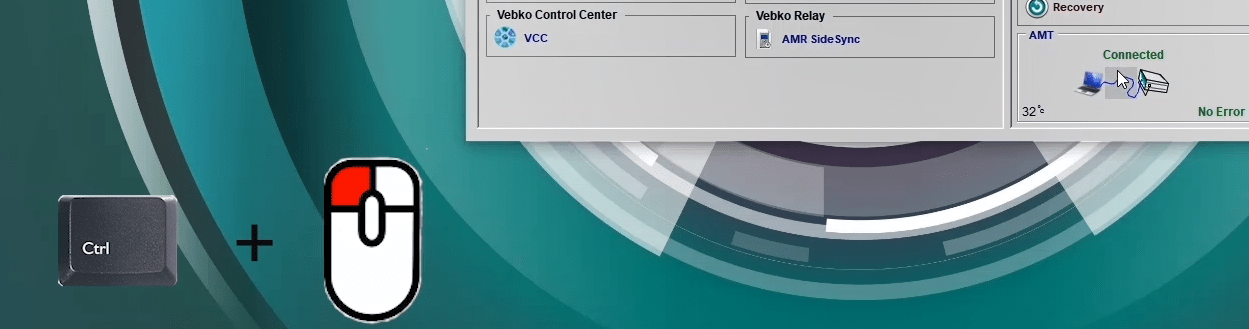

Various tasks are performed in the "AMT" section. You can directly connect or disconnect to the device by holding on the "Control" button and left-clicking on this image. The figure in this section indicates the connection status to the device. By double-clicking on this section, it is possible to enter the "Preferences" page directly. If you want to connect to multiple devices at the same time, right-click on this section and select the device name to connect to it. By doing this, the device name will appear on the left of the screen.

Generally, there are two types of testing rooms available on the main page of the software.

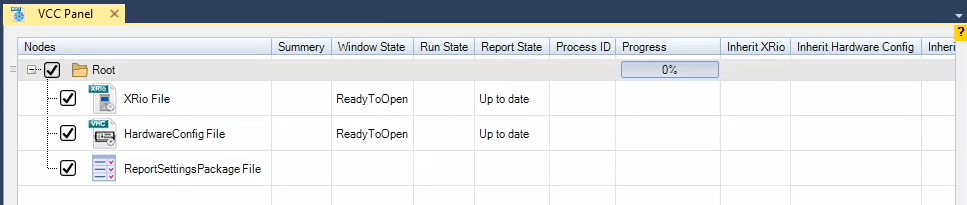

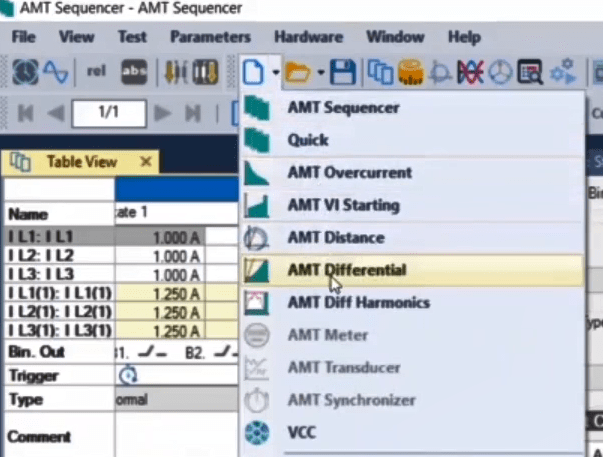

The “VCC” room: this room provides you with a place to perform a series of different tests. Also, it is possible to perform several tests from different rooms in a continuous manner in this room.

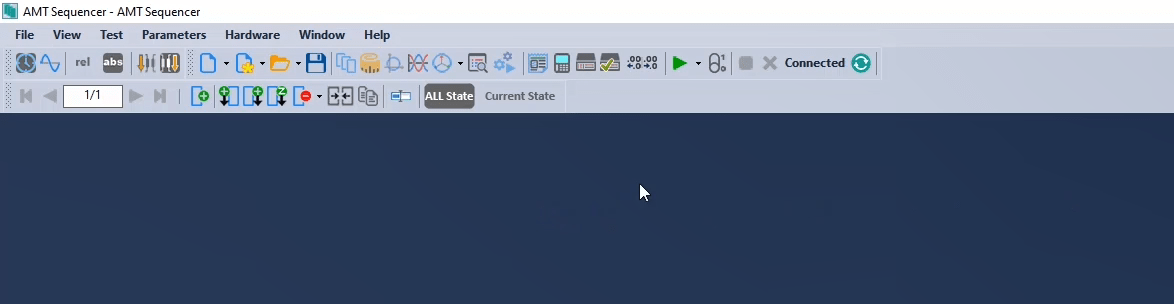

The other rooms including “AMT Sequencer”, “AMT Distance”, “AMT Transformer” and “AMT Differential”, have the same main page. The only difference is that in these rooms, a few features are made hidden or shown according to the needs. For example, in the “Hardware” section in the “Sequencer” room, there is an option for “Calibration” but in the same section in the “Distance” room, this option is not available and has been made hidden.

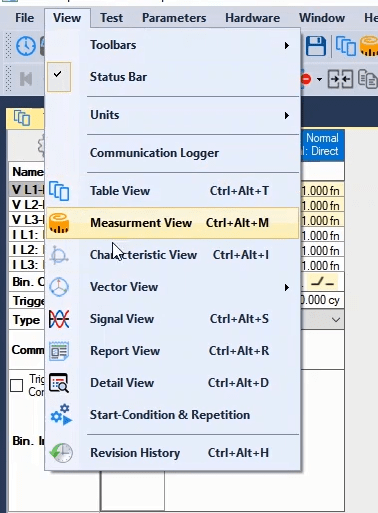

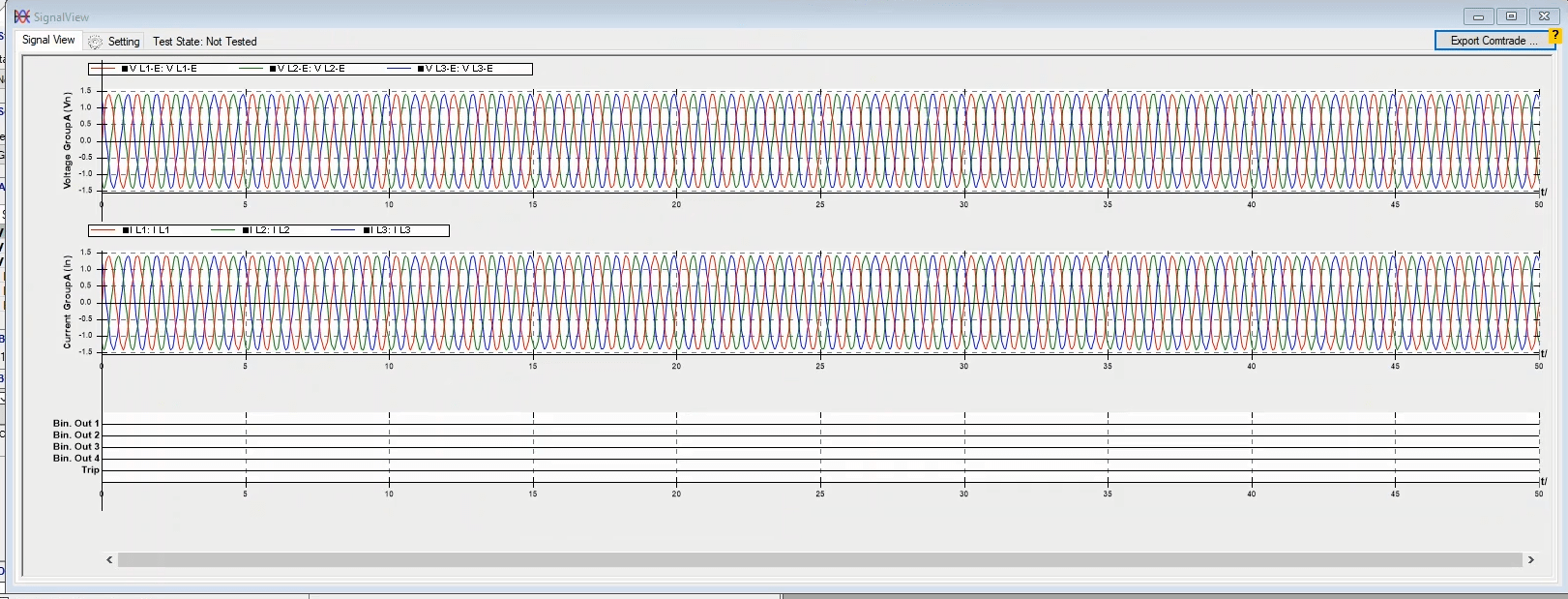

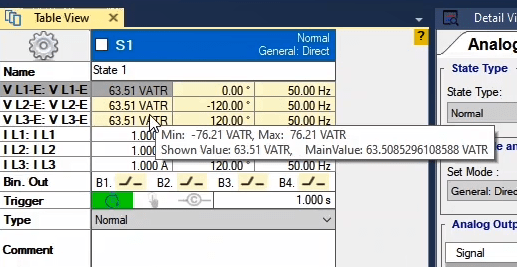

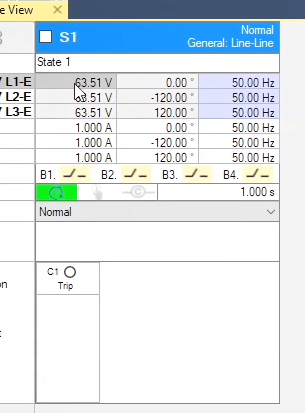

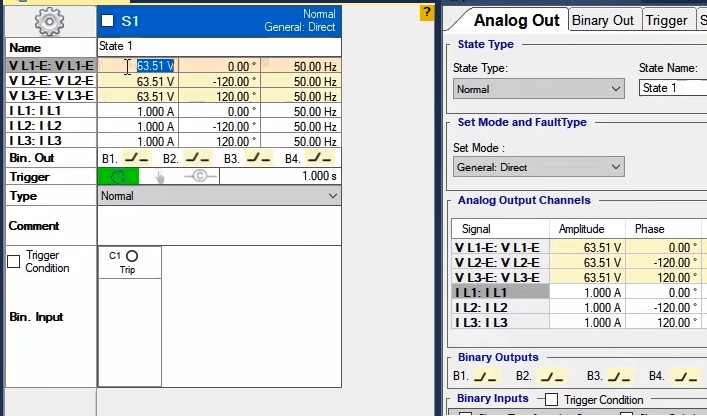

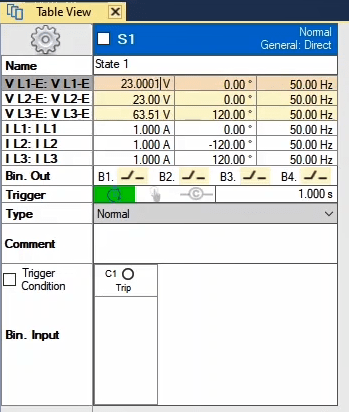

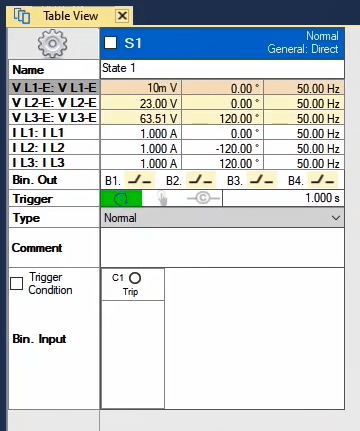

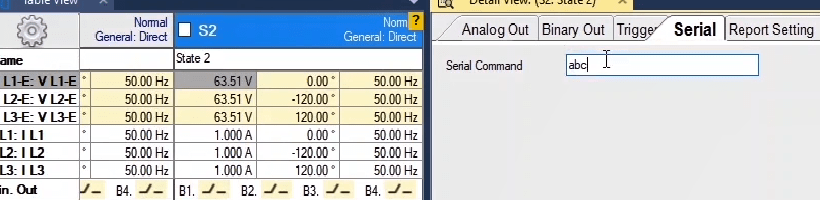

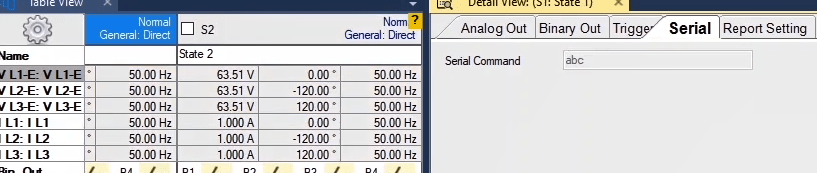

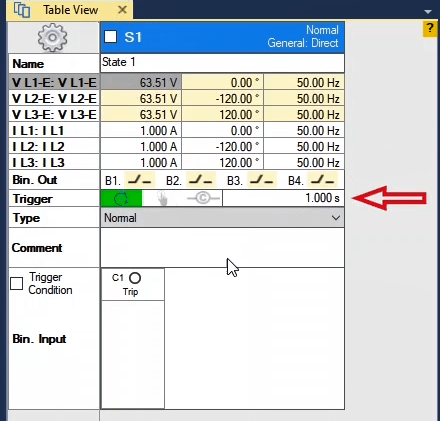

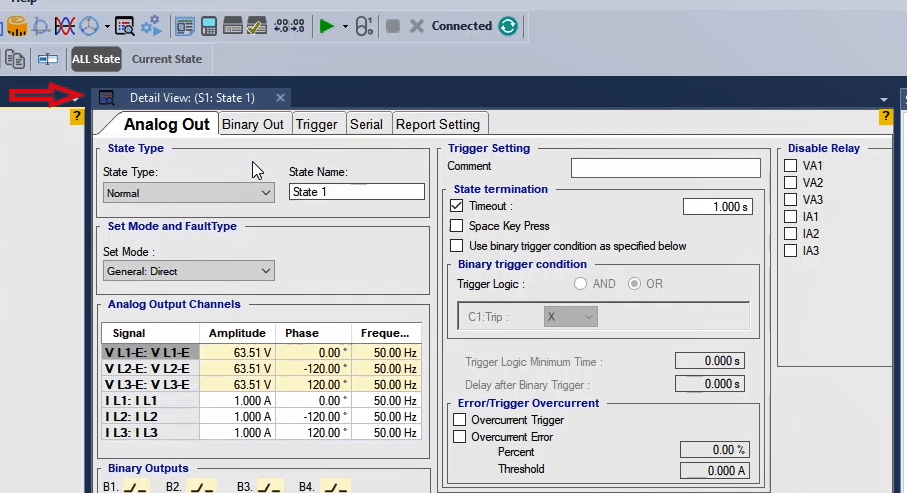

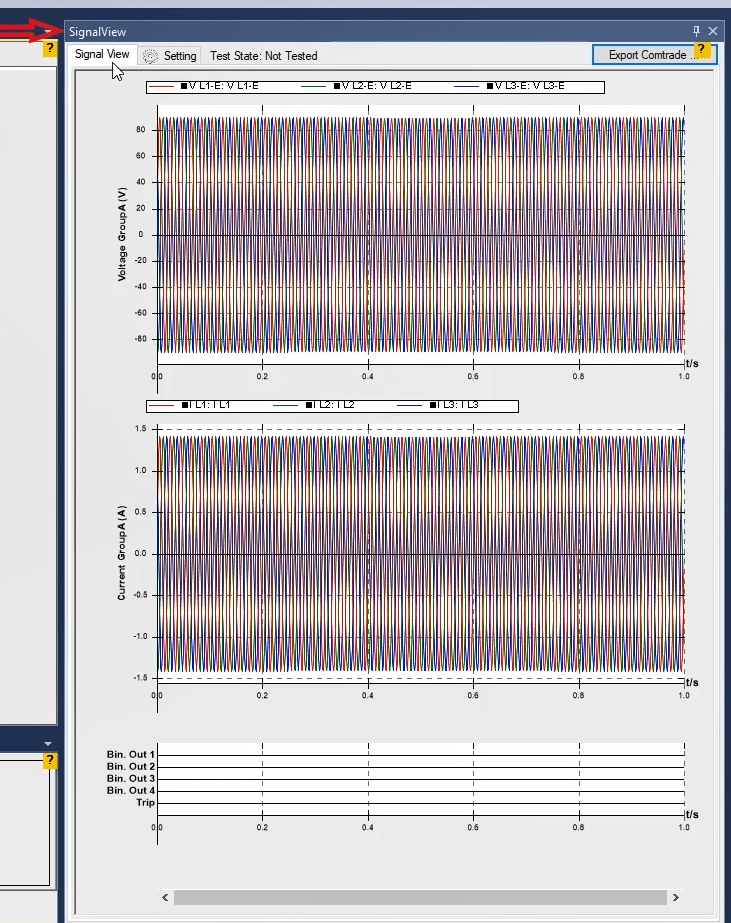

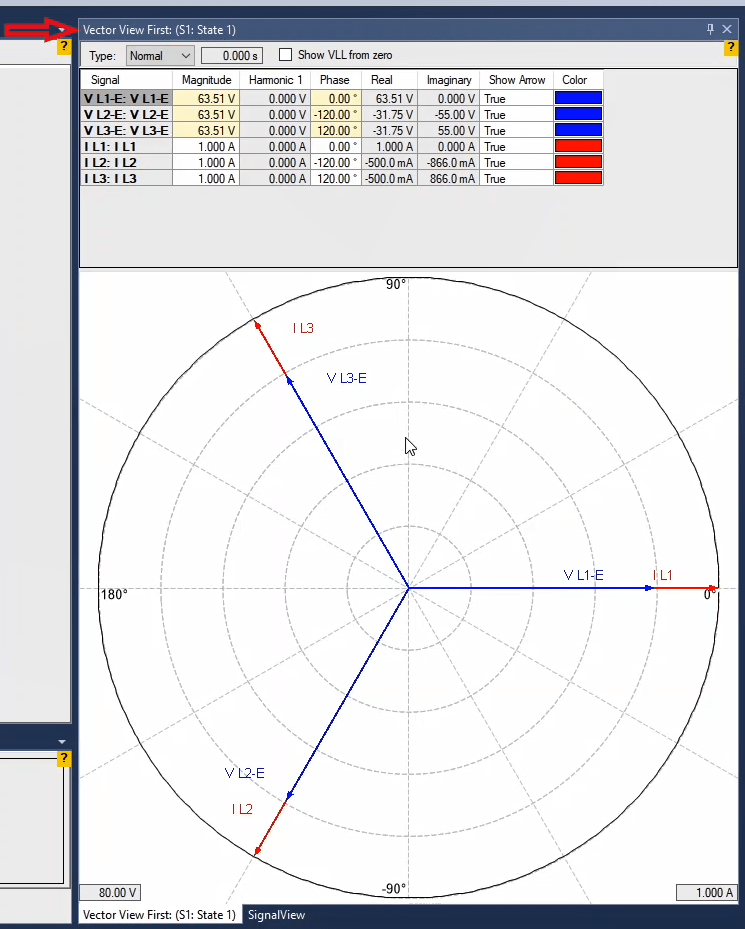

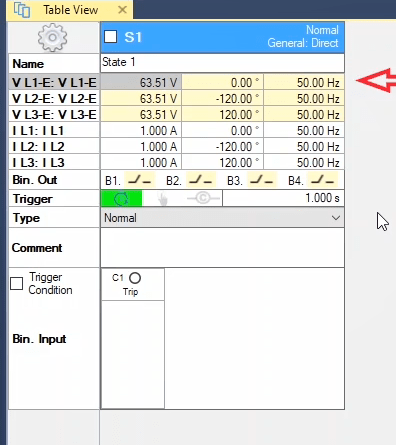

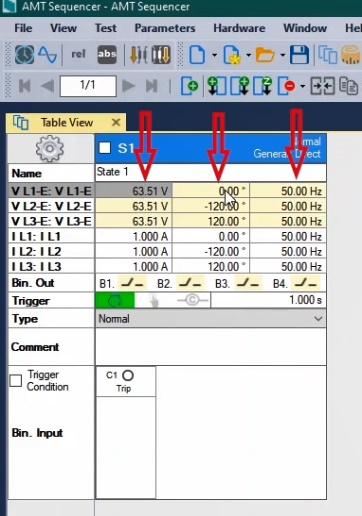

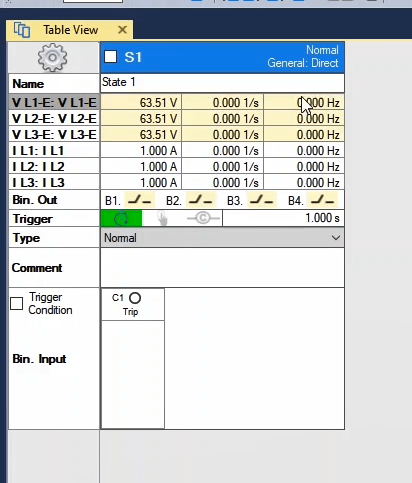

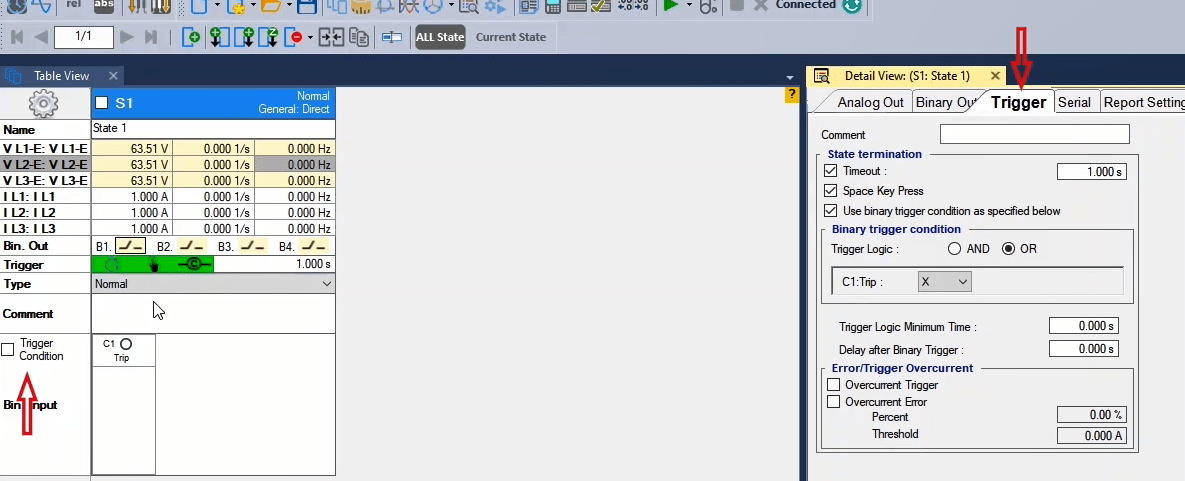

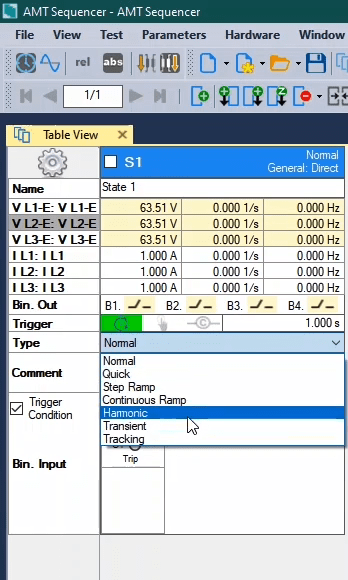

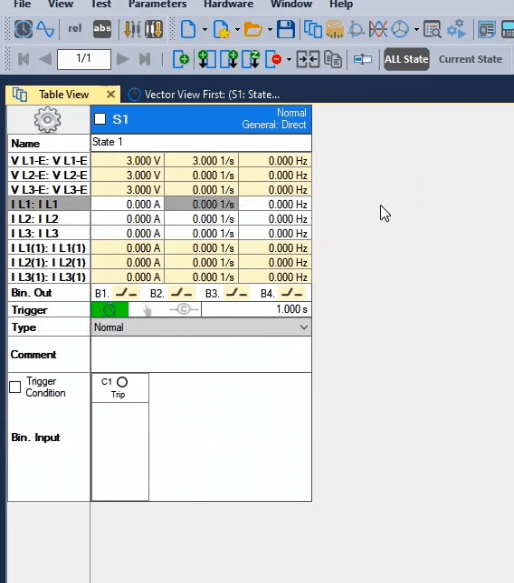

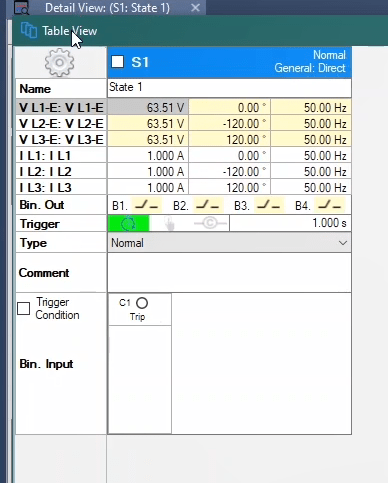

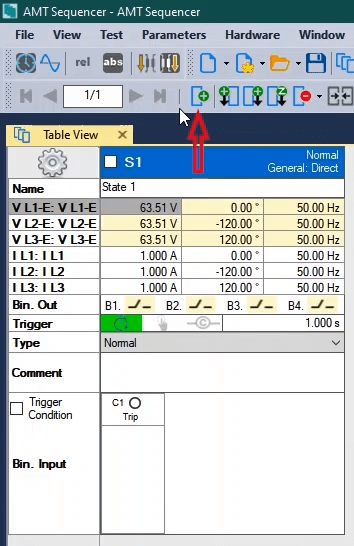

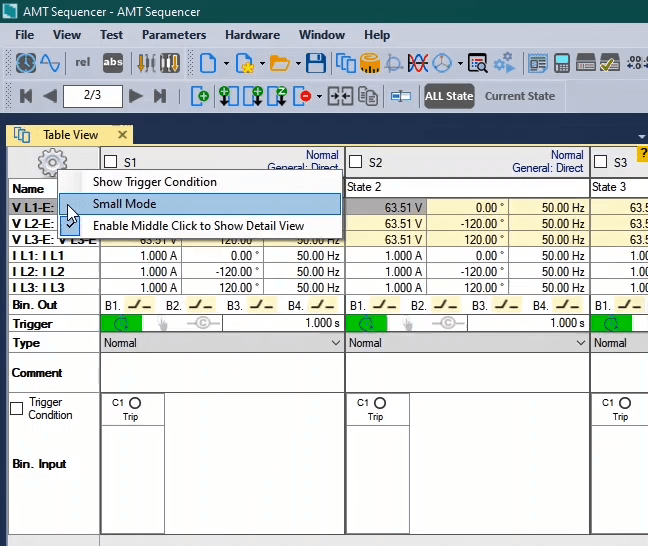

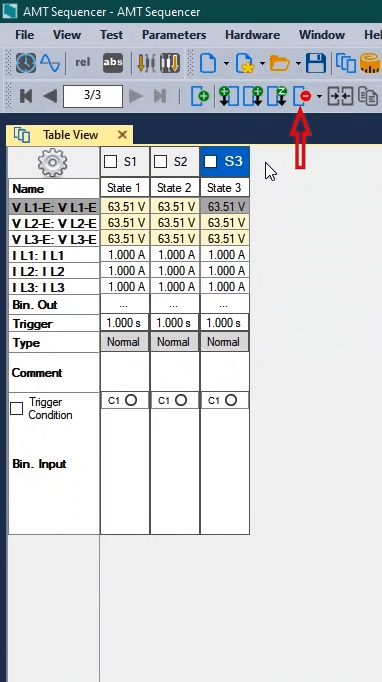

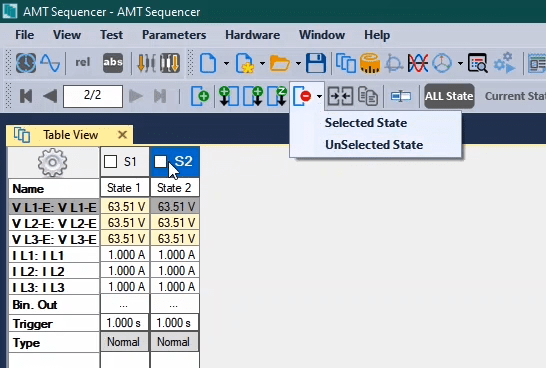

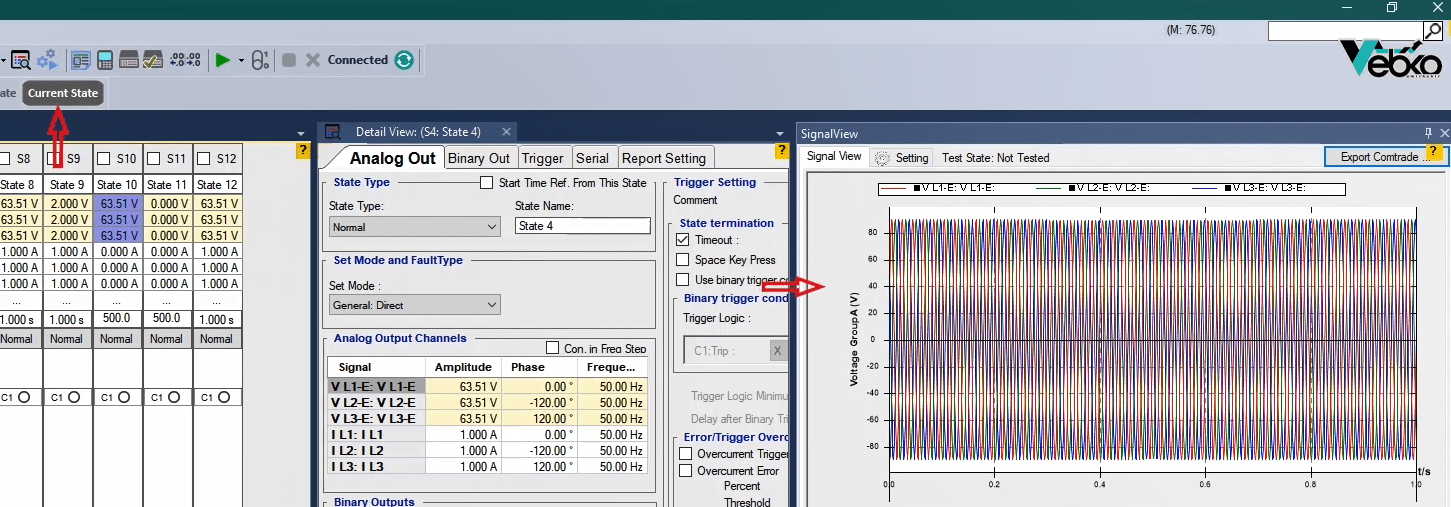

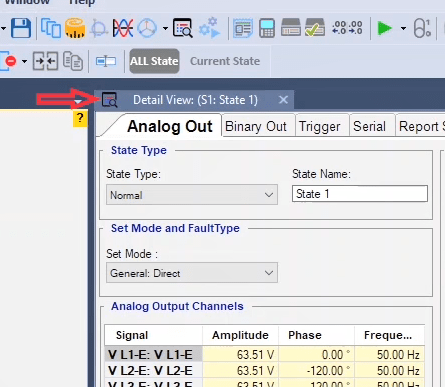

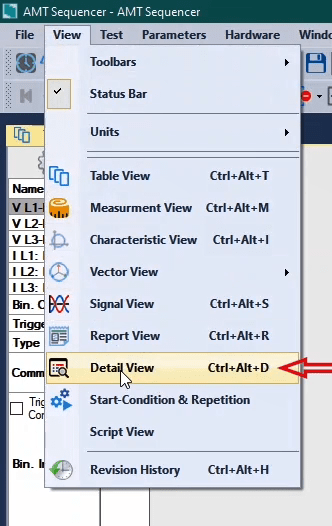

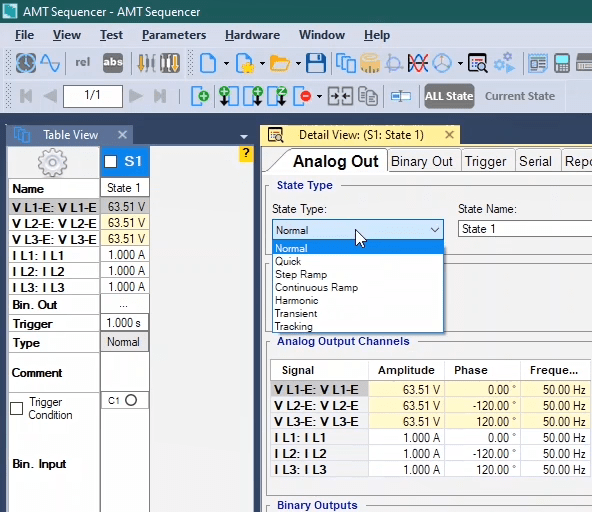

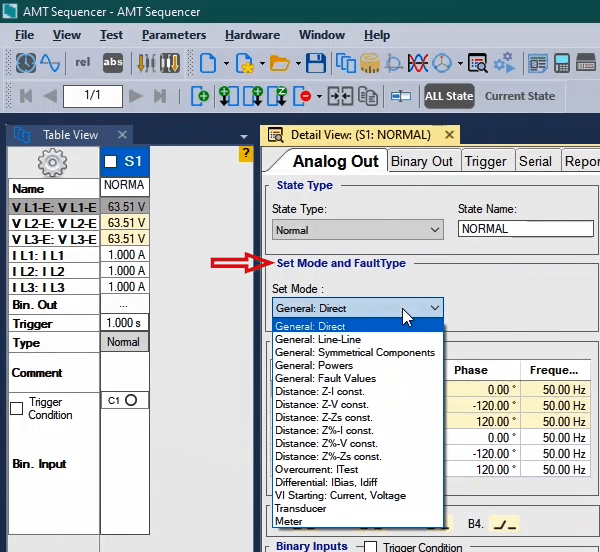

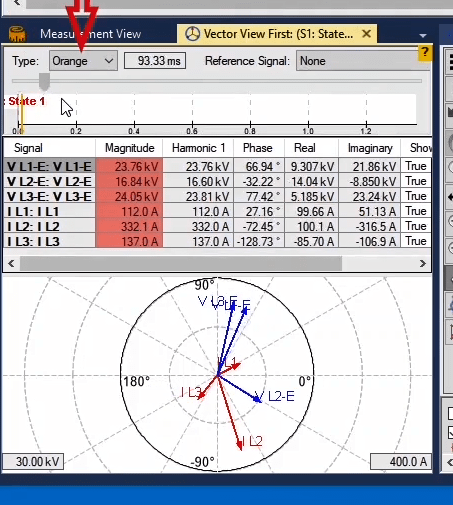

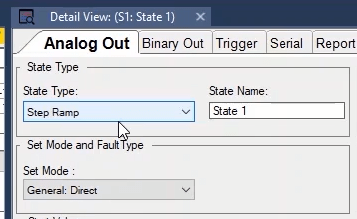

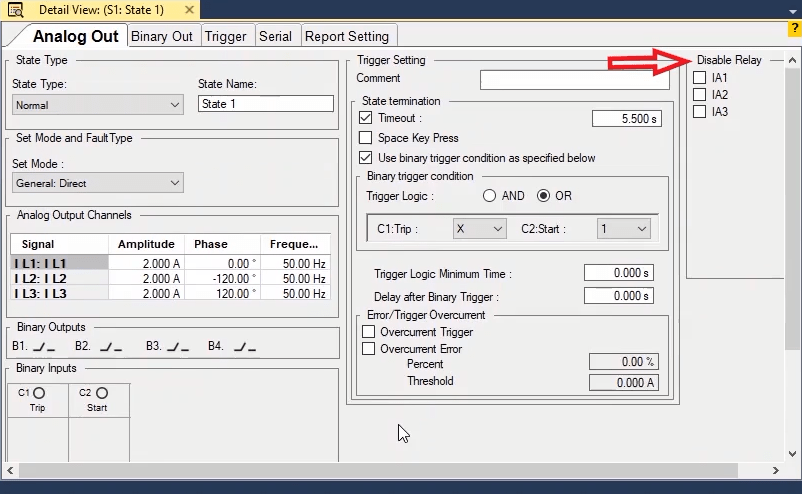

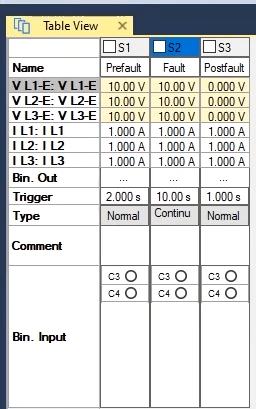

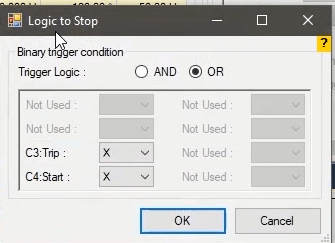

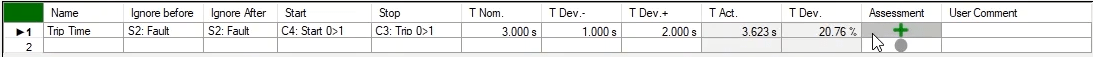

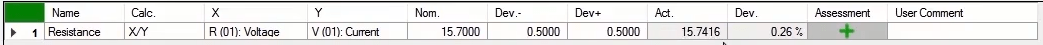

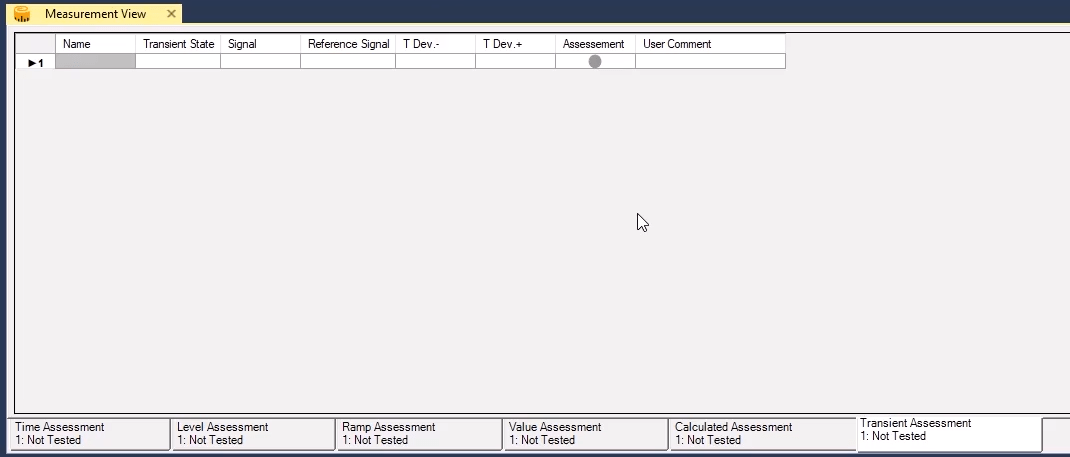

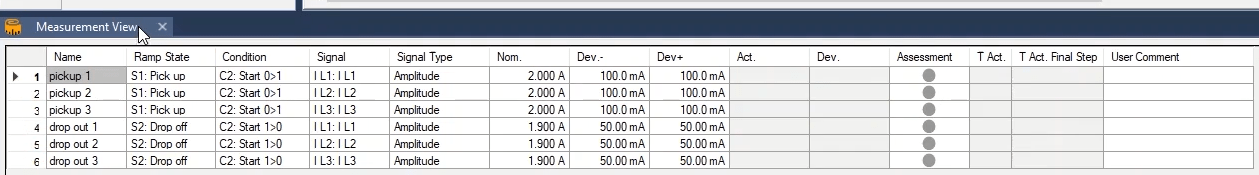

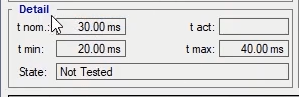

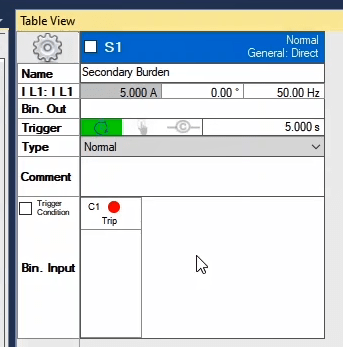

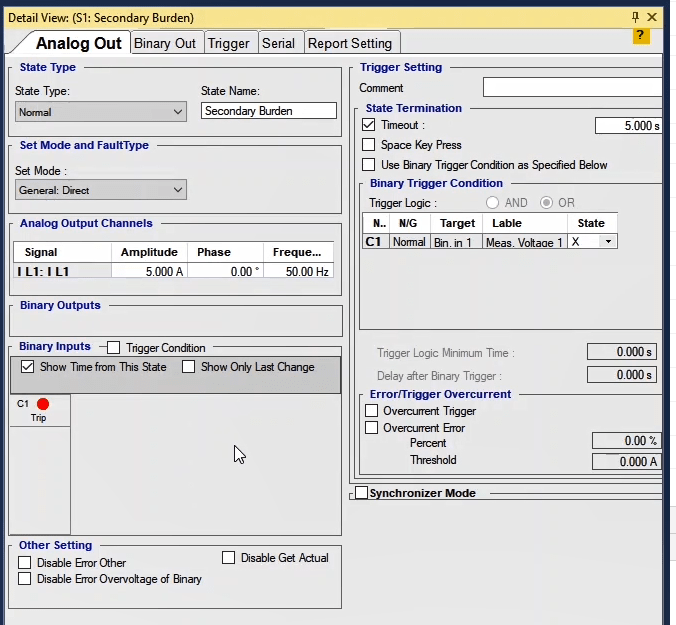

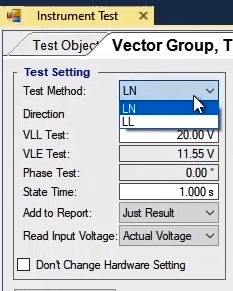

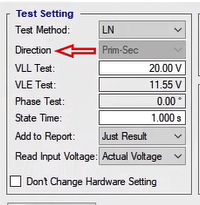

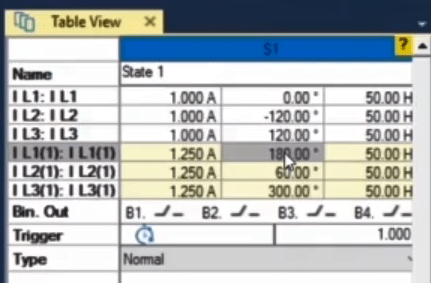

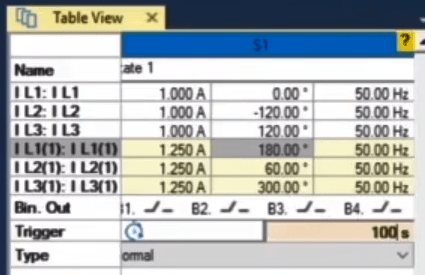

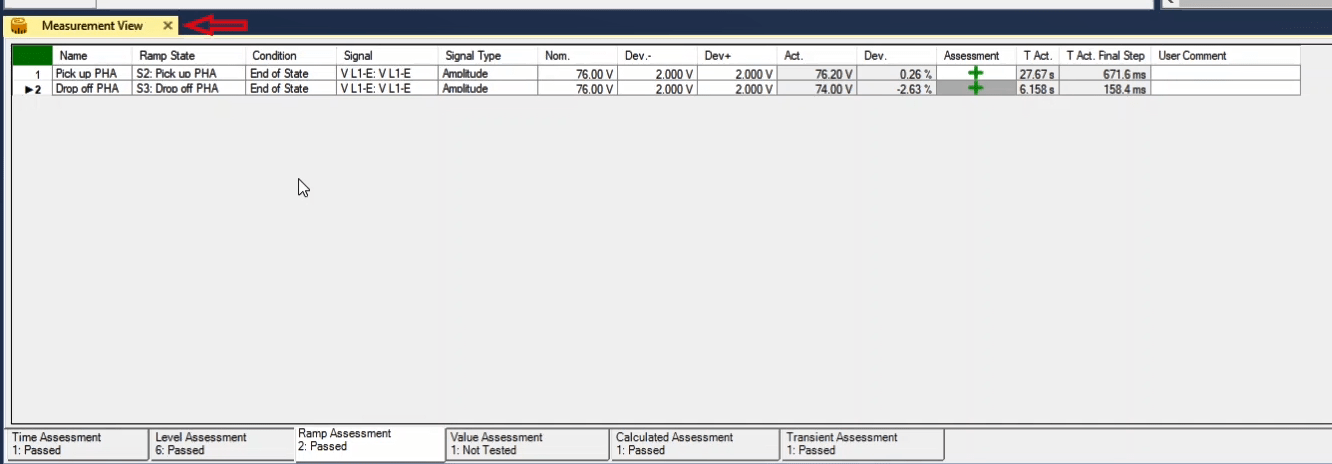

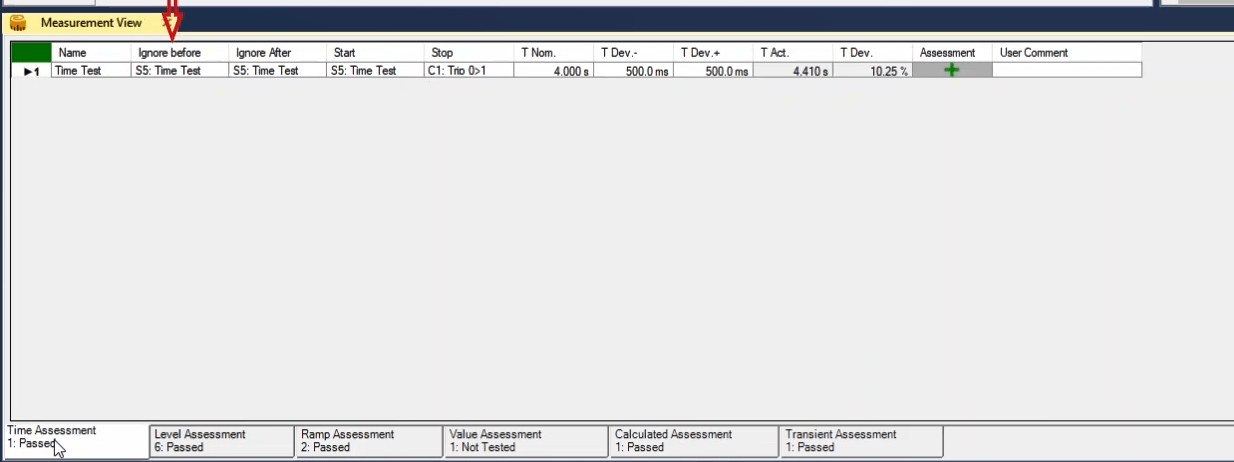

All necessary features for performing different tests are available in the “Sequencer” room. “Table View”, “Detail View” and “Measurement View” are the important windows of this page while the “Table View” and “Measurement View” are not available in the other rooms. Also, the “Detail View” window in this room is different from the “Detail View” in the other rooms like “Distance”.

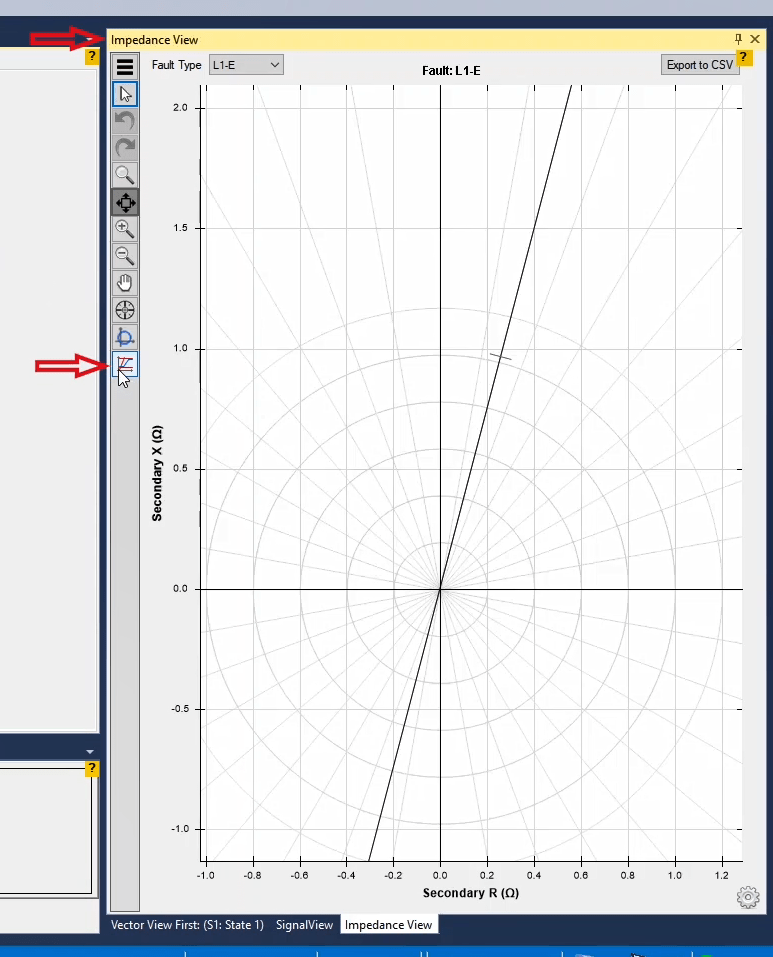

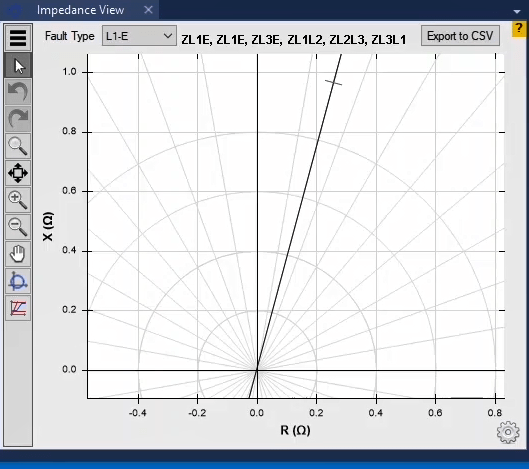

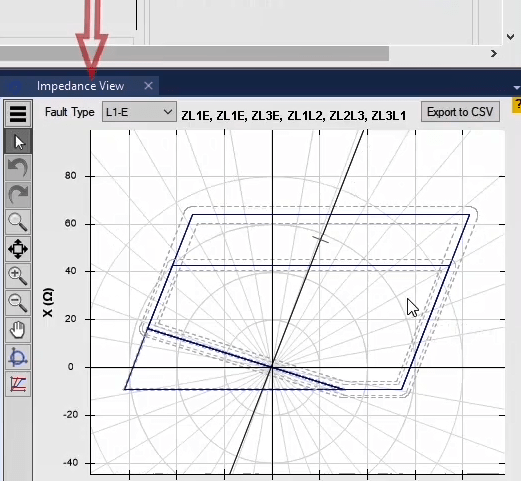

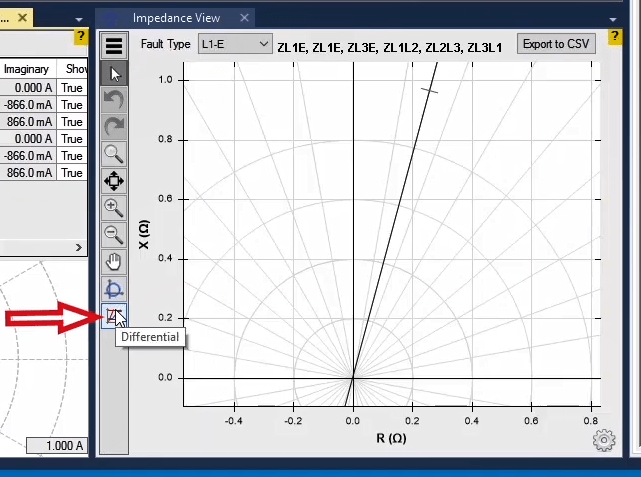

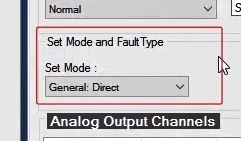

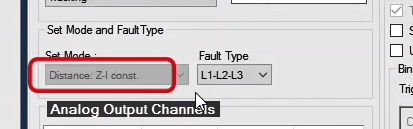

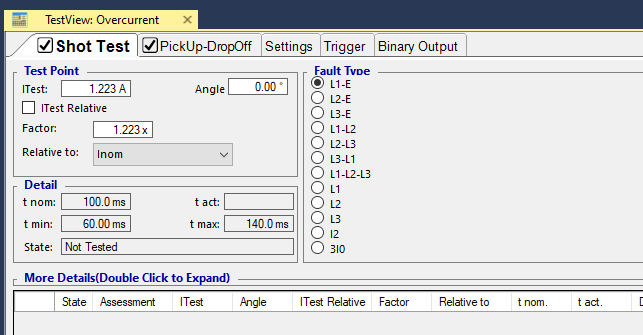

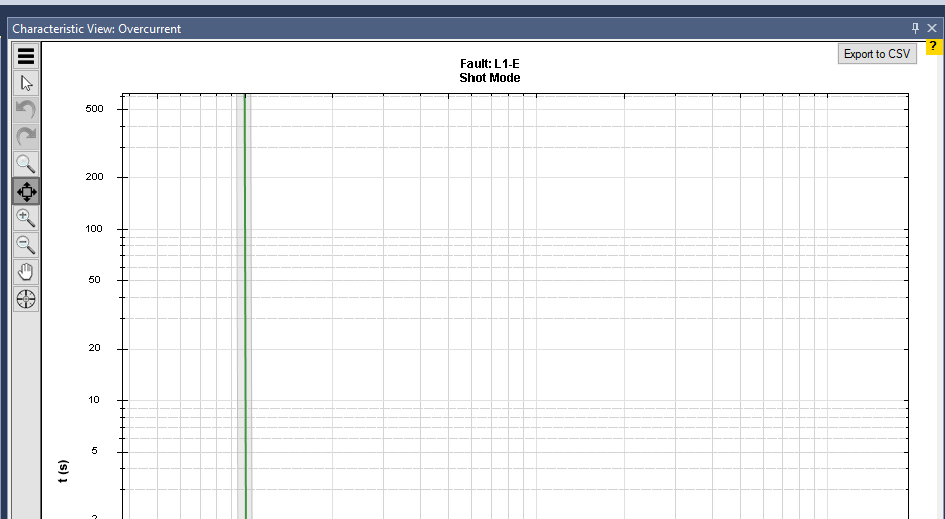

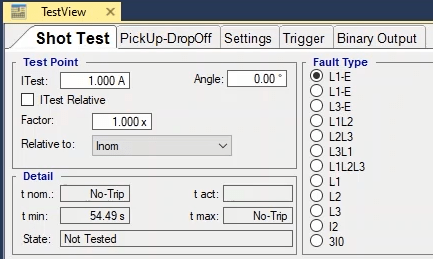

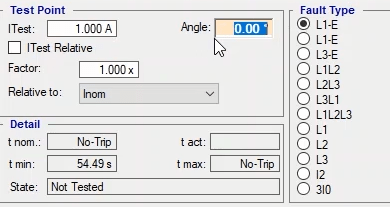

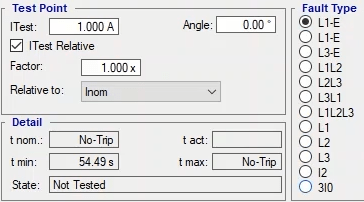

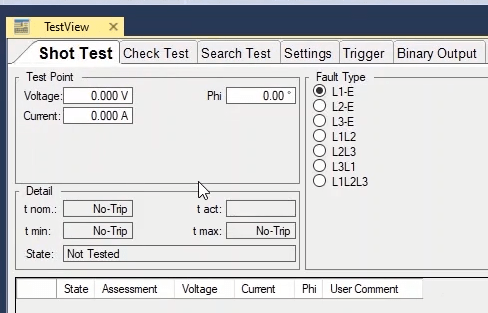

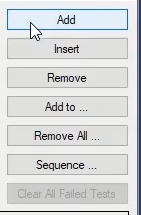

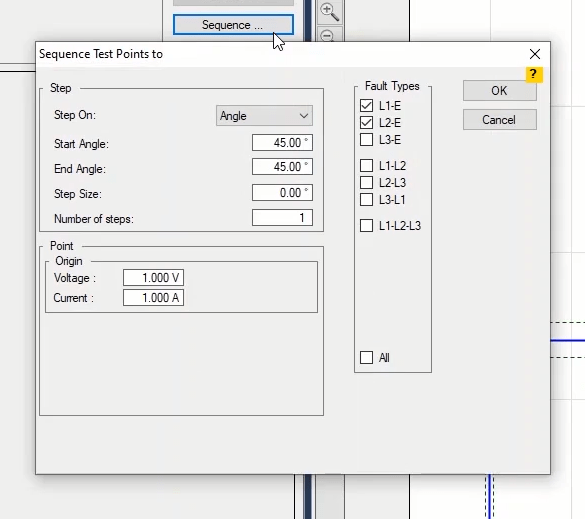

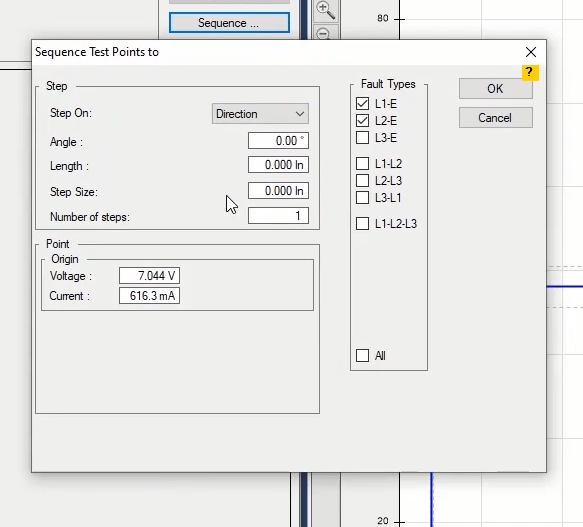

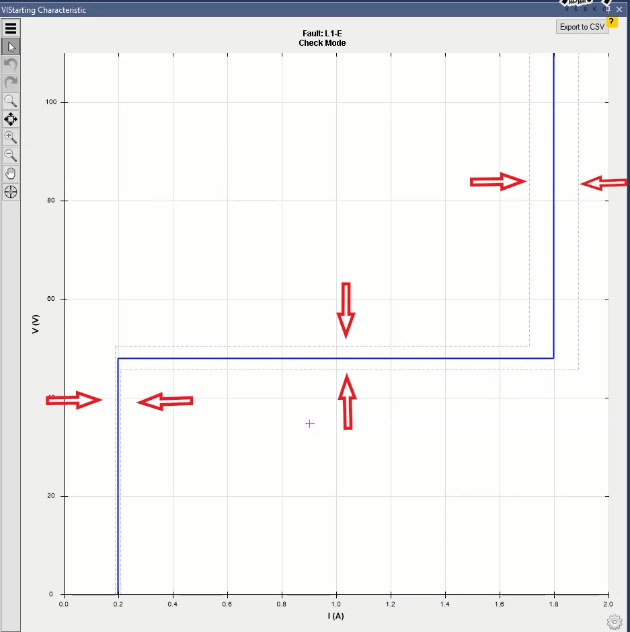

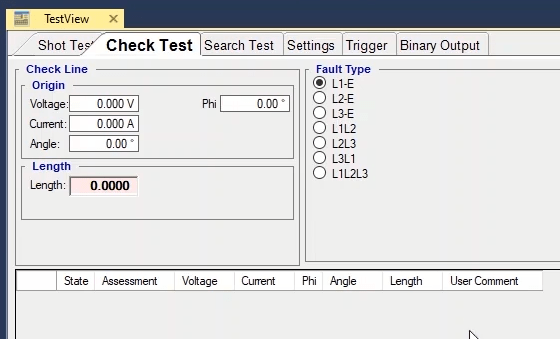

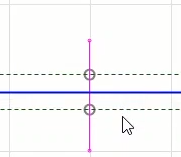

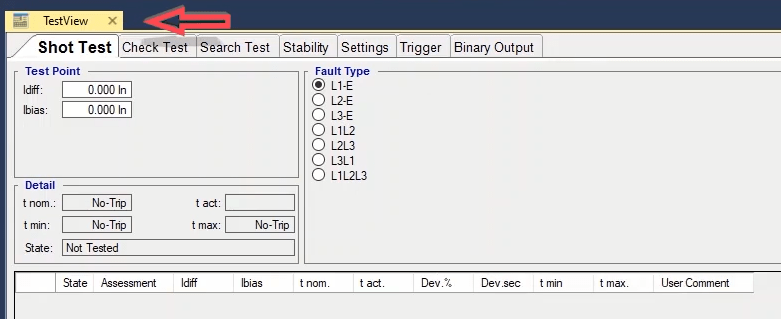

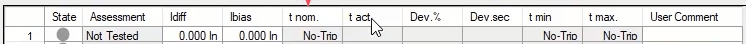

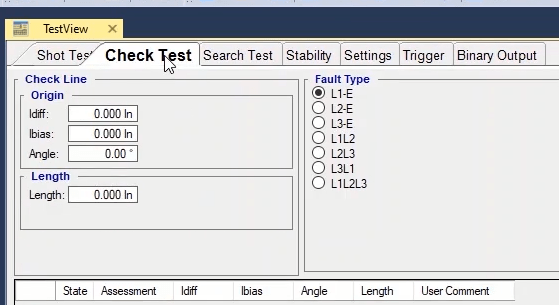

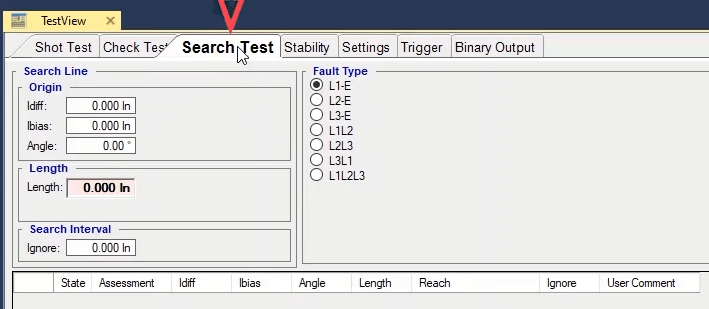

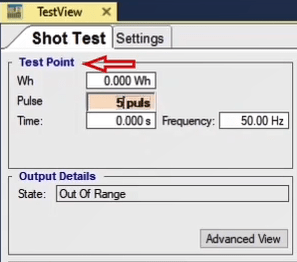

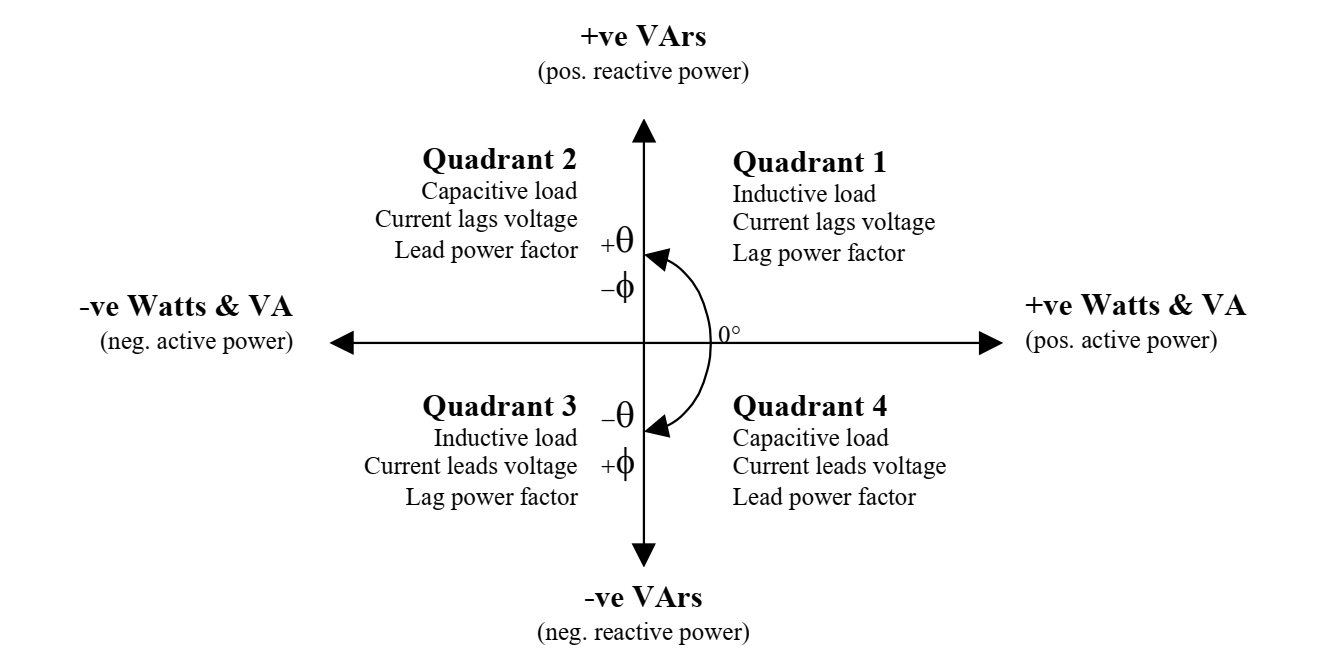

In rooms like “Overcurrent”, “Distance” and “Differential”, which are also called the “Medium” rooms, the “Table View” and “Measurement View” windows are not available but instead, the “Test View” window is available in these rooms. Generally, the “Test View” window is the same in all “Medium” rooms. In the “Test View”, some options are made hidden or shown according to the needs. For example, in the “Differential” room, the “I diff” and “I bias” fields are available, while in the “Distance” room, the “[z,Left:0,Top:0,Right:0,Bottom:0,Scale:50%]” and “phi” fields are available.

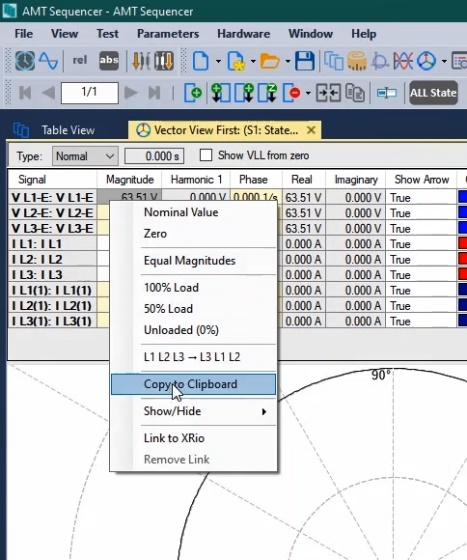

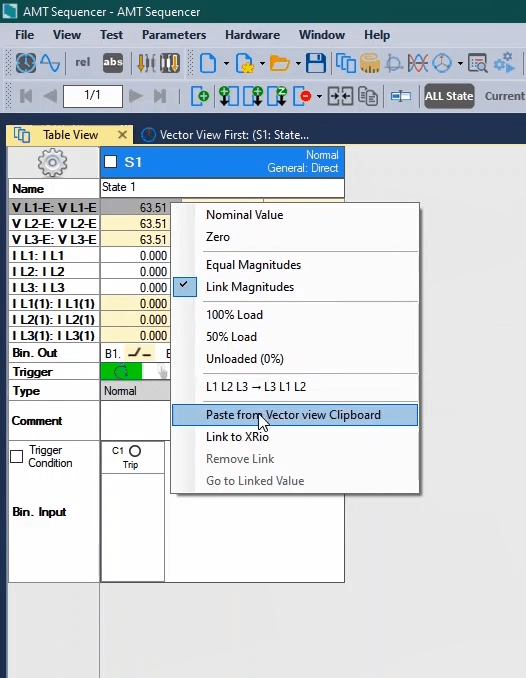

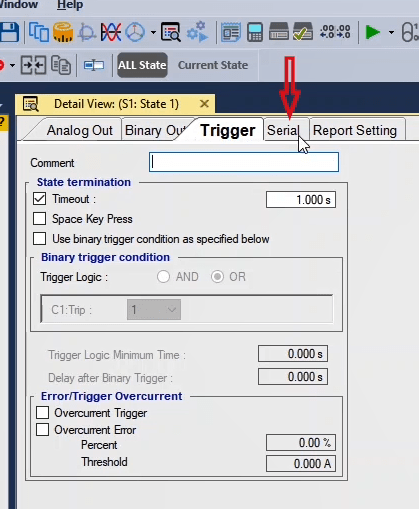

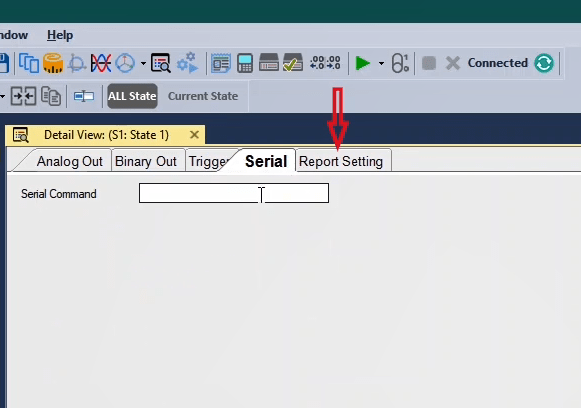

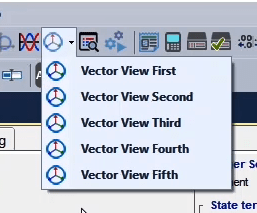

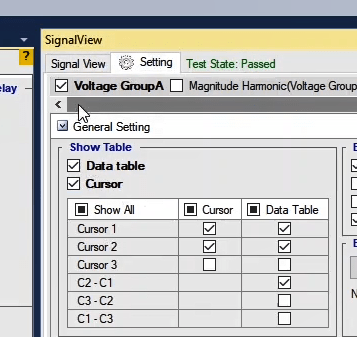

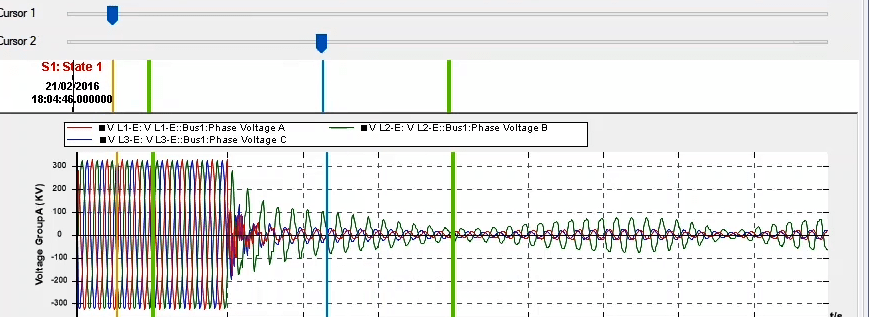

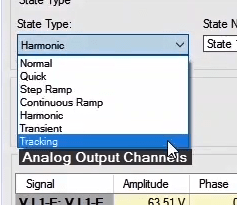

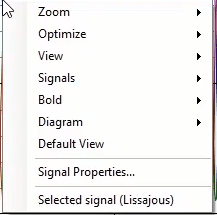

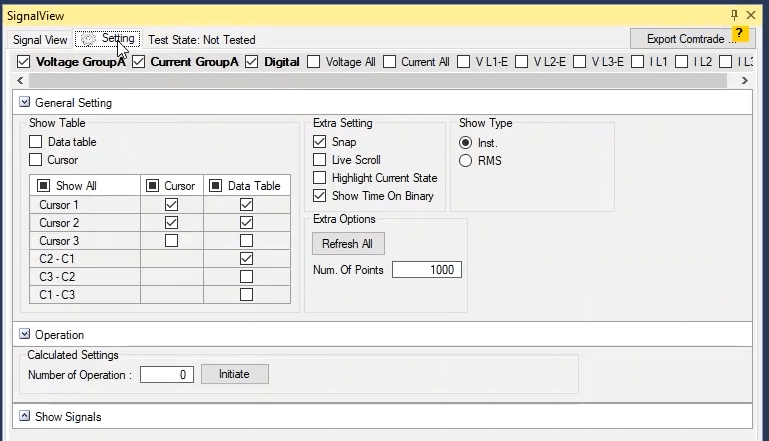

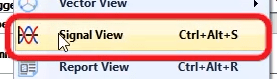

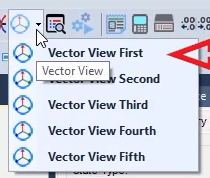

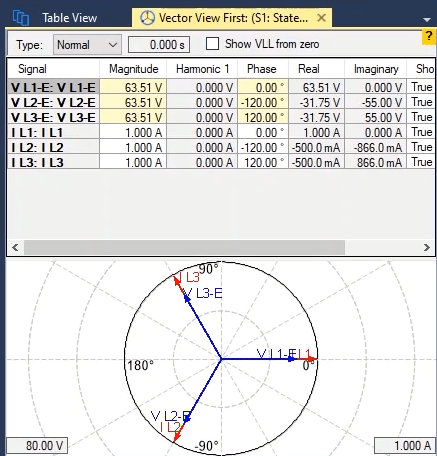

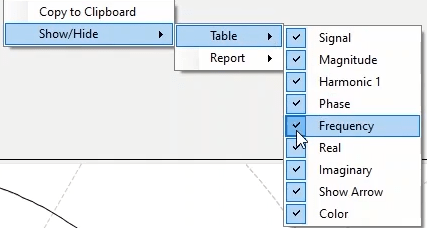

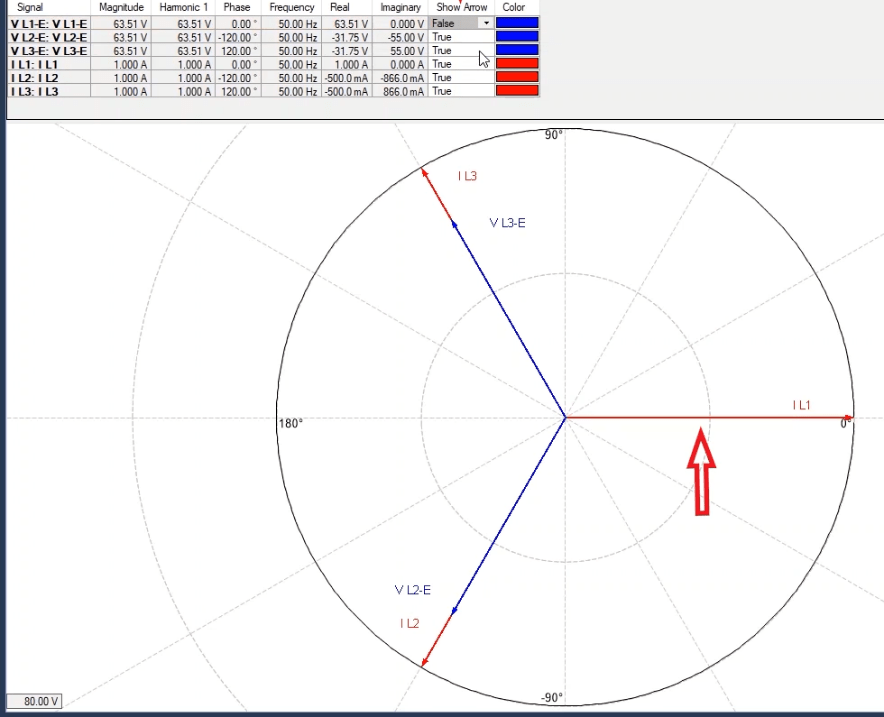

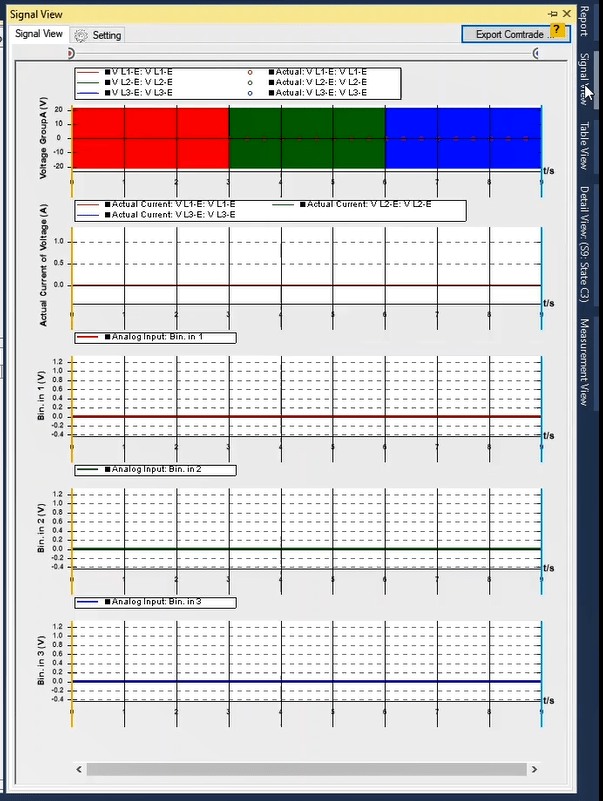

Some parts like “Trigger” and “Binary Output” are the same in all rooms because changing their parameters was not deemed to be necessary. Those rooms which are used for testing the equipment are called “State Sequencer” and the windows available in the “Sequencer” rooms are, also, available in these rooms. Moreover, the “Instrument View” window, which is not available in the “Sequencer” rooms, is added to these rooms. Some windows including “Vector View” and “Signal View” are similar in all rooms and have the same structure but it is possible that some of their information is made hidden or shown according to the needs.

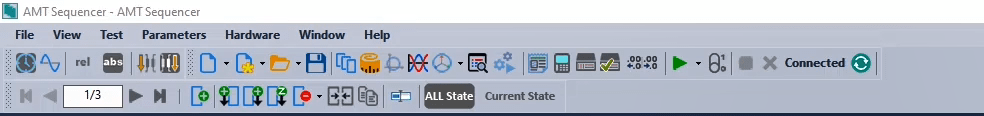

By opening each room, a page which contains several windows opens Along with these windows there is the toolbar and the status bar. After closing these windows, the explanation of different parts of the menu and the toolbar will be given in the video This toolbar is the same in all sections and the “Sequencer” room has another toolbar which is exclusive to it.

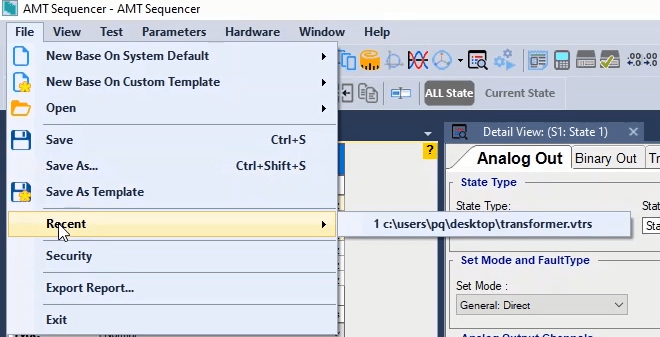

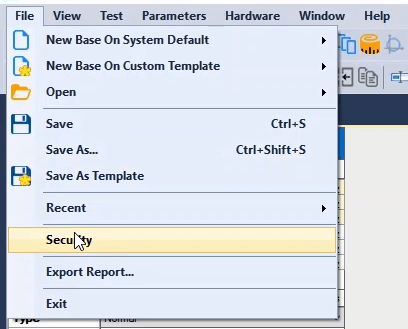

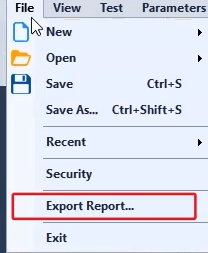

To open a new room, click on "File" and select “New". You can also access the files that have already been saved by selecting “Open". Use “Save" or “Save as" to save a file. Use “Recent" to access the files that have recently been saved.

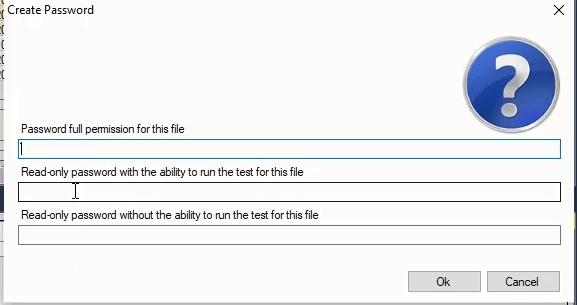

Use “Security” to encrypt a file the encryption has three levels the first level, full permission, allows users with an encryption code to access the settings, run the test file and save the output.

In the second level, users cannot change the settings but can only run the test file and save the output in the third level of encryption, users can only view the file.

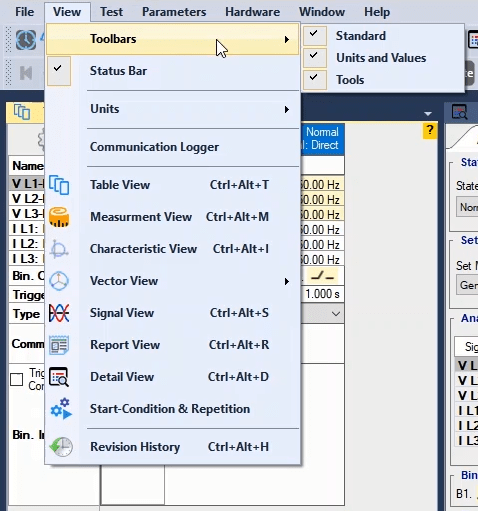

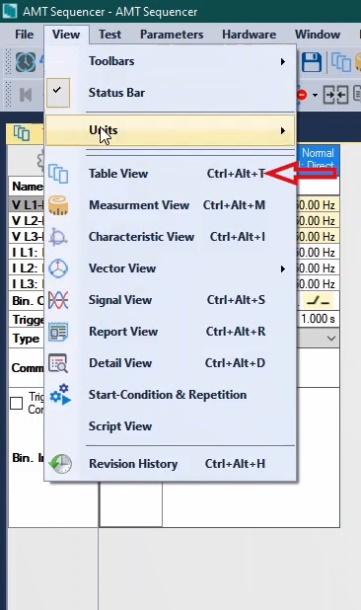

Use "Export Report" to save the test file as PDF. Use “Exit" to close and exit the test page. Click on “View" and select “Toolbars" to see different modes of the toolbar Add or remove the check mark to show or hide the icons.

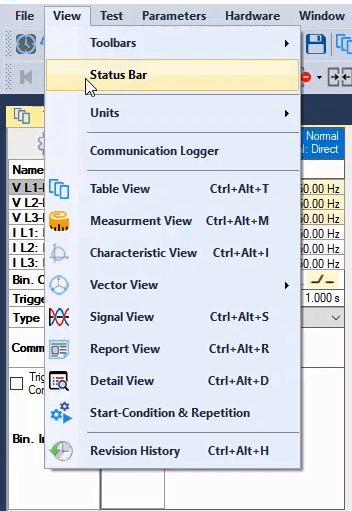

Use “Status Bar" to hide or show the status bar at the bottom of the page.

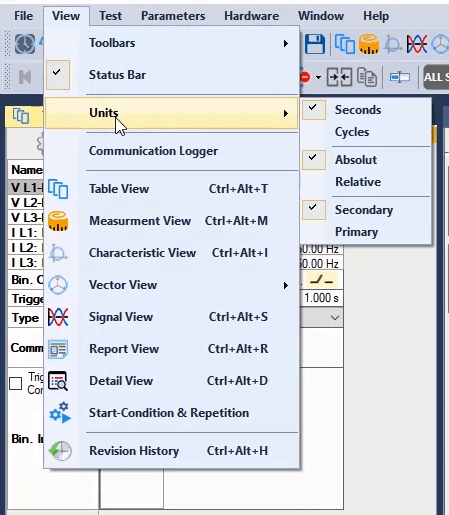

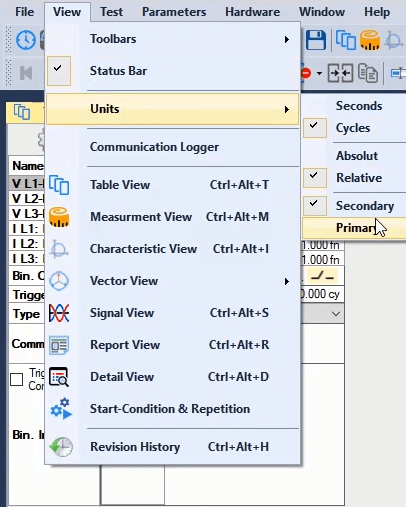

The "Units" option has three parts:

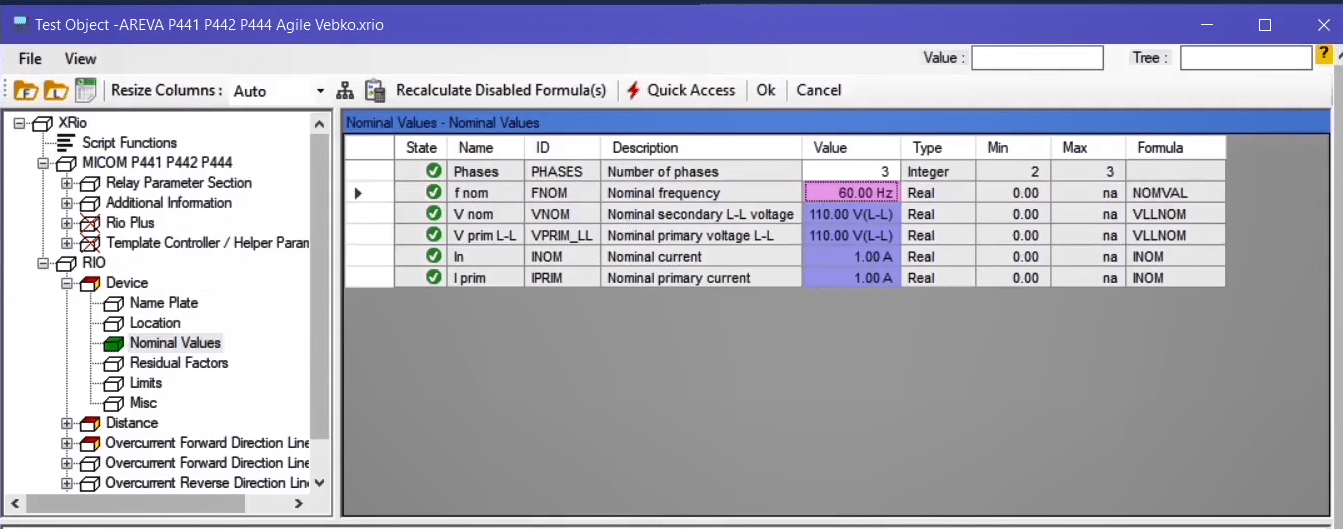

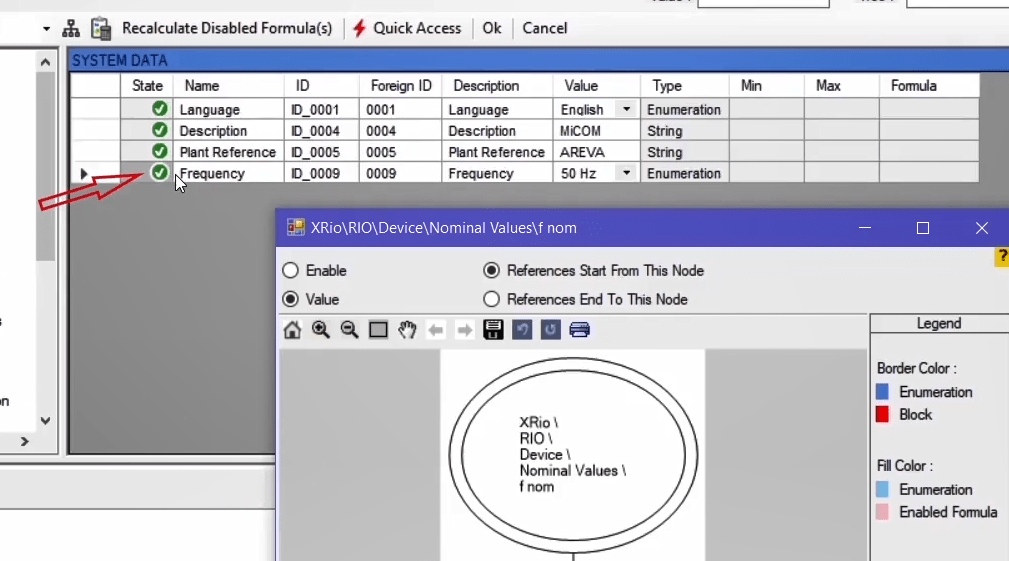

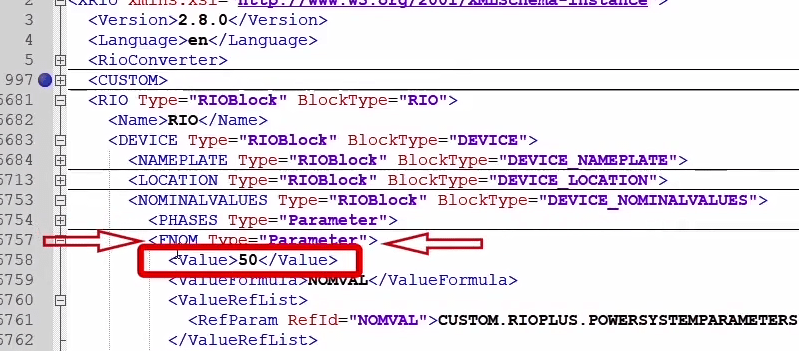

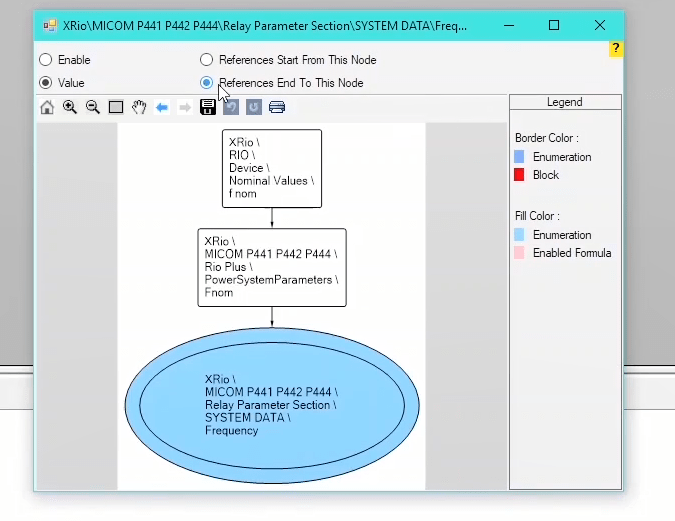

Choosing time between “Cycles" and “Seconds”. By default, time is displayed in terms of seconds while by selecting “Cycles” the time is displayed in terms of cycles. Determine the cycle time in “Test Object", the “Device” block and then in the “f nom” field. If this frequency is changed the time is change accordingly.

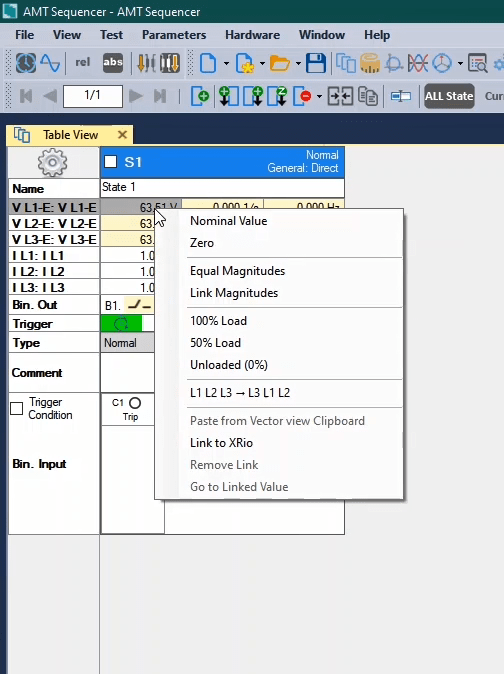

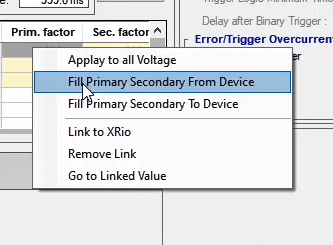

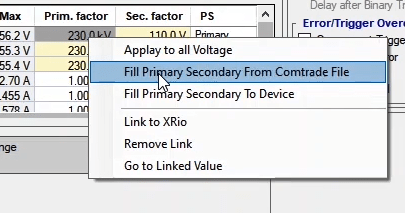

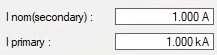

Choosing Parameter’s values between “Absolute” and “Relative” By default Parameters' values are “Absolute”. use “Relative” to see parameters' values dependent to nominal value The nominal values for voltage can be determined in the “Test Object”, “Device” and in the “V nom (secondary)” field, for current in the “I nom (secondary)” and for frequency in the (f nom) field.

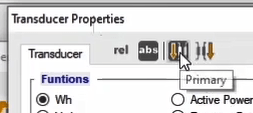

Choosing values between “Primary” and “Secondary. By default, software values are in terms of secondary. To see the values in terms of primary use the “Primary” option these values can be determined in the “Test Object”, “Device” block, “V primary” and “I primary” field

The “Communication Logger" option is for the communications of devices and laptops that the Vebko’s programmers use. Different windows in the “Sequencer” page including “Vector View" and “Signal View” are shown in this list

Use "Revision History" to access all of the files that were saved by the program every 30 seconds. By selecting each file, you can reset them as needed

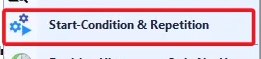

Select “Start/Continue" option in the “Test" menu to run the test. To stop the test use “Stop”. Use “Clear" to remove the test results.

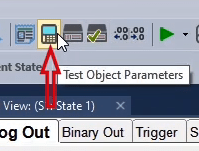

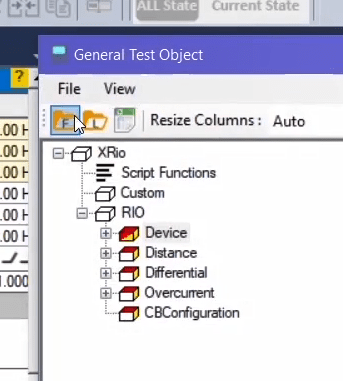

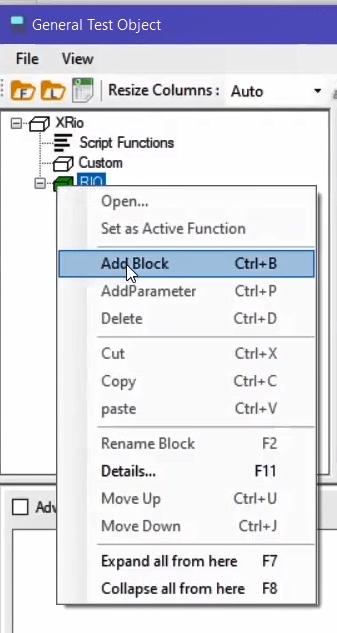

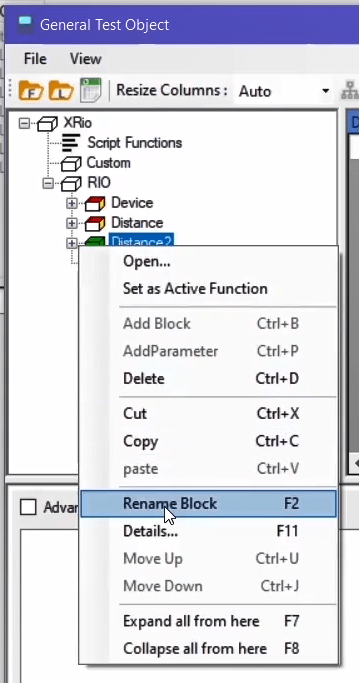

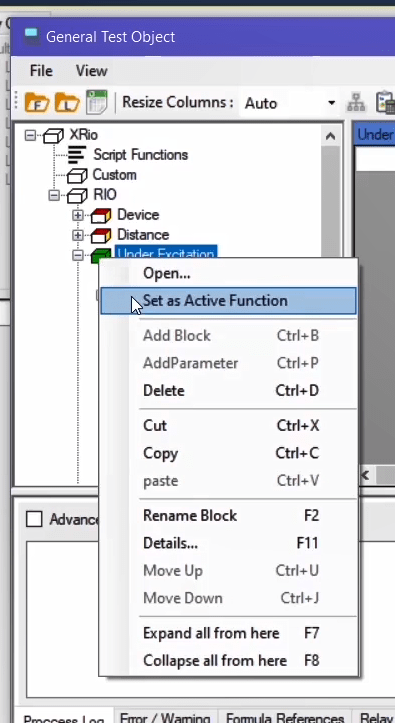

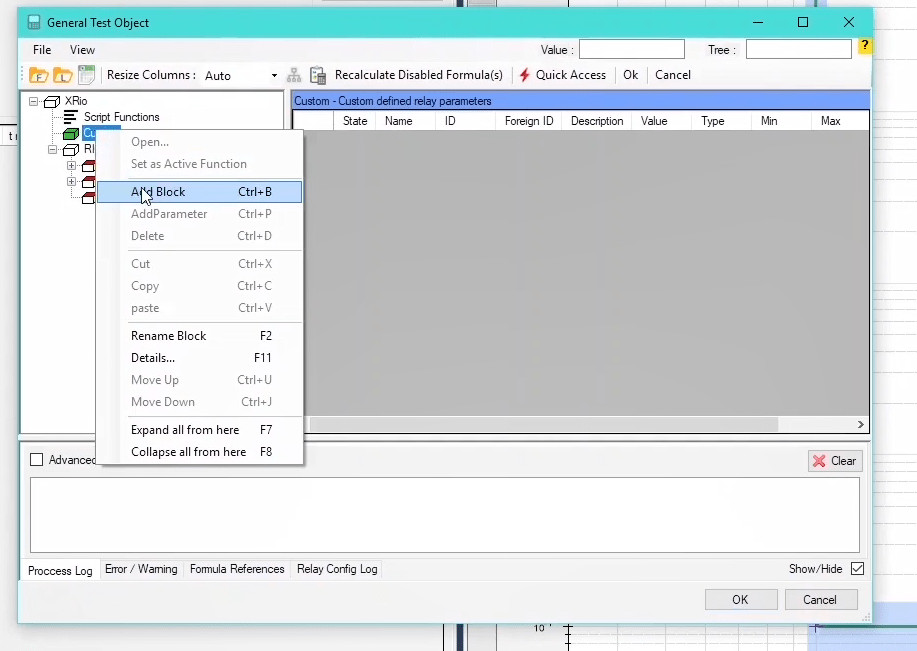

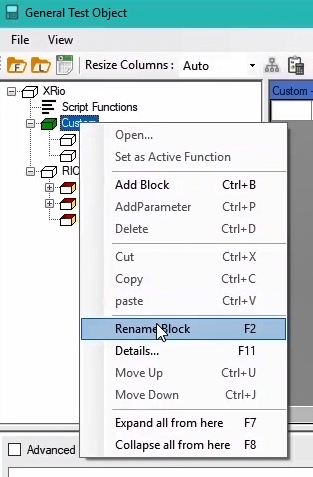

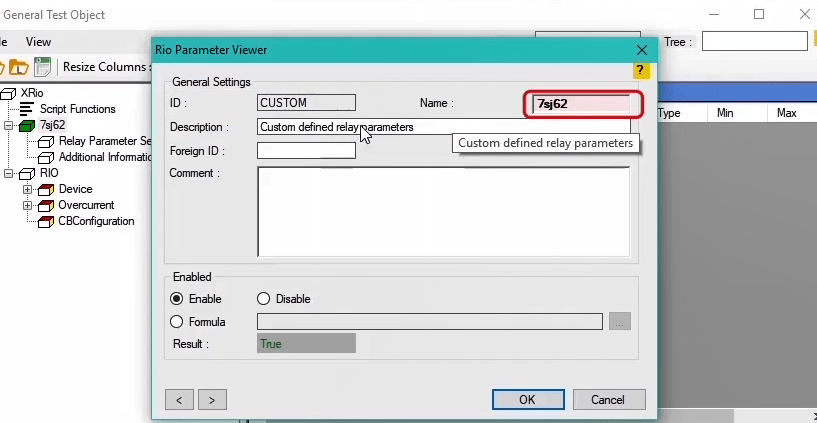

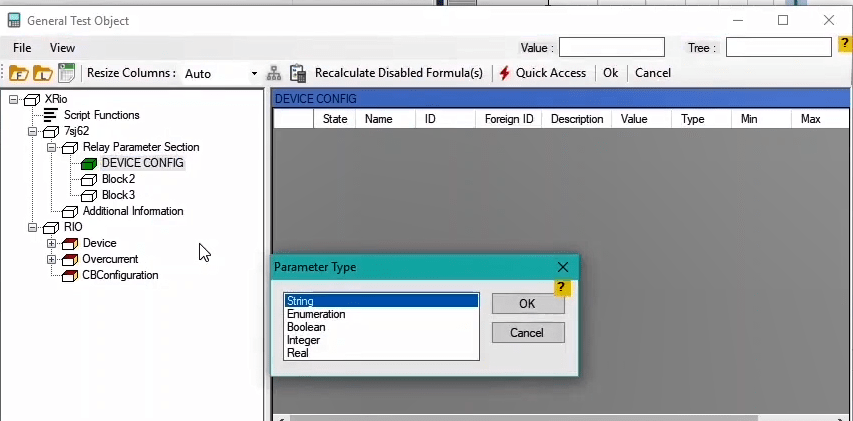

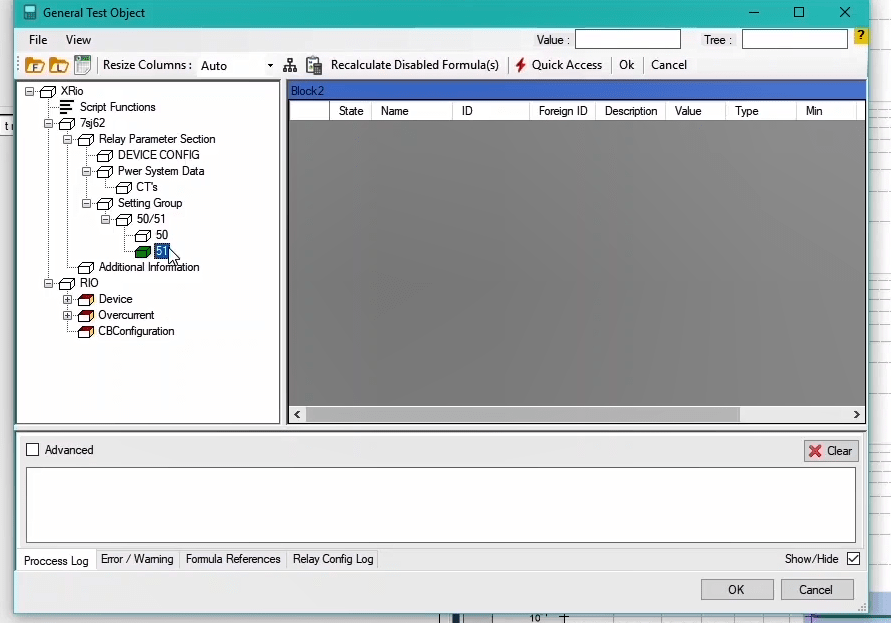

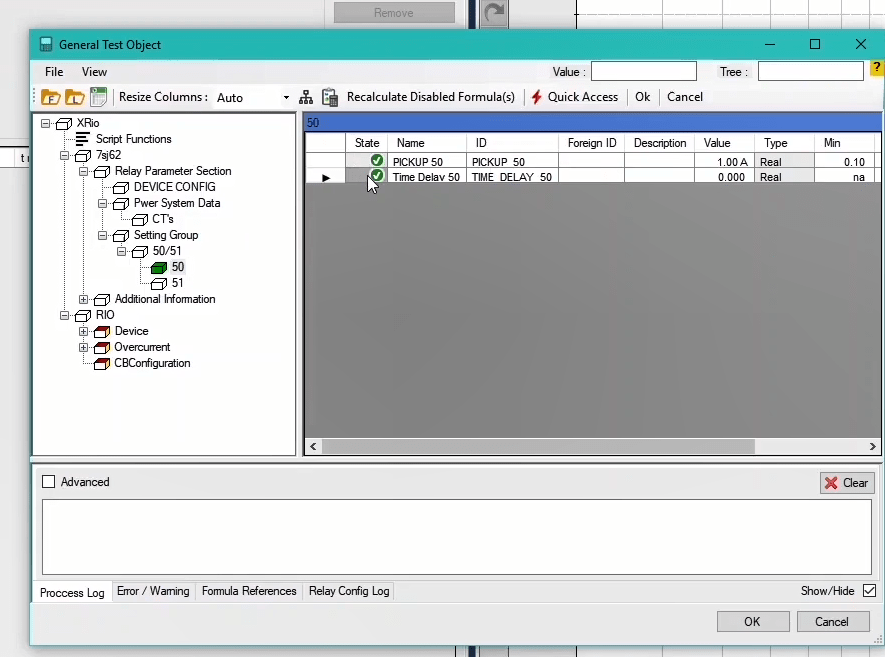

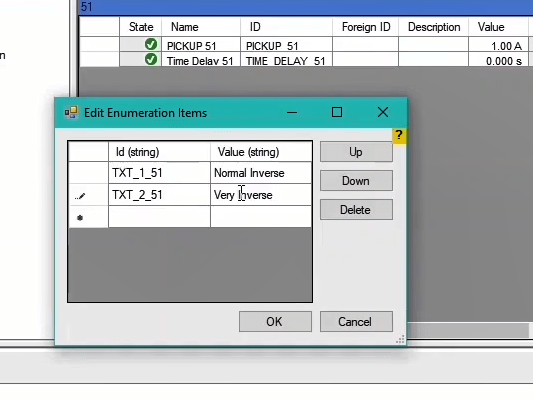

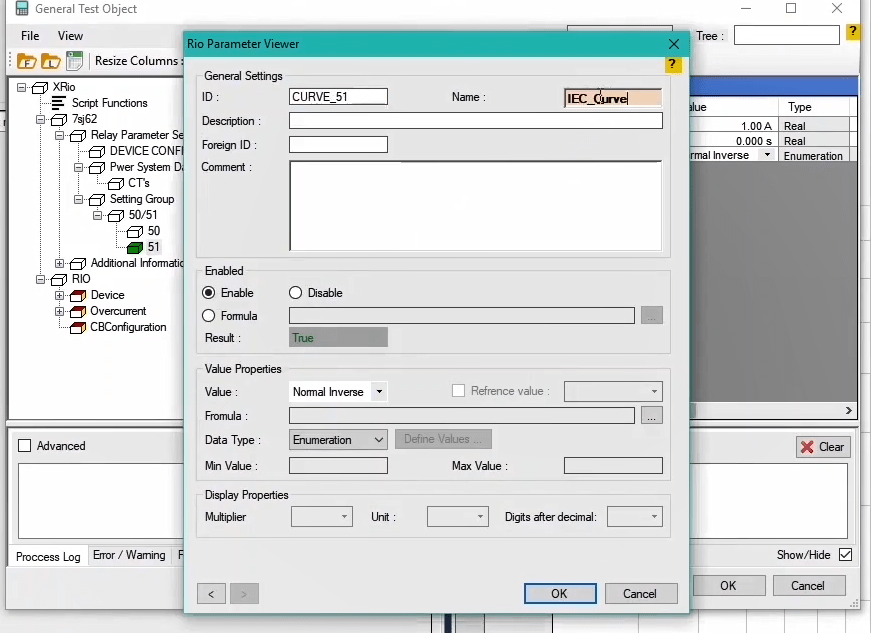

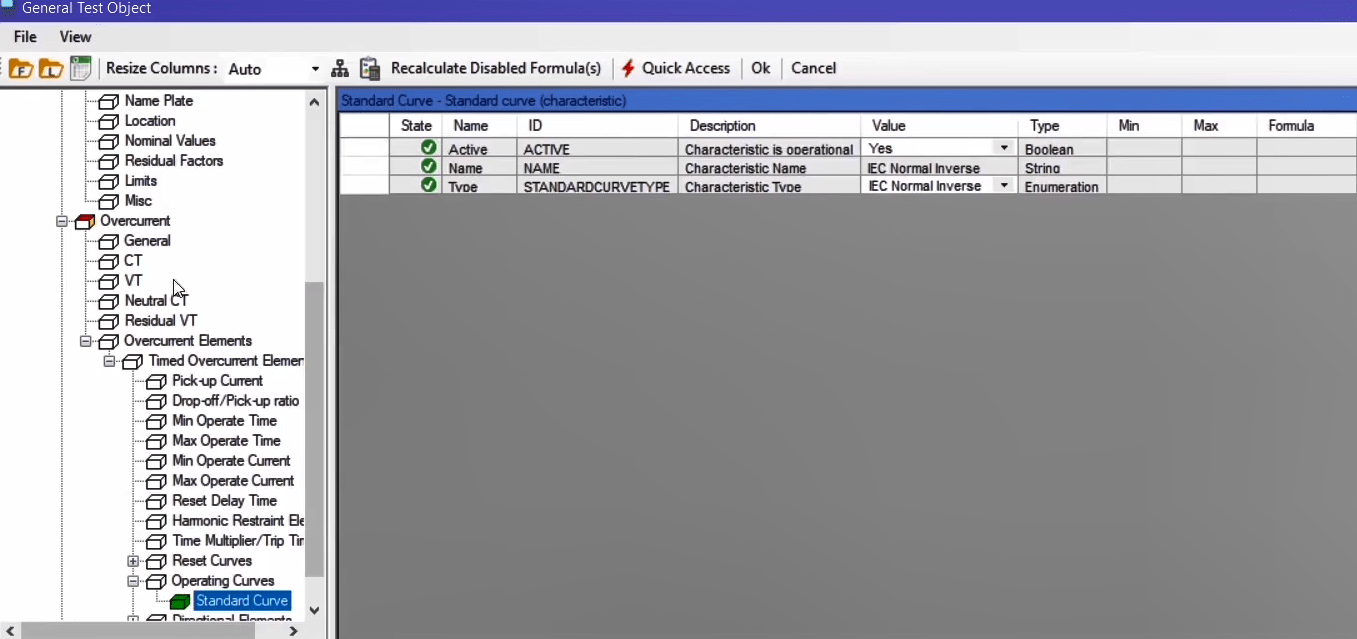

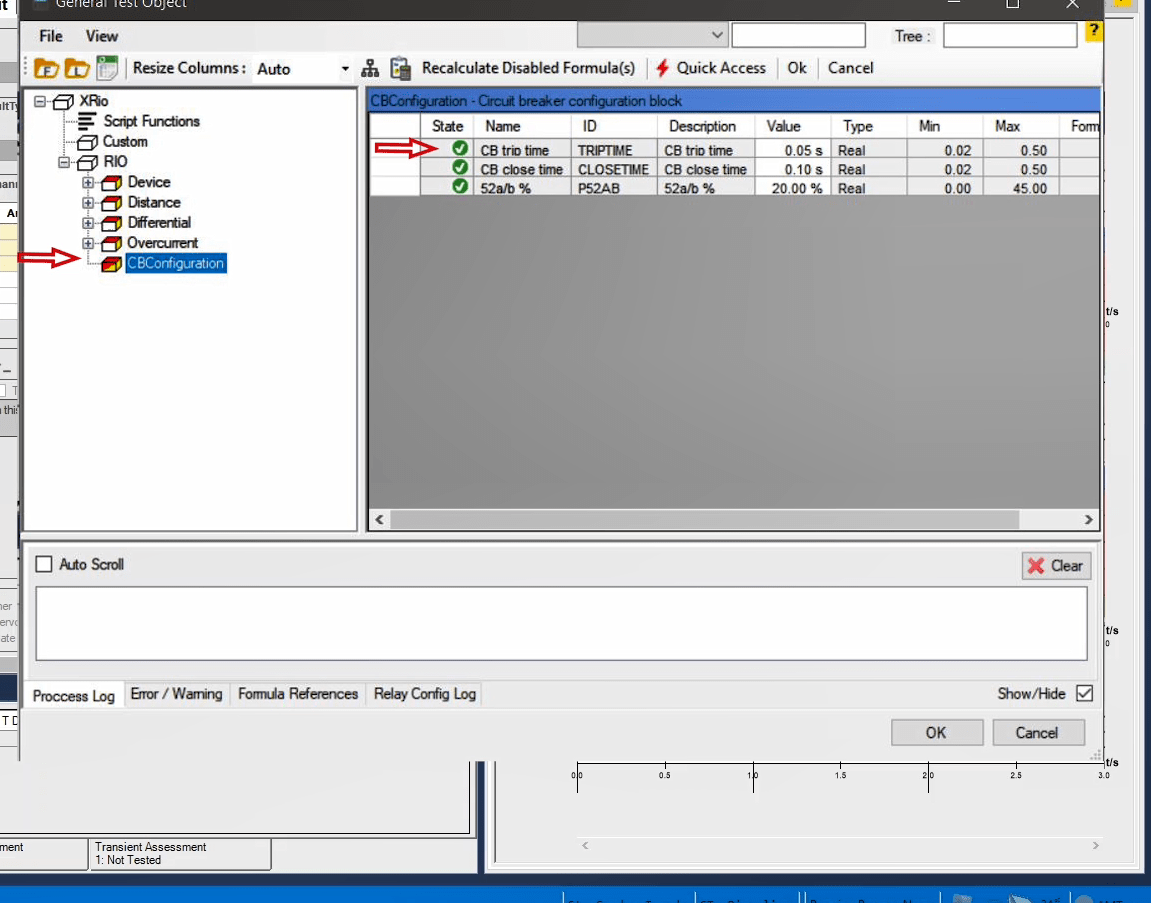

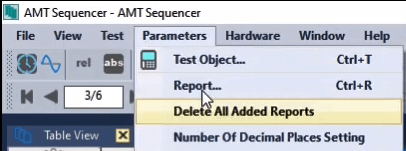

In the “Parameter” menu, select “Test Object” to open “General Test Object” page. Select “Report” to open “Report Setting” page.

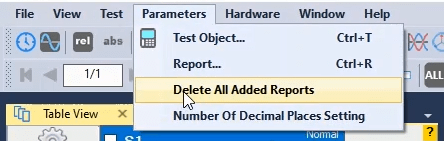

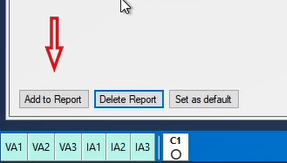

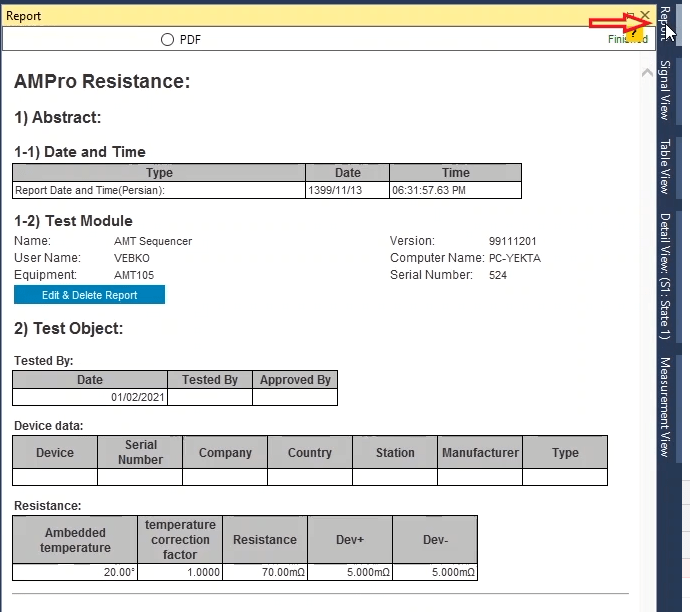

Use “Delete all Added Reports" to remove all of the reports that have been added to the output report using the “Add to Report” option.

Using "Number of Decimal Places Setting" option, depended page opens and you can determine parameter units and determine how to display numbers

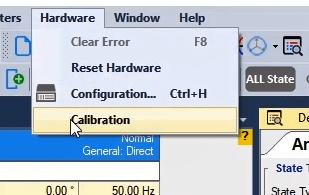

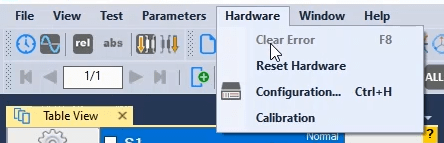

If an error occurs during the test, in the “Hardware" menu click on “Clear Error" to remove it and run the test again.

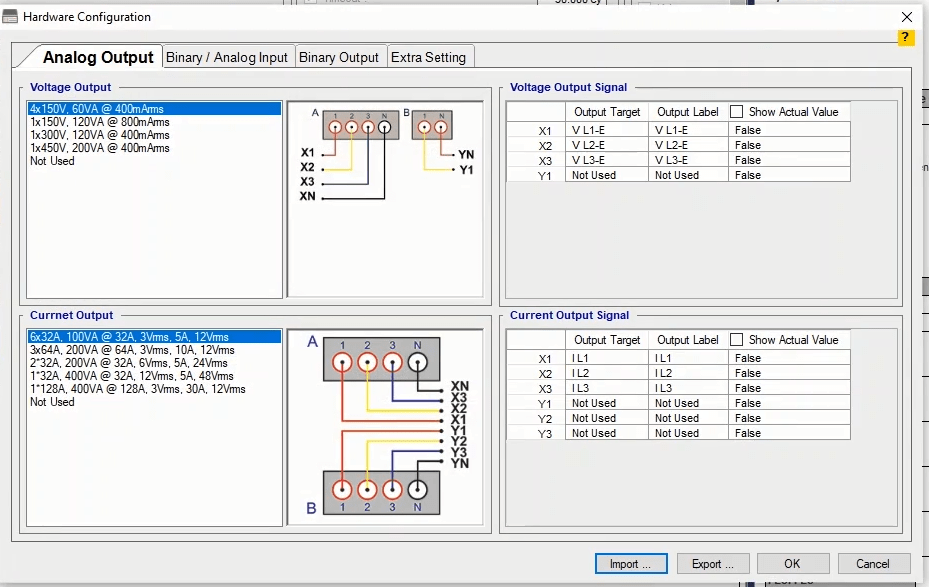

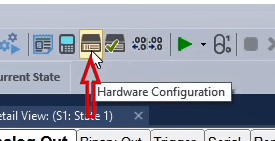

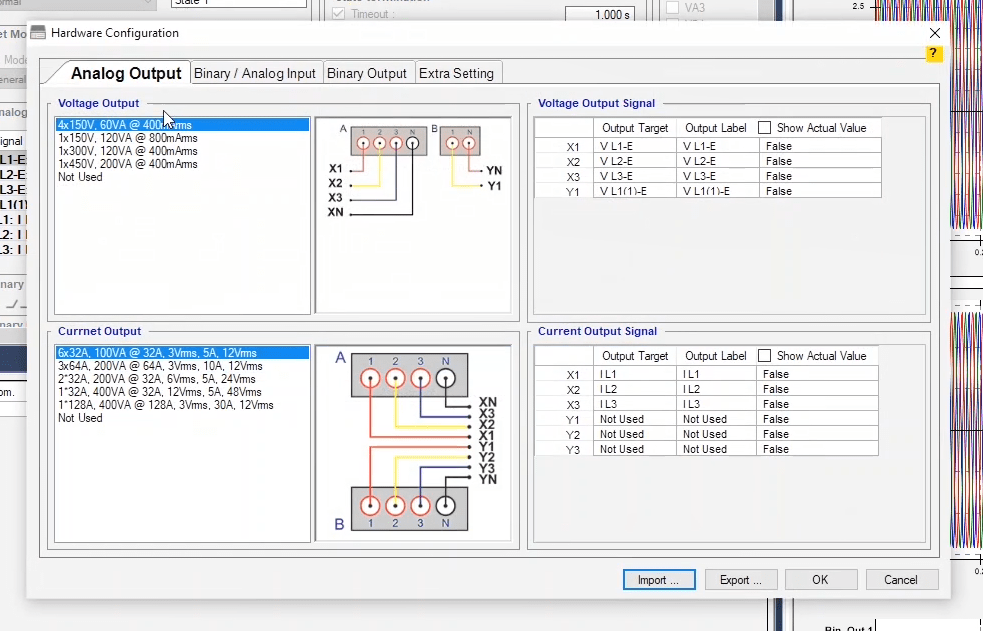

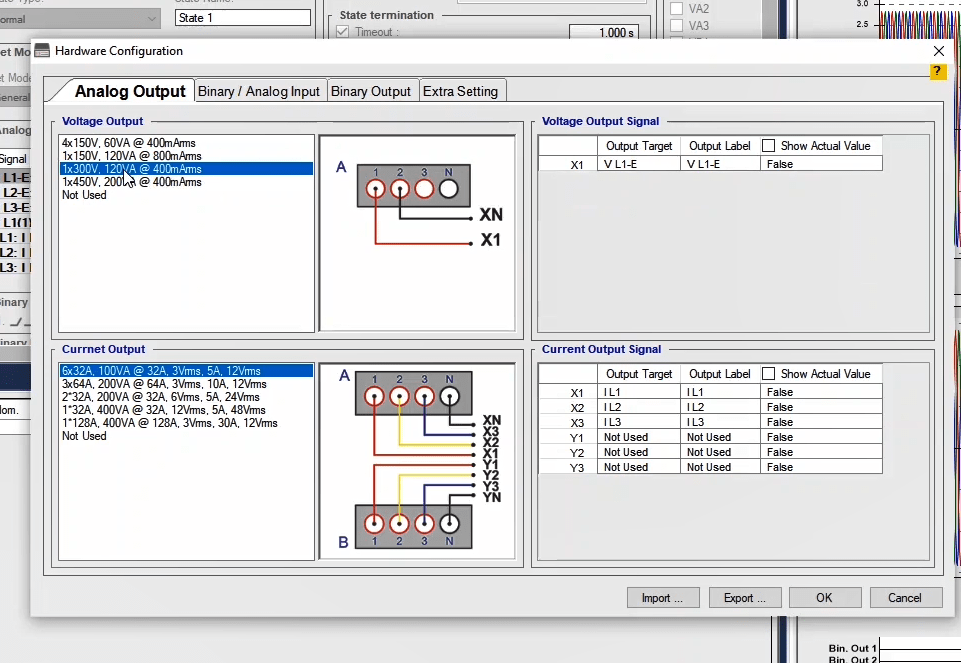

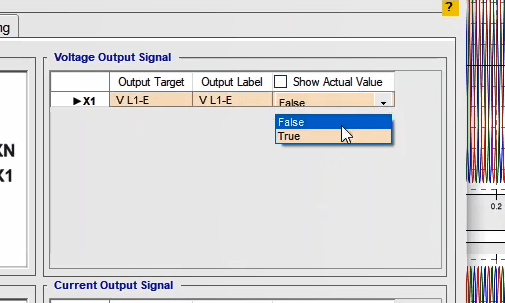

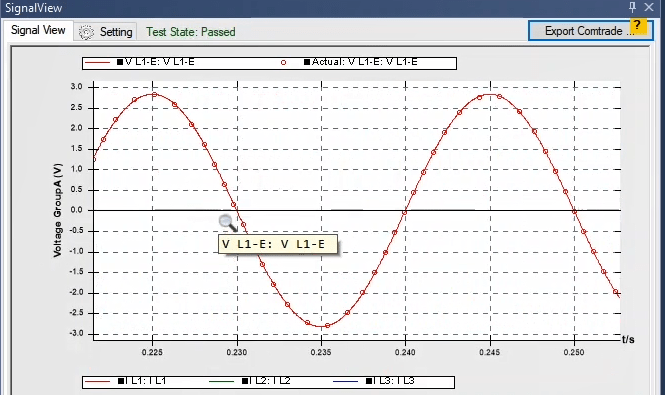

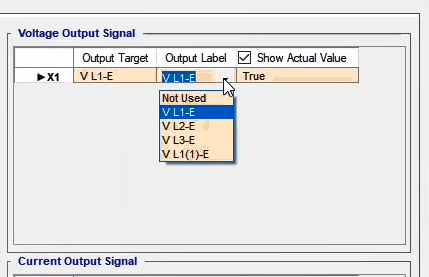

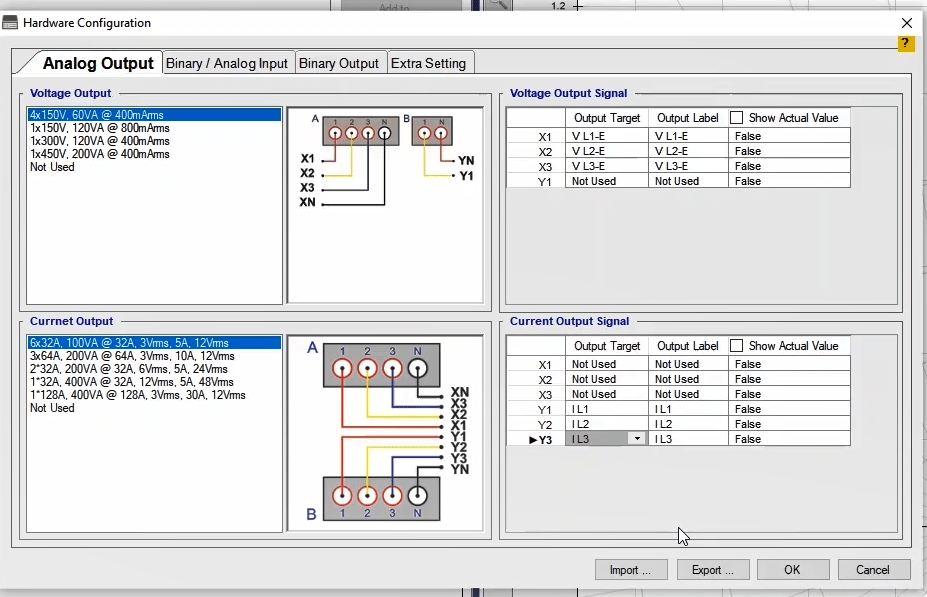

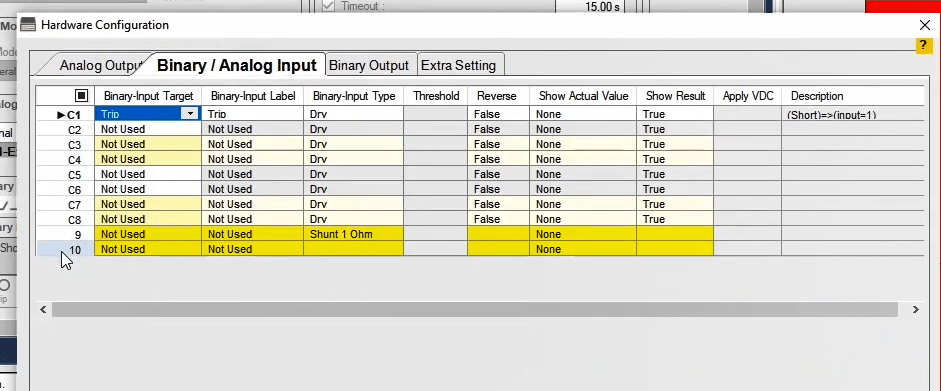

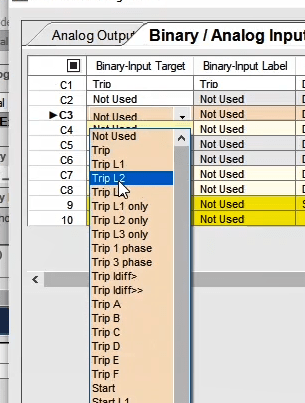

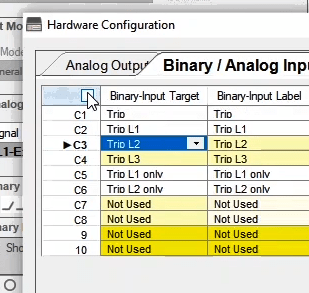

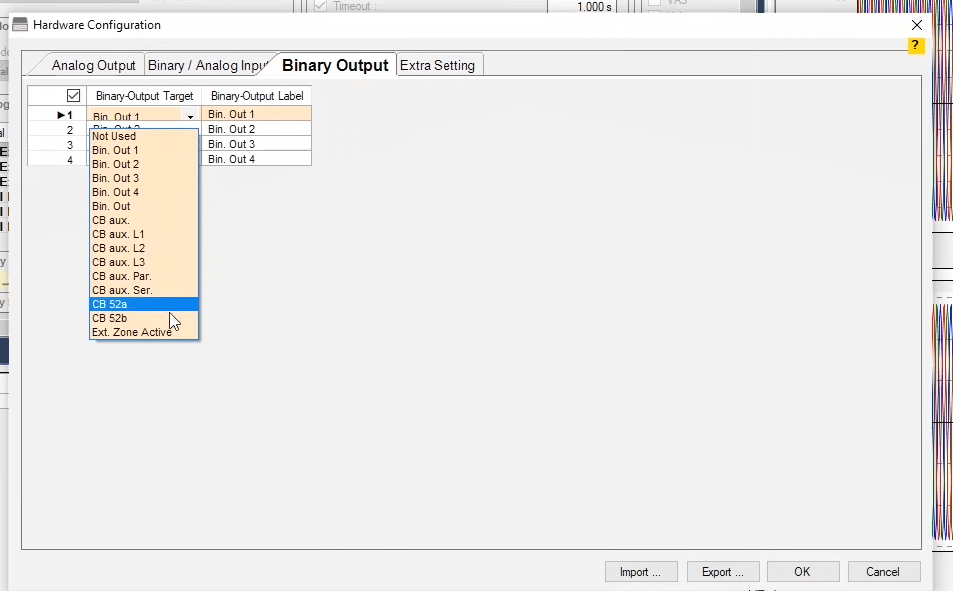

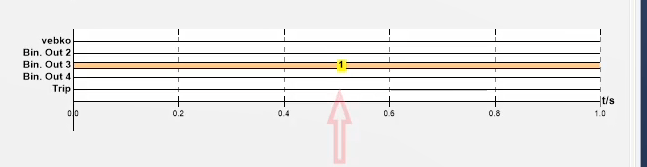

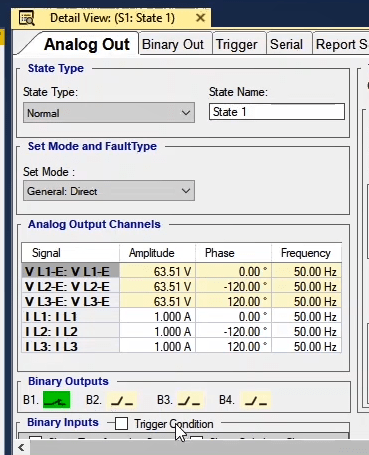

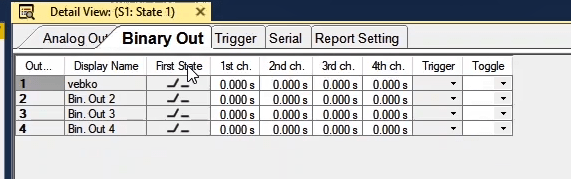

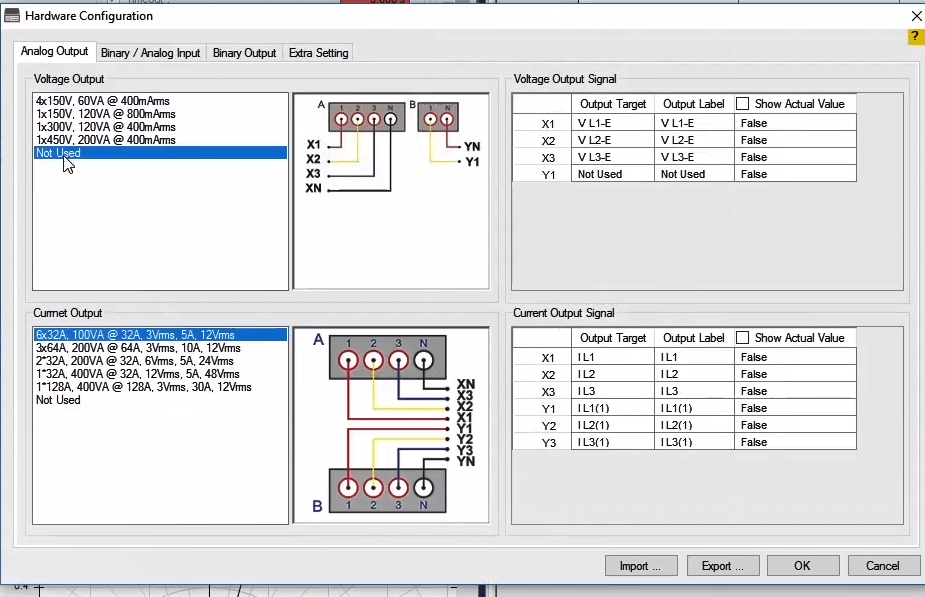

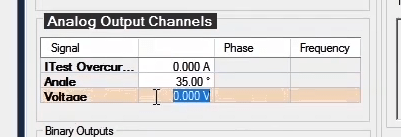

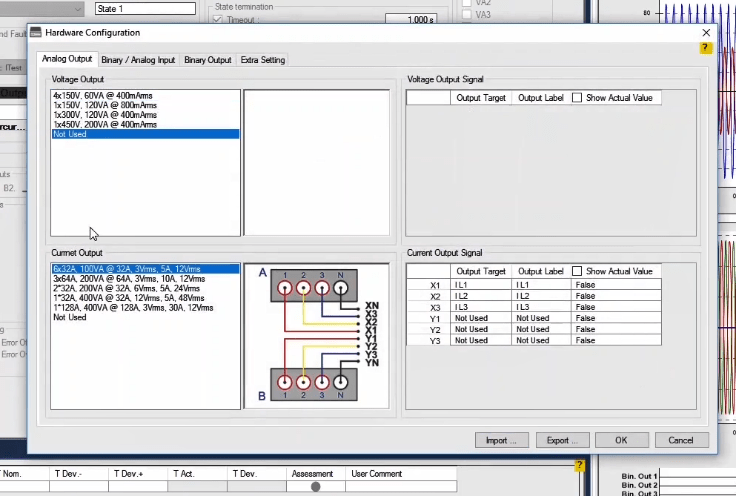

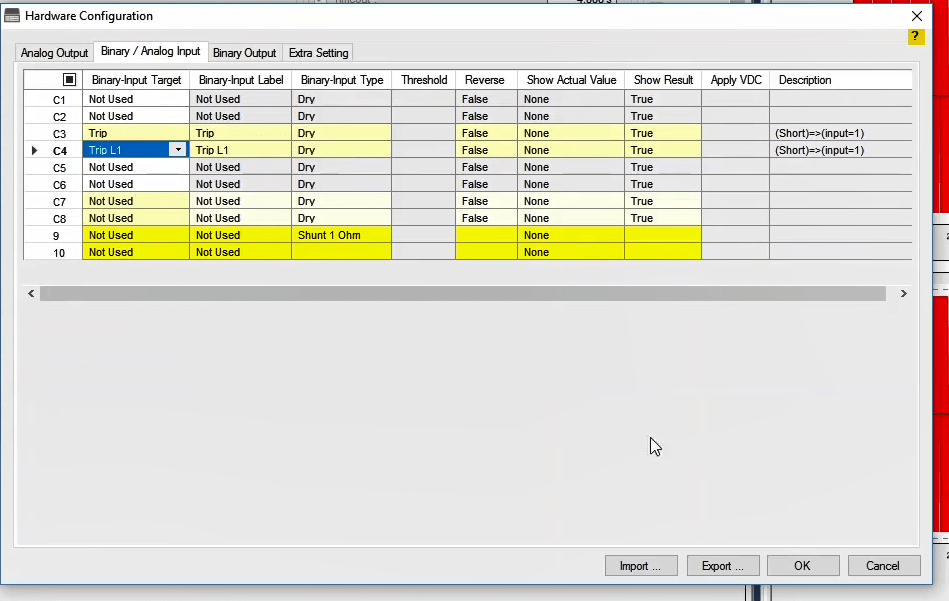

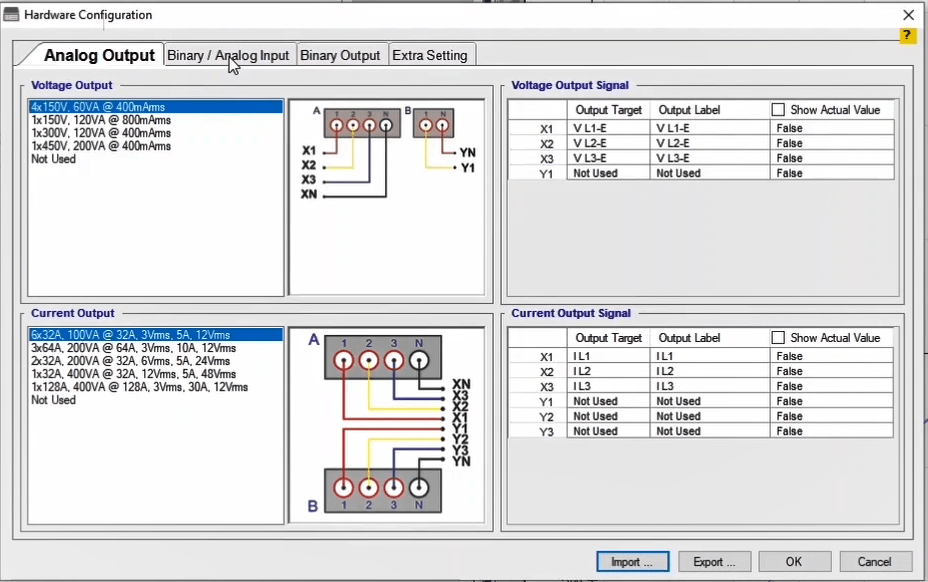

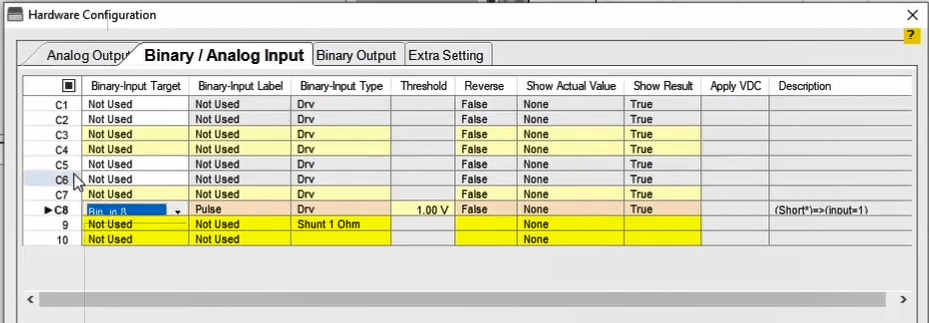

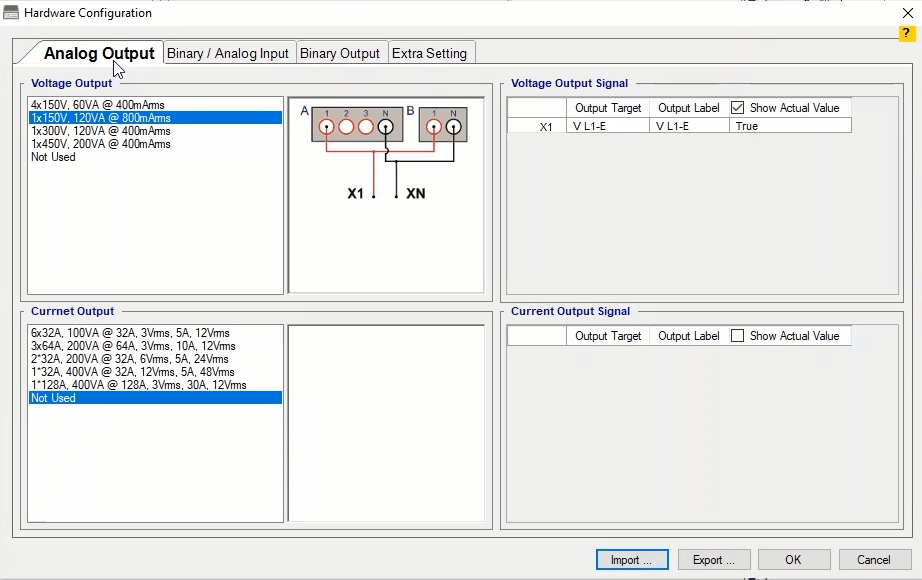

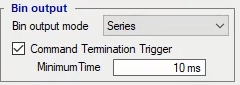

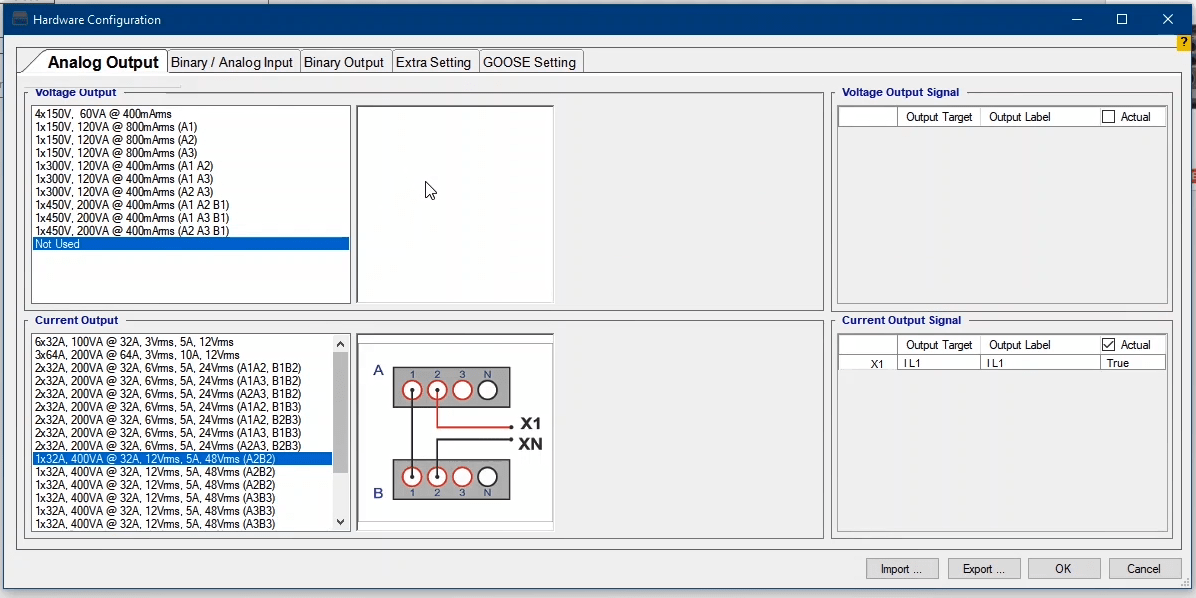

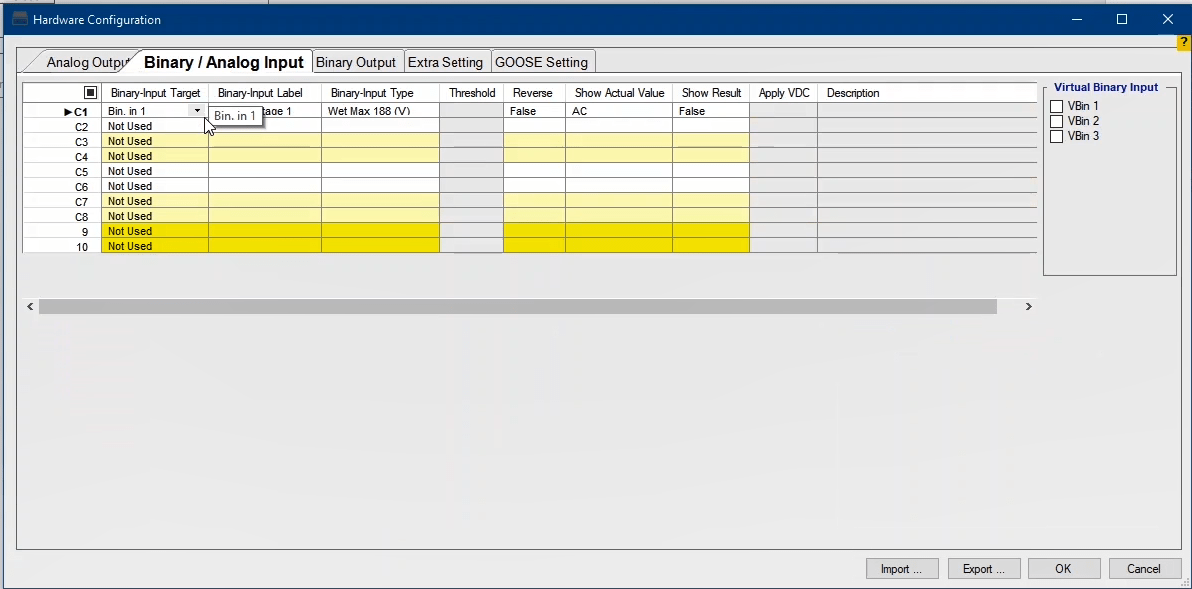

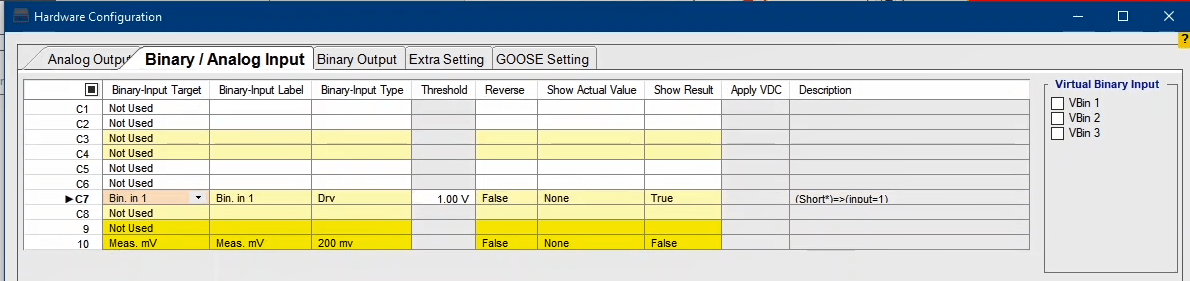

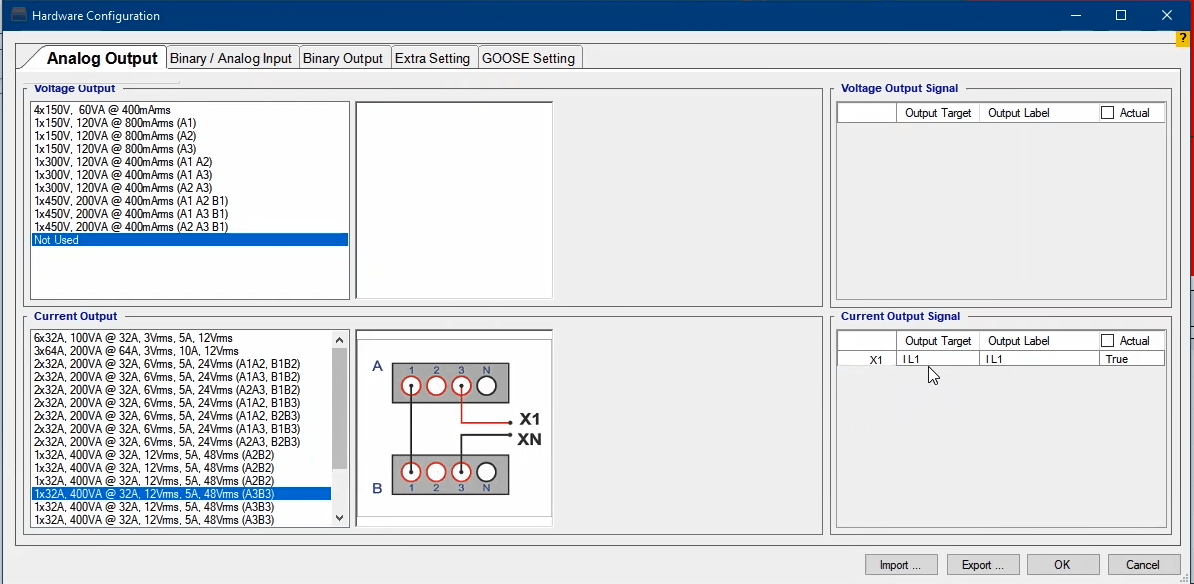

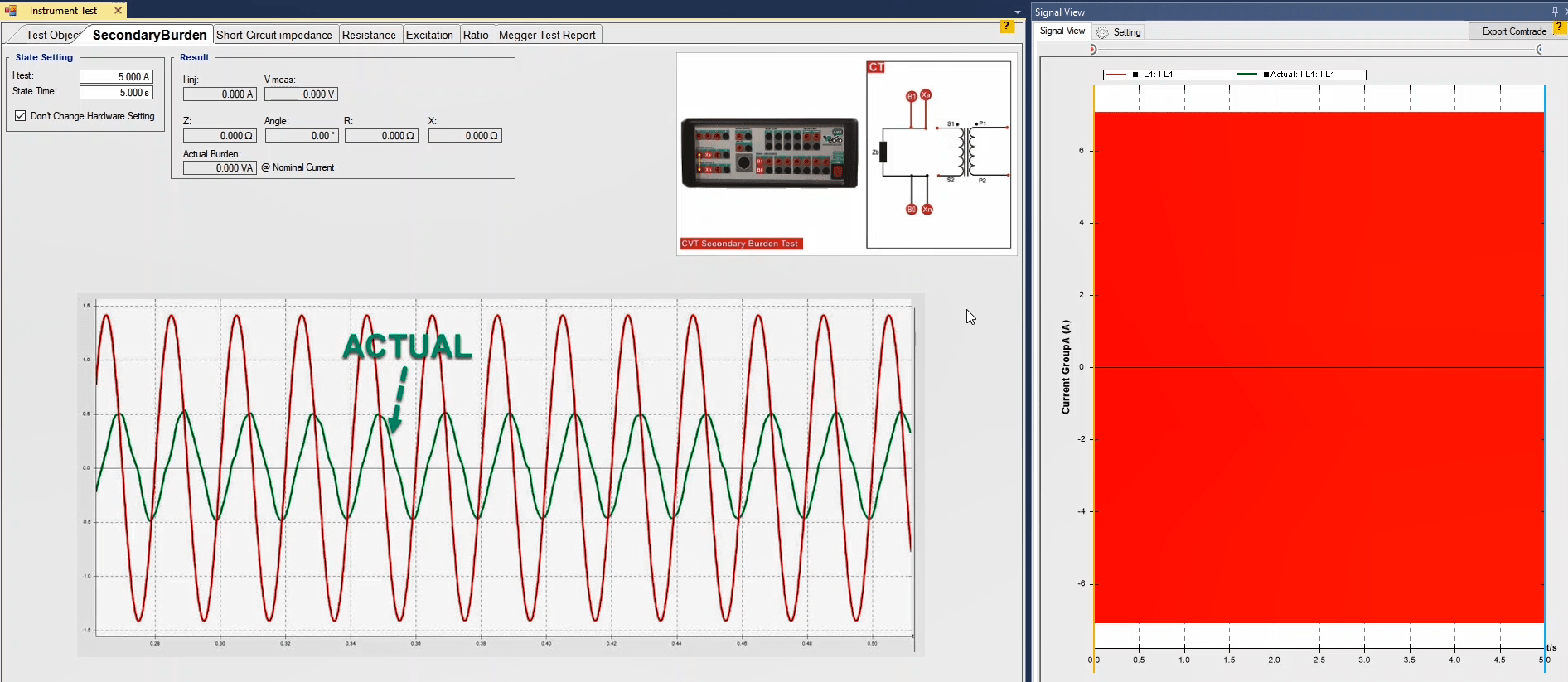

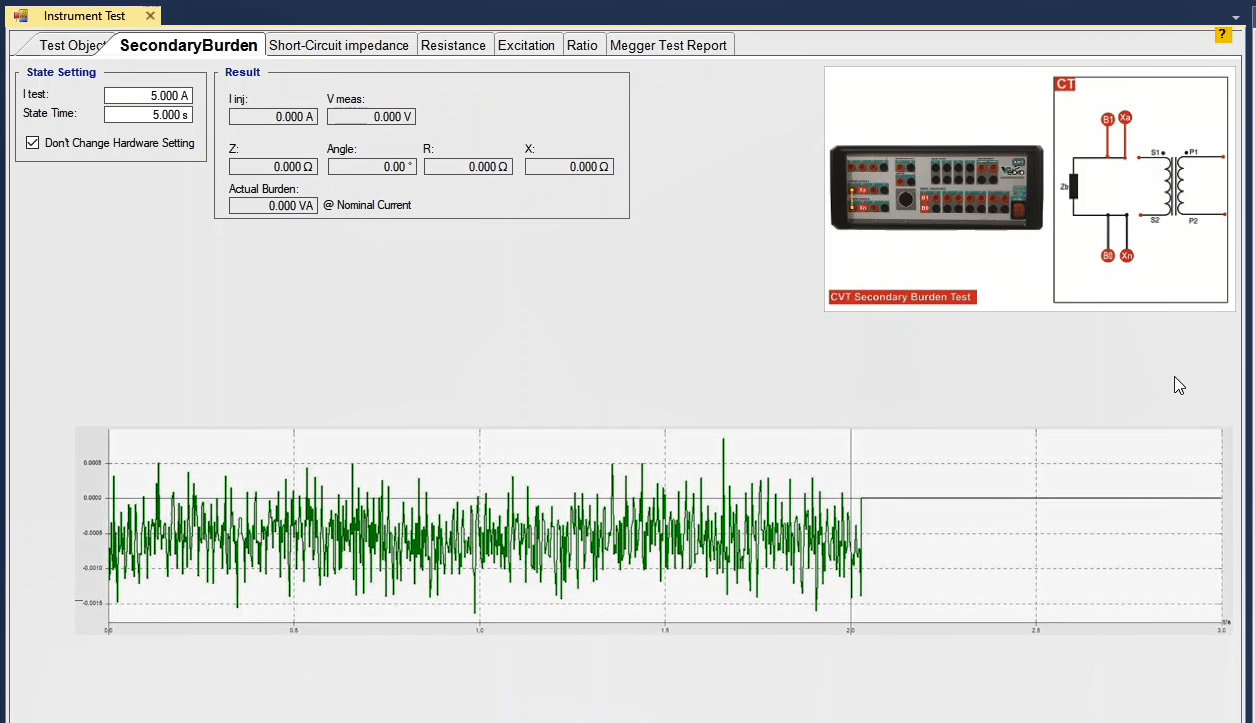

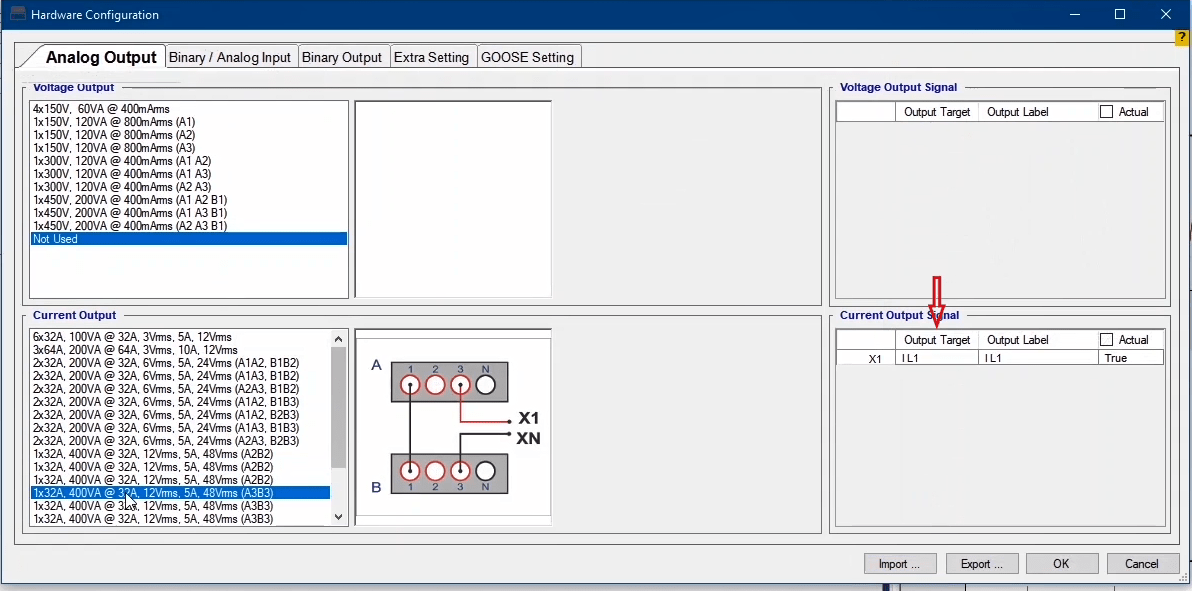

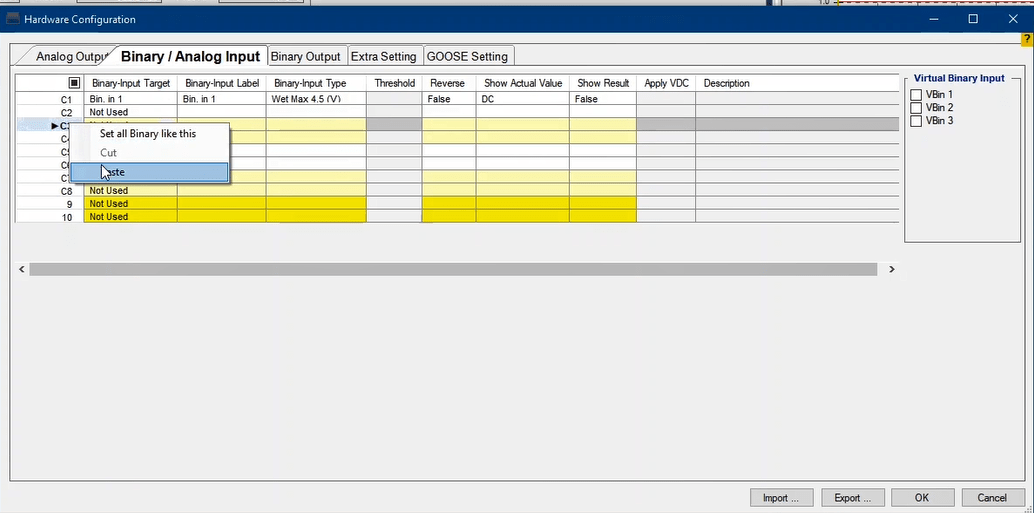

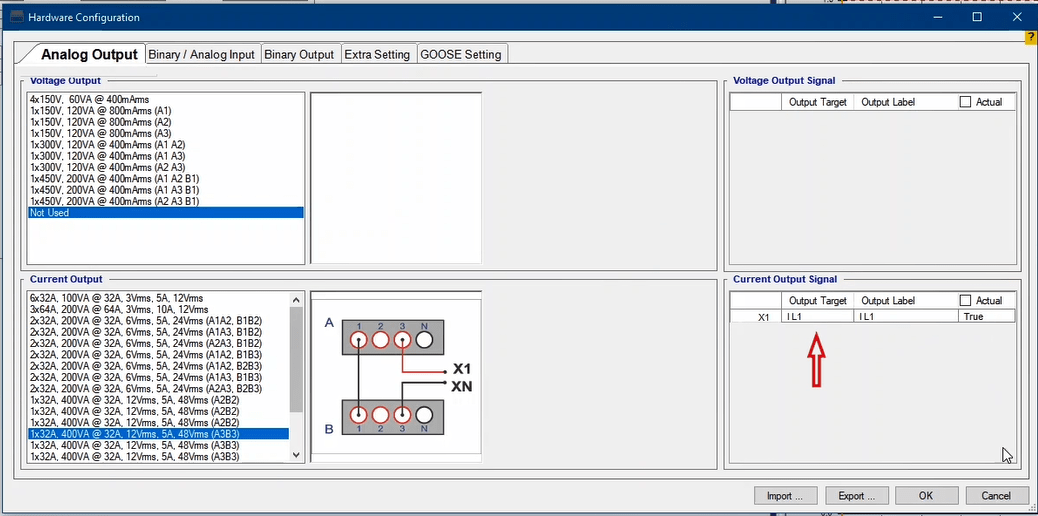

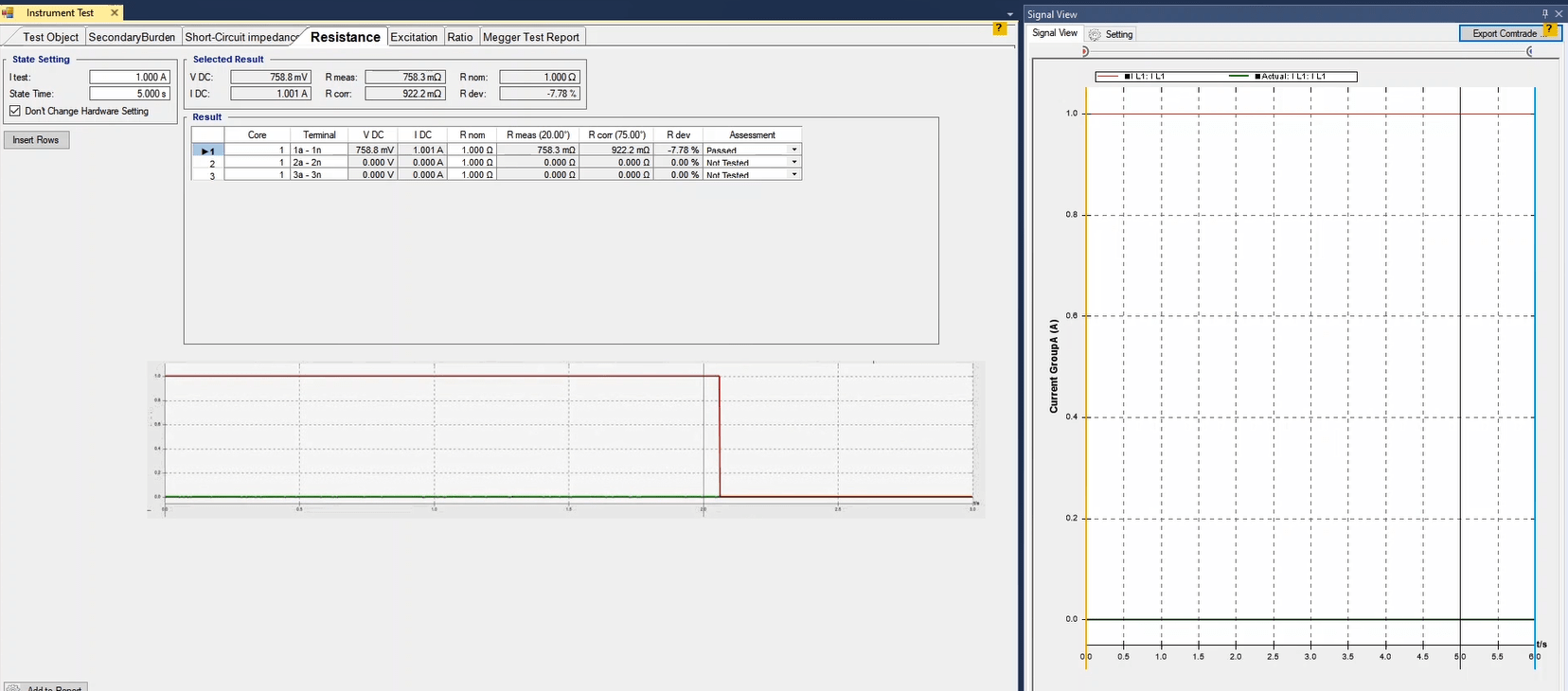

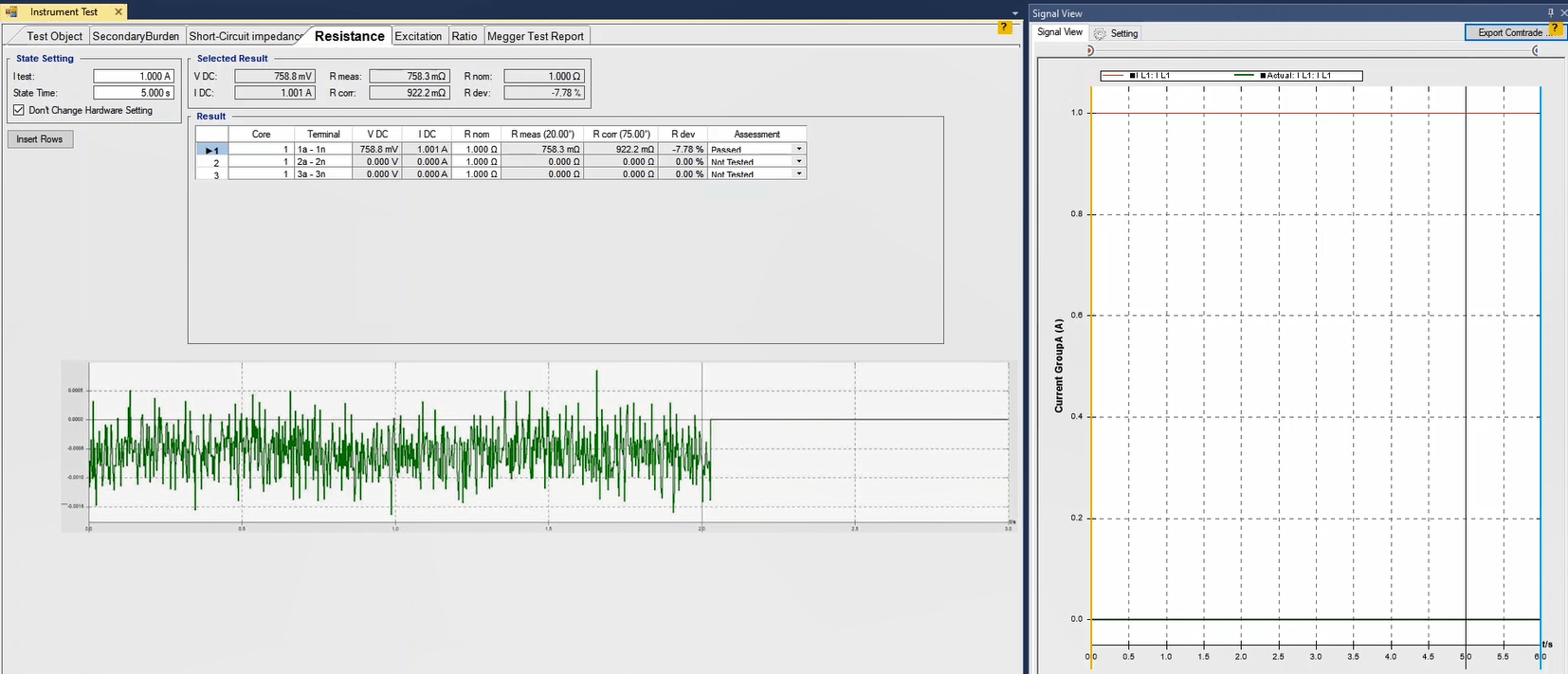

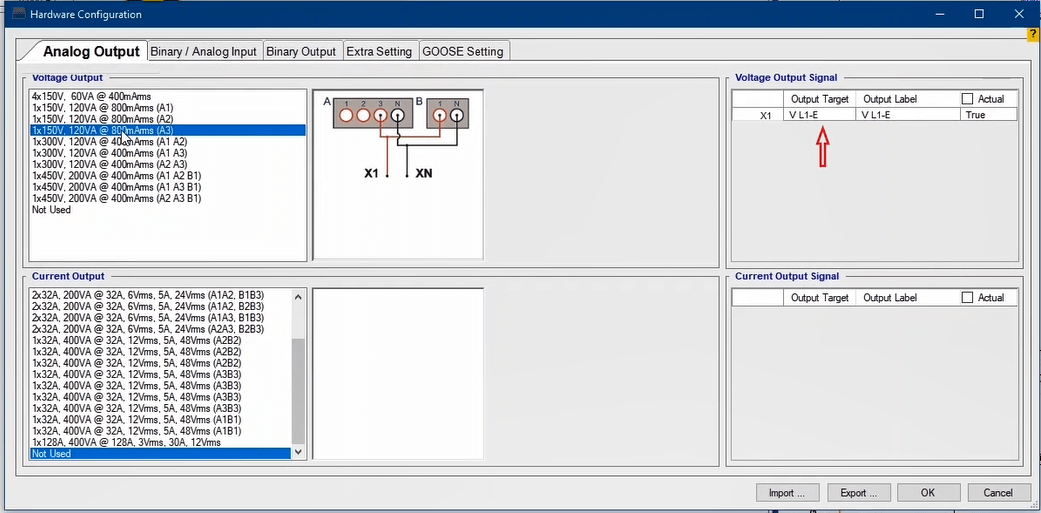

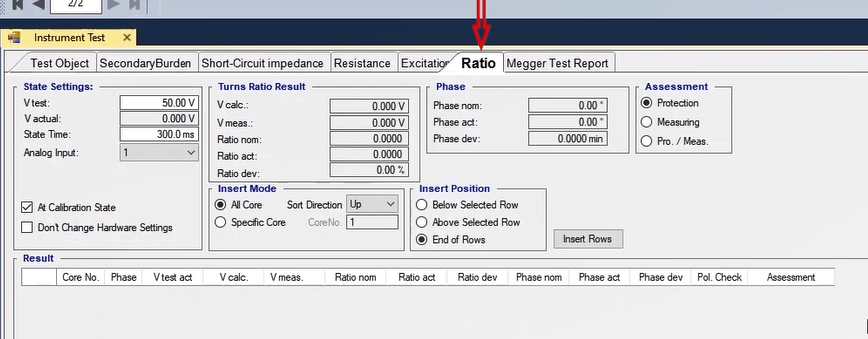

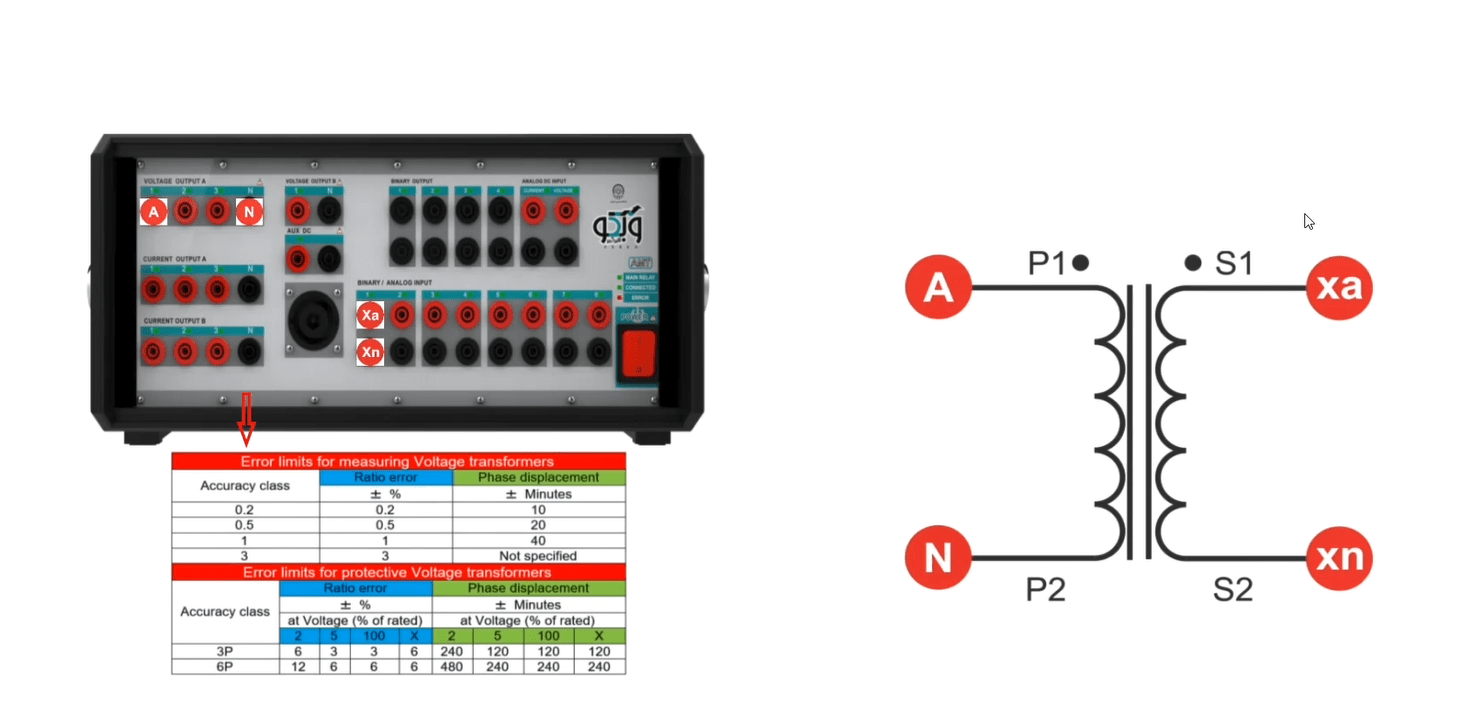

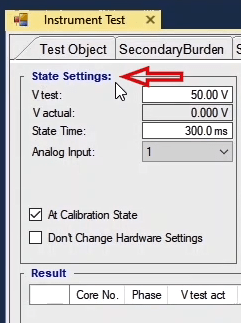

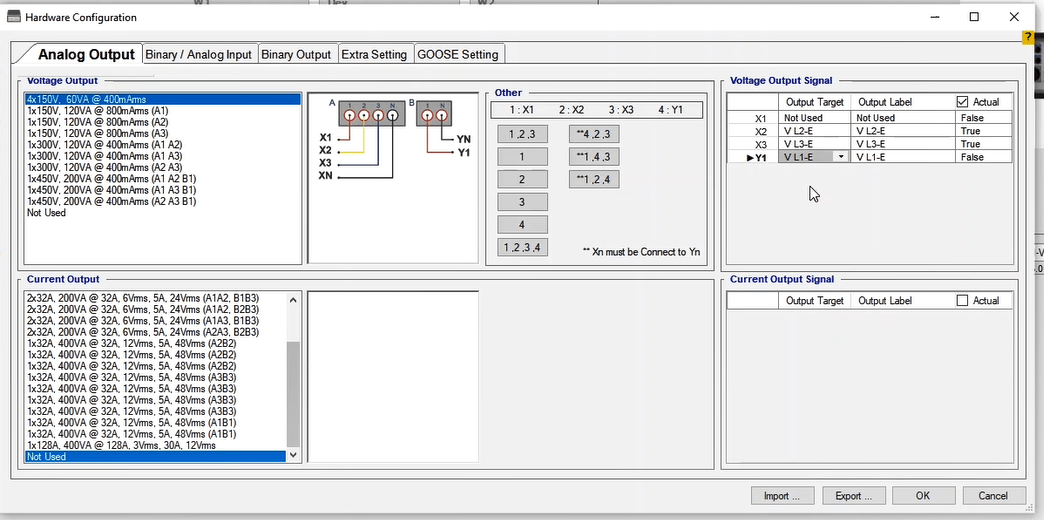

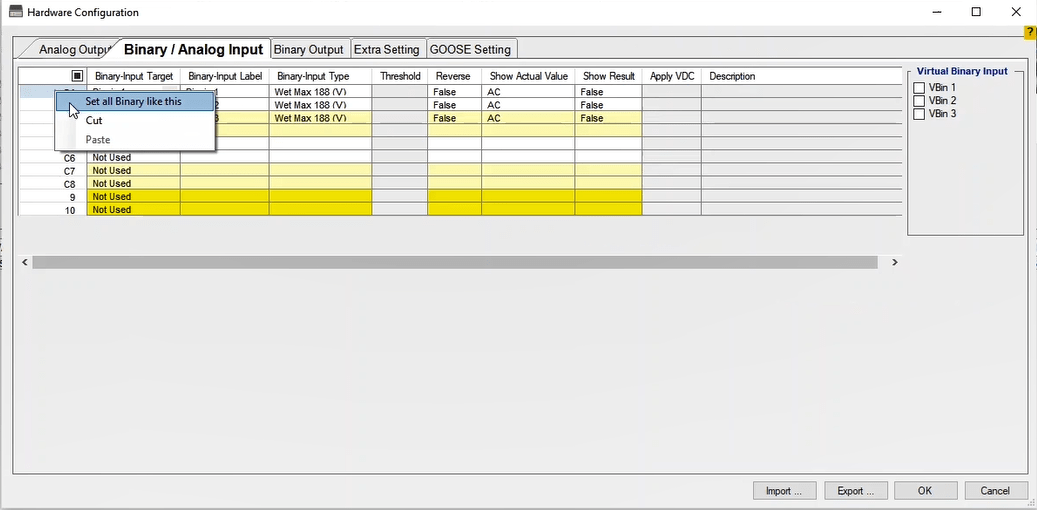

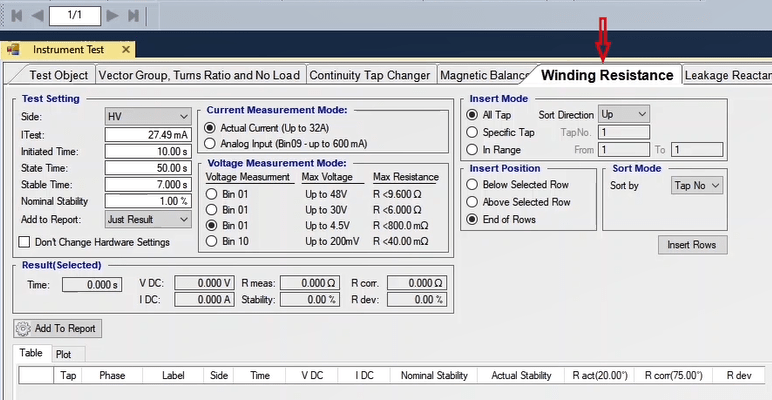

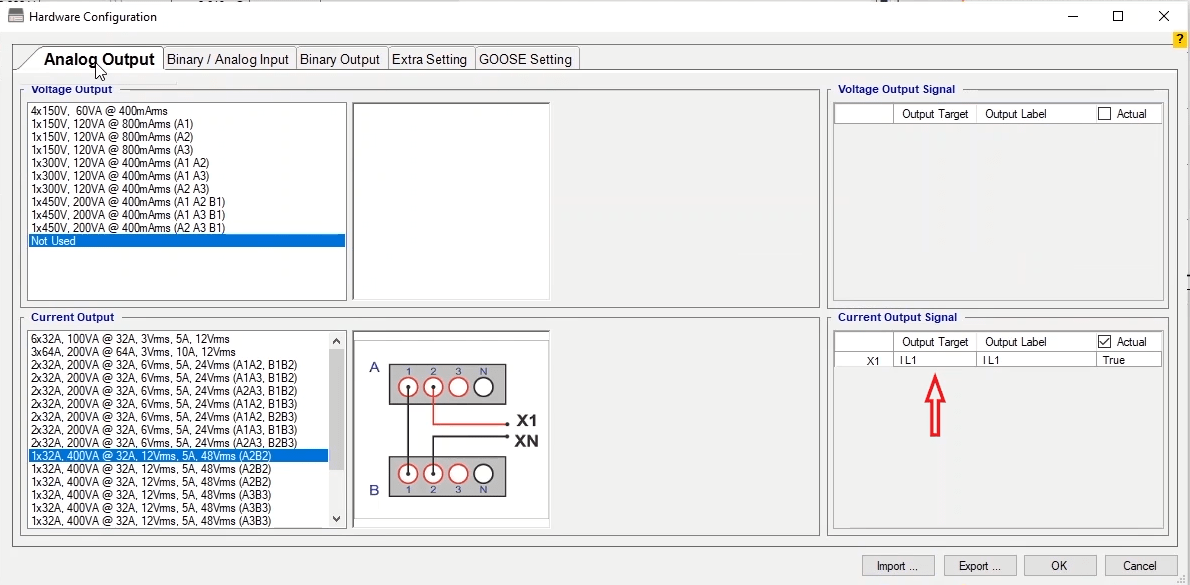

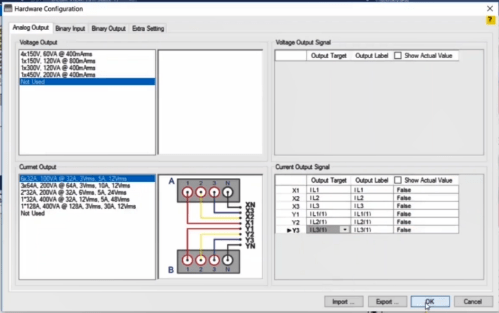

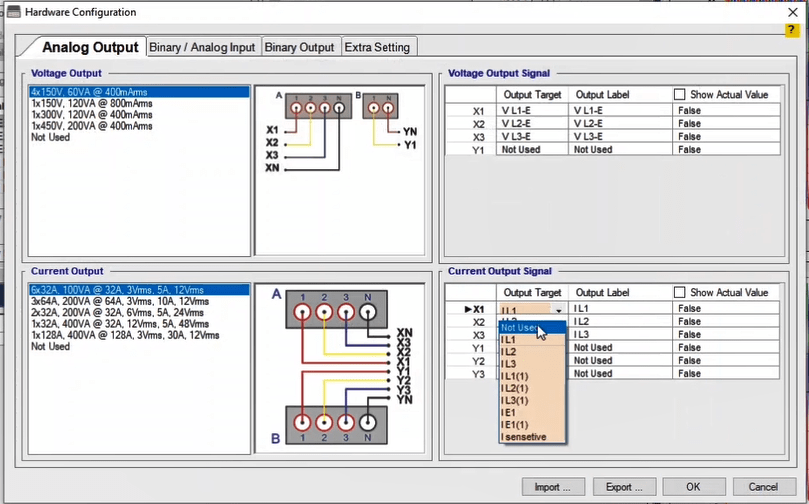

Use “Reset Hardware” to reset the device’s hardware automatically. Select “Configuration” to open the “Hardware Configuration" page. In this page output voltage and current, input and output binaries setting and extra setting is set.

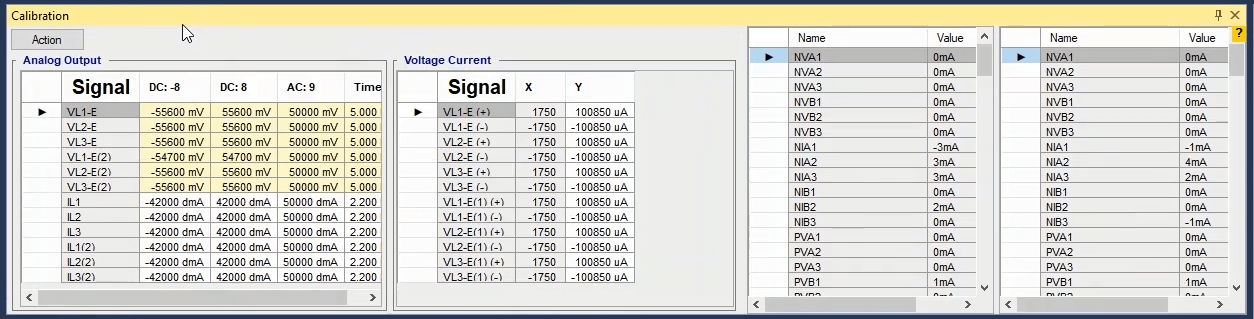

Click on "Calibration" to open the calibration page. Vebko’s experts use this page for device calibration.

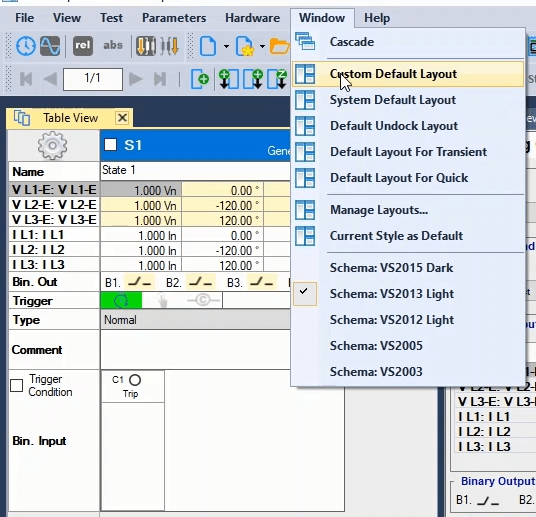

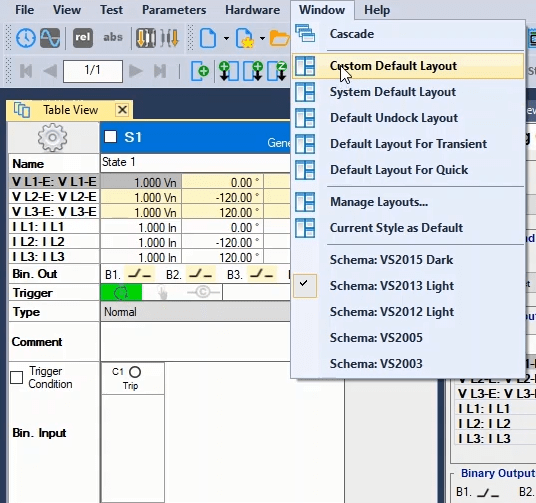

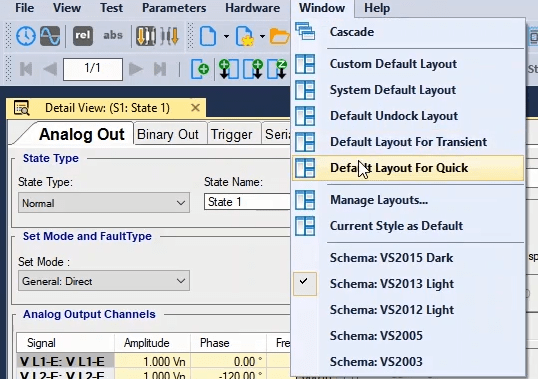

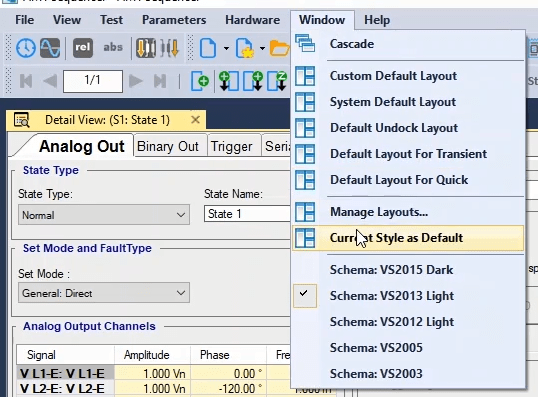

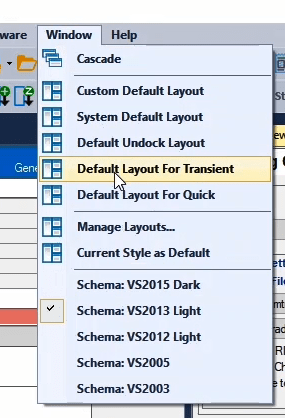

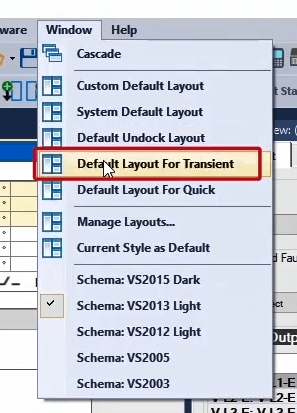

In the "Window" menu you can adjust the layouts. The “System Default Layout” option displays a default arrangement of windows for the software. Also the "Custom Default Layout" option displays the windows as "Default Layout" saved by the user.

The "Default Undock" option displays the windows as "Undock" and the location of each window can be adjusted.

With the "Cascade" option, the windows are in a row and behind each other. Note that these options are used when the room layout is in “Default Undock Layout”.

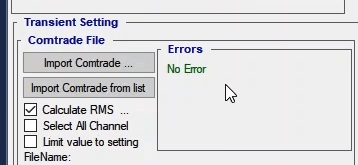

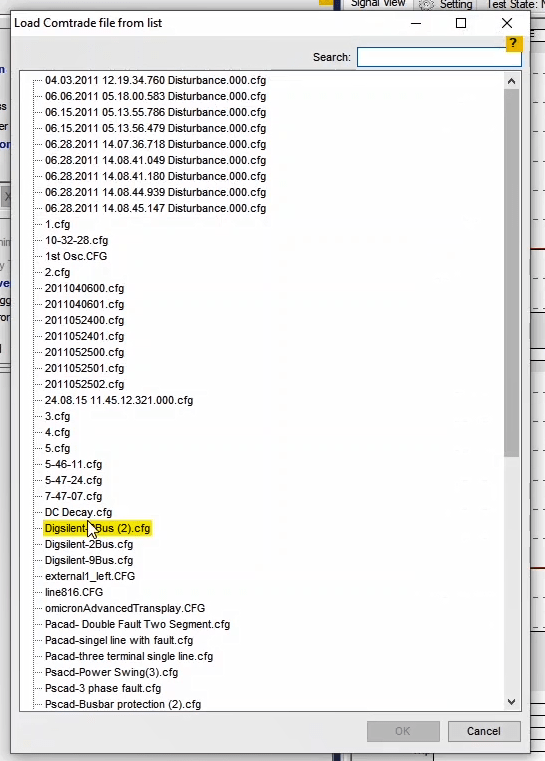

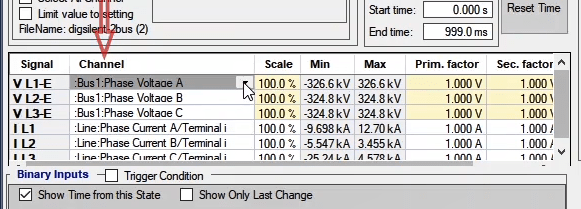

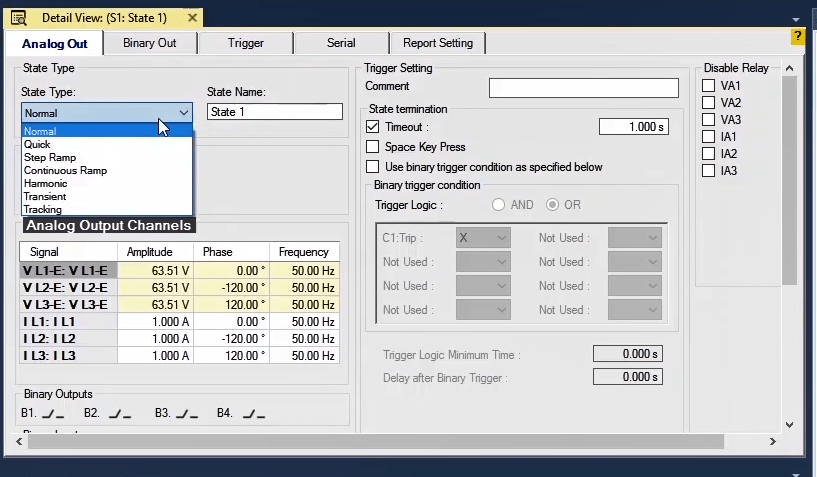

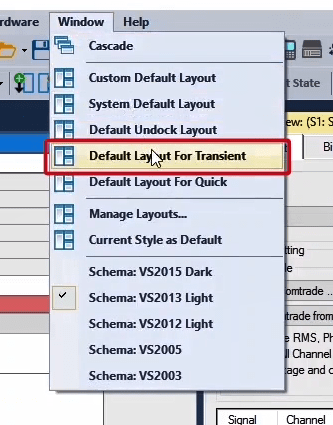

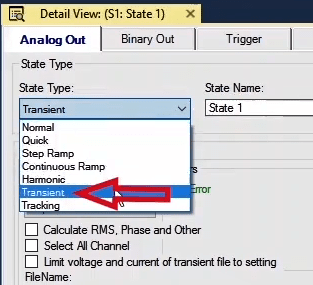

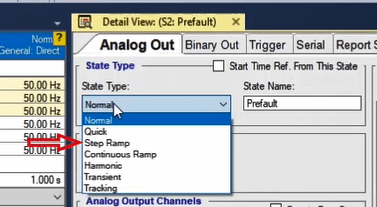

The "Default Layout for Transient" option is for the test mode and the "Default Layout for Quick" option is used for the "Quick" mode.

"Manage Layout...” is used to store the desired layouts, and even several "Layout" can be stored in it. To use a stored "Layout" click on its name, then select “Apply Layout" to open the "Layout“.

By choosing the "Current Style as Default" option, the page layout that is being used is determined a "Custom Default Layout"

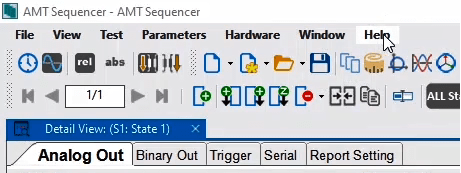

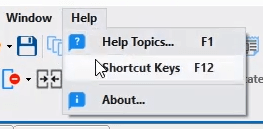

The "Schema” option shows different states and colors for the toolbar and the background of the test page which can be selected as desired. In the "Help" menu, the "Help topics" option opens the tips of the software and the tester.

The "Shortcut keys" option shows all the shortcut keys in the software. The "About" option also gives the user information about the company.

There are icons for faster and easier access in the toolbar at the top of the screen. The first six icons are, in fact, the same as the "View" menu and the "Unit" field which are available at this page too.

The "Time in Second" and "Time in Cycle", "Relative Values" and "Absolute Values", and "Primary Values" and "Secondary Values" icons are used to select the time in seconds or cycles, to specify the values in relative or absolute values and to specify whether the values entered are primary or secondary, respectively.

By clicking on the "New Room" icon, a new window opens on the test page. If you hold this icon down by the "Control" key and then click on one of the rooms, a separate room opens without closing the current room.

By clicking on the "Open" icon, a saved test file opens. If the user wishes to search for a file with a specific extension, they can click on this icon and then select the desired room. After that, they can search among the saved files in the selected room.

Also, the “Save” icon, saves the test file. These icons show the different windows on the “Sequencer” page.

In this section, you can see the “Report View”, “Test Object” and “Hardware Configuration” icons. By clicking on any of these icons, the user is referred to the respective page.

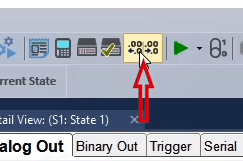

By using the "Number of Decimal Places Setting" icon, it is possible to specify the number of integers and decimal digits displayed by the software as well as the quantity of that unit.

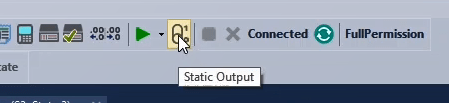

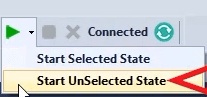

By using the "Static Output" icon, it is possible to specify that the device will only inject the values of a "State" (a selected "State"). The icons in this section are used to "Stop", "Start", and "Clear Test", respectively.

The phrase "Ready to Connect" means that the software is ready to connect to the device. The "Refresh" icon disconnects and connects the connection one more time to fix any existing problem with the test.

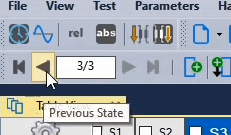

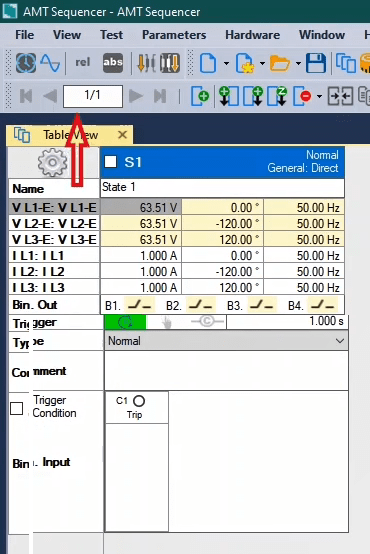

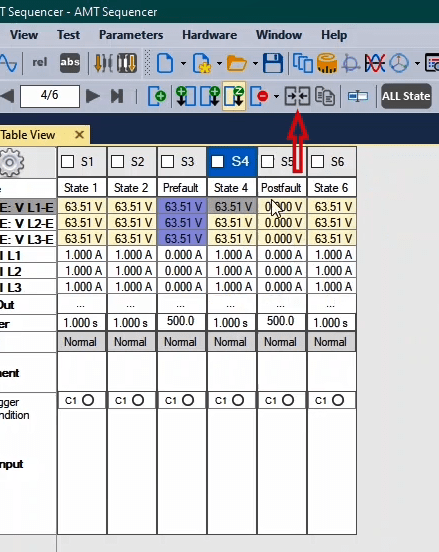

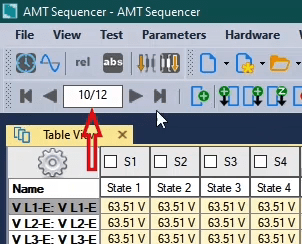

This row of the toolbar is only for the "Sequencer" room. If there are several "State"s, it is possible to select the desired "State" by using these icons and even jump to the first or last "State". By using these icons, it is possible to select the first, previous, next and last "State", in the mentioned order.

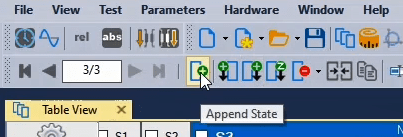

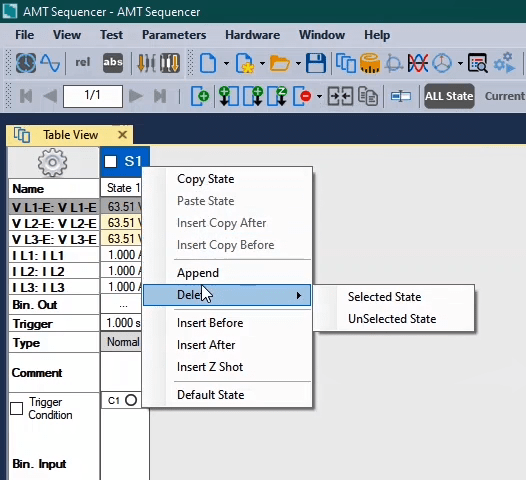

The "New State", "Delete State", "Copy Before", "Copy After" icons are used to create a new "State", delete an existing "State", create a "State" similar to the previous "State", and create a "State" similar to the next "State", respectively.

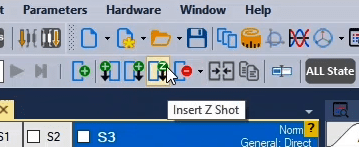

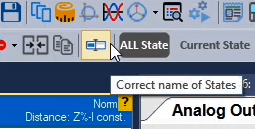

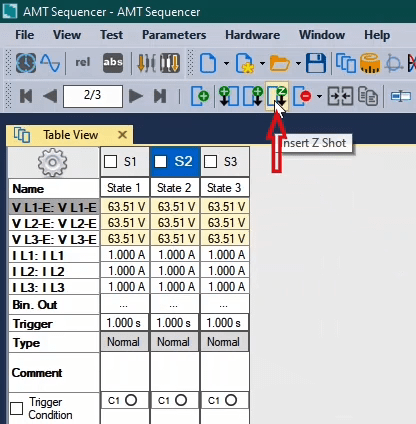

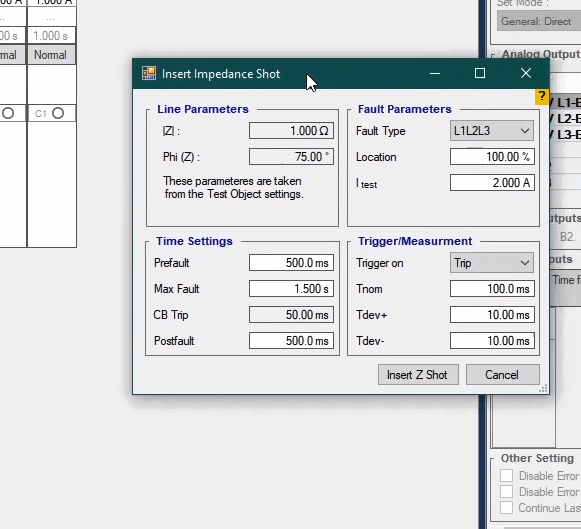

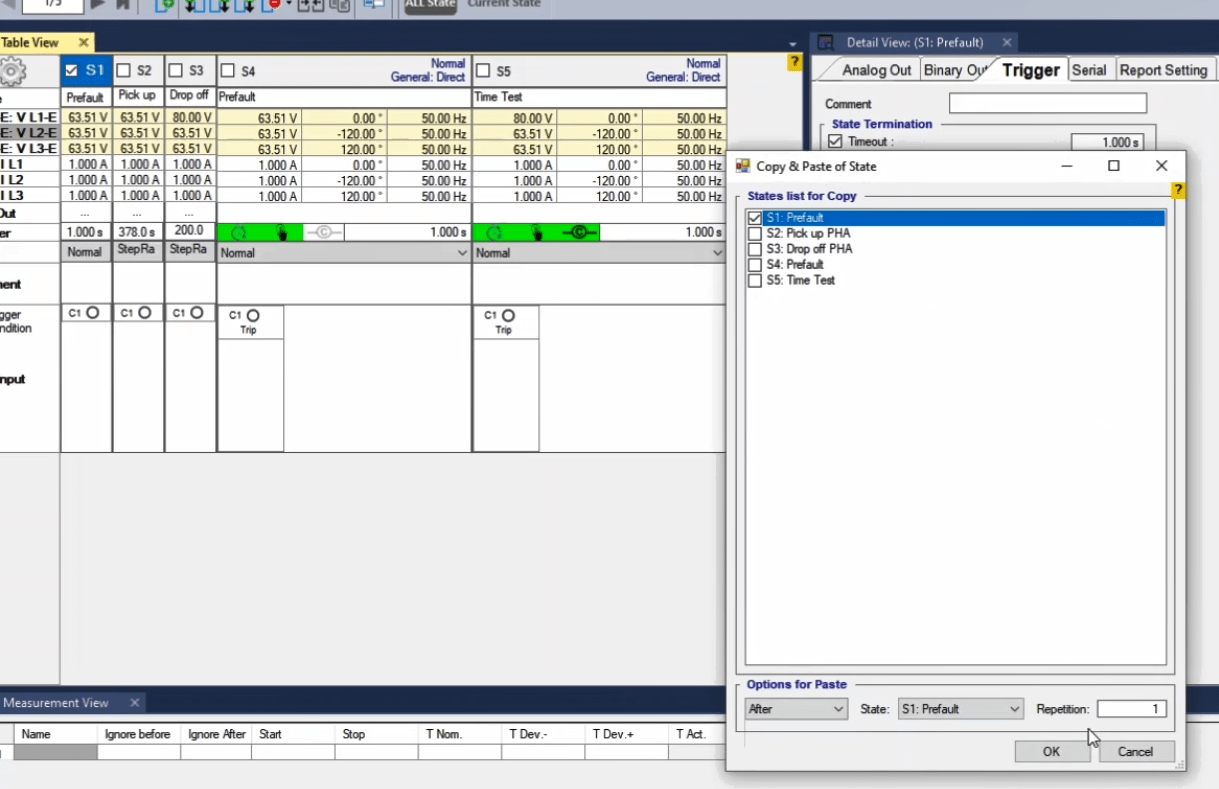

The "Insert Z shot" icon creates three "State"s as an impedance test. The "Select File to Merge" icon inserts the "State"s of other saved files in this room and adds them to the "State"s existing in the file. By using the "Copy & Paste State" icon, it is possible to copy a "State" and "Paste" it somewhere else.

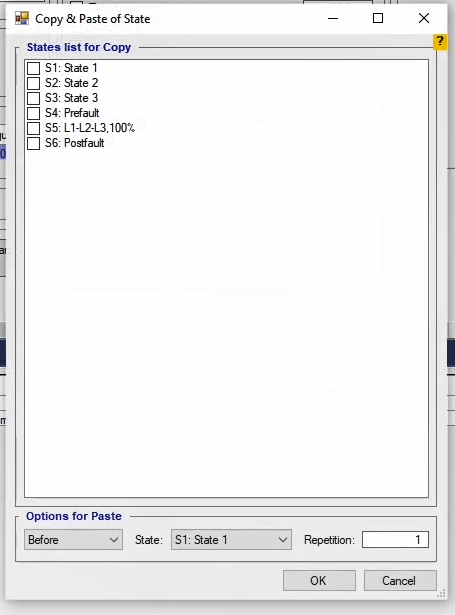

By clicking on the "Copy & Paste State", a new page opens with the same name. Then, the desired "State" is selected from the list and in the "Options for Paste" section, the location for pasting and its number are specified and, finally, "Ok" is clicked.

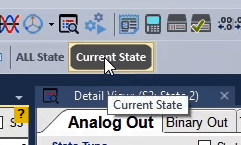

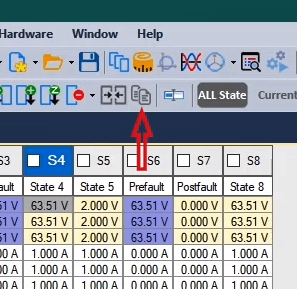

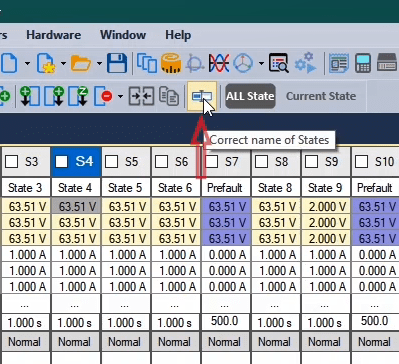

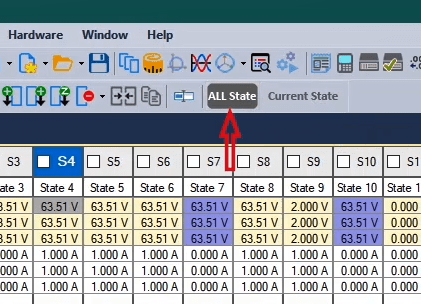

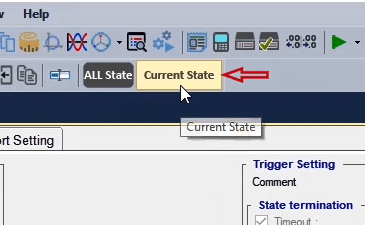

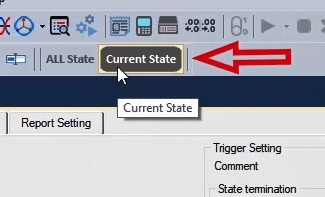

The "Correct Name of State" icon restores the default name of "State"s in case they have been changed. By clicking on the "All State" icon, the waveform of all the "State"s is displayed in "Signal View".

If the user only wants the current "State" to be displayed, they should click on the "Current State" icon. Of course, the "Current State" has other uses too, especially in transient state testing which will be explained in the future video tutorials.

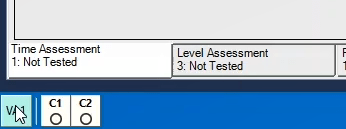

The next icon shows the status of receiving the binary signals from the inputs of the device in case they are enabled. The icons in the status bar show the status of the voltage and current ports. If there is something wrong during the test with any of the ports, the corresponding icon in this section turns red.

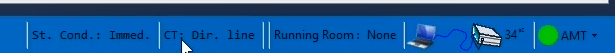

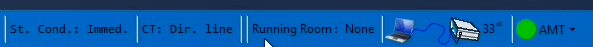

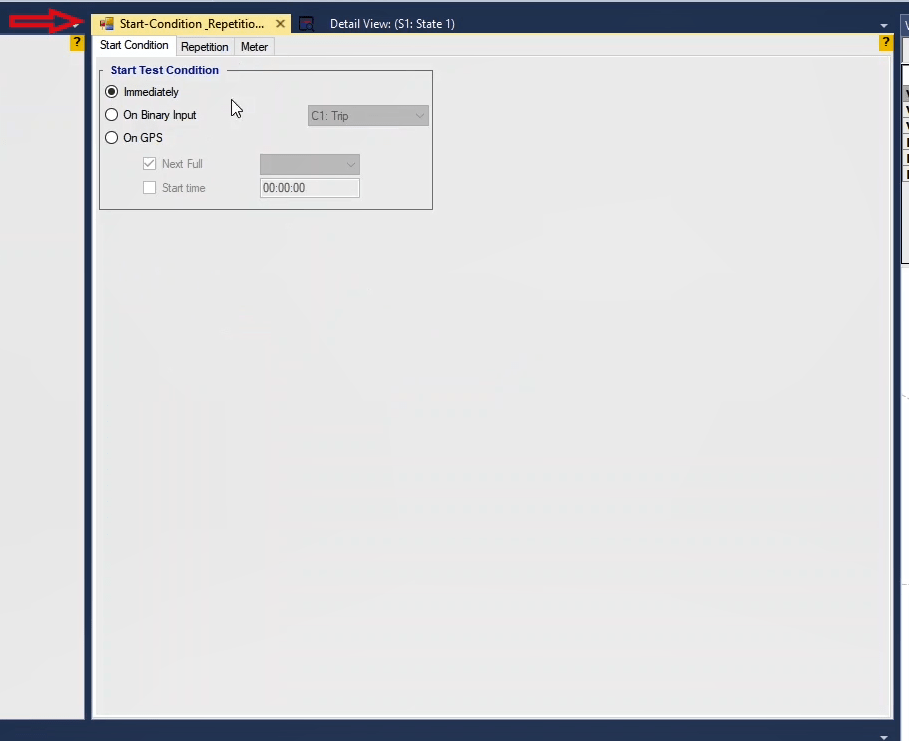

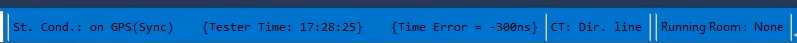

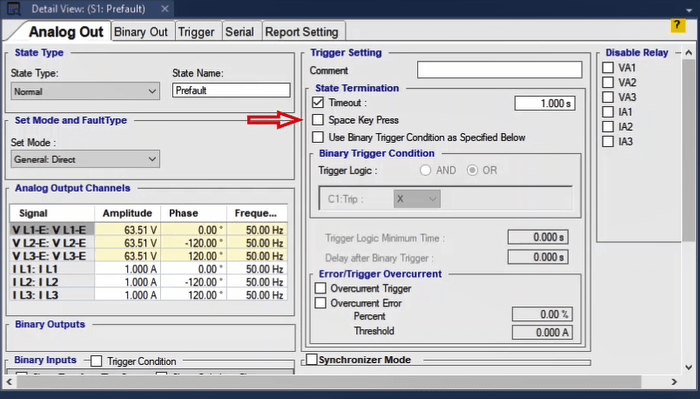

The phrase "St. Cond. "Immed" indicates the start time of the test, run by the user, which can be displayed instantaneously after clicking on "Start", in accordance with receiving signals from the binaries or the "GPS" clock time.

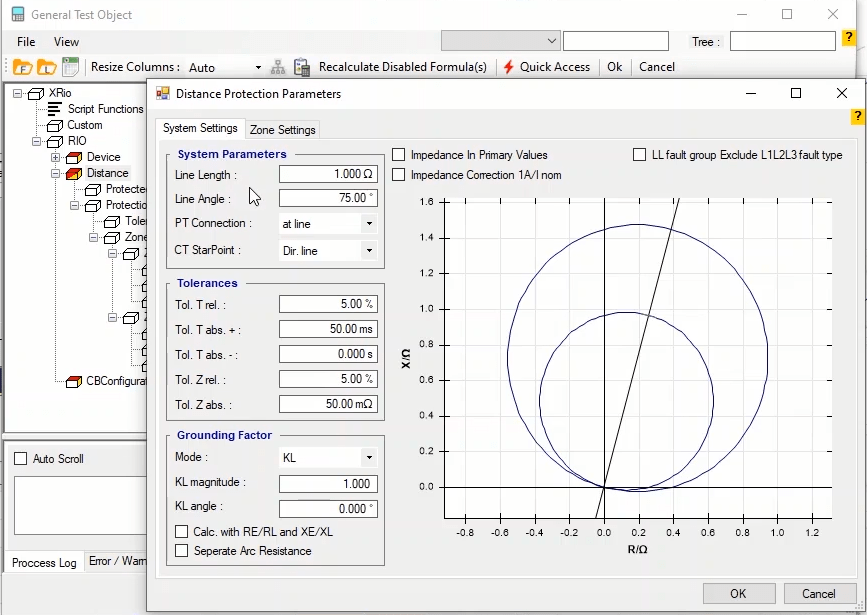

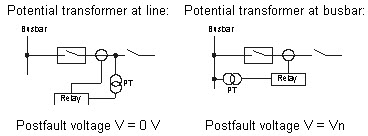

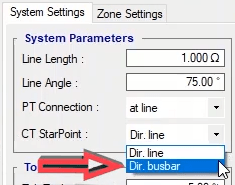

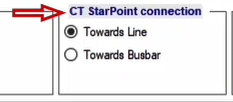

The phrase "CT: Dir. Line" indicates the location of the "CT" on the line which can be on the "Line" side or on the “Bus bar" side. This is important in tests such as "Distance" when injecting current.

The phrase "Running Room: Noun" indicates which room of the software is running the test. Also, this figure shows the connection status of the device.

In the case of connecting to several devices at the same time, from this section, it is possible to specify that to which "AMT" device should this room be connected for performing the test.

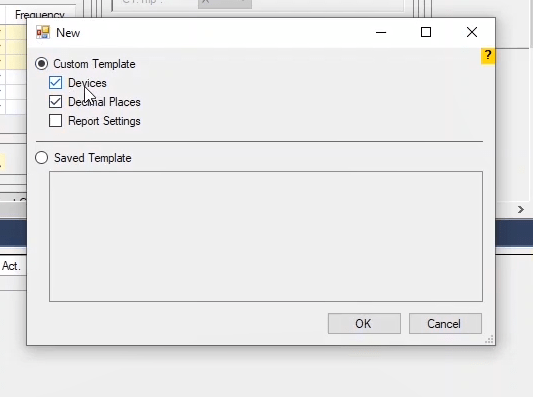

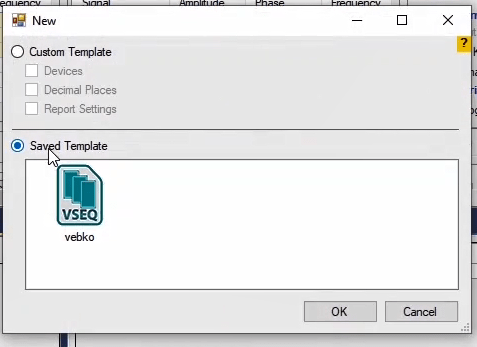

In addition to “New” option, this option is designed to ease the test and save time. It is possible for you to create a default “Template” in accordance with your needs and when necessary, by loading this “Template” apply the saved changes.

In “Custom Template” you can create a “Template” by using “Device Template”, “Report Template”, or “Decimal Places Template” modes. This can be explained by creating a “Template”. To do so, in “Preferences” in “Room” section, you can create a “Template” from “Device Template” and “Template Report Package” or “Decimal Places Template”.

For example, after entering “Preferences” window, in “Decimal Places Template” section for “Sequencer” room, select and apply “Volt” as the unit for voltage in “Template”. Enter “Vebko” in “Name” and “Manufacturer” fields in “Device” section, and then by applying the settings, save these changes as a “Template”. Now, to use these “Templates” in the rooms, you need to select the saved “Templates”. If you open “Decimal Places” in “Sequencer” room, you can see that the changes made in “Preferences” is not applied to this section. Now to apply the “Template”, by clicking on “New Based On Template” in “New” window, you can see “Custom Template” and “Saved Template” radio buttons. By selecting “Custom Template” radio button, you can specify which of the three mentioned sections is to be applied to the new file. Then, by confirming the settings by selecting “Ok” you can view the applied changes.

In “Saved Template”, you can specify the default necessary windows, arrangements and the number of fields. To better understand this, select “State Type Continuous”, open “Vector View” window and specify the desired size. Then, select “Save as Template” from ‘File” menu and select a title for it. If you wish to apply your specified “Template” in a new room, you need to click on “New Based On Template” and select “Save Template” radio button. In the end, select the desired “Template” and apply it.

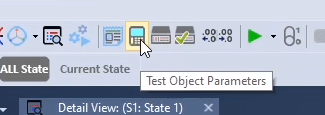

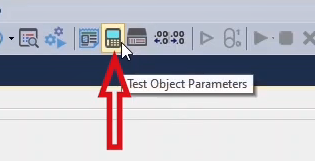

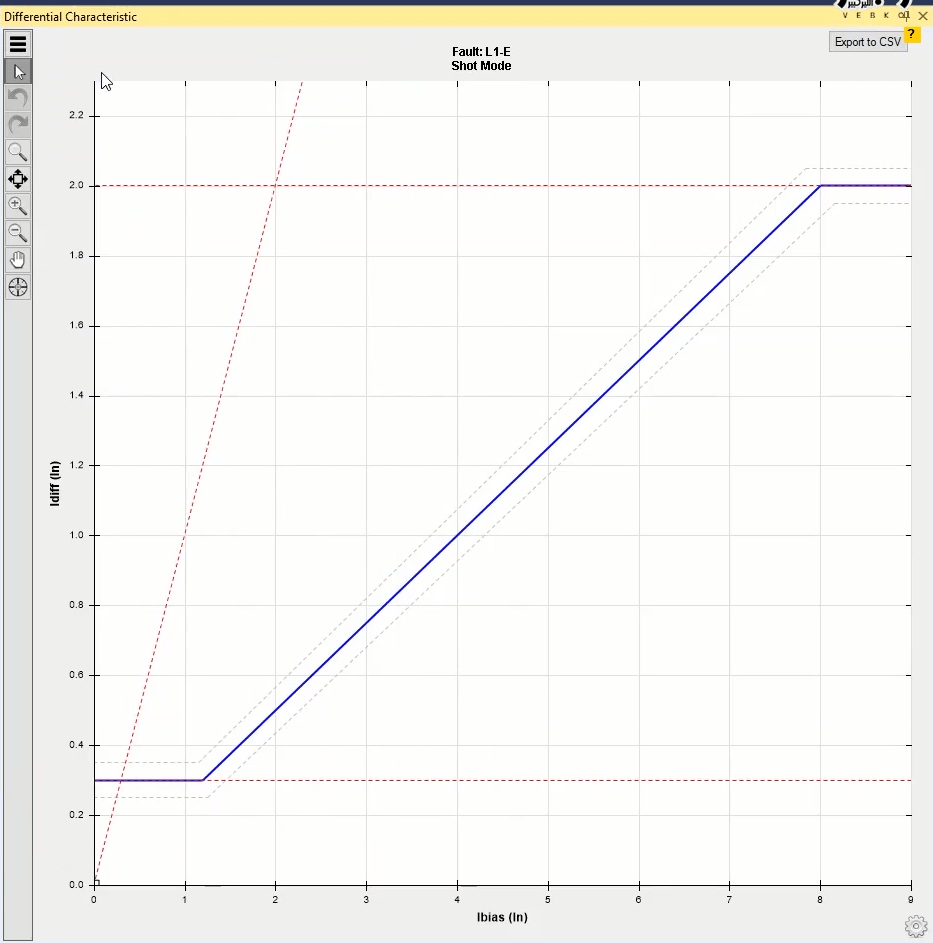

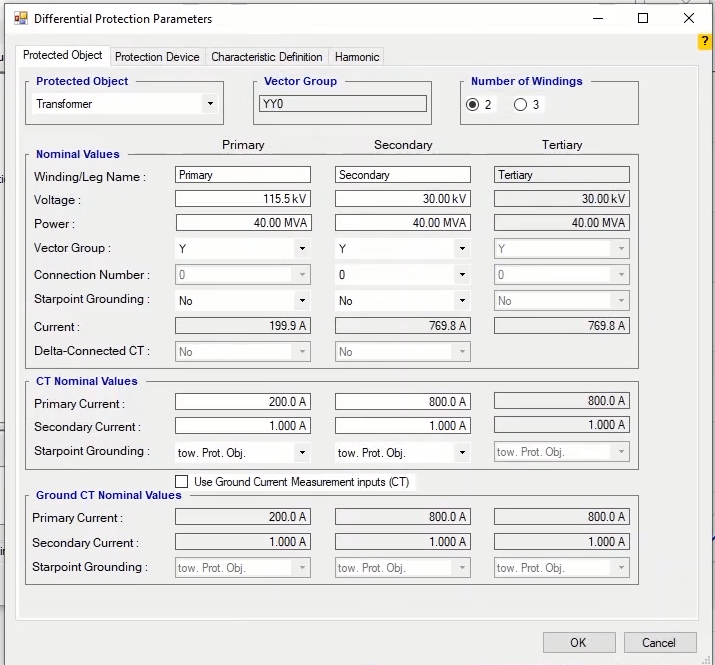

After explaining the toolbar, it is necessary to give an introductory about the basic concepts in the system. Each room includes four main parts: 1- “Number of Decimal Places Setting” Display settings for numbers and quantity units in the test rooms. 2- “Hardware configuration” For the Device hardware settings. 3- “Test Object Parameters” To access the relay settings. 4- “Report View” To access the output and the test reports. Given these four components and the nature of each window and its functions in every room, you can run a test.